5.8.2 Control by a VS 3015 C and a separate pack controller ....................................................................... 58

5.9 LT compressor in booster operation................................................................................................. 60

5.10 Regulation of the minimum superheat using a hot gas bypass valve........................................... 62

5.11 Regulation of the maximum superheat using the suction gas injection valve ............................. 63

5.12 Monitoring............................................................................................................................................ 64

5.12.1 Safety chain........................................................................................................................................... 64

Monitoring of differential oil pressure switch / compressor high pressure limiter.................................. 65

Monitoring of the compressor motor overload cut-out........................................................................... 65

5.12.2 Cylinder head temperature monitoring.................................................................................................. 66

5.12.3 Low pressure monitoring ....................................................................................................................... 68

5.12.4 High pressure monitoring ...................................................................................................................... 68

5.12.5 Monitoring of the medium pressure....................................................................................................... 70

5.12.6 Monitoring of the medium pressure valve ............................................................................................. 70

5.12.7 Monitoring of the fan motor overload cut-out......................................................................................... 70

5.12.8 Monitoring of the fan speed controller................................................................................................... 71

5.12.9 Monitoring of the compressor speed controller ..................................................................................... 71

5.12.10 External alarm monitoring ..................................................................................................................... 73

5.12.11 Monitoring of the switching frequency................................................................................................... 74

5.12.12 Refrigerant monitoring........................................................................................................................... 75

5.12.13 Monitoring of the fast unload / External Off........................................................................................... 75

5.12.14 Rupture disk monitoring ........................................................................................................................ 75

5.13 Setpoint switching .............................................................................................................................. 76

5.14 Ambient data for the setpoint switching........................................................................................... 76

5.15 Consumer lockout............................................................................................................................... 76

5.16 Spray system control.......................................................................................................................... 77

5.17 COP monitoring ................................................................................................................................... 79

5.18 COP optimisation ................................................................................................................................ 80

5.19 Operating data and archiving............................................................................................................. 80

5.19.1 Operating hours of compressors and fans ............................................................................................ 80

5.19.2 Daily run times, switching pulses and switch-on rates .......................................................................... 80

5.20 Capacity-controlled compressors ..................................................................................................... 80

5.21 Oil balancing........................................................................................................................................ 82

