Datcon DT7200 Series User manual

DOC. N°:. DT7200 x-62 Eng

Manufacturer: DATCON Ipari Elektronikai Kft.

H-1148 Budapest, Fogarasi út 5. 27. ép.

Phone: +36-1-460-1000, Fax.: 460-1001

DT7200 x

Intrinsically Safe Pressure Transmitters

User Manual

Revision 3

25.10.2021

2

3

Contents

1. Function ...................................................................................................................... 4

..................................................................................................................................... 4

2. Important information before the device is put into operation..................................... 4

..................................................................................................................................... 4

3. Operating principle...................................................................................................... 5

..................................................................................................................................... 5

4. Mechanical design of the device; installation.............................................................. 5

..................................................................................................................................... 5

4.1. Mechanical design of the device .....................................................................................5

4.2. Mounting of the device.....................................................................................................6

..................................................................................................................................... 6

5. Installation of the device ............................................................................................. 7

..................................................................................................................................... 7

6. Connecting of the device ............................................................................................ 7

..................................................................................................................................... 7

7. Putting the device into operation ................................................................................ 8

..................................................................................................................................... 8

8. Changing of factory settings ....................................................................................... 8

..................................................................................................................................... 8

9. Maintenance, repair .................................................................................................... 8

..................................................................................................................................... 8

10. Technical Specifications ........................................................................................... 9

..................................................................................................................................... 9

11. Appendix................................................................................................................. 11

11.1. ATEX Certification .......................................................................................................11

4

1. Function

.

The DT7200 family of pressure transmitters can be used for the measuring of pressure in

explosive areas. The transmitter has a two-line system; that is, it creates the 4-20 mA signal

proportionate with the input pressure in the external power supply circuit. The process medium

to be measured can be either gas or liquid. The system offers the opportunity for both absolute

and relative measurement of pressure. The three members of the family are suitable for

measuring in different temperature ranges.

2. Important information before the device is put into operation.

.

Please read the following instructions attentively, because the Manufacturer does not undertake

responsibility for those failures that arise from improper handling.

Such pressure that is higher than the maximum value specified in the User Manual and in the

data table must not be communicated to the transmitter (not even dynamically), because the

sensor might get injured.

The sensor must not come into contact, for even a short time, with such medium whose

temperature is higher than the maximum value indicated in the User Manual and in the data

table, because it may get injured, and a hazard of explosion may occur.

The sensor must not come into contact, with such medium whose temperature is lower than the

minimum value indicated in the User Manual and in the data table, because it may get injured.

The pressure sensor can’t mix with consistent media, for this must to escape be harded and

frost-bite of measured material because transmitter can damage.

The transmitter must be protected against strong physical impacts, as it might lead to an injury

of the sensor, and a failure of the system.

The penetration of vapours, saturated with chemical agents, through the opening P0may cause

damages to the transmitter.

After the electric connector has been disassembled and assembled again, care must be taken

to ensure the tightness of the system; if the system fails to be tight, it might lead to leakage and

failures.

Only such power supply units should be used for operating the system, that belong to the

category of associated apparatus in terms of intrinsical safety, and that meet the specified

safety requirements.

Leakage of the process medium may cause grave injuries. Before the system is put under

pressure, screw the process connection to its place and tighten it, and check the tightness of

the system.

Always use an open-end wrench (size: 32) for doing the tightening after the connection is

established. Using of pipe wrench or any other tool for tightening may cause damages to the

transmitter.

The measured medium must be chemically compatible with the material of the seals.*

Only persons with appropriate qualifications may put the device into operation.

Upon installation and operation the specifications of the ATEX Certification must also be taken

into consideration.

* Please do not hesitate to contact the Manufacturer to obtain chemical resistance data when needed.

5

3. Operating principle

.

The output of the pressure sensor is a voltage in proportion with the input pressure. This voltage

gets amplified by a high-impedance symmetrical amplifier. The amplified signal goes to a

voltage-current transformer. This is the place where the 4 mA output current is set as „zero”

pressure, and the 20 mA output current is set as the effect of the pressure that corresponds with

the end-position of the scale. A voltage of 12-28 VDC is necessary for the operation of the

device; the system generates the 4-20 mA current in accordance with the measured pressure in

the above supply-voltage circuitry (2-wire).

4. Mechanical design of the device; installation

.

4.1. Mechanical design of the device

The members of the DT7200 family may be divided into two types in terms of temperature

ranges:

— normal temperature, DT7200 L (Figure 1), and

— high temperature, DT7200 M and DT7200 H (Figure 2).

The operating temperature ranges belonging to the various types are presented in Chapter 8.

Technical Specifications.

In the case of connection types G ½”A and M20x1,5 the seal must be applied in accordance

with the way shown in Figure 3. It is the User's responsibility to ensure that appropriate,

chemical- and heat-resistant seals are used.

