DATREND Systems venTest User manual

Operating Manual

venTest™

Ventilator Tester

MN-108

To order this manual, use Part Number 6100-200

Revision

Revision History

Description Date

A Initial Release 2016-Mar-08

B General update 2018-Jun-28

Copyright

Datrend Systems Inc. (“DSI”) agrees to a limited copyright release that allows you to reproduce manuals and other

printed materials for use in service training programs and other technical publications. If you would like other

reproductions or distributions, submit a written request to Datrend Systems Inc.

Unpacking and Inspection

Follow standard receiving practices upon receipt of the instrument. Check the shipping carton for damage. If damage

is found, stop unpacking the instrument. Notify the freight carrier and ask for an agent to be present while the instrument

is unpacked. There are no special unpacking instructions, but be careful not to damage the instrument when unpacking

it. Inspect the instrument for physical damage such as bent or broken parts, dents, or scratches.

Claims

Our routine method of shipment is via common carrier. Upon delivery, if physical damage is found, retain all packing

materials in their original condition and contact the carrier immediately to file a claim.

If the instrument is delivered in good physical condition but does not operate within specifications, or if there are any

other problems not caused by shipping damage, please contact your local sales representative or DSI immediately.

Standard Terms and Conditions

Refunds & Credits

Please note only serialized products (products labelled with a distinct serial number) and accessories are eligible for

partial refund and/or credit. Non-serialized parts and accessory items (cables, carrying cases, auxiliary modules, etc.)

are not eligible for return or refund. In order to receive a partial refund/credit, the product must not have been damaged,

and must be returned complete (meaning all manuals, cables, accessories, etc.) within 90 days of original purchase and

in “as new” and resalable condition. The Return Procedure must be followed.

Return Procedure

Every product returned for refund/credit must be accompanied by a Return Material Authorization (RMA) number,

obtained from Datrend Customer Service. All items being returned must be sent prepaid (freight, duty, brokerage, and

taxes ) to our factory location.

Restocking Charges

Products returned within 30 days of original purchase are subject to a minimum restocking fee of 15%. Products returned

in excess of 30 days after purchase, but prior to 90 days, are subject to a minimum restocking fee of 20%. Additional

charges for damage and/or missing parts and accessories will be applied to all returns. Products which are not in “as

new” and resalable condition, are not eligible for credit return and will be returned to the customer at their expense.

Certification

This instrument was thoroughly tested and inspected and found to meet DSI’s manufacturing specifications when it was

shipped from the factory. Calibration measurements are traceable to the National Research Council of Canada (NRC)

and/or the National Institute of Standards and Technology (NIST). Devices for which there are no NRC/NIST calibration

standards are measured against in-house performance standards using accepted test procedures.

Page i

Warranty

Warranty and Product Support

Datrend Systems Inc. ("DSI") warrants the venTest Unit (the "Datrend product") to be free from defects in materials and

workmanship under normal use and service for one (1) year from the date of original purchase. During the warranty

period DSI will, at our option, either repair or replace defects in materials and workmanship at no charge; provided the

Datrend product is returned (shipping, duty, brokerage and taxes prepaid) to DSI. Any and all transportation charges

incurred are the responsibility of the purchaser and are not included within this warranty. This warranty extends only to

the original purchaser and does not cover damage from abuse, neglect, accident or misuse or as the result of service

or modification by other than DSI. IN NO EVENT SHALL DATREND SYSTEMS INC. BE LIABLE FOR

CONSEQUENTIAL DAMAGES.

This warranty is subject to the following limitations:

!Standard Accessories: 90 day limited warranty

!Re-calibration of the instrument, which has a recommended annual calibration frequency, is not covered under the

warranty.

No warranty shall apply when damage is caused by any of the following:

!Power failure, surges, or spikes,

!Damage in transit, when moving the instrument, or if the unit is dropped,

!Improper power supply such as low voltage, incorrect voltage, defective wiring or inadequate fuses,

!Accident, alteration, abuse or misuse of the instrument,

!Fire, water damage, theft, war, riot, hostility, acts of God, such as hurricanes, floods, etc.