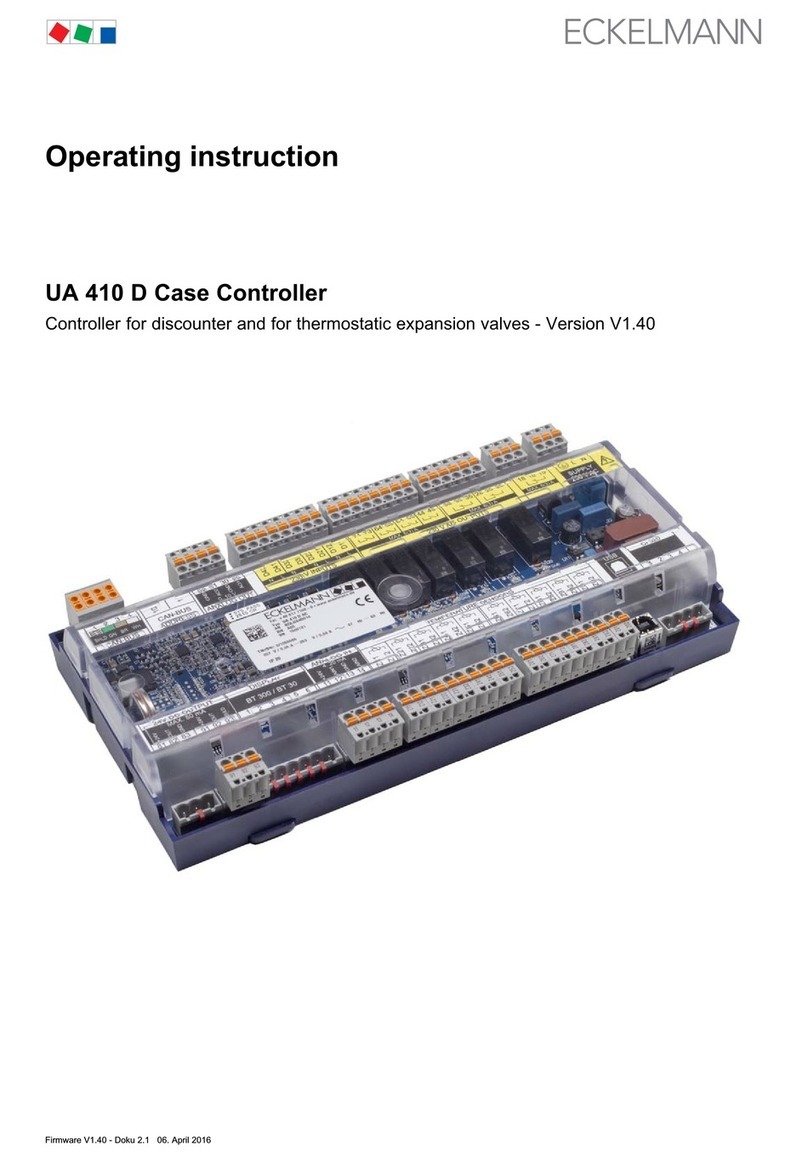

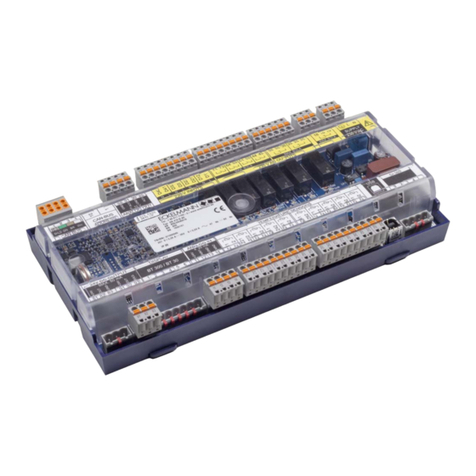

6 Installation and start-up of VS 3015 C............................................................................................... 84

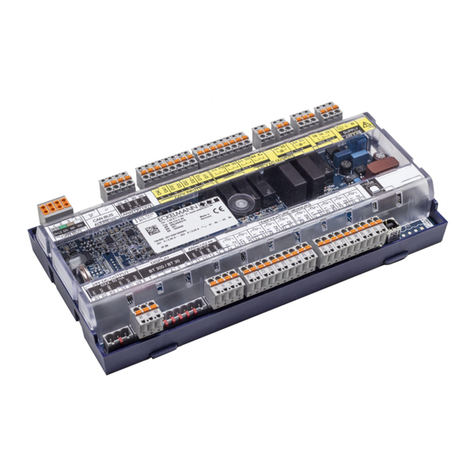

6.1 DIN rail mounting ................................................................................................................................ 84

6.2 Requirements for the activation of NT CO2 operation (transcritical) ............................................ 84

6.3 Basic hardware settings ..................................................................................................................... 85

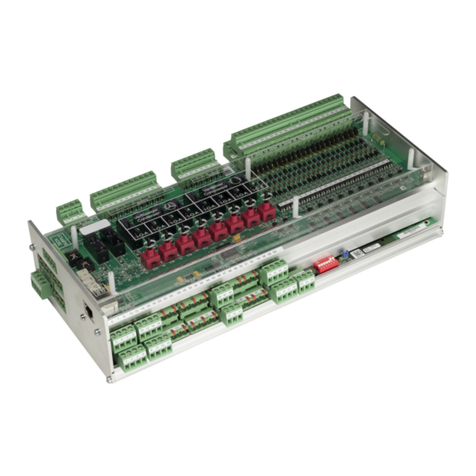

6.3.1 SIOX extension module - for DIN rail mounting .................................................................................... 86

Connection of the SIOX modules to the pack controller ....................................................................... 87