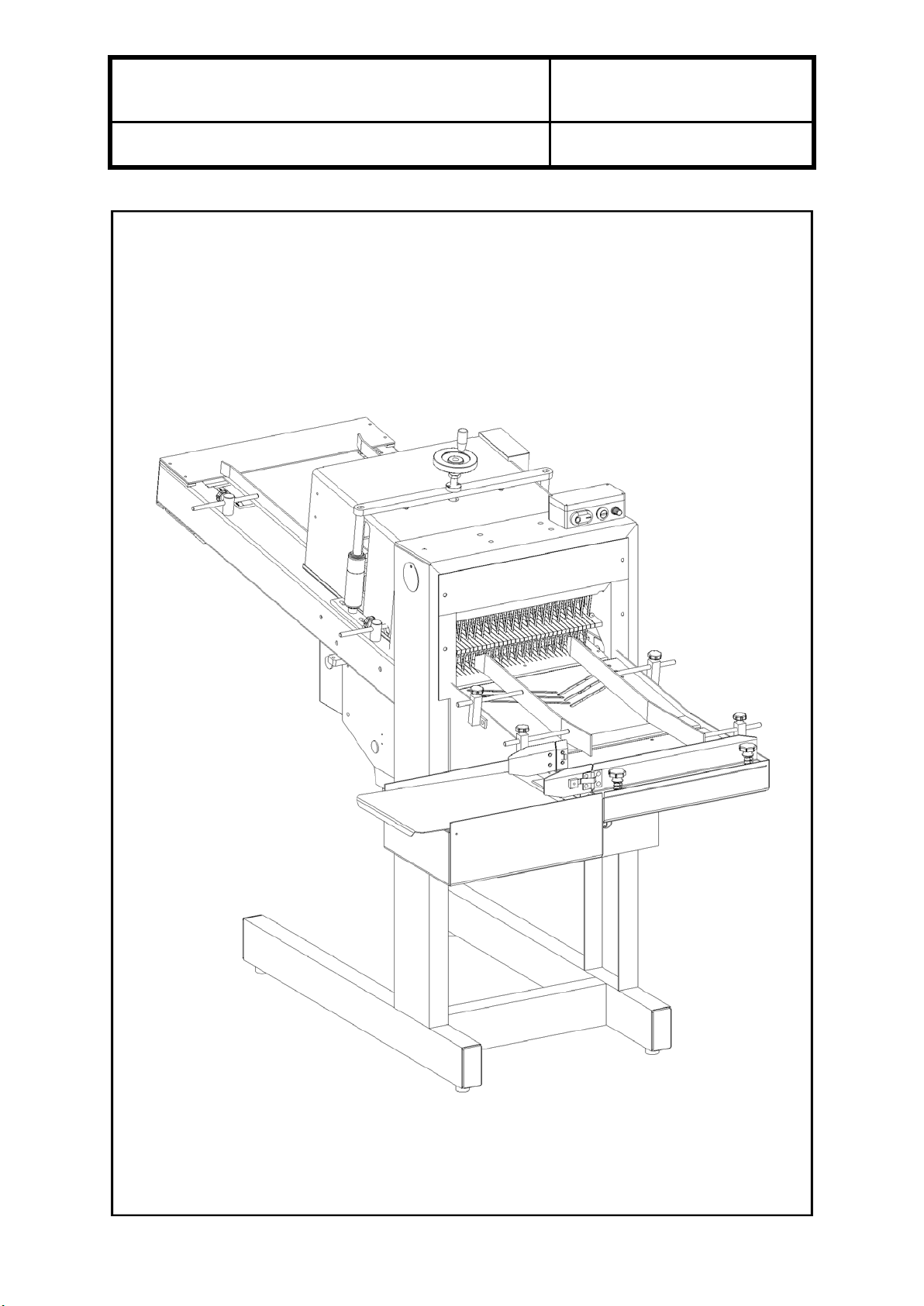

CROSS-SLICER

208 Date: 23-2-2016

Version: 06

USERS MANUAL Page 3

TABLE OF CONTENTS

GENERAL............................................................................................................................. 2

TABLE OF CONTENTS ........................................................................................................ 3