Only serialized products (those items bearing a distinct serial number tag) and their accessory items are covered under

this warranty. PHYSICAL DAMAGE CAUSED BY MISUSE OR PHYSICAL ABUSE IS NOT COVERED UNDER THE

WARRANTY. Items such as cables and non-serialized modules are not covered under this warranty.

This warranty gives you specific legal rights and you may have other rights, which vary from province to province, state

to state, or country to country. This warranty is limited to repairing the instrument to DSI's specifications.

When you return an instrument to DSI for service, repair or calibration, we recommend shipment using the original

shipping foam and container. If the original packing materials are not available, we recommend the following guide for

repackaging:

!Use a double-walled carton of sufficient strength for the weight being shipped.

!Use heavy paper or cardboard to protect all instrument surfaces. Use non-abrasive material around all projecting parts.

!Use at least four inches of tightly packed, industrial-approved, shock-absorbent material all around the instrument.

DSI will not be responsible for lost shipments or instruments received in damaged condition due to improper packaging

or handling. All warranty claim shipments must be made on a prepaid basis (freight, duty, brokerage, and taxes). No

returns will be accepted without a Return Materials Authorization ("RMA”) number. Please contact to obtain an RMA

number and receive help with shipping/customs documentation.

Page ii

Warranty Disclaimer

Should you elect to have your instrument serviced and/or calibrated by someone other than Datrend Systems or an

Authorized Service Centre, please be advised that the original warranty covering your product becomes void when the

tamper-resistant Quality Seal is removed or broken without proper factory authorization. We strongly recommend,

therefore, that you send your instrument to Datrend Systems or an Authorized Service Centre for service and calibration,

especially during the original warranty period.

In all cases, breaking the tamper-resistant Quality Seal should be avoided at all cost, as this seal is the key to your

original instrument warranty. In the event that the seal must be broken to gain internal access to the instrument (e.g.,

in the case of a customer-installed firmware upgrade), you must first contact Datrend Systems at 1-604-291-7747. You

will be required to provide us with the serial number for your instrument as well as a valid reason for breaking the Quality

Seal. You should break this seal only after you have received factory authorization. Do not break the Quality Seal before

you have contacted us! Following these steps will help ensure that you will retain the original warranty on your instrument

without interruption.

WARNING

Unauthorized user modifications or application beyond the published specifications may result in electrical shock hazards

or improper operation. Datrend Systems will not be responsible for any injuries sustained due to unauthorized equipment

modifications.

DSI DISCLAIMS ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING ANY WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OR APPLICATION.

THIS PRODUCT CONTAINS NO USER-SERVICEABLE COMPONENTS.

UNAUTHORIZED REMOVAL OF THE INSTRUMENT COVER SHALL VOID

THIS AND ALL OTHER EXPRESSED OR IMPLIED WARRANTIES.

Note: Calibration of Datrend products typically involves adjustment of parameters stored in firmware by proprietary

software. Parties other than Datrend and its Authorized Service Centers are limited to verification of the status of the

accuracy of the instrument. Do not confuse verification with calibration.

Page iii

Page iv

venTest OPERATORS MANUAL

Table of Contents

ABBREVIATIONS AND DEFINITIONS.....................................VIII

SYMBOL DEFINITIONS............................................... X

1 SPECIFICATIONS................................................. 1

1.1 Instrument Specifications.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1.1 FlowSense 300 (Hi Flow) Sensor Measurement .. . . . . . . . . . . . . . . . . 1

1.1.2 FlowSense 012 (Low Flow) Sensor Measurement . . . . . . . . . . . . . . . . 4

2

1.1.3 Oxygen (O ) Sensor Measurement .. . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.1.4 IRMA AX+ Multigas Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

TM

1.2 UserInterface. .................................................. 9

1.3 ElectricalRatings................................................. 9

1.4 EnvironmentforUse. ............................................. 9

1.5 Dimensions. ................................................... 10

1.6 Weight........................................................ 10

1.7 StandardAccessories. ........................................... 10

1.8 OptionalAccessories............................................. 10

1.9 Compliance With Standards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2 OVERVIEW.................................................... 11

2.1 Features. ..................................................... 12

2.1.1 Analyzer Base Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.1.2 Pressure Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.1.3 Flow Sensor Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.1.4 Oxygen Sensor Connection.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.1.5 IRMA Sensor Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

