EN-4

4 INSTALLATION AND ASSEMBLY

WARNING The laying, installation/wiring procedure described below must NOT be performed by the end user or NON-specialised

personnel.

CRUSHING HAZARD During bollard installation operations all possible precautions must be taken to prevent movements that could

cause damage to objects and/or persons.

WARNING All images shown in this manual are for guidance only, so that the descriptions can be understood immediately.

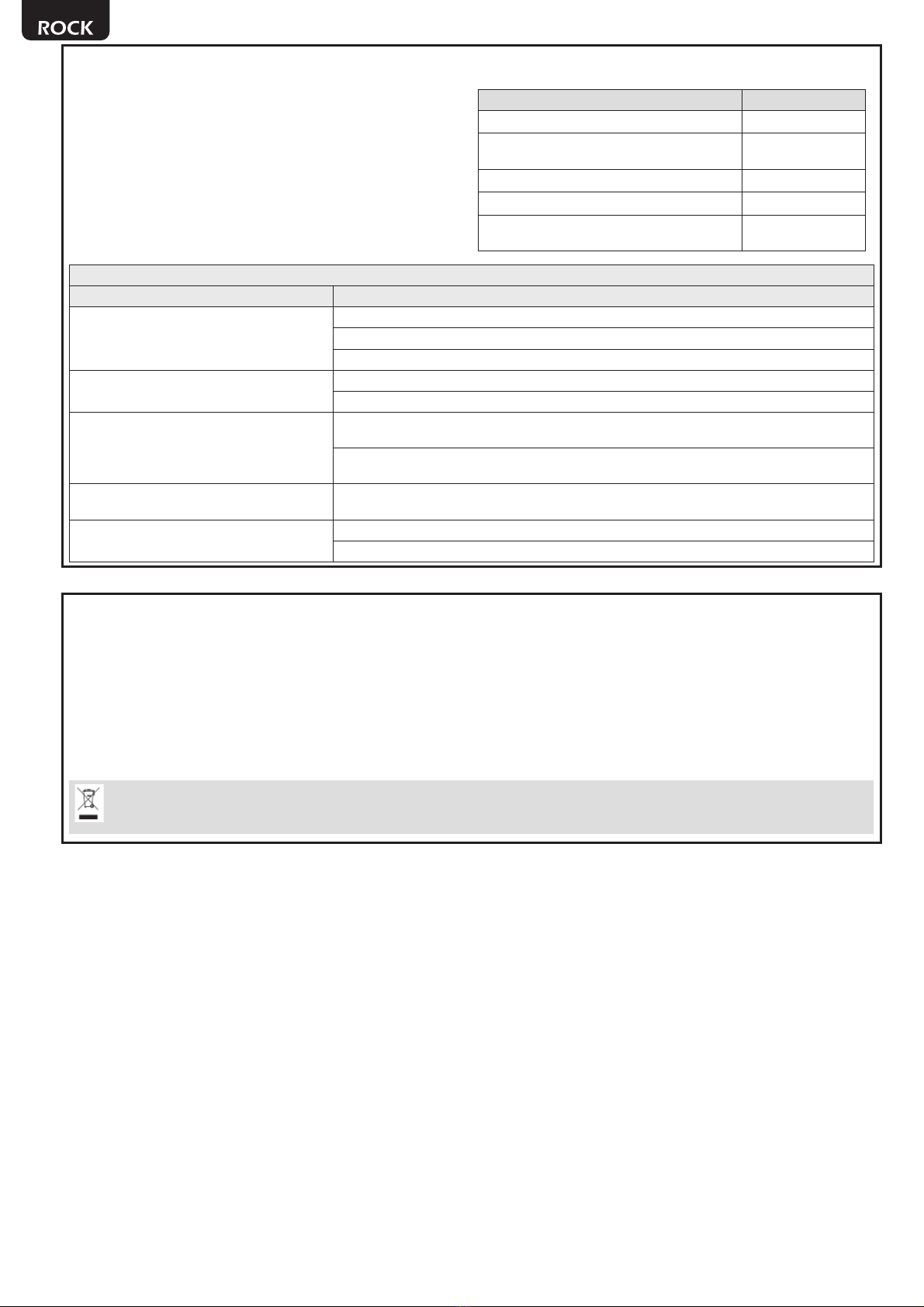

4.1 Set-ups

• Make sure that the place the bollard is positioned is not in a water collection area; where this situation should occur, the bollard must

be partly shielded by surrounding it with a draining channel with covering grid.

• The consistency of the ground must NOT be friable. If friable, envision a larger hole in the ground to stabilise the bollard, in order to

prevent the plinth escaping from the concrete after a blow.

WARNING These decisions MUST be assessed and implemented by qualified personnel.

