DAVIS TECHNOLOGIES TMS-9500-SL Short User manual

COPYRIGHT NOTICE

Copyright © 1999-2014 Davis Technologies, LLC.

All rights reserved.

Information in this document is subject to change

without notice. Other products and companies

referred to herein are trademarks or registered

trademarks of their respective companies or mark

holders. Any components shown are for illustration

or instructional purposes only.

Publication and redistribution of this manual over

the Internet or in any other medium without prior

written content is expressly forbidden. In all cases

this copyright notice must remain intact and

unchanged.

Davis Technologies, LLC.

PO Box 8250

Asheville, NC. 28787

(828) 645-1505

email: [email protected]

web: www.MORETRACTION.com

TRADEMARKS

All trademarks used herein are the property of their

respective owners.

02/14

Table of Contents

Table of Contents ......................................................... 3

Introduction ................................................................... 4

How Does It Work? ........................................................ 5

Installation .................................................................... 7

Testing ............................................................................. 8

RPM Window Test: ....................................................... 9

Traction Control Adjustments .................................10

Setting The Mode: .....................................................11

Setting The Retard Amount: ...................................12

Traction Control Setup .............................................13

Starting RPM ............................................................13

Buffer .........................................................................13

Sample Rate ...............................................................13

Small Corrections Only RPM: ................................14

Ending RPM: ...............................................................14

Factory Reset...............................................................15

Firmware Updating .......................................................16

Appendix A .....................................................................17

Traction Control Panel Software: ...........................19

Main Tab Settings: ....................................................20

Advanced Main Tab Settings: ..................................22

More Tab Settings: ...................................................24

More Tab Advanced Settings: .................................26

USB to Serial Adapter: ...........................................29

Handheld Programmer ................................................30

DISCLAIMER..................................................................31

Notes .............................................................................33

Notes .............................................................................34

4

Davis Technologies TMS-9500-SL Short

www.moretraction.com

Introduction

We would first like to thank you for your purchase of

our system. We believe it is the best system available

to you on the market today. This system balances

effectiveness with ease of installation, broad field of

uses, and cost.

As with all technical devices such as engines,

shocks, carburetors, clutches etc., the product’s

performance is based largely on your ability to use it

properly. Testing in controlled circumstances will

help you determine the proper settings for your

application and your situation. Testing is very

important since it will help you utilize this product to

its full potential.

Please read all of the instructions and information

thoroughly before attempting to install or use this

product.

5

Davis Technologies TMS-9500-SL Short

www.moretraction.com

How Does It Work?

Spinning the tires not only makes the car harder to drive,

but it also causes higher tire temps and excessive tire

wear. Lifting off the throttle or counter steering to correct

for this 5% mistake, not only upsets the rhythm, it slows

the car down!

Typically, if a driver makes a 5% mistake with the throttle,

he/she has to correct 20-25% to fix it. But if the tire slip is

detected within one cylinder worth of crank rotation, as the

Davis Technologies systems do, then a small reduction in

power can reduce or stop the tire slip.

The Non Self-Learning systems, such as our TMS-750,

periodically compare the rate of acceleration of the

crankshaft to an Adjustable Fixed Rate (AFR), known as

Threshold. If the Engine RPM rate of change is in excess

of that Threshold, then a correction is made; therefore,

reducing the slip.

The comparison is made every cylinder (1/4 of a turn of the

crank shaft).

Basically, this Patented system looks for spikes in RPM

that are caused by wheel slip. If these spikes are large

enough, then a correction is made, reducing the slip.

By adjusting the Threshold, the driver can tune the system

to the desired “feel”

Self-Learning systems, such as our TMS-750-SL, TMS-

5500-SL, and TMS-9500-SL series, compare the rate of

acceleration of the crankshaft to a calculated threshold

value that is constantly updated based on the average of

the previous measurements.