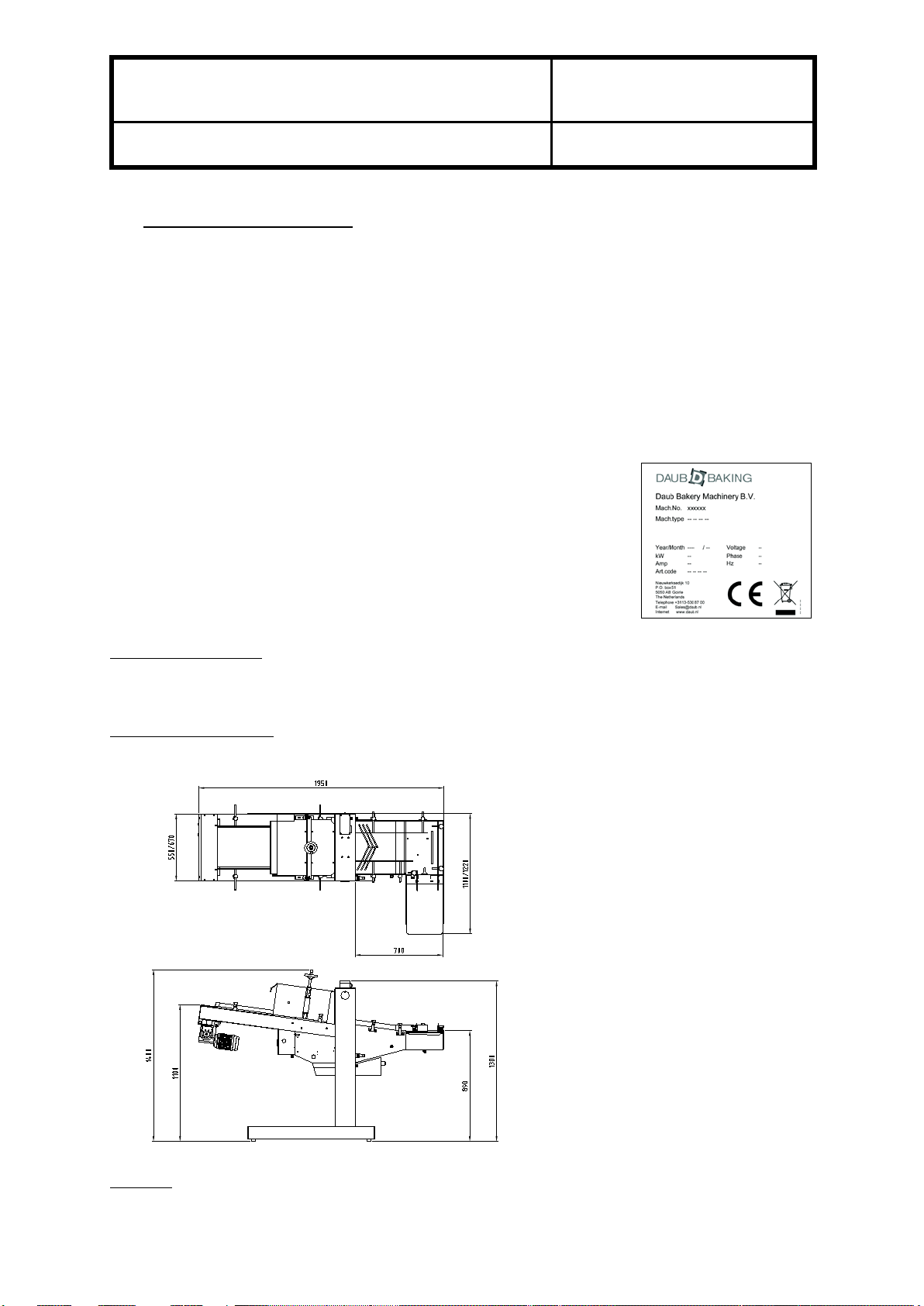

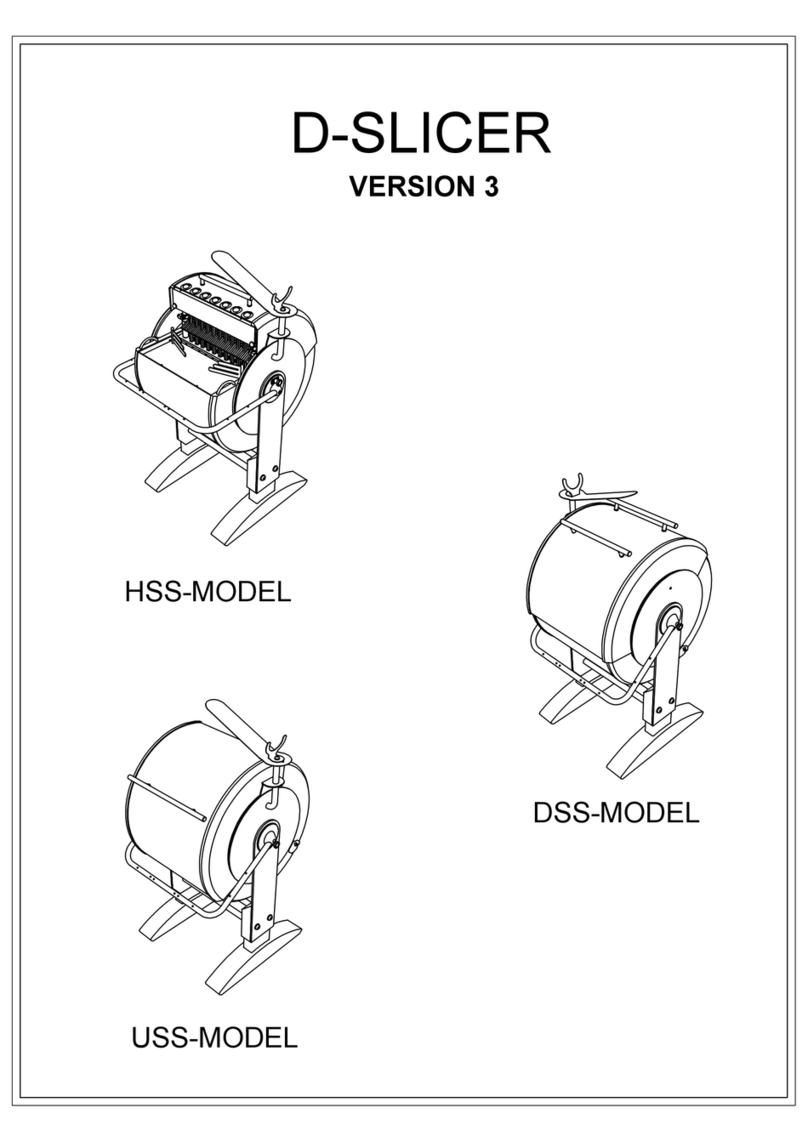

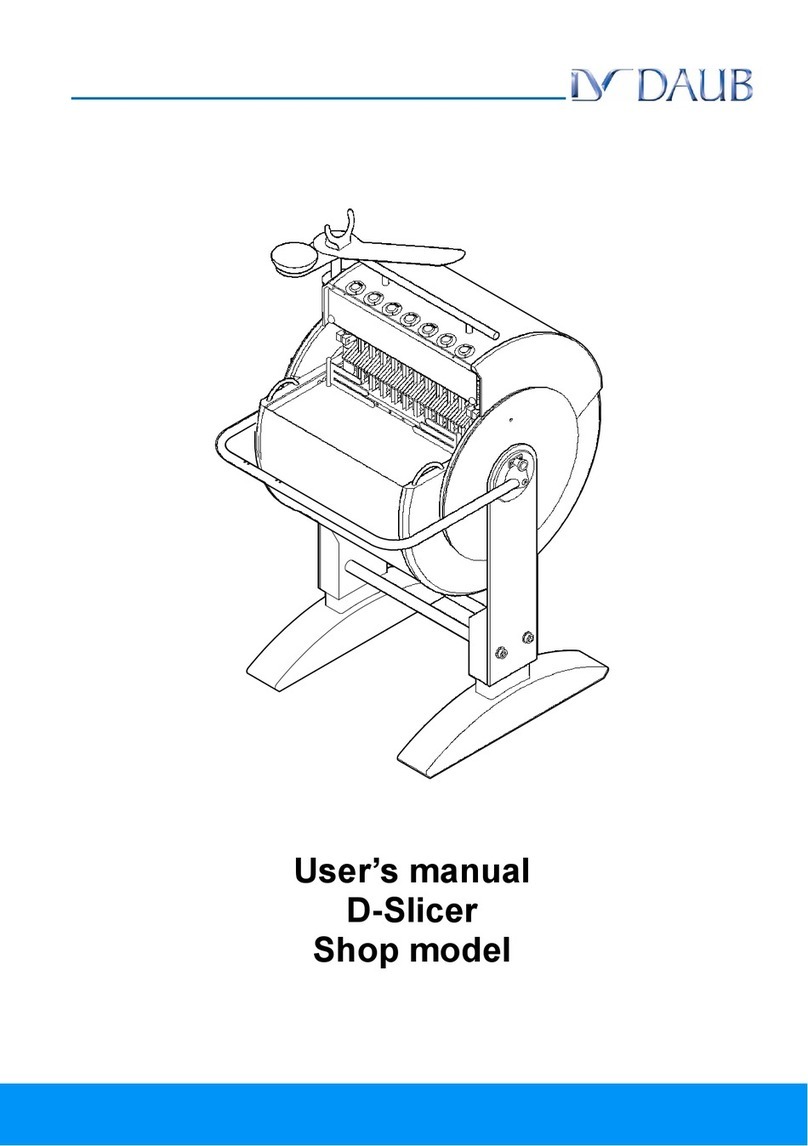

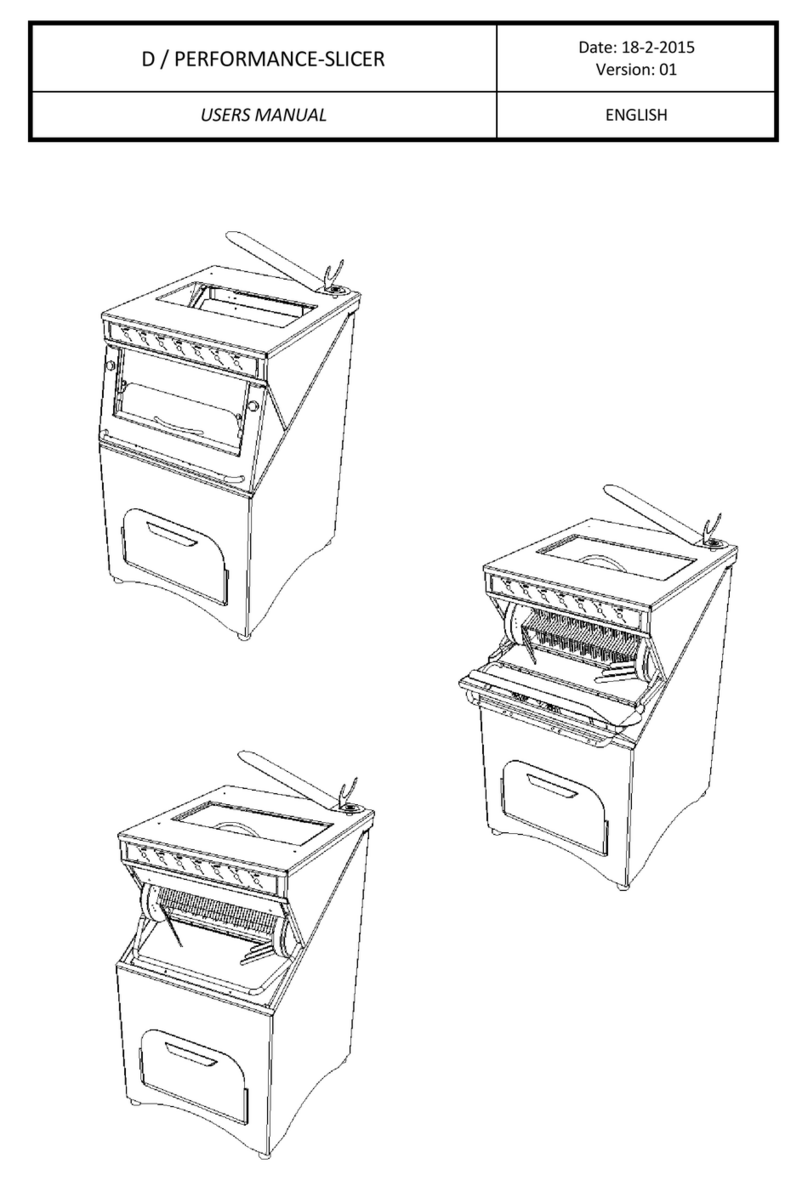

1PRODUCT INFORMATION............................................................................................ 4

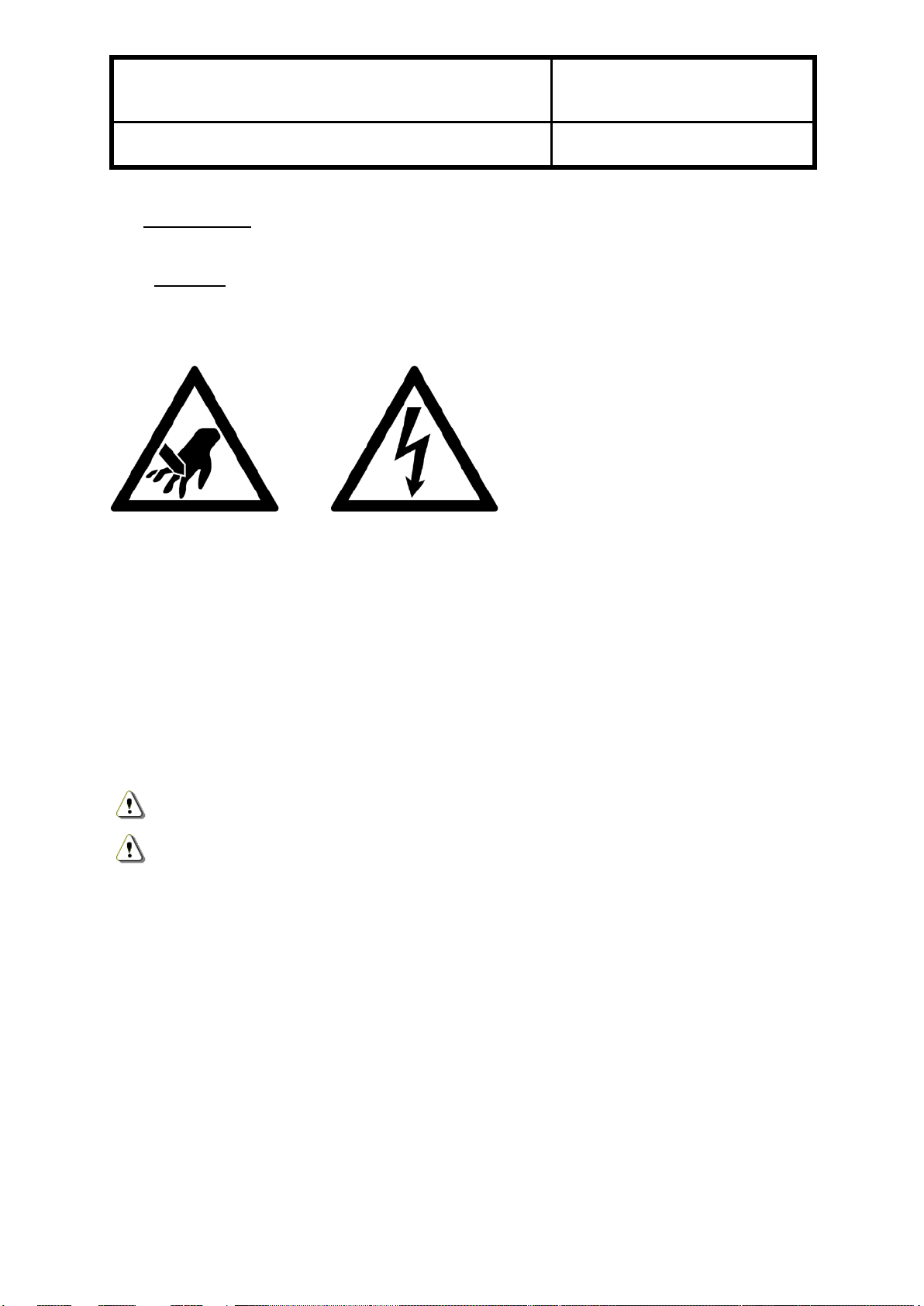

2DEFINITIONS ................................................................................................................ 5

2.1 Warnings................................................................................................................. 5

2.2 Description of parts of the machine......................................................................... 6

2.3Error notifications on diplay freq.converter .............................................................. 6

3SAFETY......................................................................................................................... 7

3.1 Safety regulations ................................................................................................... 7

