Daub D/ Compact Slicer User manual

D / COMPACT-SLICER Table Top

Date: 30-4-2015

Ver ion: 01

USERS MANUAL

ENGLISH

D / COMPACT-SLICER Table Top

Date: 30-4-2015

Ver ion: 01

USERS MANUAL

Page 1

General

It i important to read thi manual and to comply with the ugge tion , recommendation and / or

regulation when unpacking, in talling, u ing and maintaining the machine. If the machine i old on,

thi manual hould be handed over to the new owner.

Only employee who have been in tructed concerning the u e of thi machine and who have read thi

manual may operate thi machine.

Daub Bakery Machinery B.V. will accept no liability for defect which have occurred becau e of the

incorrect u e of the machine. Neither will Daub Bakery Machinery B.V. be held re pon ible for any

damage or injurie to operator or to third per on if deemed to be cau ed by the incorrect u e of the

machine.

No part of thi publication may be reproduced, duplicated or di tributed without the prior written

permi ion of the manufacturer.

Daub Bakery Machinery B.V. can not be held re pon ible for any mi take and / or mi print in thi

manual.

It i recommended that you keep thi manual clo e to, or with the machine at all time .

D / COMPACT-SLICER Table Top

Date: 30-4-2015

Ver ion: 01

USERS MANUAL

Page 2

Table of contents

GENERAL .................................................................................................................................................. 1

TABLE OF CONTENTS ............................................................................................................................... 2

1 PRODUCT INFORMATION ................................................................................................................ 3

2 DEFINITIONS .................................................................................................................................... 4

2.1 Warning ................................................................................................................................. 4

2.2 De cription of part of the machine ........................................................................................ 5

2.3 Error notification on diplay freq.converter (option).............................................................. 5

3 SAFETY ............................................................................................................................................. 6

3.1 Safety regulation .................................................................................................................... 6

3.2 Danger becau e of mechanical component . ........................................................................ 6

3.3 Danger becau e of electrical component . ........................................................................... 6

3.4 Danger becau e of lack of hygiene. ....................................................................................... 6

4 TRANSPORT AND UNPACKING ........................................................................................................ 7

4.1 Tran port ................................................................................................................................. 7

4.2 Unpacking ................................................................................................................................ 7

5 INSTALLATION ................................................................................................................................. 8

5.1 Placing and maintenance ........................................................................................................ 8

5.2 Condition ................................................................................................................................ 8

5.3 Electrical connection ............................................................................................................... 8

5.4 Carrying off material ............................................................................................................... 9

5.5 Taking out of operation ........................................................................................................... 9

6 PRODUCT DESCRIPTION ................................................................................................................ 10

6.1 Purpo e of the machine ........................................................................................................ 10

6.2 Inadmi ible u e of the machine ........................................................................................... 10

6.3 De cription of the control panel ........................................................................................... 11

6.4 Working of the control panel ................................................................................................ 11

7 WORKING WITH THE MACHINE .................................................................................................... 12

7.1 Taking u e of the machine .................................................................................................... 12

7.2 How to u e the machine ....................................................................................................... 12

8 MAINTENANCE .............................................................................................................................. 13

8.1 Cleaning ................................................................................................................................. 13

8.2 Periodically maintenance ...................................................................................................... 13

8.3 In truction changing knive ................................................................................................. 14

9 OPTIONS ........................................................................................................................................ 16

9.1 Oil-lubrication of the knive .................................................................................................. 16

10 FAULT FINDING .......................................................................................................................... 17

10.1 Trouble hooting .................................................................................................................... 17

10.2 Errorcode frequency controller ........................................................................................... 18

D / COMPACT-SLICER Table Top

Date: 30-4-2015

Ver ion: 01

USERS MANUAL

Page 3

1Product information

Manufacturer: Daub Bakery Machinery B.V.