In the case of the connection type G ¾”A with front membrane (see Figure 4) the sealing

function is performed by the "O"-ring of the plane above the thread. Its material has been

selected in accordance with the medium to be measured.

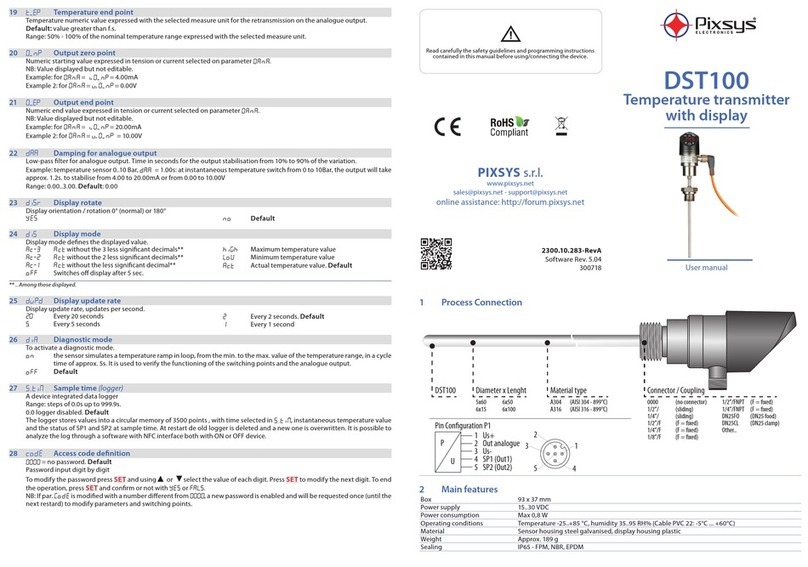

Figure 1. DT7200 L Figure 2. DT7200 M or DT7200 H

6

Figure 3. Mounting of transmitters, type M20x1.5 or G ½”A

Figure 4. Mounting of transmitter, type G ¾”A

4.2. Mounting of the device

.

The transmitter is delivered with a probe-connection in accordance with the customer order. It

can be screwed into the threaded connection socket made for this purpose in the system. An

open-end wrench (size 32) must be used for to tightening. Tightening with pipe wrench or with

any other tools may cause damages to the device.

Especially for high-temperature technology it is recommended to mount the transmitter either to

the side or to the bottom of the container tank. This way the inner heat isolation of the device

can exert its impact better. transmitters installed on the top of tanks are exposed to the effects

of high temperature communicated by the tank; this may cause overheating and failures. For

selecting the mounting place, care must also be paid to prevent the electrical connection from

getting any humidity in, as the system might get damaged when the it is not tight as a result of

improper assembling. The penetration of vapours saturated with chemical agents, through the

opening P0(Figure 5.) may cause damages to the transmitter. (in the case of absolute pressure-

measurement, there is no P0opening).

7

5. Installation of the device

.

The device can be installed at the boundary of “Zone 0” and “Zone 1” (Figure 5) or in places

with classification lower than that.

The side under measurement should be „Zone 0”. A mért oldal lehet a „0”-ás zóna. The device

should be operated by such power supply units only, that are classified as associated apparatus

in terms of intrinsical safety, and that meet the specified safety requirements, such as the power

supply unit DATCON DT1300 I4 xx, 18. See Chapter 8, Technical Specifications, for the limit

values pertaining to intrinsical safety.

Explosive area

Zone 0 Zone 1

Figure 5. Installation of the device

6. Connecting of the device

.

A Hirschmann GDM 2009 type connector belongs to the electrical connection of the device.

When the connector is connected to the system, the system must be dead. First remove the

screw, and click out with a thin screwdriver from its place (see Figure 5 for the connection

terminals). The device is protected against reverse connection (up to 28 V). When the

connector is re-assembled, care must be taken to ensure that the seals are put back properly,

and that the retaining screw of the connector is tightened, or else the device may leak and get

damaged.

Figure 6. Connection of the device

Terminal 1.: negative (I-)

Terminal 2.: positive (I+)

Terminal 3.: not connected.

The fourth terminal is the earth bonding point.

8

7. Putting the device into operation

.

The transmitter becomes operable after it has been mounted and after its electrical connections

are established. (checking of seals!)

Supply voltage values higher than those specified in the Technical Specifications may cause

damages to the transmitter.

After the device has got to its operating temperature (when there are no more temperature

drifts; in about 5-10 minutes) the transmitter is conform to the Technical Specifications.

8. Changing of factory settings

.

If the user wants to modify the set values, the GDM connector should be removed, and the user

can perform the adjustment through the holes, with a screwdriver of max. 2 mm Ø, using the

potentiometers mounted on the printed wiring board (Figure 6.).