TM

2.1.6 Ethernet. .............................................. 17

2.1.7 USB................................................... 17

2.1.8 SDCardslot............................................ 17

2.1.9 Reset.................................................. 17

3 GENERAL INSTRUCTIONS.......................................... 18

3.1 Safety. ....................................................... 18

3.1.1 Responsibility of Operating Staff. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.2 Maintenance. .................................................. 19

3.3 Manufacturer Liability.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.4 Precautions.................................................... 20

3.5 IntendedUse................................................... 21

4 OPERATION. .................................................. 22

4.1 Power. ....................................................... 22

4.1.1 PowerON.............................................. 23

Table of Contents #Page v

venTest OPERATORS MANUAL

4.1.2 Power OFF/Power Button Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.1.3 Energy Saving Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.1.4 Screenshots. ........................................... 24

4.2 UserInterface. ................................................. 25

4.2.1 Keyboard............................................... 26

4.2.2 Swipescreens........................................... 27

4.2.3 TraceDisplay. .......................................... 28

4.2.4 Measured Value Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.2.5 MainDisplay............................................ 30

4.3 StatusBar..................................................... 31

4.4 Structure of Measured Values Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.4.1 Measured Value Configuration Menu. . . . . . . . . . . . . . . . . . . . . . . . . 33

4.5 Overview: Measured Value. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4.5.1 Flow Measured Values. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4.5.2 Ventilation Values. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4.5.3 Pressure Measured Values. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

4.5.4 Gas Concentration Values.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

4.5.5 Other.................................................. 38

4.6 Overview: Standard Conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4.7 Filter. ........................................................ 40

4.8 FlowSense Settings Button. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

4.9 Graph Configuration Menu.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

4.10 MainMenu.................................................... 42

4.10.1 SetupSubMenu........................................ 43

4.10.1.1 InfoandUpdate.......................................... 44

4.10.1.2 Date, Sound and Language. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4.10.1.3 Network................................................ 46

4.10.1.4 Service................................................. 48

4.10.2 Display Sets Sub Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

4.10.3 Selection of Display Sets.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

4.10.4 Creation of New Display Sets. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

4.10.5 Modifying Existing Display Sets.. . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

4.10.6 Import / Export of Display Sets. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

4.10.7 Deleting Display Sets. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

4.11 ‘Logging’SubMenu............................................. 53

4.12 SensorsSubMenu. ............................................ 56

4.12.1 Zeroing of Pressure Sensors.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

4.12.2 FlowSense Hi and Lo Sensors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

4.12.2.1 'General'............................................... 59

4.12.2.2 Inspiration & Expiration Trigger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

4.12.2.3 'Adjustment' Button. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

2

4.12.3 O-Sensor............................................. 65

4.12.4 IRMA™AX+........................................... 67

4.13 Creating Test Procedures and Test Reports (optional). . . . . . . . . . . . . . . . . . 68

4.14 SensorStartup................................................. 69

4.14.1 FlowSense Airflow Sensor.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Table of Contents #Page vi

venTest OPERATORS MANUAL

2

4.14.2 O -Sensor (optional). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

4.14.3 IRMA™AX+........................................... 70

4.15 Troubleshooting & Error Handling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

4.15.1 BiFlow-Sensor Error Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

4.15.2 IRMA™ AX+ Sensor Error Messages. . . . . . . . . . . . . . . . . . . . . . . . 71

4.16 Cleaning. .................................................... 72

4.16.1 Housing.............................................. 72

4.16.2 Display............................................... 72

4.16.3 FlowSense Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

4.17 Maintenance and Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

4.17.1 venTest. ............................................. 73

4.17.2 Oxygensensor......................................... 73

4.17.3 Waste Management. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

4.17.4 Technical Support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

APPENDIX A: TRIGGERING OPTIONS.................................... 77

1 Trigger Options of venTest. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

2 Volume measuring of Gases.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

3 Consequences of Physical Characteristics Of a Gas . . . . . . . . . . . . . . . . . . . . . 83

APPENDIX B: UNDERSTANDING DATA RECORDS........................... 87

1 Recording Data from a Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

APPENDIX C: CONNECTING TO A WINDOWS DATA SHARE. ................... 91

1 General........................................................ 91

2 WorkgrouporDomain?............................................ 93

3 Connecting to a Workgroup Share. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

4 Connecting to a Domain Share. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Table of Contents #Page vii

venTest OPERATORS MANUAL

Abbreviations and Definitions

The following abbreviations, terms and acronyms are used throughout this manual:

