Datakom DKG-307 User manual

DKG-307 User Manual V-37 (01.03.2012)

DKG-307 AUTOMATIC

MAINS FAILURE UNIT

CANBUS AND MPU VERSIONS

The controller is a comprehensive AMF unit for

single genset standby or dual genset mutual standby

operations.

The unit is available with MPU or CANBUS versions.

The CANBUS version connects to ECU controlled

electronic engines providing engine control,

protection and instrumentation without extra senders.

The unit is able to initiate modem calls and send

SMS messages in fault conditions through external

modems.

The unit provides a comprehensive set of digitally

adjustable timers, threshold levels, input and output

configurations, operating sequences and engine

types. All programs may be modified via front panel

pushbuttons, and do not require an external unit.

Last 100 faults are stored in the event log file. The

event log includes not only the date-time information,

but also a comprehensive list of measured genset

parameters at the time that the fault has occurred.

The WINDOWS based RAINBOW program allows

remote monitoring and control.

The unit supports MODBUS protocol enabling

communication with PLCs and building management

systems. The MODBUS protocol is also supported

through GSM and PSTN modems.

True RMS measurements

ECU connection through J1939 CAN option

MPU input option

Dual genset mutual standby operation

Event logging with time stamp and

measurements

Battery backed-up real time clock

Built in daily / weekly / monthly exerciser

Weekly operation schedule programs

Field adjustable parameters

RS-232 serial port

Free MS-Windows Remote monitoring SW

GSM and PSTN modem support

GSM SMS message sending on fault

MODBUS communications

Customer logo display capability

10ADC relay outputs

Configurable analogue inputs: 4

Configurable digital inputs: 7

Configurable relay outputs: 2

Total relay outputs: 6

I/O expansion capability

Plug-in connection system

FEATURES

DESCRIPTION

DKG-307 User Manual V-37 (01.03.2012)

- 2 -

Section

1. INSTALLATION

1.1. Introduction to the Control Panel

1.2. Mounting the Unit

1.3. Wiring the Unit

2. INPUTS AND OUTPUTS

3. DISPLAYS

3.1. Led Displays

3.2. Digital Displays

4. ALARMS AND WARNINGS

5. MODES OF OPERATION

6. OTHER FEATURES

6.1. Remote start operation

6.2. Sender type selection

6.3. Engine heating operation

6.4. Engine Idle Speed Operation

6.5. Engine Block Heater

6.6. Fuel Pump Control

6.7. Mains Simulation (Disable Start)

6.8. Delayed Mains Simulation, Battery Charging

6.9. Dual Genset Mutual Standby Operation

6.10. Service Request Display

6.11. Engine Hours Meter

6.12. Date-Time Display

6.13. Display of Software Version

6.14. Modem connection

6.15. SMS message sending

6.16. Remote Monitoring and Programming

6.17. Automatic Exerciser

6.18. Resuming to factory set parameters

6.19. Gas engine fuel solenoid control

6.20. Load Shedding / Dummy Load

6.21. Fuel Theft / Fuelling Messages

6.22. Firmware Update

6.23. Changing the Default Engine Speed in Volvo Engines

6.24. Engine Control Mode

6.25. Dual Voltage and Frequency

6.26. Single Phase Operation

7. J1939 ENGINE MONITORING AND CONTROL PORT

8. MODBUS COMMUNICATION

9. WEEKLY OPERATION SCHEDULE

10. EVENT LOGGING

11. STATISTICAL COUNTERS

12. MAINTENANCE

13. PROGRAMMING

14. TROUBLESHOOTING

15. DECLARATION OF CONFORMITY

16. TECHNICAL SPECIFICATIONS

17. CONNECTION DIAGRAMS

TABLE OF CONTENTS

DKG-307 User Manual V-37 (01.03.2012)

- 3 -

The unit is a control and protection panel used in gensets. It shows the measured values on its

displays. The unit is designed to provide user friendliness for both the installer and the user.

Programming is usually unnecessary, as the factory settings have been carefully selected to fit most

applications. However programmable parameters allow the complete control over the generating set.

Programmed parameters are stored in a Non Volatile Memory and thus all information is retained even

in the event of complete loss of power.

The measured parameters are:

Mains voltage phase L1 to neutral

Mains voltage phase L2 to neutral

Mains voltage phase L3 to neutral

Mains voltage phase L1-L2

Mains voltage phase L2-L3

Mains voltage phase L3-L1

Gen voltage phase L1 to neutral

Gen voltage phase L2 to neutral

Gen voltage phase L3 to neutral

Gen voltage phase L1-L2

Gen voltage phase L2-L3

Gen voltage phase L3-L1

Gen current phase L1

Gen current phase L2

Gen current phase L3

Gen frequency

Engine speed (rpm)

Gen total kW

Gen total pf

Battery voltage,

Coolant temperature

Oil pressure

Oil temperature

Fuel level

1.1 Introduction to the Control Panel

1. INSTALLATION

DKG-307 User Manual V-37 (01.03.2012)

- 4 -

The unit is designed for panel mounting. The user should not be able to access parts of the

unit other than the front panel.