The adjustment should be performed in the following order:

zero-setting with PZERO potentiometer (setting of 4 mA),

setting the end-value PMAX (setting of 20 mA)

(the final setting should be achieved by repeating the above

process several times).

Figure 6. Setting points of the transmitter

9. Maintenance, repair

.

pressure transmitters operated in accordance with the User Manual require no maintenance

other than the cleaning of its surfaces.

For cleaning, use water with some small amount of detergent. Cover the P0opening during the

cleaning (when the cleaning is completed, remove the covering of P0!)

The transmitter must be protected against strong physical impacts.

Generally the transmitters cannot be repaired in site.

In the case of a failure, contact the Manufacturer.

The Manufacturer provides 1-year guarantee for the pressure transmitter.

Those failures that are caused by usage differing from the instructions of the User Manual entail

the cessation of the guarantee.

9

10. Technical Specifications

.

Measurement limits: 0 – 100 mbar

0 – 160 mbar

0 – 250 mbar

0 – 400 mbar

0 – 600 mbar

0 – 1.00 bar

0 – 1.60 bar

0 – 2.50 bar

0 – 4.00 bar

0 – 6.00 bar

0 – 10.0 bar

0 – 16.0 bar

0 – 25.0 bar (as recommended)

(however, optional values within the ranges are also possible, by worse accuracy).

Overloadability: with a pressure up to 150% of the measuring limit. See the Quality Certification

and the Data Table for cases different from the above.

Output, transmitter: from 4-20 mA, with a two-line system

Maximum serial resistance of two-line transmitters:

Rmax = (Ut-12) / 0.02 [Ohm]

Accuracy at the current output:

- nominal value: ±0.25%, referring to the end-value

(at special cases see on the data label)

- linearity: 0.5%

- hysteresis, repeatability together: nominally 0.5%, referring to the end-value

- temperature dependency: ±0.5% / 10 °C (between 0 and 60 °C)

- supply voltage dependency: 0.1% / 10 V

Supply voltage: 12–28 VDC

Protection: IP 65, in accordance with MSZ EN 60529

Mechanical data:

- weight: DT7200 L ~0.3 kg

DT7200 M ~0.35 kg

DT7200 H ~0.35 kg

Electric shock protection:

The cover is groundable.

- insulation breakdown value: 500 V

- electric connection: IP 65

Hirschmann GDM 2009 type connector (IEC 60529)

Electromagnetic compatibility: The device is compatible with the relevant prescriptions

of the standard MSZ EN IEC 61326-1:2021 in terms of

electromagnetic compatibility and noise emission.

Materials in contact with the medium to be measured:

KO36steel

- seal: Teflon (PTFE) or Buna EP (EPDM) or Viton (FKM) or

Isolast 9503 (FFKM)

10

Ambient conditions:

- operating temperature range:

Type Seal Ambient temperature Temperature of medium

PTFE, EPDM -25 °C ≤Ta ≤60 °C -25 °C ≤Tp ≤70 °C

FKM -15 °C ≤Ta ≤60 °C -15 °C ≤Tp ≤70 °C

DT7200 L

FFKM -20 °C ≤Ta ≤60 °C -20 °C ≤Tp ≤70 °C

PTFE, EPDM -25 °C ≤Ta ≤70 °C -25 °C ≤Tp ≤90 °C

FKM -15 °C ≤Ta ≤70 °C -15 °C ≤Tp ≤90 °C

DT7200 M

FFKM -20 °C ≤Ta ≤70 °C -20 °C ≤Tp ≤90 °C

T4: -25 °C ≤Tp ≤130 °C

PTFE -25 °C ≤Ta ≤70 °C T3: -25 °C ≤Tp ≤140 °C

EPDM -25 °C ≤Ta ≤70 °C T4: -25 °C ≤Tp ≤130 °C

T4: -15 °C ≤Tp ≤130 °C

FKM -15 °C ≤Ta ≤70 °C T3: -15 °C ≤Tp ≤140 °C

T4: -20 °C ≤Ta ≤130 °C

DT7200 H

FFKM -20 °C ≤Ta ≤70 °C T3: -20 °C ≤Tp ≤140 °C

- storing temperature range: -25 °C – +70 °C

- shock resistance: max. 20 g

Class of intrinsical safety:

DT7200 L II 1 G Ex ia IIC T4 Ga

DT7200 M II 1 G Ex ia IIC T4 Ga

DT7200 H II 1 G Ex ia IIC T4…T3 Ga

Certificate: BKI15ATEX0037 X

BKI15ATEX0037 X/1

BKI15ATEX0037 X/2

Safety data: Ui: 28 V Ii: 100 mA Pi: 0.7 W

C

i: 37 nF Li: 506 H

11

11. Appendix

11.1. ATEX Certification

12

13

14

15

16

17

18

19

20

This manual suits for next models

6

Table of contents

Other Datcon Transmitter manuals