3.2 Dangers because of mechanical components......................................................... 7

3.3 Dangers because of electrical components............................................................. 7

3.4 Dangers because of lack of hygiene........................................................................ 7

4TRANSPORT AND UNPACKING................................................................................... 8

4.1 Transport................................................................................................................. 8

4.2 Unpacking............................................................................................................... 8

5INSTALLATION.............................................................................................................. 9

5.1 Placing and maintenance........................................................................................ 9

5.2 Conditions............................................................................................................... 9

5.3 Electrical connection ............................................................................................... 9

5.4 Carrying off material...............................................................................................10

5.5 Taking out of operation...........................................................................................10

6PRODUCT DESCRIPTION...........................................................................................11

6.1 Purpose of the machine .........................................................................................11

6.2 Inadmissible use of the machine ............................................................................11

6.3 Description of the control panel..............................................................................12

6.4 Working of the control panel...................................................................................12

7WORKING WITH THE MACHINE .................................................................................13

7.1 Taking use of the machine .....................................................................................13

7.2 How to use the machine.........................................................................................14

8MAINTENANCE............................................................................................................15

8.1 Cleaning.................................................................................................................15

8.2 Maintenance ..........................................................................................................15

8.3 Instructions changing infeed belt............................................................................16

8.4 Instructions changing knives ..................................................................................16

9OILLUBRICATION OF THE KNIVES (OPTIONAL) .......................................................19

9.1 Adjustment of the oil quantity .................................................................................19

10 FAULT FINDING........................................................................................................20