This update occurs on every crankshaft revolution. So, if

the last 1/4 of a turn of the crankshaft (one cylinder) is

faster than the average of the last full revolution (4

6

Davis Technologies TMS-9500-SL Short

www.moretraction.com

cylinders), then a slip is detected.

Through this very advanced Patented process, the system

constantly accounts for track conditions, tire condition,

even driving style to constantly update the internal

settings.

These settings are updated as many as 200 times a second

to keep the unit calibrated to exactly the right settings

regardless of changing conditions.

Basically, the systems learn the average rate of

acceleration of the crankshaft, and if there is a sudden

spike in RPM above that rate, then a correction is made.

This allows the system to adjust to the Correct settings

even if one corner has more grip than another, or even one

groove to another.

The user does have an adjustment referred to as “Mode”

that sets the overall sensitivity of the system to make a

correction based the extent of the tire slip. By

adjusting the Mode, the driver can tune the system to the

desired “feel”.

This system is not simply a few lines of code added to an

existing fuel injection or ignition system, and called

traction control. This system utilizes a patented method

and multiple high speed processors to very accurately and

effectively monitor rates of acceleration to determine

wheel speed, and tire slip. In fact, Davis Technologies’

systems are at least 20 times faster than other systems

which are integrated into the fuel injection or ignition

system.

Our systems only job is Traction Control!

7

Davis Technologies TMS-9500-SL Short

www.moretraction.com

Installation

Installation of the system is very simple. It is very

important to make all connections correctly. Improper

installation could result in poor system performance or

damage to the unit.

Keep all wires away from any spark plug wires and

coils or other sources of electrical noise and heat.

The unit should be mounted away from any sources

of electrical noise or high heat. It can be easily

mounted with Velcro to allow for easy removal.

It is very important that the distributor pickup wires

are kept away from the spark plug and coil leads.

Make Connections as follows:

Connect the terminal marked “+”to 12V+ .

Connect the terminal marked “--”to 12V- .

Connect the terminal marked “DIST”to positive

distributor pickup wire. This should be the purple

wire coming out of the ignition box.

A toggle switch may be used, if desired to turn the

unit on/off.

8

Davis Technologies TMS-9500-SL Short

www.moretraction.com

Testing

After installation it is recommended that you test the

system. To do so please follow these instructions

step by step.

Forced Activation Test:

This test is useful to check both stages of retard.

1. Turn “ON” the power, the LED will flash to

indicate that power is on. Next the LED will blink

to show the current Mode setting.

(Example-ON-ON-off-off-ON-ON-off-off-ON-

ON-off-off-ON-ON-off-off, to show Mode 4).

2. Connect a timing light to the engine.

3. Start the engine.

4. With the engine idled up to about 3500 rpm; press

the Test button on the unit until the LED glows solid.

The first timing retard stage will activate for 4

seconds, then the second stage for the next 4

seconds.

9

Davis Technologies TMS-9500-SL Short

www.moretraction.com

RPM Window Test:

This mode is useful to check that the system is

reading the RPM signal properly and activating the

retard stages.

1. Set the “Mode” to 9.

2. Start the engine and accelerate the engine.

3. When the RPM is within the window of 2000 to

5000 rpm the LED will glow solid and the unit will

make a large timing correction.

DO NOT USE WINDOW MODE ON TRACK!!

Note: After the test is complete, the LED will blink to

show the firmware version.

10

Davis Technologies TMS-9500-SL Short

www.moretraction.com

Traction Control Adjustments

Davis Technologies’ patented systems have the

ability to learn the amount of acceleration that the

vehicle is achieving on average and activate the

outputs if this learned average is exceeded.

Different tracks, cars, conditions, etc. require

different settings for the system to function

effectively. There are two values that must be set.

These values will allow you to tune the system for

changing conditions. They are called “Mode” and

“Retard”.