Mount the unit on a flat, vertical surface. Before mounting, remove the mounting brackets and

connectors from the unit, then pass the unit through the mounting opening. The unit will be maintained in

its position bythe mounting brackets spring.

The output of the current transformers shall be 5 Amperes. The input current rating of the current

transformers may be selected as needed (between 10/5 and 9000/5 amps). Current transformer outputs

shall be connected byseparate cable pairs from each transformer, to related inputs. Never use common

terminals or grounding. The power rating of the transformer should be at least 5 VA. It is recommended to

use 1% precision transformers.

If analogue senders (e.g. temperature, oil pressure or fuel level) are connected to the unit, it is not

possible to use auxiliary displays, otherwise the unit may be damaged. If temperature or oil pressure or

fuel level displays are already present on the generator control panel, do not connect the senders to the

unit. The unit is factory programmed for VDO type senders. However different types of senders are

selectable via programming menu. Please check the programming section.

The programmable digital inputs are compatible with both „normally open‟ and „normally

closed‟ contacts, switching either to BAT- or BAT+.

The charge alternator connection terminal provides also the excitation current, thus it is not

necessaryto use an external charge lamp.

WARNING: ELECTRICITY CAN KILL

ALWAYS disconnect the power BEFORE connecting

the unit.The fuse rating should be 6 Amps.

1) ALWAYS remove the plug connectors when inserting wires with a

screwdriver.

2) An appropriate and readily accessible set of disconnection devices

(e.g. automatic fuses) MUST be provided as part of the installation.

3) The building mains supply MUST incorporate appropriate short-circuit

backup protection (e.g. a fuse or circuit breaker) of High Breaking

Capacity (HBC, at least 1500A).

Use cables of adequate current carrying capacity (at least 0.75mm2)

and temperature range.

WARNING: THE UNIT IS NOT FUSED.

Use external fuses for Mains phases: L1,L2,L3,

Generator phase: L1,L2,L3, Battery positive: BAT(+).

Install the fuses as nearly as possible to the unit in a

place easily accessible for the user.

The fuse rating should be 6 Amps.

Engine body must be grounded for correct operation of

the unit, otherwise incorrect voltage and frequency

measurements may occur.

1.3 Wiring the Unit

1.2 Mounting the Unit

DKG-307 User Manual V-37 (01.03.2012)

- 5 -

RS-232 SERIAL PORT: This connector provides serial data input and output for various purposes like

remote monitoring and remote programming.

EXTENSION CONNECTOR: This connector is intended for the connection to output extension modules.

The optional relay extension module provides 8 programmable 16A relay outputs. The unit allows the use

of up to 2 I/O extension modules.

Term

Function

Technical data

Description

1

GENERATOR CONTACTOR

Relay output, 16A-AC

This output provides energy to the generator

contactor. If the generator phases do not have

acceptable voltage or frequency values, the

generator contactor will be de-energized. In

order to provide extra security, the normally

closed contact of the mains contactor should

be serially connected to this output.

2

GEN-L1

Generator phase

inputs, 0-300V-AC

Connect the generator phases to these inputs.

The generator phase voltages upper and

lower limits are programmable.

3

GEN-L2

4

GEN-L3

5

GENERATOR NEUTRAL

Input, 0-300V-AC

Neutral terminal for the generator phases.

6

MAINS NEUTRAL

Input, 0-300V-AC

Neutral terminal for the mains phases.

7

MAINS-L3

Mains phase inputs,

0-300V-AC

Connect the mains phases to these inputs.

The mains voltages upper and lower limits are

programmable.

8

MAINS-L2

9

MAINS-L1

10

MAINS CONTACTOR

Relay output, 16A-AC

This output provides energy to the mains

contactor. If the mains phases do not have

acceptable voltages, the mains contactor will

be de-energized. In order to provide extra

security, the normally closed contact of the

generator contactor should be serially

connected to this output.

11

GROUND

O VDC

Power supply negative connection.

12

BATTERY POSITIVE

+12 or 24VDC

The positive terminal of the DC Supply shall

be connected to this terminal. The unit

operates on both 12V and 24V battery

systems.

13

FUEL LEVEL SENDER

Input, 0-5000 ohms

Analogue fuel level sender connection. Do not

connect the sender to other devices. The input

has programmable ohms for VDO senders.

14

OIL PRESSURE SENDER

Input, 0-5000 ohms

Analogue oil pressure sender connection. Do

not connect the sender to other devices. The

input has programmable characteristics and

connects to anykind of sender.

