Finishing Options

Datacard and Attacher are registered trademarks,

trademarks and/or service marks of DataCard

Corporation in the United States and/or other

countries. Names and logos on sample cards are

fictitious. Any similarity to actual names, trademarks

or tradenames is coincidental.

©2006-2008 DataCard Corporation.

All rights reserved.

CD8-4108

Specifications

Datacard St. Louis

11640 Adie Road

St. Louis, MO 63043

+1 314 576 2007

+1 314 576 5801 FAX

Datacard Group

Corporate Headquarters

11111 Bren Road West

Minnetonka, MN 55343-9015

+1 952 933 1223

www.datacard.com

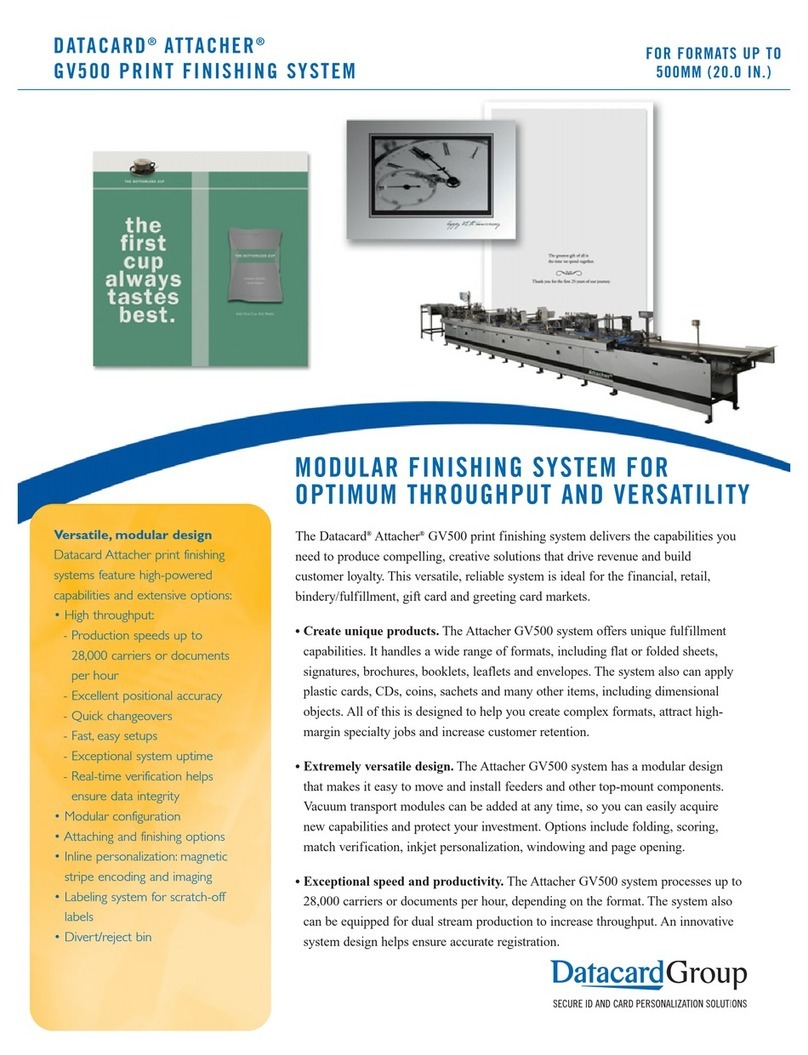

Feeders

• VF-III feeder:Versatile feeder handles a variety of items

• VF-II/ES feeder: Extended-size version of the VF-III feeder

• CR80 card feeder: Feeds plastic cards

• Card feeder/ME: Card feeder with top and bottom magnetic stripe encoding capability

• Rotary feeder: Feeds three-dimensional items, such as coins and keys

• Rotary pick-n-place: Affixes items such as 3D objects, CDs/DVDs, magnets and secure tags

Gluing

Mechanically driven pattern gluer, extrusion system for cold glue or hot-melt system available.

Folders

Fold components can be mounted on any vacuum transport to make a plow fold, and can be

interchanged with feeders and opening components. A vacuum transport equipped with two plow

folding components will make a V, C, Z or roll-fold. A cross-fold option is also available.

• Minimum fold: 0.75 in. (19.0 mm)

• Maximum fold: Depends on fold type

Scoring Li

neal scoring for a variety of paper stock. Plow folding requires prescoring or inline scoring.

Personalization

Continuous inkjet and UV-curable Drop-on-Demand inkjet options are available to personalize the

carrier and items attached to the carrier.

Match verification

Verifies the match of card to carrier, using one or more of the following technologies: OCR, bar

code, magnetic stripe, 2D bar code.

Read/print

Reads preprinted bar codes or magnetic stripes, performs database lookup and/or drives an inkjet

printer to personalize documents.

Turning (90º)

Rotates documents 90º for finishing.

Page opening

Left and/or right components open flaps or prefolded documents, such as brochures, letters,

signatures, greeting cards, mailers and folding cartons.

Label application

Applies a variety of labels for scratch-off activation, direct mail packages and other applications.

Additional options

• 6.0 in. repeat package (for small documents)

• High-performance package (for greater speed)

Power supply

230VAC (480VAC with inline UV-curable Drop-on-Demand inkjet printing; transformers required

for other voltages)

Compressed air

7-10 cfm @ 80-90 psi

Dimensions

Width: 68.0 in. (1.73 m); Length varies according to configuration

Carrier sheet

• Width: 3.9 in. to 12.0 in. (100.0 mm to 305.0 mm)

• Length: 3.9 in. to 9.0 in. (100.0 mm to 228.0 mm)

• Thickness: 60 gsm to < 0.125 in. (3.0 mm) (product dependent)

Width is measured across the belt. Length is measured in the running direction. Perfect bound

stock will not feed.

Throughput

Up to 13,000 carriers or documents per hour. Upgrade kit enables up to 25,000 per hour.

Vacuum transport

Perforated moving vacuum belt transports the carrier document in register while it undergoes

bases/modules

additional processing. Each transport has three mounting positions to accept a feeder or other

components. Feeders and components can be interchanged.

Maximum

Two (2) fully functional modules that can be configured with any option and one (1) non-driven

modules/bases

module. Can also add one (1) servo-driven module with plow-folding or gluing. (Feeders cannot

be added on the servo-driven module.) Non-driven modules can accept folding components, hot

melt glue systems, labeling heads or continuous inkjet printing options.

Infeed table

Stock shingled on 48.0 in. (1.22 m) long table and fed by vacuum wheel into aligner section. Holds

approximately 1,500 sheets.

Aligner module

Separates the product, aligns and registers it, then transports it to the vacuum belt of the next

module. A double detect can be fitted here.

Divert/reject

Diverts stock that does not meet preset specifications, such as a mismatched carrier and card.

Delivery

Shingle delivery table at the end of the system shingles stock. Overlap is operator-adjustable.

Automatic batch counter separates stock at a pre-determined number. Standard delivery is straight.

Right angle delivery is also available.

System Requirements

DATACARD®ATTACHER®GV300

PRINT FINISHING SYSTEM