The Mode setting is used to tune the sensitivity

of the system. The Mode controls the allowable

percentage of acceleration change. The higher the

number the more sensitive the system is. A good

starting point is 5. Valid settings for Mode are 1-8.

(Mode 9 activates window RPM test).

The Retard adjustment is used to set how much

timing is retarded when the unit makes a correction.

The more the timing is retarded, the more the power

is reduced. Too much retard may slow the car down.

Too little retard will not reduce power enough to

correct the wheel slip condition.

Different tracks, cars, conditions, etc. may require

different settings for the system to function

effectively. The dials on the unit are used for these

settings. The values are referred to as Threshold, and

Mode.

11

Davis Technologies TMS-9500-SL Short

www.moretraction.com

Setting The Mode:

To change the Mode, follow these steps.

1. Hold down the “Test” button

2. Turn the power On

3. The LED will flash to indicate that the power is

on. After the LED goes off, release the button and

quickly press it down and hold it down. The

LED will blink once to show that the button has been

pressed. Each consecutive press will raise the Mode

by one, starting at zero.

4. Once the desired Mode has been reached,

release the button. After about 4 seconds

the LED will blink to indicate the new Mode

value.

12

Davis Technologies TMS-9500-SL Short

www.moretraction.com

Setting The Retard Amount:

Retard is another adjustment that is used to tune the

system to your preferences. This adjustment set the

amount of timing that is removed with each

correction. The small screw adjuster (Pot) sets the

amount of retard. The more clockwise you turn Pot,

the more retard. Range is approx. 10 to 30 degrees of

retard. Start with the adjuster at 12 O’clock.

With testing and good record keeping, you should be

able to easily predict the necessary settings for

current conditions. The settings will not vary much

once you determine what works best for your setup.

13

Davis Technologies TMS-9500-SL Short

www.moretraction.com

Traction Control Setup

The following parameters are adjustable; however

they are factory set to the most common settings, and

should not need to be adjusted by most users.

(These settings are only accessible using the

“Traction Control Panel Software” or Handheld

Programmer)

Trigger Count:

The unit is factory set for 4 triggers per revolution, for

8 cylinder operation. The unit can be configured to

use between 1 –9 triggers per revolution.

Starting RPM is a user adjustable setting that

allows the racer to set the point at which the unit

begins making corrections. If the Starting RPM is set

to 5000 RPM, then the unit is active and monitoring

the engine, but not making any corrections until the

Starting RPM is reached. Once the Starting RPM is

reached, the unit will make corrections as needed

above 2000 RPM.

Buffer is another setting that can be used to fine

tune the system. The buffer sets the number of

consecutive errors required to cause a correction.

Buffer 0 will react to each error in acceleration. Buffer

1 will require at least 2 consecutive slip conditions to

cause a correction. This is useful to filter out small

tire slips that may occur quickly, but have no ill effect

on the car. (Default=1)

Sample Rate of the unit can also be changed by

the user, however this should only be done after

consulting w/ tech support. The lower the number the

faster the Sample Rate, which makes the unit less

sensitive, but faster to react. The higher the number

the slower the Sample Rate, which makes the unit

14

Davis Technologies TMS-9500-SL Short

www.moretraction.com

more sensitive, but slower to react. Valid settings are

1-5. (Default=5)

Minimum Corrections:

Minimum correction is a user adjustable setting that

allows the user to tune the minimum number of crank

rotations that the timing will be retarded during a

correction. This is useful to force the timing to stay

retarded long enough to stop a high momentum spin,

even though the RPM spike was very brief.

Small Corrections Only RPM:

The percent of Max engine RPM at which the unit

makes only small corrections can be set by the user.

Some users may want the unit to make smaller

corrections after a certain RPM while others may want

the unit to be able to make full corrections for more

of the strait. Once set the value will remain until

changed by the user. The RPM is set in a % of the

maximum RPM turned at the end of the strait.

(Default=75-85%)

Ending RPM:

The percent of Max engine RPM at which the unit

Stops to make corrections can be set by the user.

