Daub Slim 700 User manual

Daub Bakery Machinery B.V.

Manual

Date: 01-08-2018

Version: 08

SLIM 700/1400/1700/2x200

English

Daub Bakery Machinery B.V.

Manual

Date: 05-04-2017

Version: 07

SLIM 700/1400/1700

Page 3of 21

1. GENERAL.............................................................................................................................. 4

2. PRODUCT INFORMATION..................................................................................................... 5

3. EXPLANATIONS .................................................................................................................... 7

3.1. Warnings ................................................................................................................... 7

3.2. Qualified employees .................................................................................................. 8

3.3. Machine Part Descriptions......................................................................................... 8

3.4. Error messages on frequency converter display. ....................................................... 8

4 SAFETY................................................................................................................................. 9

4.1 Safety regulations ...................................................................................................... 9

4.2 Danger because of mechanical components.............................................................. 9

4.3 Danger because of electrical components. ................................................................ 9

4.4 Danger because of lack of hygiene ............................................................................ 9

5 TRANSPORT AND UNPACKING ........................................................................................... 10

5.1 Transport ................................................................................................................. 10

5.2 Unpacking................................................................................................................ 10

6 INSTALLATION ................................................................................................................... 11

6.1 Placing and maintenance......................................................................................... 11

6.2 Conditions of use ..................................................................................................... 11

6.3 Electrical connection ............................................................................................... 11

6.4 Disposal of materials ............................................................................................... 12

6.5 Taking out of operation ........................................................................................... 12

7 PRODUCT DESCRIPTION..................................................................................................... 13

7.1 Machines purpose ................................................................................................... 13

7.2 Inadmissible use of the machine.............................................................................. 13

7.3 Description of the control panel .............................................................................. 13

7.4 Working of the control panel................................................................................... 14

7.5 Starting up the machine .......................................................................................... 14

8 WORKING WITH THE MACHINE ......................................................................................... 15

8.1 Basic working order of the machine ........................................................................ 15

8.2 Using the counter .................................................................................................... 15

8.3 Using the machine with the “soft dough” option .................................................... 16

9 WEIGHT ACCURACY ........................................................................................................... 17

10 MAINTENANCE .................................................................................................................. 18

10.1 Cleaning................................................................................................................... 18

10.2 Maintenance............................................................................................................ 20

10.3 Instructions changing out feed belt ......................................................................... 20

11 FAULT FINDING.................................................................................................................. 21

Daub Bakery Machinery B.V.

Manual

Date: 01-07-2018

Version: 08

SLIM 700/1400/1700/2x200

Page 4 of 21

1. GENERAL

It is important to read this manual and to comply with the suggestions, recommendations and / or

regulations when unpacking, installing, using and maintaining the machine. If the machine is sold on,

this manual should be handed over to the new owner.

Only employees who have been instructed concerning the use of this machine and who have read this

manual may operate this machine.

Daub Bakery Machinery B.V. will accept no liability for defects which have occurred because of the

incorrect use of the machine. Neither will Daub Bakery Machinery B.V. be held responsible for any

damage or injuries to operators or to third persons if deemed to be caused by the incorrect use of the

machine.

No part of this publication may be reproduced, duplicated or distributed without the prior written

permission of the manufacturer.

Daub Bakery Machinery B.V. can not be held responsible for mistakes and/or misprints in this manual.

It is recommended that you keep this manual close to, or with the, machine at all times.

Daub Bakery Machinery B.V.

Manual

Date: 01-07-2018

Version: 08

SLIM 700/1400/1700/2x200

Page 5 of 21

2. PRODUCT INFORMATION

Manufacturer: Daub Bakery Machinery B.V.