Nieuwkerk edijk 10

5051 HT Goirle

P.O. box 51

5050 AB Goirle

The Netherland

Tel: +31 13 5308700

Fax: +31 13 5308729

After ale ervice: Your upplier

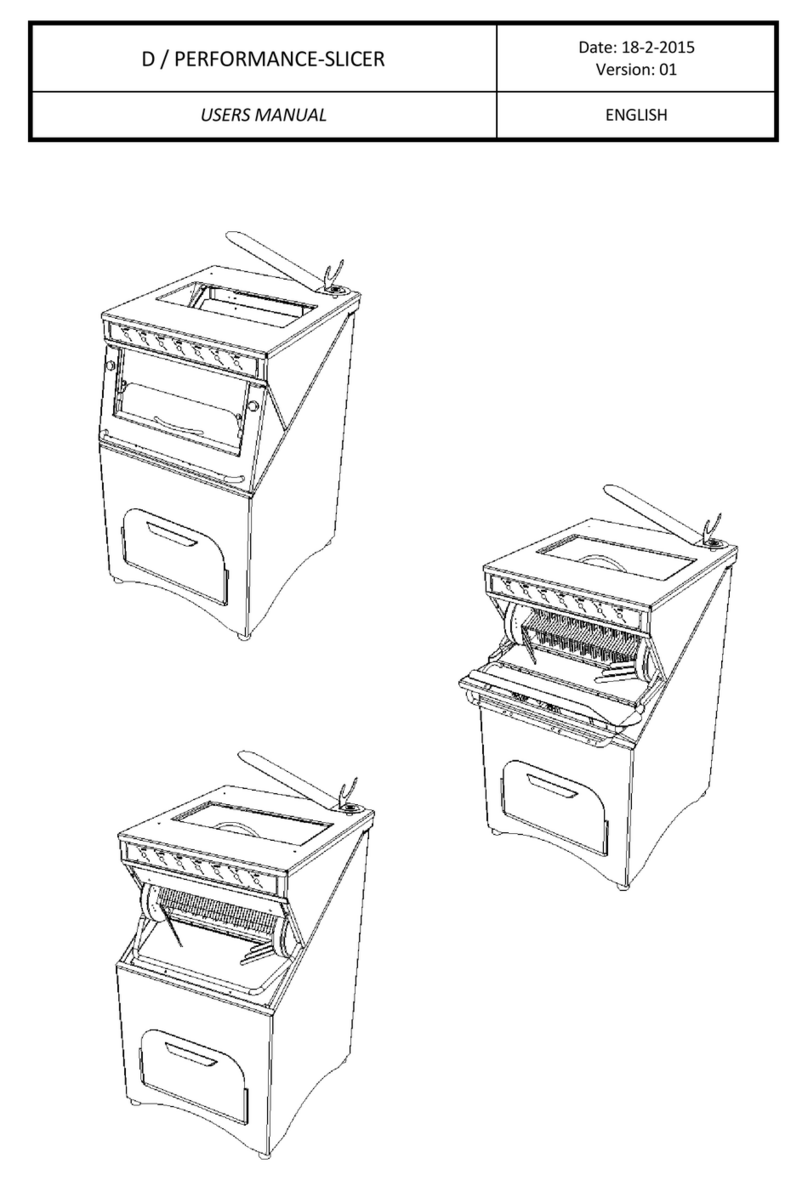

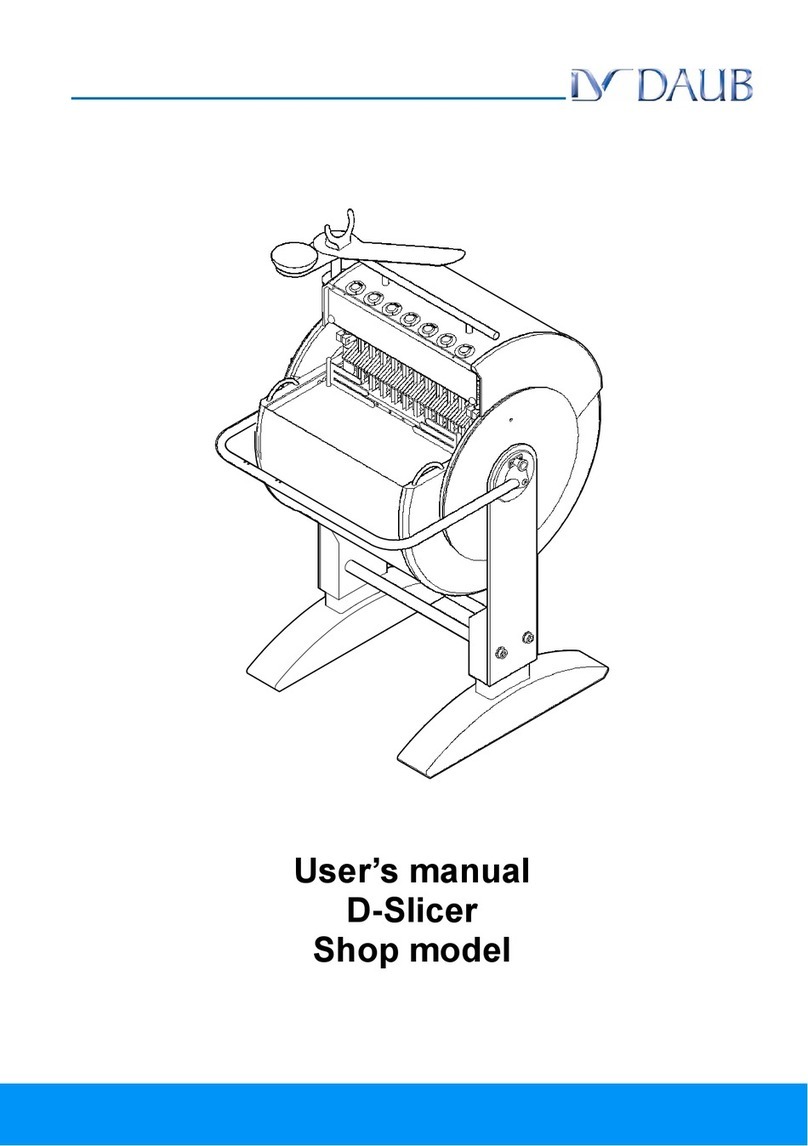

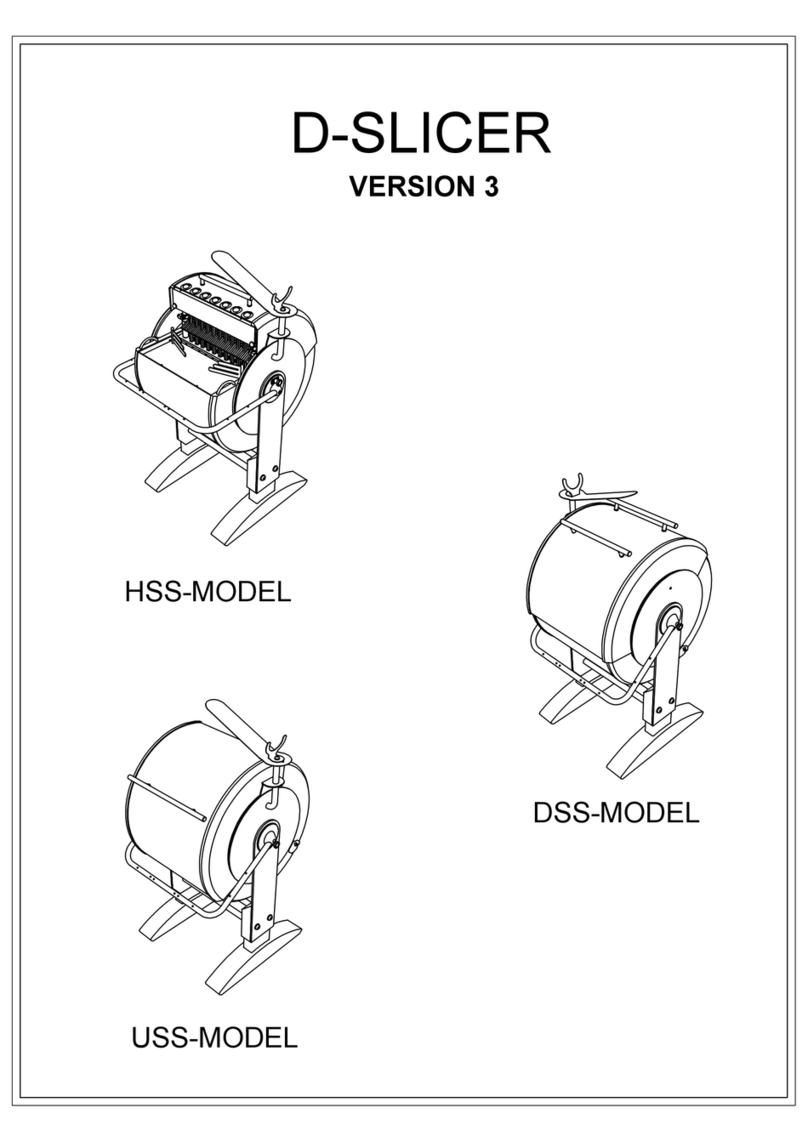

Machine naming: D / COMPACT-SLICER Table Top

Machine number: ee machine plate

Date of manufacturing: ee machine plate

Power: ee machine plate

Voltage: ee machine plate

Current: ee machine plate

Weight: 120 kg

Sound: <65 dB(A)

Po ible execution :

Voltage: 3*400V/50Hz+N, 3*230V/50Hz, 3*440V/60Hz+N, 3*230V/60Hz

Other voltage on reque t

Technical information:

Option :

-Electronic oil lubrication of the knive

-Safety cover for infeed

-Emergency top button

D / COMPACT-SLICER Table Top

Date: 30-4-2015

Ver ion: 01

USERS MANUAL

Page 4

2Definitions

2.1 Warning

The following ign warn the operator for a po ible danger becau e of mechanical or electrical

component .