ENF enflurane

DES desflurane

HAL halothane

ISO isoflurane

SEV sevoflurane

lliter

ml milliliter

l/min liters per minute

ml/min milliliters per minute

l/s liters per second

cfm cubic feet per minute

s, sec second

ms, msec millisecond

kPa kilopascal

hPa hectopascal

MPa megapascal

2

cmH O centimeters of water

psi pounds-force per square inch

bar bar

mbar millibar

%percent

mmHg millimeters of mercury

Torr Torr

2

inH O inches of water

inHg inches of mercury

F

odegrees Fahrenheit

C

odegrees Celcius

Definitions #Page viii

venTest OPERATORS MANUAL

Hz Hertz

1/min 1 per minute

% Vol Volume percent

% r.f. Percent relative humidity

% h Percent per hour

mAh milliamp-hours

Definitions #Page ix

venTest OPERATORS MANUAL

Symbol Definitions

The following symbols may be found on venTest:

CONSULT MANUAL FOR PROPER OPERATION

The operating manual provides valuable information on the proper use of venTest. It is highly recommended the operator

read the instructions thoroughly before operating the device. It is possible to damage the Equipment and/or cause harm

to the operator if venTest is used incorrectly.

The following symbols may appear on the device or in the manual.

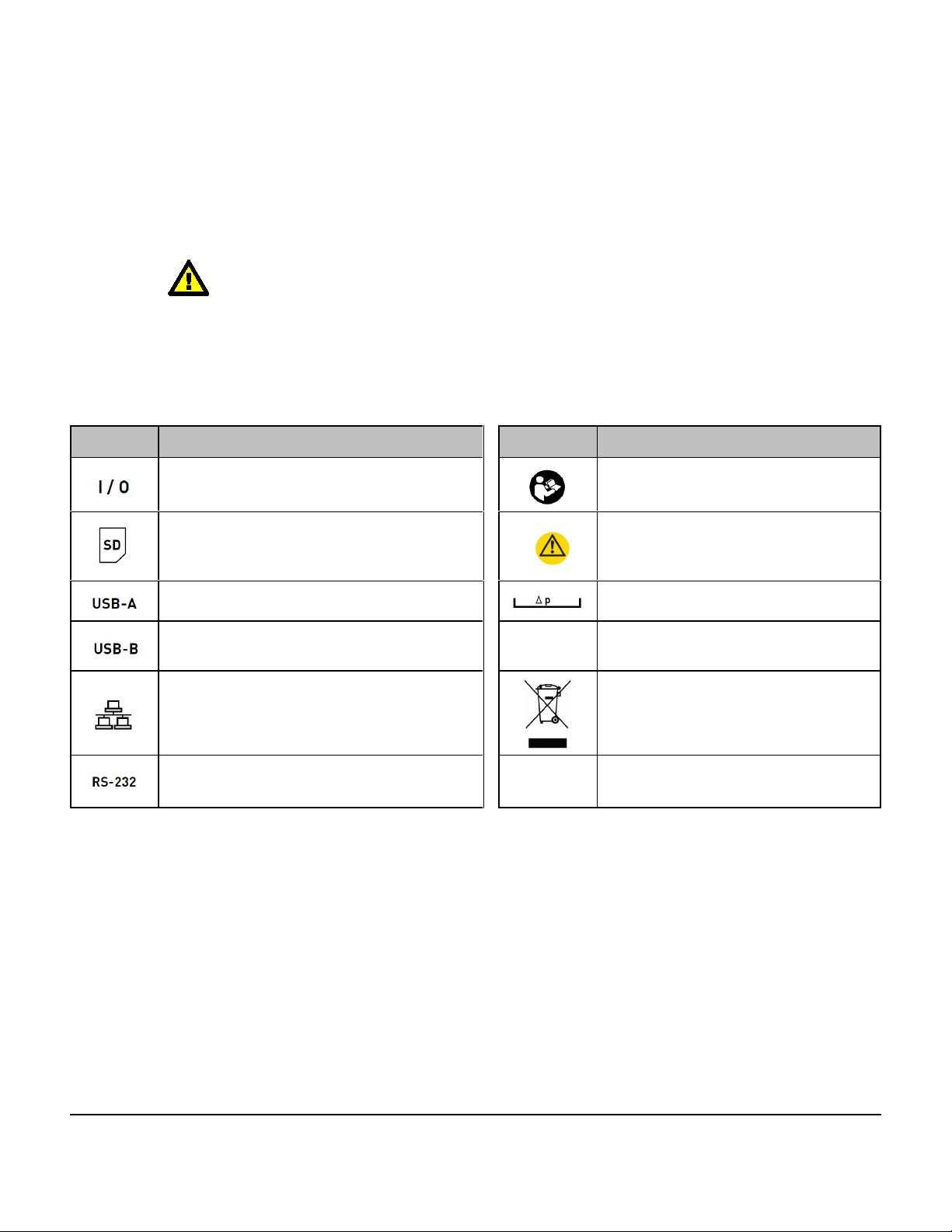

Symbol Description Symbol Description

ON/OFF Button Read Instruction Manual

SD Memory Card Warning

USB Type A, Host port Differential Pressure

USB Type B, Device Port LAttention/Information

Ethernet Port Note on waste disposal

DB9 Female, serial port

(*special purpose)

Definitions #Page x

venTest OPERATORS MANUAL

1 Specifications

Performance Specifications

1.1 Instrument Specifications

1.1.1 FlowSense 300 (Hi Flow) Sensor Measurement