15

COOLANT TEMP. SENDER

Input, 0-5000 ohms

Analogue high temperature sender

connection. Do not connect the sender to

other devices. The input has programmable

characteristics and connects to any kind of

sender.

2. INPUTS AND OUTPUTS

DKG-307 User Manual V-37 (01.03.2012)

- 6 -

Term

Function

Technical data

Description

16

CHARGE

Input and output

Connect the charge alternator‟s D+ terminal to

this terminal. This terminal will supply the

excitation current and measure the voltage of

the charge alternator.

17

RELAY-2 (HORN RELAY)

Output 10A/28VDC

This relay has programmable function,

selectable from a list.

18

RELAY-1 (STOP RELAY)

Output 10A/28VDC

This relay has programmable function,

selectable from a list.

19

START RELAY

Output 10A/28VDC

This relaycontrols the engine cranking.

20

FUEL RELAY

Output 10A/28VDC

This relayis used for fuel solenoid control.

21

EMERGENCY STOP

Digital inputs

These inputs have programmable

characteristics selected via the program

menu. Each input may be driven by a

„normally closed‟ or „normally open‟ contact,

switching either battery+ or battery-. The effect

of the switch is also selectable from a list. See

PROGRAMMING section for more details.

22

SPARE-2

23

PROGRAM LOCK

24

SPARE-1

25

COOLANT LEVEL

26

HIGH TEMP

27

LOW OIL PRESSURE

28

RECTIFIER FAIL

29

CURR_1+

Current transformer

inputs, 5A-AC

Connect the generator current transformer

terminals to these inputs. Do not connect the

same current transformer to other instruments

otherwise a unit fault will occur. Connect each

terminal of the transformer to the unit‟s related

terminal. Do not use common terminals. Do

not use grounding. Correct polarity of

connection is vital. If the measured power is

negative, then change the polarity of each 3

current transformers. The rating of the

transformers should be the same for each of

the 3 phases. The secondary winding rating

shall be 5 Amperes. (For ex. 200/5 Amps).

30

CURR_1-

31

CURR_2+

32

CURR_2-

33

CURR_3+

34

CURR_3-

35

OIL TEMP. SENDER

Input, 0-5000 ohms

Analogue oil temperature sender connection.

Do not connect the sender to other devices.

The input has programmable characteristics

and connects to anykind of sender.

CANBUS VERSIONS

36

CANBUS-L

Digital communication

port

Connect the J1939 port of an electronic

engine to these terminals.

The 120 ohm terminating resistors are inside

the unit. Please do not connect external

resistors.

Use a twisted cable pair or coaxial cable for

best results.

37

CANBUS-H

MPU INPUT VERSIONS

36

MPU -

Analog input, 0.5 to

30V-AC

Connect the MPU unit to these inputs

Use a twisted cable pair or coaxial cable for

best results.

37

MPU +

DKG-307 User Manual V-37 (01.03.2012)

- 7 -

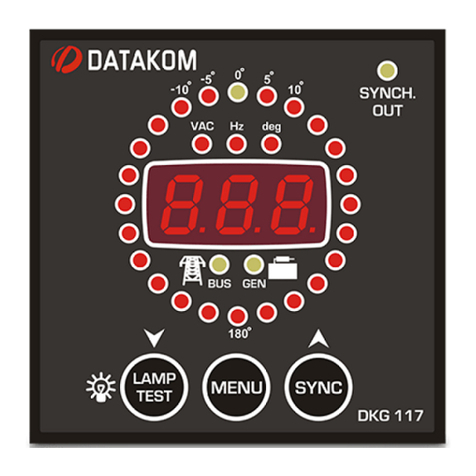

The unit has 12 LEDs, divided in 3 groups:

-Group_1: Operating mode: This group indicates the genset function.

-Group_2: Mimic diagram: This group indicates the current status of the mains and genset

voltages and contactors.

-Group_3: Warnings and alarms: This group indicates the existence of abnormal conditions

encountered during operation.

Function

Color

Description

MAINS ON

Green

The LED will turn on when all 3 mains phase voltages

are within the limits.

MAINS OFF

Red

The LED will turn on when at least one of the mains

phase voltages is outside limits.

LOAD MAINS

Green

It turns on when the mains contactor is activated.

LOAD GENERATOR

Yellow

It turns on when the generator contactor is activated.

GENERATOR

Yellow

The LED will flash when the engine is running. It will

turn on steadily when all 3 generator phase voltages

are within the programmed limits.

TEST

Yellow

It turns on when the related operation mode is

selected. One of these LEDs is always on and

indicates which operation mode is selected.

If the operation of the genset is disabled bythe

weekly operation schedule, then the AUTO led will

flash.