Some users may want the unit to stop at a certain

RPM while others may want the unit to be able to

make corrections for more of the strait. Once set the

value will remain until changed by the user. The RPM

is set in a % of the maximum RPM turned at the end

of the strait. (Default=85-95%)

15

Davis Technologies TMS-9500-SL Short

www.moretraction.com

Factory Reset

All TC settings can be restored to Factory Defaults at

any time by following these steps.

1. Set the to Mode to 15

2. After about 3 seconds the LED will flash

rapidly to indicate the Factory Settings have

been restored.

3. Turn the power Off

16

Davis Technologies TMS-9500-SL Short

www.moretraction.com

Firmware Updating

Davis Technologies, LLC may release firmware

updates or upgrades periodically to ensure the best

possible functionality of the Traction Control System.

The traction control unit will need to be returned to

Davis Technologies to have the updates installed and

configured.

Users should log onto www.moretraction.com, or call

Davis Technologies, LLC tech department

occasionally to check for updates.

17

Davis Technologies TMS-9500-SL Short

www.moretraction.com

Appendix A

Another advantage of these systems is that they are

actually able to detect wheel slip better than most

wheel speed sensor based systems. The reason for

this is that our systems monitor the rotation of the

driveline. With 8 triggers on the driveline you can

measure slip within 1/8 of a rotation. Now factor in a

5:1 final drive (rear end) ratio and tire rotation can be

measured within 1/40 of a turn (that is about 2-3

inches on most tires). The fact that the driveline is

turning much faster than the wheels, amplifies the

slip at the driveline, making these systems much

more sensitive than the typical wheel speed systems.

Put simply, if the tires slip the driveline revs. The only

reason for the sudden increases in revs in the

driveline is wheel spin.

Sensor based systems usually measure tire rotation

about every 1/4 of a turn. The front and rear are

compared to each other to check for slip. With a

margin of error of 1/4 of a turn at each wheel, it may

take as much as 1/2 of a turn of tire slip for the system

to react. If a tire is allowed to slip a half a turn before

a correction is made, it is very hard to stop the slip.

A system that uses a preset percentage of slip,

between the rear wheel speed to front wheel (or

ground) speed, cannot compensate for these

changing conditions that are inherent in all types of

racing.

Traction Control Is What We Do!

18

Davis Technologies TMS-9500-SL Short

www.moretraction.com

This Page Left Blank

19

Davis Technologies TMS-9500-SL Short

www.moretraction.com

Traction Control Panel

Software:

The optional Traction Control Panel (TCP) software

interface is used to adjust advanced tuning features

of the traction control system.

These tuning features can be used to fine tune the

system to exactly what the user desires.

On a circle track systems, this includes being able to

tune the engine RPM at which the system becomes

active, as well as the RPM at which the system can be

deactivated.

The user can also tune the length of corrections, and

the amount of power that is cut on different parts of

the race track.

The software based interface is included with the

TMS-9500-SL, and easily downloaded from the web

site and installed on your computer. The Traction

Control is connected to the computer via a serial

cable or through a secure wireless Bluetooth

connection. Tuning is achieved through a few simple

mouse clicks.

20

Davis Technologies TMS-9500-SL Short

www.moretraction.com

Main Tab Settings:

The Self Learning units incorporate two different

methods to control wheel spin.

The second patented method is a less advanced

process where the users sets a threshold of

acceleration that if exceeded will cause the timing to

retard.

The second- Non-Self Learning system is activated

when the “Threshold” setting is set to anything other

than zero. The Non-Self Learning Method is only

accessible using the “Traction Control Panel

Software”.

Threshold is used to set this value. The higher the

number the more sensitive the system is. A good

starting point is 4. Valid settings for threshold are 1-

9.

Mode is used to adjust the Mode of the unit using the

software instead of the button on the unit as

described earlier in this manual.