Nieuwkerksedijk 10

5051 HT Goirle

The Netherlands

Tel: +31 13 5308700

www.daub.nl

After sales service: Consult your local distributor, dealer or supplier

Machine name: SLIM

Machine number: see machine plate

Date of manufacture: see machine plate

Power: see machine plate

Voltage: see machine plate

Current: see machine plate

Weight: 320-340 kg

Noise: <65 dB(A)

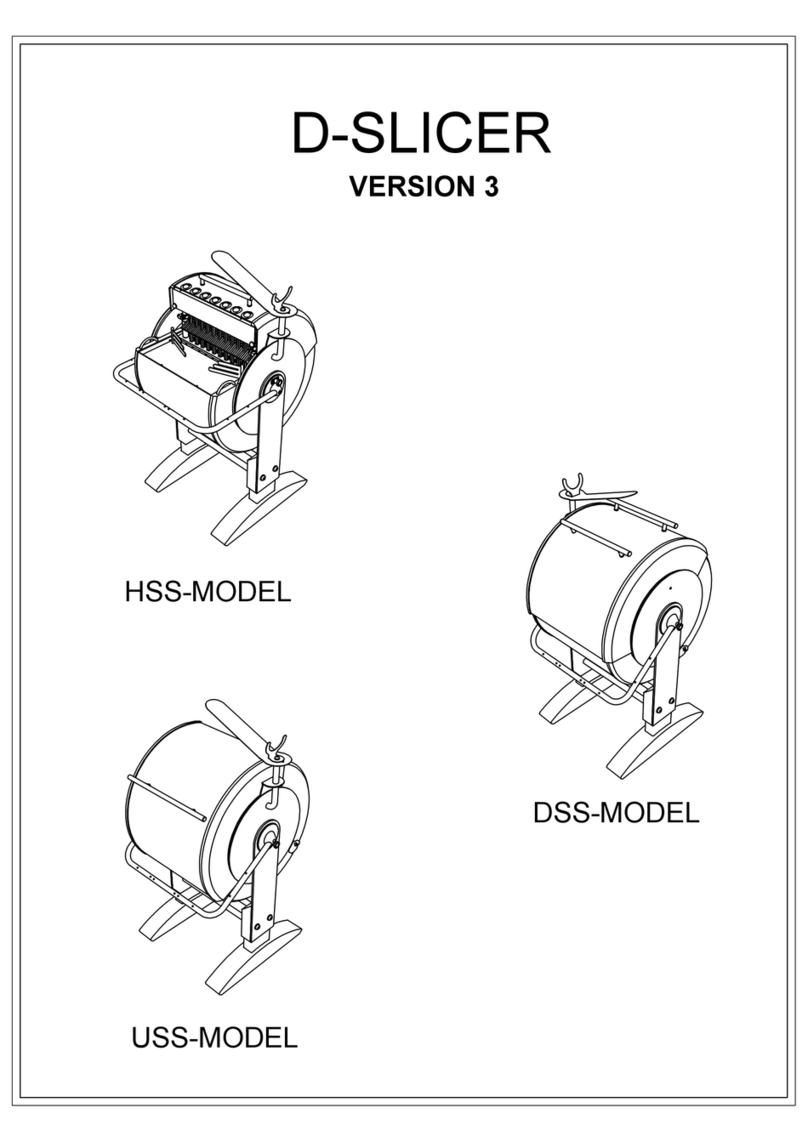

Model versions:

Models Weight range*

SLIM 700 80-700 gram

SLIM 1400 200-1400 gram

SLIM 1700 300-1700 gram

SLIM 2x200 50-200 gram

*) The weight range is dependent on the dough consistency

With 90 kg hopper

Length standard out feed belt 50 cm

Safety guard on hopper

Voltage:

1* 200-230 V, 50-60 Hz

Options:

Out feed belt 100 cm

Oiling of hopper plate

Extra oiling on hopper block

50 kg hopper

Lightbeam as safety guard on hopper

Flour duster

Scraper out feed belt (only available with 100cm out feed belt)

Quick-lock on hopper

Soft dough configuration

Daub Bakery Machinery B.V.

Manual

Date: 01-07-2018

Version: 08

SLIM 700/1400/1700/2x200

Page 6 of 21

Technical information:

Hopper: Stainless steel with Teflon coating

Hopper block: Teflon coated

Hopper plate: Stainless steel

Cylinder components: Stainless steel and Ertalyte

Transport system: Plastic and stainless steel

N.B. All parts, which could come in contact with the dough, are food industry approved.

Daub Bakery Machinery B.V.

Manual

Date: 01-07-2018

Version: 08

SLIM 700/1400/1700/2x200

Page 7 of 21

3. EXPLANATIONS

3.1. Warnings

The following signs warn the operator of potential danger due to mechanical (figure 3-1a) or electrical

(figure 3-1b) components.