RUN

Yellow

STOP

Yellow

AUTO

Green

WARNINGS & ALARMS

Red

If a fault condition resulting to the engine shutdown or

loaddump condition has occurred, the related alarm

led turns on steadily. If a warning condition occurs,

this led will flash. Alarms work on a first occurring

basis. The occurrence of a fault will disable other

faults of lower or equal priority.

SERVICE REQUEST

Red

Engine periodic maintenance request indicator. It

turns on when the preset engine hours or time

duration after previous service has elapsed.

3.1 Led Displays

3. DISPLAYS

DKG-307 User Manual V-37 (01.03.2012)

- 8 -

The unit has 3 seven segment displays. Theyshow:

-Measured parameters,

-Service counters,

-Statistical counters,

-Program parameters.

The navigation between different screens in a group is made with the MENU►button.

Holding the MENU►button pressed for 1 second makes the display to switch to the next group.

VOLTAGE DISPLAY: This display shows:

-phase R voltage if the load is on mains

-Phase U voltage if the load is on the genset

By pressing the MENU key, below values may be displayed:

-(L1-L2-L3) mains phase to neutral voltages

-(L1-L2-L3) generator phase to neutral voltages

-(L12-L23-L31) mains phase to phase voltages

-(L12-L23-L31) generator phase to phase voltages

If the service counters group is displayed, then this display will show the counter name.

In programming mode it displays (PGM).

CURRENT DISPLAY: This display will show the current values measured using the current

transformers. Using the programming menu, current transformers within the range of 10/5A to 9000/5A

may be programmed.

In programming mode it displays the program number.

MULTIFUNCTION DISPLAY: By pressing the MENU key below values may read:

-oil pressure (bar)

-coolant temperature (ºC)

-fuel level

-generator frequency (Hz)

-generator active power (KW)

-battery voltage (V-DC),

In programming mode it displays the program value.

3.2 Digital Displays

DKG-307 User Manual V-37 (01.03.2012)

- 9 -

Alarms indicate an abnormal situation in the generating set are divided into 3 priority levels:

1- ALARMS: These are the most important fault conditions and cause:

-Therelated ALARM led to be on steadily,

-The genset contactor to be released immediately,

-The engine to be stopped immediately,

-The Horn, Alarm,Alarm+Load_dump and Alarm+Load_dump+Warning digital

outputs to operate, (if selected via programming menu)

2- LOAD_DUMPS: These fault conditions cause:

-Therelated ALARM led to be on steadily,

-The genset contactor to be released immediately,

-The engine to be stopped after Cooldown period,

-The Horn, Alarm+Load_dump and Alarm+Load_dump+Warning digital outputs to

operate, (if selected via programming menu)

3- WARNINGS: These conditions cause:

-Therelated ALARM led to flash,

-The Horn and Alarm+Load_dump+Warning digital outputs to operate, (if selected

via programming menu)

If the ALARM MUTE button is pressed, the Horn output will be deactivated; however the

existing alarms will persist and disable the operation of the genset.

Alarms operate in a first occurring basis:

-If an alarm is present, following alarms, load_dumps and warnings will not be accepted,

-If a load_dump is present, following load_dumps and warnings will not be accepted,

-If a warning is present, following warnings will not be accepted.

Alarms may be of LATCHING type following programming. For latching alarms, even if the alarm

condition is removed, the alarms will stay on and disable the operation of the genset. The existing alarms

may be canceled by pressing one of the operating mode buttons (LOAD TEST / TEST / OFF / AUTO).

Most of the alarms have programmable trip levels. See the programming chapter for adjustable

alarm limits.

4. ALARMS AND WARNINGS

DKG-307 User Manual V-37 (01.03.2012)

- 10 -

LOW OIL PRESSURE: Set if a signal is detected at the Low Oil Pressure Switch input or the oil

pressure value measured from the sender is below the programmed limit. Warning and alarm limits are

separately programmable for the oil pressure sender input. This fault will be monitored with Holdoff

Timer delay after the engine is running. Also if the oil pressure switch is open at the beginning of a start

attempt, then the engine will not be started and the oil pressure alarm led will flash. When the oil

pressure switch closes, normal operation will be resumed.

HIGH TEMPERATURE: Set if a signal is detected at the High Temperature Switch input or the coolant

temperature value measured from the sender is above the programmed limit. Warning and alarm limits

are separately programmable for the temperature sender input.

LOW TEMPERATURE (warning) : Set if the coolant temperature value measured from the sender is

blow the Engine Heating Temperature limit.

LOW SPEED / HIGH SPEED: Set if the generator frequency or rpm is outside programmed limits.

These faults will be monitored with Holdoff Timer delay after the engine is running. Low and high limits

for warning and alarm are separately programmable. Another high shutdown limit which is 12% above

the high limit is always monitored and stops the engine immediately.