Physical Data

Dimensions 150 mm x 41 mm x 58 mm (L x W x H)

Connector 1 Cone ID 22 mm

Connector 2 Cone OD 22 mm, ID 15 mm

Weight Approx. 290 g

Environmental Conditions

Parameter Operation Storage

Temperature 10 to 40 EC -20 to 50 EC

Ambient Humidity 5 to 95% RH

(non-condensing)

5 to 95% RH (non-condensing)

Gas Temperature 10 to 40 EC

Gas Humidity 0 to 95% RH

(non-condensing)

Ambient Pressure 60 - 110 kPa 60 - 110 kPa

Specifications/Chapter 1 #Page 1

venTest OPERATORS MANUAL

Range and Accuracy

Parameter Units Range

Accuracy

(whichever is

greater)

Flow: Air ± 300 l/min ± 2% or 0.1 l/min

(STPD)

2

Flow: O ± 200 l/min ± 4% or 0.2 l/min

(STPD)

2

Flow: Air/O ± 200 l/min ± 4% or 0.2 l/min

(STPD)

Vti l; ml 0 - 10 L ± 2% of m.v. or 0.2 l

(AIR) **

± 4% of m.v. or 0.4 l

2 2

(O , AIR/O ) **

Vte l; ml 0 - 10 L ± 2% of m.v. or 0.2 l

(AIR) **

± 4% of m.v. or 0.4 l

2 2

(O , AIR/O ) **

MVi l/min; ml/min 0.5 - 50 L/min (AIR)

2

0.5 - 50 L/min (O ,

2

AIR/O )

± 2% of m.v. or 0.2

l/min (AIR) **

± 4% of m.v. or 0.4

2 2

l/min (O , AIR/O ) **

MVe l/min; ml/min 0.5 - 50 L/min (AIR)

2

0.5 - 50 L/min (O ,

2

AIR/O )

± 2% of m.v. or 0.2

l/min (AIR) **

± 4% of m.v. or 0.4

2 2

l/min (O , AIR/O ) **

Breath Rate (Freq) BrPM 1 - 100 BrPM

101 - 200 BrPM

± 0.1 BrPM ‡

± 0.2 BrPM ‡

2

Ventilation Pressure kpa; mbar; cmH O;

mmHg; psi; hpa

0 - 10 kPa ± 1% of m.v. or

0.2 hPa

2

PEEP kpa; mbar; cmH O;

mmHg; psi; hpa

0 - 10 kPa ± 1% or 0.02 kPa* **

Peak 2

kpa; mbar; cmH O;

mmHg; psi; hpa

0 - 10 kPa ± 1% or 0.02 kPa* **

Specifications/Chapter 1 #Page 2

venTest OPERATORS MANUAL

Range and Accuracy

Parameter Units Range

Accuracy

(whichever is

greater)