Note: To use the Mode and Threshold sliders in the

software, you must check the “Set Dials Here” box.

When checked, the TC unit only uses the TCP

settings, and the setting cannot be changed using the

button on the unit. To use the button method, YOU

MUST UN-CHECK THIS BOX!

Table of contents

Other DAVIS TECHNOLOGIES Control System manuals

Popular Control System manuals by other brands

Sanyo

Sanyo CDM-200A operating instructions

Strand

Strand Vision.net RS232 user manual

Oxford Plastics

Oxford Plastics AVALON BARRIER Technical specification

PendoTECH

PendoTECH PressureMAT PMAT1 user guide

Amerec

Amerec T100 operating instructions

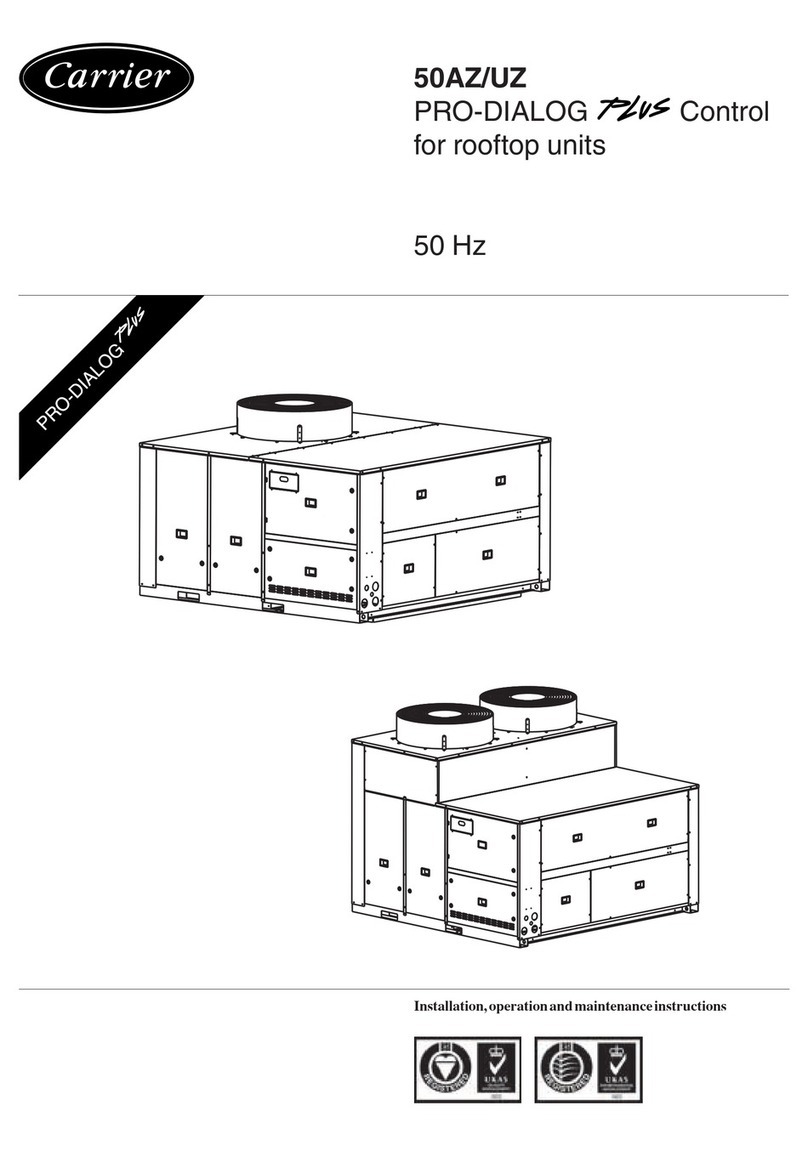

Carrier

Carrier PRO-DIALOG PLUS 50AZ Installation, operation and maintenance instructions