START FAIL (alarm): Set if the engine is not running after programmed number of start attempts.

STOP FAIL (warning): Set if the engine has not stopped before the expiration of the Stop Timer.

ECU FAIL (warning): Set when an engine fault code is received from the ECU of the electronic engine.

This fault will not cause an engine stop. If necessary, the engine will be stopped by the ECU.

ECU FAIL (alarm): Set if no information has been received during 3 seconds from the ECU of the

electronic engine. This fault condition is only controlled if fuel is on.

OVERLOAD (load_dump): Set if at least one of the genset phase currents goes over the Overcurrent

Limit for Overload Timer. If currents go below the limit before expiration of the timer then no alarm will

be set.

EXCESS POWER (load_dump): Set if the genset power (KW) supplied to the load goes over the

Excess Power limit for Overload Timer. If the power goes below the limit before expiration of the timer

then no alarm will be set.

GENSET LOW VOLTAGE: Set if any of the generator phase voltages goes outside programmed limits

for Overload Timer. This fault will be monitored with holdoff timer delay after the engine is running.

GENSET HIGH VOLTAGE: Set if any of the generator phase voltages goes outside programmed limits

for Overload Timer. This fault will be monitored with holdoff timer delay after the engine is running.

LOW COOLANT LEVEL: Set if a signal is detected at the low coolant level input.

HIGH BATTERY VOLTAGE: Set if the battery voltage goes above programmed limits. Both warning and

alarm levels for high battery voltage are programmable.

LOW BATTERY VOLTAGE (warning): Set if the battery voltage goes below the programmed limit.

During engine cranking this fault is not monitored.

CHARGE: Set if a charge alternator failure (or broken belt) occurs. This fault condition may result to a

warning or alarm following programming.

RECTIFIER FAIL: Set if a signal is detected at the rectifier fail input. This input is only monitored when

mains voltages are present.

EMERGENCY STOP: Set if a signal is detected at the emergency stop input.

SPARE: Set if a signal is detected from the related spare fault input.

DKG-307 User Manual V-37 (01.03.2012)

- 11 -

The modes of operation are selected by pushing the front panel keys. Changing the operation

mode while the genset is running will result into a behavior suitable for the new operating mode. For

example, if the TEST mode is selected when genset is running at RUN mode, then the genset will take

the load.

STOP: In this mode, the mains contactor will be energized if mains phase voltages are within the

programmed limits. The engine will be stopped.

AUTO: It is used for genset and mains automatic transfer. If at least one of the mains phase voltages is

outside limits, the mains contactor will be deactivated.

The diesel will be started for programmed times after the preheat timer. When the engine runs, the crank

relay will be immediately deactivated. The engine will run without load during engine heating period. After

this, if alternator phase voltages and frequency are within limits, then the unit will wait for the generator

contactor period and the generator contactor will be energized.

When all the mains phase voltages are within the limits, the engine will continue to run for the mains

waiting period. At the end of this period the generator contactor is deactivated and the mains contactor will

be energized. If a cooldown period is given, the generator will continue to run during cooldown period. At

the end of the period, the fuel solenoid will be de-energized and the diesel will stop. The unit will be ready

for the next mains failure.

If the operation of the genset is disabled by the weekly schedule, then the AUTO led will flash, and the

operation of the genset will be as in the OFF mode.

RUN:It is used to test the generator when the mains are on, or keep the generator running in the

emergency backup mode. The operation of the generator is similar to the AUTO mode, but the mains

contactor will not be deactivated if the mains are not off. If the mains are off, mains contactor will be

deactivated and the generator contactor will be activated. When the mains are on again, a changeover to

the mains will be made, but the engine will be kept running unless another mode is selected. To stop the

engine, select AUTO or OFF mode.

TEST: It is used to test the genset under load. Once this mode is selected, the engine will run and the

load will be transferred to the genset. The genset will feed the load indefinitely unless another mode is

selected.

5. MODES OF OPERATION

DKG-307 User Manual V-37 (01.03.2012)

- 12 -

The unit offers the possibility of REMOTE START mode of operation. The SPARE-2 input may

be assigned as Remote Start Input using the program parameter P_083.

The REMOTE START signal may be a NO or NC contact, switching to either battery positive or

battery negative. These selections are made using programming menu.

It is also necessary to set the ACTION program parameter of the SPARE-2 input to 3in order to

prevent any alarm from this input.

In this mode the mains phases are not monitored. If the REMOTE START signal is present

then the mains will be supposed to fail, inversely if the REMOTE START signal is absent, then mains

voltages will be supposed to be present. The front panels mimic diagram‟s mains LEDs will reflect the

status of the REMOTE START input.

The unit has the ability to adapt to any type of oil pressure and temperature senders. The

commonly used standard sender characteristics are recorded in memory and selectable from a list.