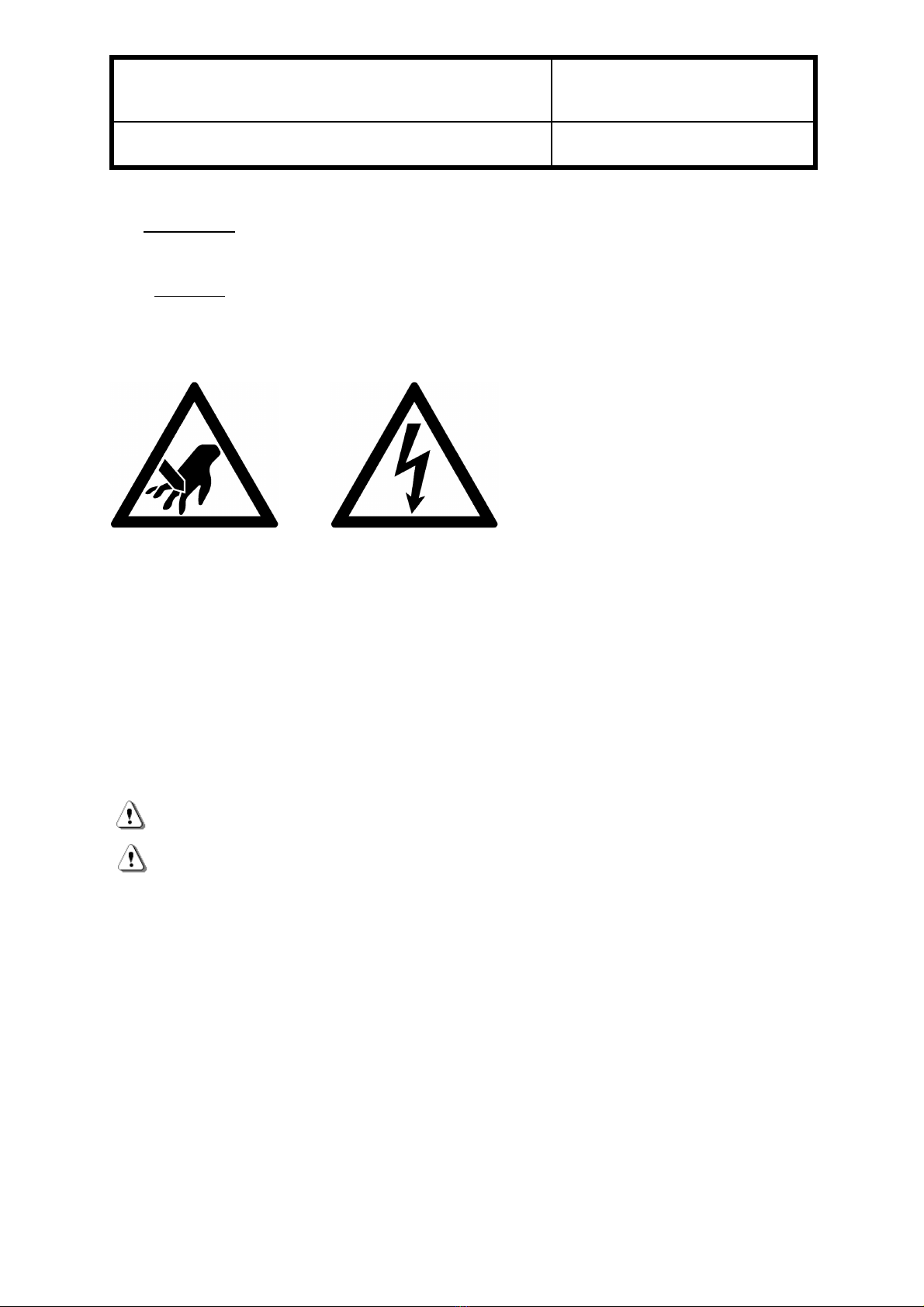

Figure 2.1.1 Figure 2.1.2

Figure 2.1.1 i a ticker which i u ed on the machine indicating the harpne of the knive . Do not

come near the knive when machine i running.

Figure 2.1.2 i a ticker which i u ed on the machine indicating where electrical power i pre ent.

Before taking in u e of the machine, you hould carefully read thi manual and follow the in truction .

Make ure that the warning ticker tay in good condition, and if nece ary replace them. When you

u e the machine for the fir t time, follow the in truction in thi manual carefully, o that you will not

be urpri ed.

Do not allow unqualified employee to operate the machine.

Only qualified employee may operate the machine.

Be ure the machine i witched off during cleaning, maintenance and lubrication.

After maintenance of the machine do not forget to replace the afety cover and the crumbtray.

Qualified employee mu t do all repair , mechanical a well a electrical.

Table of contents

Other Daub Commercial Food Equipment manuals

Popular Commercial Food Equipment manuals by other brands

Diamond

Diamond AL1TB/H2-R2 Installation, Operating and Maintenance Instruction

Salva

Salva IVERPAN FC-18 User instructions

Allure

Allure Melanger JR6t Operator's manual

saro

saro FKT 935 operating instructions

Hussmann

Hussmann Rear Roll-in Dairy Installation & operation manual

Cornelius

Cornelius IDC PRO 255 Service manual

Moduline

Moduline HSH E Series Service manual

MINERVA OMEGA

MINERVA OMEGA DERBY 270 operating instructions

Diamond

Diamond OPTIMA 700 Installation, use and maintenance instructions

Diamond

Diamond G9/PLCA4 operating instructions

Cuppone

Cuppone BERNINI BRN 280 Installation

Arneg

Arneg Atlanta Direction for Installation and Use