Plateau 2

kpa; mbar; cmH O;

mmHg; psi; hpa

0 - 10 kPa ± 1% or 0.02 kPa* **

2

Mean kpa; mbar; cmH O;

mmHg; psi; hpa

0 - 10 kPa ± 1% or 0.02 kPa* **

I/E 300/1 - 1/300 ± 0.1 **

Ti s; ms 0 - 60 sec ± 1% ± 0.02sec **

Te s; ms 0 - 60 sec ± 1% ± 0.02sec **

Tip s; ms 0 - 60 sec ± 1% ± 0.02sec **

Tep s; ms 0 - 60 sec ± 1% ± 0.02sec **

Humidity % rh 5 - 95% 5 - 80 % rh: ± 3%

80 - 95 % rh: ± 4%

Insp. Peak Flow l/min; ml/min 0 - 300 L/min (AIR)

2

0 - 200 L/min (O ,

2

AIR/O

± 2% of m.v. or 0.1

l/min (AIR) **

± 4% of m.v. or 0.2

2 2

l/min (O , AIR/O ) **

Exp. Peak Flow l/min; ml/min 0 - 300 L/min (AIR)

2

0 - 200 L/min (O ,

2

AIR/O

± 2% of m.v. or 0.1

l/min (AIR) **

± 4% of m.v. or 0.2

2 2

l/min (O , AIR/O ) **

2

HFO Pmean kpa; mbar; cmH O;

mmHg; psi; hpa

0 - 10 kPa ± 2% of m.v. or 0.04

kPa* **

2

HFO PMax kpa; mbar; cmH O;

mmHg; psi; hpa

0 - 10 kPa ± 2% of m.v. or 0.04

kPa* **

2

HFO PMin kpa; mbar; cmH O;

mmHg; psi; hpa

0 - 10 kPa ± 2% of m.v. or 0.04

kPa* **

2

HFO amplitude kpa; mbar; cmH O;

mmHg; psi; hpa

0 - 10 kPa ± 2% of m.v. or 0.04

kPa* **

HFO frequency Hz 0 - 20 ± 1 Hz

HFO I/E 3/1 - 1/3 ± 0.3

(*) Please note that due to the pneumatic resistance of the Flowsense 300 Sensor the measured pressure from the ventilation pressure sensor may differ from values

measured at other places in breathing system, especially at high flows .

(**) Subject to trigger settings

Specifications/Chapter 1 #Page 3

venTest OPERATORS MANUAL

1.1.2 FlowSense 012 (Low Flow) Sensor Measurement

Physical Data

Dimensions 125 mm x 41 mm x 58 mm (L x W x H)

Connector 1 6 mm tube connection

Connector 2 6 mm tube connection

Weight Approx. 290 g

Environmental Conditions

Parameter Operation Storage

Temperature 10 to 40 EC -20 to 50 EC

Ambient Humidity 5 to 95% RH

(non-condensing) 5 to 95% RH (non-condensing)

Gas Temperature 10 to 40 EC

Gas Humidity 0 to 95% RH

(non-condensing)

Ambient Pressure 60 - 110 kPa 60 - 110 kPa

Range and Accuracy

Parameter Units Range

Accuracy

(whichever is

greater)

Flow: Air ± 12 l/min ± 2% or 0.01 l/min

(STPD)

2

Flow: O ± 12 l/min ± 4% or 0.02 l/min

(STPD)

2

Flow: Air/O ± 12 l/min ± 4% or 0.02 l/min

(STPD)

Vti l; ml 0 - 7.5 L ± 2% of m.v. or 20 ml

(AIR) ‡

Vte l; ml 0 - 7.5 L ± 2% of m.v. or 20 ml

(AIR) ‡

Specifications/Chapter 1 #Page 4

venTest OPERATORS MANUAL

Range and Accuracy

Parameter Units Range

Accuracy

(whichever is

greater)

