S62 SERIES

INSTRUCTION MANUAL

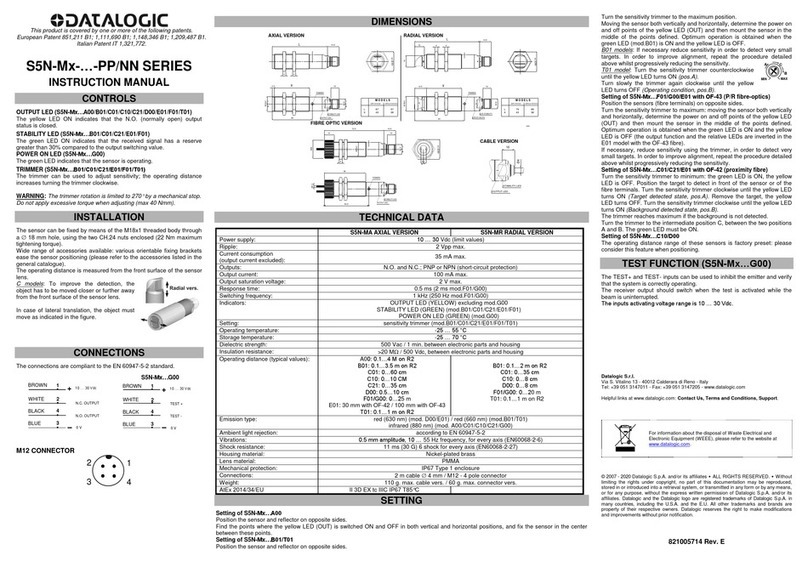

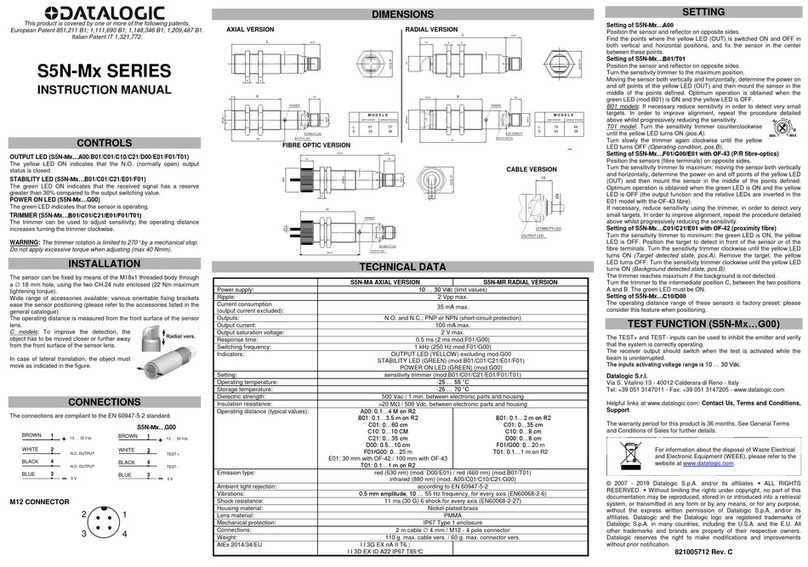

CONTROLS

OUTPUT LED (yellow) (S62..A/B/C/F)

The yellow LED ON indicates the output status.

STABILITY LED (green) (S62..A/B/C/F)

The green LED permantely ON indicates a stable operating

condition, where the signal received has a safety margin

higher than 30% respect to the output switching value.

The sensor is ready to function correctly.

POWER ON LED (green) (S62..G)

The green LED ON indicates the powering status and the laser

emission presence.

SENSIBILITY TRIMMER (ADJ.) (S62..A/B/C/F)

A mono-turn trimmer adjusts the sensitivity and the sensor

operating distance.

Please refer to “SETTING” paragraph for the correct use

procedure.

DARK/LIGHT TRIMMER (S62..RX/PN)

The LIGHT/DARK mode is selected using a mono-turn

trimmer.

LIGHT MODE: clockwise rotation

DARK MODE: counter-clockwise rotation.

WARNING: the maximum mechanical rotation range of the

trimmer is 240°. Do not force over of the maximum and

minimum positions.CONNECTIONS

DC models:

S62-PA-2/5-PN

S62-PA-2/5-PP/NN S62-2/5-G

AC models:

S62-PA-1-A/B/C/F S62-PA-1-G

TECHNICAL DATA

S62-PA-2/5 S62-PA-1

Power supply: 10 … 30 VDC– Class 2 (UL508) 24…240 VAC / 24…60 VDC

Ripple: 2 Vpp max. 10 % max

Current consumption

(output current excluded): < 30 mA < 3 VA

Outputs:

S62..PP/NN: PNP or NPN N.A./N.C.

30 VDC

S62..PN: NPN/PNP; 30 VDC max

(short-circuit protection)

Electromechanical SPDT

250 VAC / 30 VDC

Output current: 100 mA max

(overload and overvoltage protection)

2 A max.

(resistive load)

Output saturation voltage: 2 V -

Response time: S62…A/B/C: 500 s max.