However non standard senders may also be used by entering their characteristics to the table.

Oil Pressure Sender Type Selection:

Selectable sender types are:

0: Sender characteristics are defined in Sender Characteristics table.

1: VDO 0-7 bars (10-180 ohms)

2: VDO 0-10 bars (10-180 ohms)

3: DATCON 0-7 bars (240-33 ohms)

4: DATCON 0-10 bars (240-33 ohms)

5: DATCON 0-7 bars (0-90 ohms)

6: DATCON 0-10 bars (0-90 ohms)

7: DATCON 0-7 bars (75-10 ohms)

Temperature Sender Selection:

Selectable sender types are:

0: Sender characteristics are defined in Sender Characteristics table.

1: VDO

2: DATCON DAH type

3: DATCON DAL type

Fuel Level Sender Selection:

The Fuel Level Sender characteristic is programmable through table.

Oil Temperature Sender Selection:

Selectable sender types are:

0: Sender characteristics are defined in Sender Characteristics table.

1: VDO

2: DATCON DAH type

3: DATCON DAL type

6.2 Sender type Selection

6.1 Remote Start Operation

6. OTHER FEATURES

DKG-307 User Manual V-37 (01.03.2012)

- 13 -

Especially on engines without a body heater, or with a failing one, it may be desired that the

genset should not take the load before reaching a suitable temperature. The unit offers 2 different

ways of engine heating.

1. Timer controlled heating:

This operation mode is selected when the Engine Heating Method parameter is set to 0. In this

mode, the engine will run during parameter Engine Heating Timer, and then the genset will take the

load.

2. Timer and temperature controlled heating:

This operation mode is selected when the Engine Heating Method parameter is set to 1. In this

mode, at first the engine will run during parameter Engine Heating Timer, then it will continue to run

until the measured coolant temperature reaches the limit defined in parameter Engine Heating

Temperature. When the requested temperature is reached, the load will be transferred to the genset.

This operation mode may be used as a backup to the engine body heater. If the engine body is warm

the heating will be skipped.

It may be required that the engine runs at the idle speed for a programmed duration for engine

heating. The idle operation duration is adjusted with the parameter Idle Speed Timer. The idle speed

will be set by the governor control unit of the engine.

Any of the spare relay outputs may be assigned as IDLE output using Relay Definition

program parameters. Also relays on an extension module may be assigned to this function.

The Idle speed operation is performed both in engine start-up and cool-down sequences.

Speed and voltage protections are disabled during idle speed operation.

The unit is able to provide a relay output in order to drive the block heater resistor. The

temperature reference is the coolant temperature measured from the the analog sender input.

The block heater relay function may be assigned to spare relays using Relay Definition

program parameters. Also relays on an extension module may be assigned to this function.

The engine body temperature limit is adjusted using the parameter Engine Heating

Temperature. The same parameter is used for engine heating operation.

The relay will become active if the body temperature falls to 4 degrees below the limit set by

Engine Heating Temperature. It turns off when the body temperature exceeds Engine Heating

Temperature.

6.5 Engine Block Heater

6.4 Engine Idle Speed Operation

6.3 Engine Heating Operation

DKG-307 User Manual V-37 (01.03.2012)

- 14 -

The unit is able to provide a relay output in order to drive the fuel pump motor. The fuel pump

is used in order to transfer fuel from the large capacity main tank (if exists) to the genset daily tank

which is generally integrated in the chassis and has a limited capacity.

The fuel level reference is measured through the analog fuel level sender. When the

measured fuel level falls below Fuel Pump Low Limit parameter, the fuel pump relay output will

operate. When the fuel level reaches Fuel Pump High Limit parameter, the relay will turn off. Thus

the chassis fuel tank level will be always kept between Fuel Pump Low Limit and Fuel Pump High

Limit parameters.

The fuel pump relay function may be assigned to spare relays using Relay Definition program

parameters. Also relays on an extension module may be assigned to this function.

The unit offers an optional SIMULATE MAINS signal input. The SPARE-2 digital input may be

assigned as Simulate Mains using program parameter P_084.

It is also necessary to set the ACTION program parameter of the related input to 3in order to

prevent any alarms generated from this input.

The SIMULATE MAINS signal maybe a NO or NC contact, switching to either battery positive or

battery negative. These selections are made using the programming menu.

If the Simulate Mains input is defined and the input signal is active, the mains phases are not

monitored and supposed to be inside limits. This will prevent the genset from starting even in case of a

mains failure. If the genset is running when the signal is applied, then usual Mains Waiting and

Cooldown cycles will be performed before engine stop. When the SIMULATE MAINS signal is present,

the front panels mimic diagram‟s mains LEDs will reflect the mains voltages as present.