MVi l/min; ml/min 0.5 - 12 L/min (AIR)

2

0.5 - 12 L/min (O ,

2

AIR/O )

± 2% of m.v. or 20

ml/min (AIR) ‡

± 4% of m.v. or 40

2 2

ml/min (O , AIR/O ) ‡

MVe l/min; ml/min 0.5 - 12 L/min (AIR)

2

0.5 - 12 L/min (O ,

2

AIR/O )

± 2% of m.v. or 0.2

l/min (AIR) ‡

± 4% of m.v. or 0.4

2 2

l/min (O , AIR/O ) ‡

Breath Rate (Freq) BrPM 1 - 100 BrPM

101 - 200 BrPM

± 0.1 BrPM ‡

± 0.2 BrPM ‡

Ventilation Pressure kpa; Mpa; bar; mbar;

2

cmH O; mmHg; psi;

2

hpa; Torr; inH O; inHg

0 - 10 kPa ± 1% of m.v. or

0.2 hPa

2

PEEP kpa; mbar; cmH O;

mmHg; psi; hpa

0 - 10 kPa ± 1% or 0.02 kPa

† ‡

2

Peak kpa; mbar; cmH O;

mmHg; psi; hpa

0 - 10 kPa ± 1% or 0.02 kPa

† ‡

2

Plateau kpa; mbar; cmH O;

mmHg; psi; hpa

0 - 10 kPa ± 1% or 0.02 kPa

† ‡

2

Mean kpa; mbar; cmH O;

mmHg; psi; hpa

0 - 10 kPa ± 1% or 0.02 kPa

† ‡

I/E 300/1 - 1/300 ± 0.1 ‡

Ti s; ms 0 - 60 sec ± 1% ± 0.02sec ‡

Te s; ms 0 - 60 sec ± 1% ± 0.02sec ‡

Tip s; ms 0 - 60 sec ± 1% ± 0.02sec ‡

Tep s; ms 0 - 60 sec ± 1% ± 0.02sec ‡

Humidity % rh 5 - 95% 5 - 80 % rh: ± 3%

80 - 95 % rh: ± 4%

Specifications/Chapter 1 #Page 5

venTest OPERATORS MANUAL

Range and Accuracy

Parameter Units Range Accuracy

(whichever is

greater)

Insp. Peak Flow l/min; ml/min 0 - 300 L/min (AIR)

2

0 - 200 L/min (O ,

2

AIR/O

± 2% of m.v. or 0.1

l/min (AIR) ‡

± 4% of m.v. or 0.2

2 2

l/min (O , AIR/O ) ‡

Exp. Peak Flow l/min; ml/min 0 - 300 L/min (AIR)

2

0 - 200 L/min (O ,

2

AIR/O

± 2% of m.v. or 0.1

l/min (AIR) ‡

± 4% of m.v. or 0.2

2 2

l/min (O , AIR/O ) ‡

2

HFO Pmean kpa; mbar; cmH O;

mmHg; psi; hpa

0 - 10 kPa ± 2% of m.v. or

0.04 kPa

† ‡

2

HFO PMax kpa; mbar; cmH O;

mmHg; psi; hpa

0 - 10 kPa ± 2% of m.v. or

0.04 kPa

† ‡

2

HFO PMin kpa; mbar; cmH O;

mmHg; psi; hpa

0 - 10 kPa ± 2% of m.v. or

0.04 kPa

† ‡

2

HFO amplitude kpa; mbar; cmH O;

mmHg; psi; hpa

0 - 10 kPa ± 2% of m.v. or 0.04

kPa

† ‡

HFO frequency Hz 0 - 20 ± 1 Hz

HFO I/E 3/1 - 1/3 ± 0.3

(†) Please note that due to the pneumatic resistance of the Flowsense 012 Sensor the measured pressure from the ventilation pressure sensor may

differ from values measured at other places in breathing system, especially at high flows .

(‡) Subject to trigger settings

Specifications/Chapter 1 #Page 6

Table of contents

Other DATREND Systems Test Equipment manuals