Figure 3-1a Figure 3-1b

Figure 3.1a is a sticker used on the machine indicating the position where caution must be taken to

avoid mechanical crushing in the machine.

Figure 3.1b is a sticker which is used on the machine indicating where electrical power is present.

Figure 3.2.

Figure 3.2 is a sticker warning you to grease the hopper, clean the filter and not to put your hands into

the hopper whilst it is moving.

Before using the machine, you should carefully read this manual and follow the instructions. Make sure

that the warning stickers remain in good condition, and if necessary replace them. When you use the

machine for the first time, follow the instructions in this manual carefully, so you are familiar with the

machine.

Do not allow unqualified employees to operate the machine.

Be sure the machine is switched off during cleaning, maintenance and lubrication.

After maintenance of the machine do not forget to replace all the covers, hopper and the lid of

the switch box.

All repairs, mechanical as well as electrical, may only be completed by qualified employees.

GREASE HOPPER

CLEAN FILTER REGULARY

NEVER PUT HANDS

IN MOVING HOPPER

Daub Bakery Machinery B.V.

Manual

Date: 01-07-2018

Version: 08

SLIM 700/1400/1700/2x200

Page 8 of 21

3.2. Qualified employees

Means: persons who are familiar with the installation, assembly, installation and operation of the

machine and who have the correct qualifications.

3.3. Machine Part Descriptions

Figure 3-3

3.4. Error messages on frequency converter display.

Do not use the machine when E-messages appear. First read the information in the supplied

manual about the frequency converter which is located in the control box. Call your dealer,

distributor or supplier with the error code; DO NOT attempt to resolve the error message by

yourself under any circumstances.

Hopper Block

Transport Belt

Cover

Damper Fixation

Control Panel

Hopper

Daub Bakery Machinery B.V.

Manual

Date: 01-07-2018

Version: 08

SLIM 700/1400/1700/2x200

Page 9 of 21

4SAFETY

4.1 Safety regulations

Remove the plug from the power supply when cleaning and/or maintaining the machine.

Only qualified or well instructed employees can do repairs of a mechanical or electrical nature.

Never put your hands into the hopper and/or cylinder

Keep covers in place when operating the machine.

Do not use the machine when certain notifications (mentioned in chapter 3.4) appear in the

display. Read more about the error and what to do!

4.2 Danger because of mechanical components.

With the correct use of the machine as described in chapter 8 no danger will occur.

BE AWARE of the hopper movement.

Covers protect all parts. Keep the covers closed and secured during operation.

When maintaining the machine not respecting the safety regulations and/or incorrect

maintenance, could result in injury.

Therefore all operators must be familiar with the current safety regulations.

During cleaning be sure the machine is disconnected from the power supply.

4.3 Danger because of electrical components.

Please keep all electrical boxes and covers closed when the machine is connected to a power

supply. Do not use the machine when error messages (mentioned in chapter 3.4) appear in the

display. Read more about the error and what to do in such events!

Broken or damaged cables and electrical components should be replaced immediately by a

qualified electrician.

Danger could occur if the measures, as described in chapter 10 “Maintenance”, are not followed

correctly.

4.4 Danger because of lack of hygiene

Danger could occur if the measures, as described in chapter 10 “Maintenance”, are not

followed correctly

Daub Bakery Machinery B.V.

Manual

Date: 01-07-2018

Version: 08

SLIM 700/1400/1700/2x200

Page 10 of 21

5TRANSPORT AND UNPACKING

5.1 Transport

The machine must be transported in its original packaging. During transport the packaging must be

secured against sliding and tipping. The machine should be moved with the correct lifting

equipment.

Transport damage caused by not having followed the above mentioned regulations, can not be

claimed. Transport of goods is always at the buyer’s risk, unless explicitly agreed otherwise.

Do not stack anything on the top of the packaging.

The machine should always be transported in an upright position.

5.2 Unpacking

Place the packaging in an upright position.

Carefully unpack the machine and check if there are any signs of transport damage. Should you find

any, please inform the transport agent immediately. We advise you to take photographs of the

damage.