When the signal is passive, the unit will revert to normal operation and monitor the mains

voltage status.

The REMOTE START operation overrides SIMULATE

MAINS and FORCE TO START operations.

6.7 Mains Simulation (Disable Start)

6.6 Fuel Pump Control

DKG-307 User Manual V-37 (01.03.2012)

- 15 -

The Delayed Mains Simulation feature is used in battery backed up telecom systems where

batteries are able to supply the load during a certain period. The genset is requested to run only when

battery voltage drops below the critical level. Once the engine runs, the rectifier system starts charging

the batteries and the battery voltage goes up immediately. Thus the engine should continue to run a

programmed period for effective charging. The critical battery voltage level will be detected by an

external unit which provides the digital Simulate Mains signal for the genset control unit.

The unit offers an optional SIMULATE MAINS signal input. The SPARE-2 digital input may be

assigned as Simulate Mains using program parameter P_084.

It is also necessary to set the ACTION program parameter of the related input to 3in order to

prevent any alarms generated from this input.

The SIMULATE MAINS signal maybe a NO or NC contact, switching to either battery positive or

battery negative. These selections are made using the programming menu.

If the Delayed Simulate Mains program parameter (P_085) is set to 1 and the input signal is

active when the genset is not feeding the load, the mains phases are not monitored and supposed to

be inside limits. This will prevent the genset from starting when the simulate mains signal is present

(batteries charged). The genset will start when mains voltages are out of limits and the simulate mains

signal not present.

If the genset is running when the signal is applied, then MAINS SIMULATION will be

prevented during P_086 Flashing Relay Timer program parameter. After this, usual Mains Waiting

and Cooldown cycles will be performed before engine stop. When the SIMULATE MAINS signal is

present, the front panels mimic diagram‟s mains LEDs will reflect the mains voltages as present.

When the signal is passive, the unit will revert to normal operation and monitor the mains

voltage status.

The REMOTE START operation overrides DELAYED

SIMULATE MAINS operation. When both parameters

“Remote Start Operation” and “Delayed Simulate

Mains” are set then REMOTE START operation mode is

performed.

6.8 Delayed Mains Simulation, Battery Charging

DKG-307 User Manual V-37 (01.03.2012)

- 16 -

Dual genset intermittent operation consists of regular switching of the load between 2 gensets.

The use of 2 gensets instead of one is due either to safety purposes in case of a genset failure or to a

continuous operation requesting service stops.

The running period for each genset is adjustable using Flashing Relay Timer program

parameter. If the time is adjusted as 0 hours, it will be actually set to 2 minutes for faster testing

purposes.

A flashing relay output function is provided, based on the parameter Flashing Relay Timer.

Each time the period programmed using Flashing Relay Timer elapses, the relay output will change

position.

The flashing relay function may be assigned to spare relays using Relay Definition program

parameters. Also relays on an extension module may be assigned to this function.

The dual genset intermittent operation uses also the Mains Simulation feature. Please review

chapter 6.7 for a detailed explanation of this feature.

Please contact DATAKOM for a complete application

manual.

6.9 Dual Genset Mutual Standby Operation

DKG-307 User Manual V-37 (01.03.2012)

- 17 -

This led is designed to help the periodic maintenance of the genset to be made consistently.

The periodic maintenance is basically carried out after a given engine hours (for example 200

hours), but even if this amount of engine hours is not fulfilled, it is performed after a given time limit (for

example 12 months).

The unit has both programmable engine hours and maintenance time limit. The engine hours is

programmable with 50-hour steps, the time limit is programmable with 1 month steps. If any of the

programmed values is zero, this means that the parameter will not be used. For example a maintenance

period of 0 months indicates that the unit will request maintenance only based on engine hours, there will

be no time limit. If the engine hours is also selected as 0 hours this will mean that the SERVICE

REQUEST display will be inoperative.

When the engine hours OR the time limit is over, the SERVICE REQUEST led (red) will start to

flash and the service request relay function will be active.

The service request relay function may be assigned to spare relays using Relay Definition

program parameters. Also relays on an extension module may be assigned to this function.

The remaining engine hours and the remaining time limit are kept stored in a non-volatile memory

and are not affected from power supply failures.

The time and engine hours to service are displayed in the STATISTICAL COUNTERS menu.

To turn off the SERVICE REQUEST led, and reset the

service period, press together the ALARM MUTE and

LAMP TEST keys for 5 seconds.

The SERVICE REQUEST led has no effect on the

genset operation.

6.10 Service Request Display

DKG-307 User Manual V-37 (01.03.2012)

- 18 -

The unit features a non-erasable incremental engine hour meter. The hour meter information is

kept in a non-volatile memoryand is not affected from power supply failures.

The engine hours may be displayed STATISTICAL COUNTERS menu.

The date & time display is provided for verification.

