(2) Pay attention to the load weight.

Set the load weight of each cylinder by following

the procedures for selecting a product by model

selection. This product controls the cylinder

velocity by increasing the back pressure through

compression of the air in the cylinder. Therefore, if

the 2nd speed knob (gray) is excessively throttled,

the cylinder may bounce at the stroke end

depending on the load weight or initial velocity.

When an adequate deceleration is not possible

due to forces such as moment of inertia, set the

deceleration timing earlier or decrease the initial

cylinder velocity.

(3) Pay attention to the piping tube length.

The larger the piping volume between the

product (deceleration controller) and cylinder, the

lower the deceleration effect as because the back

pressure does not increase.

We recommend that you install the product as

close to the cylinder as possible. When the piping

tube is long, adjust the tube length by referring to

the formula below as a guide.

※

>

Example) When connecting TU0604 tube to the

cylinder (ø25, 500 mm stroke) and starting

deceleration at 75% point of the stroke length.

The formula is: (25^2 / 4^2) * 500 * (1 - 0.75) >

4,882. Therefore, the piping tube must be 4.8 m or

shorter.

*2 When starting deceleration at 75% point of the

cylinder stroke length, insert multiplication by 0.25

(= 1 - 0.75). When starting deceleration at 90%

point of the cylinder stroke length, insert

multiplication by 0.1 (= 1 - 0.9).

When the piping tube length cannot be adjusted

in the above range, set the deceleration timing

earlier or decrease the initial cylinder velocity.

(4) When using the product along with the

built-in air cushion incorporated in the

cylinder, pay attention to the adjustment

method.

If an air cushion is already incorporated in the

cylinder, the stroke movement may temporarily

stop at the original air cushion position or the stick-

slip phenomenon may occur during the 2nd speed

setting of this product.

If this is the case, readjust the cushion needle

incorporated in the cylinder by gradually opening

the cushion needle.

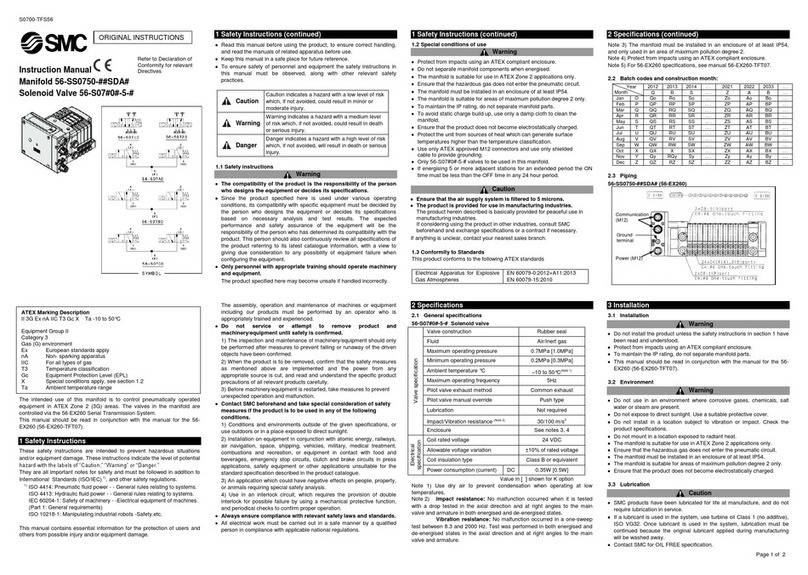

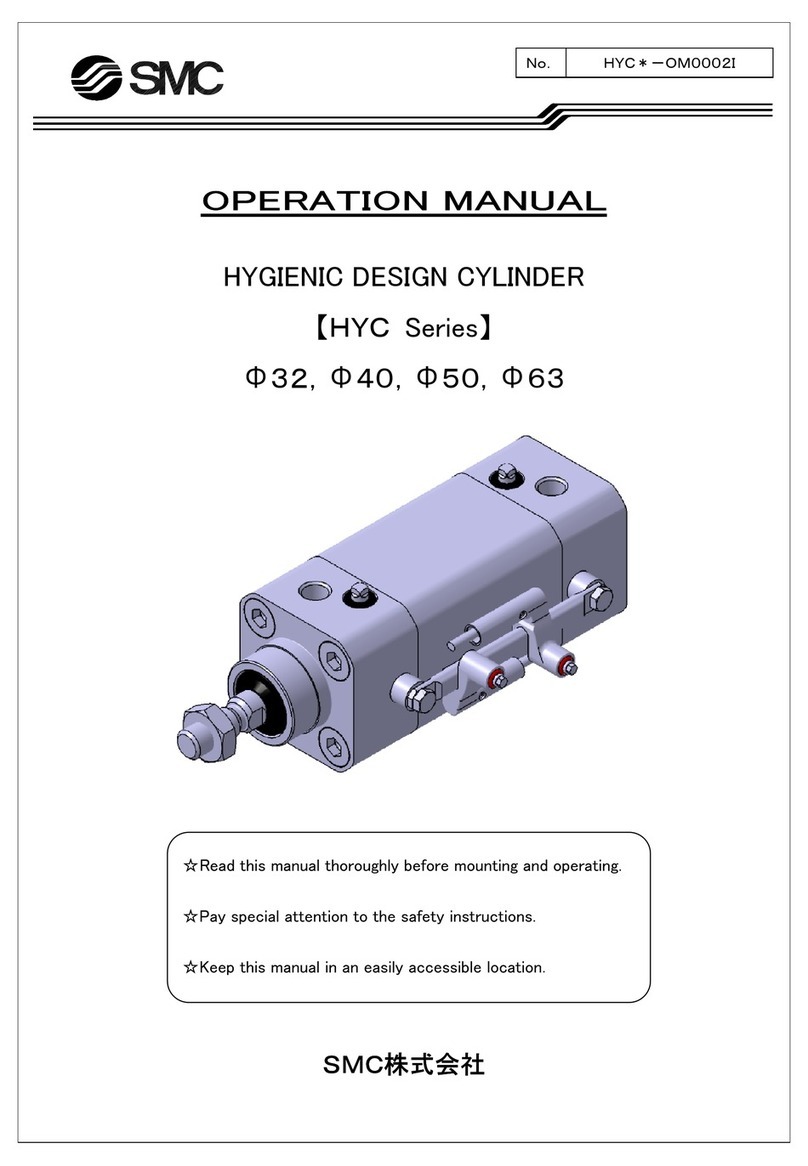

(1)Keep the operation manual and check its

contents.

Install the products and operate it only after

reading the operation Manual carefully and

understanding its contents. Also, keep the

Manual where it can be referred to as

necessary.

(2)Ensure sufficient space for maintenance

activities. When installing the products, allow

access for maintenance

(3) Check the piping direction, and then mount

the product.

If this product is mounted in the opposite

direction, speed adjustment and deceleration

effect may not be observed, and the cylinder may

suddenly move at an uncontrollable speed.

(4) Mount the product by using the mounting

bracket.

When installing the product, use the mounting

holes of the bracket bottom face and secure the

product with M3 screws.

(The screws should be prepared by the user.)

Tighten the screws to the appropriate torque for

mounting the product.