Remove the machine from the pallet by means of a (fork) lift truck or other suitable lifting equipment.

By using the forks of the (fork) lift truck under the base of the machine, it can be lifted from the pallet.

Remove the side covers for a better view and to protect the covers from damage.

Weight of the machine is approximately 320 kg.

Out of safety considerations it is advisable to keep a safe distance when lifting the machine.

Daub Bakery Machinery B.V.

Manual

Date: 01-07-2018

Version: 08

SLIM 700/1400/1700/2x200

Page 11 of 21

6INSTALLATION

6.1 Placing and maintenance

Only qualified employees are allowed to install the machine.

The machine can only be used for its purpose.

Guarantee can not be claimed if changes have been made to the machine without the

manufacturers’ permission and/or not-original parts are used.

The machine should be placed on a solid flat floor and free from its surroundings like walls, other

machines etc. To prevent movement rotate the damper until it meets the floor and secure this using

the counter screw.

6.2 Conditions of use

Temperature: 15°C to 40°C

Relative humidity: 20% to 95%

6.3 Electrical connection

A qualified engineer must carry out the installation and an electrician should connect the machine to

the main power supply. Always check first if the voltage and phases of the electrical connection are in

accordance with those of the machine (see machine plate). If this is not the case, please contact your

supplier.

Be aware the machine contains an electronic frequency converter, so a stabilised power supply is

required.

The machine is fitted with a phase controller to check the order of the phases. If the machine does not

start up, switch the two phases in the power supply connector.

Daub Bakery Machinery B.V.

Manual

Date: 01-07-2018

Version: 08

SLIM 700/1400/1700/2x200

Page 12 of 21

6.4 Disposal of materials

When disposing of a complete machine, parts or only the packaging, you must comply with the

applicable legal regulations. Specifications concerning the material or the parts can be requested at the

manufacturer.

6.5 Taking out of operation

Switch off the machine by turning the main switch to “0”. Then clean it and check the lubrication points

as described in chapter 10 “Maintenance”. Protect the machine from outside influences and store it in

a closed, dry room.

Correct disposal of this product

This marking shown on the product or its literature indicates that it should not be disposed with

other household wastes at the end of its working life. To prevent possible harm to the environment

or human health from uncontrolled waste disposal, please separate this from other types of wastes

and recycle it responsibly to promote the sustainable reuse of material resources.

Household users should contact either the retailer where they purchased this product, or their local

government office, for details of where and how they can take this item for environmentally safe

recycling.

Business users should contact their supplier and check the terms and conditions of the purchase

contract. This product should not be mixed with other commercial wastes for disposal.

Daub Bakery Machinery B.V.