Some additional features are installed within consecutive software releases. In order to be

sure of the validity of the status of the unit, the software version needs to be known.

The software version of the unit is displayed together with the data –time information.

The software version consists of 2 numbers. The first number represent the operating software

version of the unit.

The unit is capable of making modem calls in case of alarm, as well as answering modem

calls made from a remote location. GSM modems and classic cable network (PSTN) modems are

acceptable.

If the modem is connected to the unit, the Modem Enable program parameter should be set

to 1, otherwise faulty operation may occur.

A maximum of 2 telephone numbers can be defined for outgoing modem calls. In case of

alarm, the unit will attempt to reach control centers associated with each number. In case of modem

connection failure, the call will be repeated up to 30 times with 2 minute intervals.

Advised modems are DATAKOM types which are powered up from the same DC battery

voltage than the unit. Most of other desktop modems with standard AT commands are also usable, but

it is the user‟s responsibility to provide an uninterrupted AC supply source to the modem. The

necessary modem cable will be supplied by DATAKOM.

Modem calls are always terminated by the central RAINBOW software. However the unit does

not allow connection durations exceeding 2 minutes, and hangs up the modem when this period

expires.

The PC program used for remote monitoring and programming is the same RAINBOW

software used for RS-232 connection.

Please note that the modem operation is also compatible with the MODBUS communication.

Thus the unit can iniate and receive calls to/from a MODBUS master station. Please review chapter_8

for more details on MODBUS communication.

If Modem Enable or SMS Enable or MODBUS Address

parameters are different from zero, the local PC

connection will not work.

6.14 Modem Connection

6.13 Software Version Display

6.12 Date & Time Display

6.11 Engine Hour Meter

DKG-307 User Manual V-37 (01.03.2012)

- 19 -

The GSM SMS sending is activated by setting the SMS Enable program parameter to 1.

When a fault condition occurs, the unit will compose an SMS message and will send it to up to 6

phone numbers. If modem is enabled, only 4 telephone numbers are available for SMS sending.

The unit is also able to send SMS messages in below conditions, without creating a visible alarm

or warning:

Mains Fail, Mains Restored (enabled via SMS on Mains Change program parameter)

Fuel Theft, Fuelling (enabled by setting the Fuel Consumption / Hour parameter to other than 0)

If both modem and SMS are enabled, the unit will send SMS messages first and attempt modem

connection afterwards.

The maximum number of alarms transmitted in a SMS message is 4. This limitation is due to the

maximum length of an SMS message which is 160 characters.

A sample GSM SMS message is given below:

DKGxxx <SITE-ID>

STOP :LOW OIL PRESSURE SW.

END OF ALARM LIST

The first line of the message carries information about the unit type and the site identity string.

This line is intended for the identification of the genset sending the SMS message.

Each following line will give one fault information. The message will always be terminated by the

“END OF ALARM LIST” string.

When the message is sent, the existing alarms will be masked, causing the audible alarm relayto

release and preventing consecutive GSM SMS messages. Any new upcoming alarm will result in a new

GSM SMS message. The new message will indicate all existing alarms, even masked ones.

The necessary GSM modem cable will be supplied by DATAKOM. This is the same cable as

PSTN (land) modems.

If Modem Enable or SMS Enable or MODBUS Address

parameters are different from zero, the local PC

connection will not work.

6.15 SMS Message Sending

DKG-307 User Manual V-37 (01.03.2012)

- 20 -

Thanks to its standard serial RS-232 port, the unit offers the remote monitoring and

programming feature.

The remote monitoring and programming PC software is called RAINBOW and may be

downloaded from www.datakom.com.tr internet site with password login.

The modem, SMS and Modbus modes are not compatible with the local PC connection. Modem

Enable, SMS Enable and MODBUS Address program parameters should be set to 0 before

connection.

The RAINBOW software allows the visualization and recording of all measured parameters.

The recorded parameters may then be analyzed graphically and printed. The software also allows the

programming of the unit and the storage of the program parameters to PC or the downloading of

stored parameters from PC to the unit.

For PCs without a serial port, below USB to serial adapters are tested and approved :

DIGITUS USB 2.0 TO RS-232 ADAPTER (PRODUCT CODE: DA70146 REV 1.1)

DIGITUS USB 1.1 TO RS-232 ADAPTER (PRODUCT CODE: DA70145 REV 1.1)

FLEXY USB 1.1 TO SERIAL ADAPTER (PRODUCT CODE BF-810)

CASECOM USB TO SERIAL CONVERTER (MODEL: RS-01)

The necessary PC connection cable will be supplied by DATAKOM. The cable length should

not be over 3 meters.

6.16 Remote Monitoring and Programming

Other manuals for DKG-307

1

Table of contents

Other Datakom Control Panel manuals