S62…F/G: 1 ms 25 ms

Switching frequency: S62…A/B/C: 1 kHz

S62…F/G: 500Hz 20Hz

Emission type: RED (640 nm) (S62..A/B/C/G)

Operating distance (typical values): S62...B: 0.1…8 m on R2 (Ø63 mm reflector) (EG = 2)

S62…A: 13m on R2 (Ø63 mm reflector) (EG = 2)

S62...C01: 90 cm on 90% White target (EG = 2)

S62...C11: 200 cm on 90% White target (EG = 2)

S62…F/G: 0…25 m

Indicators: S62…A/B/C/F: OUTPUT LED (YELLOW) / STABILITY LED (GREEN)

S62…G: POWER ON LED (GREEN)

Adjustment: Mono-turn sensitivity adjustment trimmer

Mono-turn light/dark trimmer (S62..RX/PN)

Operating temperature: -10 … 55 °C

Storage temperature: -20 … 70 °C

Dielectric strength: 500 VAC, 1 min between electronics and housing

Insulating resistance: > 20 M, 500 VDC between electronics and housing

Ambient light rejection: according to EN 60947-5-2

Vibrations: 0.5 mm amplitude, 10 … 55 Hz frequency, for every axis (EN60068-2-6)

Shock resistance: 11 ms (30 G) 6 shock for every axis (EN60068-2-27)

Housing material: ABS

Lens material: PMMA window, policarbonate lens

Mechanical protection: IP67

Connections: 2 m cable 4 mm / M12 4-pole connector 2 m cable 5 mm

UL requirements:

VDC models: they are intended to be connected to a Class 2 transformer or class

2 power supply. VAC models: these devices shall be connected to a power-

supply or system,including filters or air-gaps, of overvoltage category II

(“load level – secondary circuit of a protected utility transformer”), suitable to

control over-voltages at the maximum “rated impulse withstand voltage peak of

1.2KV and with a short-circuit power limit at max 500VA.

Weight: 90 g. max. cable versions / 40 g. max. connectors versions

SETTINGS

S62..A/B setting: Position the sensor and reflector on opposite sides. Turn the sensitivity trimmer to maximum.

Find the points where the yellow LED (OUT) in both vertical and horizontal positions and fix the sensor in the centre

between these points. Optimum operation is obtained when both LEDs switch ON. If necessary, reduce sensitivity using the

trimmer, in order to detect very small targets. In order to improve alignment, repeat the procedure detailed above whilst

progressively reducing the sensitivity.

S62..C setting: Position the sensor and turn the sensitivity trimmer at minimum: the yellow LED is OFF

(litgh mode). Place the target opposite the sensor. Turn the sensitivity trimmer clockwise until the yellow LED

turns ON (Target detected state, pos.A). Remove the target, the yellow LED turns OFF.

Turn the trimmer clockwise until the yellow LED turns ON (Background detected state, pos.B).

The trimmer reaches maximum if the background is not detected. Turn the trimmer in intermediate position C,

between the two positions A and B. The green LED must be ON.

S62…F/G setting: Position the sensors on opposite sides. Turn the sensitivity trimmer to maximum. Find the points where

the yellow LED (OUT) is switched ON and OFF in both vertical and horizontal positions, and fix the sensor in the centre

between these points. Optimum operation is obtained when both LEDs switch ON.

If necessary, reduce sensitivity using the trimmer, in order to detect very small targets.

In order to improve alignment, repeat the procedure detailed above whilst progressively reducing the sensitivity.

DIMENSIONS

INSTALLATION

The sensor can be positioned by

means of the two housing holes

using two screws (M4x35 or longer,

1.2Nm maximum tightening

torque).

Various orientable fixing brackets to

ease the sensor positioning are

available (please refer to the accessories listed in the general

catalogue). The operating distance is measured from the front

surface of the sensor optics. The M12 connector can be oriented

at two different positions using the specific fastening spring and

rotating the block of 180°.

TEST FUNCTION (S62...G)

The TEST+ and TEST- inputs can be used to switch off the

emitter light and verify that the system is correctly operating: the

receiver output should switch when the test is activated while the

beam is uninterrupted: the inputs activating voltage range is

12…30 VDC, respecting the polarity.

The emission is switched OFF connecting TEST+ to VDC and

TEST- to 0V.

The sensors are NOT safety devices, and so MUST NOT be used in the

safety control of the machines where installed.

Datalogic S.r.l.

Via S. Vitalino 13 - 40012 Calderara di Reno - Italy

Tel: +39 051 3147011 - Fax: +39 051 3147205 - www.datalogic.com

Helpful links at www.datalogic.com: Contact Us, Terms and Conditions,

Support.

The warranty period for this product is 36 months. See General Terms and

Conditions of Sales for further details.

Under current Italian and European laws, Datalogic is not obliged to

take care of product disposal at the end of its life. Datalogic

recommends disposing of the product in compliance with local laws or

contacting authorised waste collection centres.

© 2007 - 2017 Datalogic S.p.A. and/or its affiliates ALL RIGHTS

RESERVED. Without limiting the rights under copyright, no part of this

documentation may be reproduced, stored in or introduced into a retrieval

system, or transmitted in any form or by any means, or for any purpose,

without the express written permission of Datalogic S.p.A. and/or its affiliates.

Datalogic and the Datalogic logo are registered trademarks of Datalogic

S.p.A. in many countries, including the U.S.A. and the E.U. All other

trademarks and brands are property of their respective owners. Datalogic

reserves the right to make modifications and improvements without prior

notification.

821002352 Rev. C

MIN MAX

A

B

C

RELAY