Manual

Date: 01-07-2018

Version: 08

SLIM 700/1400/1700/2x200

Page 13 of 21

7PRODUCT DESCRIPTION

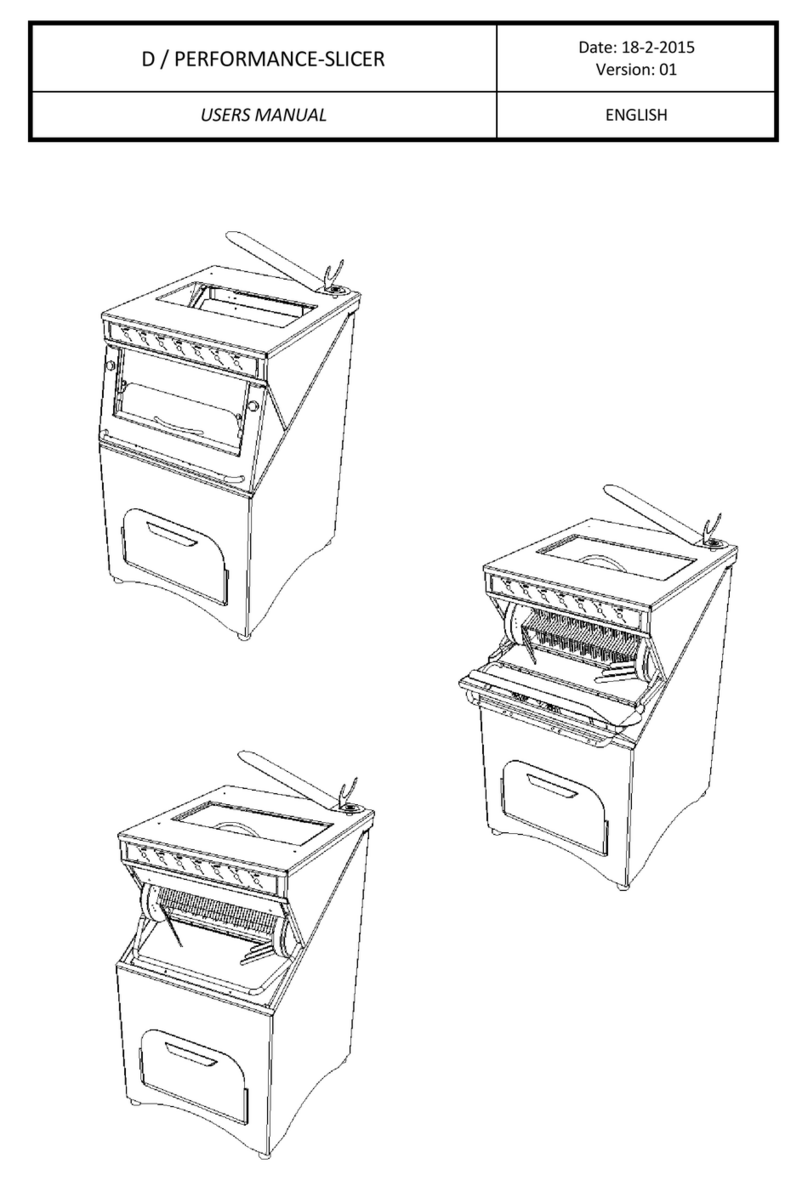

7.1 Machines purpose

The machine is designed and manufactured to divide dough.

All parts of the machine which come into contact with the dough are approved for use in the food

industry.

7.2 Inadmissible use of the machine

The machine is only meant for activities described in chapter 7.1.

The machine should only be cleaned with cleaning products which are approved for use in the food

industry. Never use corrosive products!

Be sure the machine is placed on a flat floor and correctly secured to the floor with the damper fixation

The machine should only be used when all the safety guards are in place.

Never put your hands into either the hopper or the cylinder (see figure 3.3).

Only use original spare parts.

Do not use dough with metals, stones or other foreign objects in them.

7.3 Description of the control panel

Figure 7-2

Daub Bakery Machinery B.V.

Manual

Date: 01-07-2018

Version: 08

SLIM 700/1400/1700/2x200

Page 14 of 21

7.4 Working of the control panel

See figure 7-2

Position 3; Emergency button

With this button the machine will stop immediately. Use this button only for emergencies, not as a

normal stop button.

Position 4; Speed control knob

Rotate this knob to regulate the speed of the machine depending on the required output. Be aware,

the accuracy of the dough weight depends also on the speed used.

Position 2; Start/stop button

Start and stop the machine with these buttons.

Position 7; Weight indicator

The indicator shows the depth of the cylinder and thus can be seen as an indication of the weight. The

indication is a percentage of the maximum.

Position 5; Counter

The counter can be used to stop the machine after a required number of dough pieces have been

made.

Position 6; Wheel for weight adjustment

Rotate the wheel to get the desired weight.

Position 1; Main power switch

Turn to switch the machine on and off. After use always turn the machine off.

7.5 Starting up the machine

Check if the machine has been placed correctly, as described in chapter 6 “Installation”.

Check if it is necessary to clean the machine due to potential transport dirt.

Also check if the voltage on the machine plate is in accordance with that of your main power supply.

Make sure the machine is placed on a solid flat floor.

Turn the main power switch to “ON” by rotating the main switch to position “I” (position 7 in figure 7.2)

You can now proceed with the first test.

Daub Bakery Machinery B.V.

Manual

Date: 01-07-2018

Version: 08

SLIM 700/1400/1700/2x200

Page 15 of 21

8WORKING WITH THE MACHINE

Only qualified employees older than 16 years of age may operate the machine

Never put hands into a moving hopper

The results obtained with this machine can only be guaranteed when machine is regularly

cleaned and maintained (see various chapters)

Only use vegetable oils for lubricating the hopper, hopper plate and table. OVAM 25 from the

company Zeelandia is also acceptable. Do not use “squeezed oils” like salad oil because these

often contain resins which build up on and in the machine and will negatively influence both the

operation of the machine and the frequency of cleaning. Also the machines life maybe adversely

affected.

8.1 Basic working order of the machine

1. Oil the hopper and the upper plate lightly

2. Fill the hopper with dough; Fresh dough will give the best weighing results

3. Set the dough weight by turning the weight adjustment wheel

4. Turn on the main switch

5. Check the emergency button is not activated

6. Press the start button

7. Check the weight of the first three pieces while running the machine and adjust the weight

using the weight adjustment wheel accordingly.

8.2 Using the counter

With the help of the counter a specific amount of required pieces can be set. When the counter has

reached the set amount the machine will stop.

1. Current count

a. Press the “->” button, the current status of the amount of pieces is shown while

the led “X” will light up.

b. Resetting this value to zero can be done by pressing the “C” button.

2. Pre-set value

a. The amount of pieces which must be counted; by pressing the “->” button again

the led “P” will light up.

b. Changing this value can be done by pressing the “^” (up button) and “<-“left

button. When the value is okay it can be stored by pressing the “->” button again.

Daub Bakery Machinery B.V.

Manual

Date: 01-07-2018

Version: 08

SLIM 700/1400/1700/2x200

Page 16 of 21

8.3 Using the machine with the “soft dough” option

Remove the standard upper piston (left in

the picture) with the upper piston woth

extra scraper one on the right by using the

special supplied tool

By unscrewing the screw the upper piston

will come up and out

Place the special upper piston by rotating

the screw of this piston softly in.

When using the upper piston for softer

dough

Please be sure the extra switch at

the belt is into “OFF”

Daub Bakery Machinery B.V.

Manual

Date: 01-07-2018

Version: 08

SLIM 700/1400/1700/2x200

Page 17 of 21

9WEIGHT ACCURACY

The accuracy of the weight of the dough pieces is dependent on the following items:

- The consistency of the dough. The fresher the dough the better the weight result

- The speed of the machine. The lower the speed the better the result will be.

- Cleaning. If the filter and O-ring are maintained and cleaned properly the results will better.

Table to check the vacuum system

Behind the cover a gauge is mounted where the vacuum pressure can be seen.

WITHOUT

DOUGH

SOLUTION

WITH DOUGH

SOLUTION

Vacuum

between

-0.8 and–0.2

OK

Machine is OK

Vacuum between

-0.8 and –0.2

WRONG

Vacuum loss:

Check: O-ring (14)

Check: O-ring (4)

Check: Vacuum tubes

for leakage.

Check: Is there dirt in-

between the two upper

pistons.

Vacuum

between

-0.8 and –0.6

WRONG

No vacuum at dough

Check: Hoses, filters or

valves could be dirty or

blocked

Check: Water in the

system, vacuum tank

or compressor tank.

Check: Excessive oil

use.

Vacuum between

-0.8 and –0.6

OK

Machine is OK

Maximum

vacuum

-0,6 and lower

WRONG

Check: if there is a air

loss between vacuum

tank and vacuum

pump.

Check: vacuum on the

pump itself -> new

partition and internal

cleaning

After cleaning check that the small black O-ring is placed back in the machine.

Lubricate the hopper with oil before starting to weigh, a film of oil is enough. The oil may

otherwise enter the vacuum system. Only use vegetable oil, see section 8 working with the

machine.

NOTE: Excessive oil use could shut down the system

Lowering the speed will increase the accuracy of the weight of dough.

Daub Bakery Machinery B.V.

Manual

Date: 01-07-2018

Version: 08

SLIM 700/1400/1700/2x200

Page 18 of 21

10 MAINTENANCE

10.1 Cleaning

The numbers in the text refer to those in figure 3.3 which is to be found on page 7.

Always turn the main switch to “0” (off) before starting any kind of maintenance.

Never clean the machine with water. The use of water will cause oxidation and electrical

problems.

Only qualified employees may clean the machine. Other persons should keep their distance.

Daily:

Cleaning the hopper (standard equipment)

1. Remove the 4 bolts from the block with the supplied key 13 and 17 mm

Or cleaning the hopper with Quick-Lock

1. Rotate the two quick-lock into “OFF”

2. If oil on hopper block; unscrew oil tube

3. Unlock the plug of the safety guard on the control panel

4. Tilt the hopper with two people side to side up and remove the hopper

Daub Bakery Machinery B.V.

Manual

Date: 01-07-2018

Version: 08

SLIM 700/1400/1700/2x200

Page 19 of 21

Clean the inside of the hopper only with a plastic scraper or sponge

Never use a steel scraper; it will damage the Teflon coating

Clean the bottom of the hopper block with a plastic scraper until the surface feels smooth to the touch.

When placing back the hopper please be sure the 4 bolts are tightened or the quick-lock

system is closed again

Cleaning the upper white piston and filter

Make sure the hopper is at the back position for easy access

1. Use the special tool supplied with the machine for to unscrew the bolt with upper

piston together to take out upper piston

2. Clean the piston, also not forgetting to clean the sides. Make sure they are smooth and

free from dough pieces.

3. Now remove the filter from the cylinder and, using water in this case, remove any

dough. Soak the filter in a solution of ammonia and warm water for about 4 hours.

4. After soaking rinse the filter thoroughly with warm water to remove any remaining

ammonia.

5. Dry the filter thoroughly and put this back into the machine. Never grease the filter.

6. Replace the upper piston and assemble this using the tool.

Cleaning the special white upper piston for softer dough

Make sure the hopper is at the back position for easy access

The upper piston for use of the soft doughs is made of two pieces; for removing the scraper and the o-

ring please split the lower part unscrewing the 4 bolts underneath.

Cleaning the middle piston

Make sure the hopper is at the back position for easy access

1. Disassemble the three bolts visible on the top of the middle piston and the insert the

tool into the centre of the middle piston.

2. Remove the middle piston by pulling out with the tool

Daub Bakery Machinery B.V.

Manual

Date: 01-07-2018

Version: 08

SLIM 700/1400/1700/2x200

Page 20 of 21

Be aware: there is a small black O-ring underneath the middle piton as well; do no loose it

3. Be aware: there is a small black O-ring as well; do no loose it

4. Remove the “O-Ring” from the piston with a small pointed object. Be careful NOT to

damage the “O-Ring”.

5. Clean the parts thoroughly with warm water.

Re-assembly of the middle piston

1. Assemble the “O-Ring” to the middle piston and put the middle piston back into the

cylinder BY HAND.

2. Ensure that also the small “O-Ring” is in the lower piston and that the arrow on the

top of the middle piston points to the out feed belt (the middle piston can only be

mounted one way.

3. Tighten the 3 middle piston bolts down. These should be tightened to “hand tight”. If

the bolts are tightened too much this could damage the threads.

4. Put the filter back and re-assemble the upper piston as already shown above.

5. Re-assemble the hopper and your machine is ready for use.

10.2 Maintenance

Maintenance should only be performed by qualified technicians. Please contact your supplier for

maintenance instructions and assistance.

10.3 Instructions changing out feed belt

The out feed belt should only be changed by qualified technicians. Please contact your supplier

for maintenance instructions and assistance.

This manual suits for next models

3

Table of contents

Other Daub Commercial Food Equipment manuals

Popular Commercial Food Equipment manuals by other brands

Diamond

Diamond AL1TB/H2-R2 Installation, Operating and Maintenance Instruction

Salva

Salva IVERPAN FC-18 User instructions

Allure

Allure Melanger JR6t Operator's manual

saro

saro FKT 935 operating instructions

Hussmann

Hussmann Rear Roll-in Dairy Installation & operation manual

Cornelius

Cornelius IDC PRO 255 Service manual

Moduline

Moduline HSH E Series Service manual

MINERVA OMEGA

MINERVA OMEGA DERBY 270 operating instructions

Diamond

Diamond OPTIMA 700 Installation, use and maintenance instructions

Diamond

Diamond G9/PLCA4 operating instructions

Cuppone

Cuppone BERNINI BRN 280 Installation

Arneg

Arneg Atlanta Direction for Installation and Use