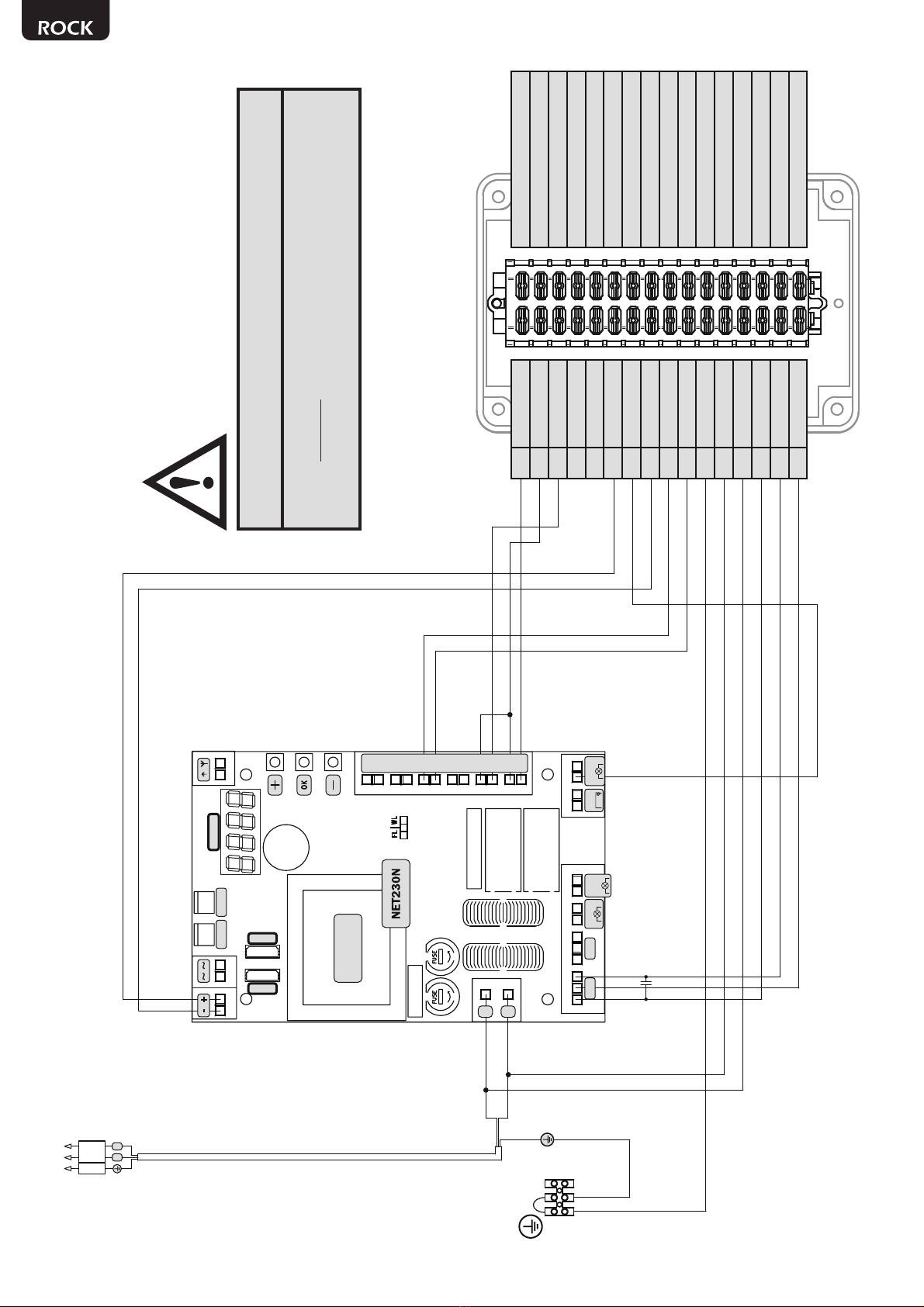

4.2 Excavation (Fig. 2)

Assess the level of shock resistance desired and proceed with excavation:

Fixing via additional reinforcement

Excavate to a depth of approx. 155 cm.

The excavation must have dimensions of 140x190 cm.

Fixing via anchor bolts

Excavate to a depth of approx. 155 cm.

The excavation must have dimensions of 90x125 cm.

WARNING Pay attention to the direction of travel as indicated in Fig. 3.

4.3 Connection to sewer system

Make sure that the land has good draining capacity by introducing approx. 40 litres of water and checking emptying takes place in less

than 30 minutes. If this is not the case, drain the waters via piping to be connected to each individual formwork (pipe diameter 80

mm) and connected to the sewer system with siphon, or to a pit with a water emptying system.

4.4 Cementing via additional reinforcement

• Introduce gravel (grain with diameter of approx. 22/32 mm) with thickness of approx. 30 cm, making sure it is compacted well to

prevent future “settling withdrawals”.

• Lay the layer of geotextile (300 g.) on the compacted gravel.

• Position a PVC pipe with diameter of 200 mm and length of 220 mm in the centre of the hole and ABOVE the geotextile (the PVC pipe

is necessary to channel the rain water).

• Introduce concrete (RCK45 type) into the hole to a height of 200 mm, making sure that the pipe remains in the centre and escapes

by at least 20 mm.

Warning: the concrete casting must be level (check that the concrete base is level with the ground in order to obtain a good support for

the bollard).

Warning: make sure that the height from the base of the cementing just performed is 1000 mm at the road surface (Fig. 4c).

• Assemble the reinforcement cage as indicated in Fig. 6 (n°36 bars Ø8 and n°5 horizontal brackets to be fixed in an equidistant way,

using the classical metal wire for reinforcement).

• Place the cage inside the excavation, making sure is is true and plumb.

• Assemble the metal pit (Fig. 5) using the rivets supplied and fix it to the secondary frame using the relative bolts supplied.

• Place the metal pit complete with secondary frame, making sure it is plumb. The upper level of the secondary frame must be

positioned 20 mm higher with respect to ground height (to limit the entry of rain water into the pit).

Warning: make sure that the metal pit is positioned correctly with respect to the direction of travel.

• Assemble n°11 anchor bolts in Ø12 B450C steel bars as indicated in Fig. 3; make sure that improved adhesion steel bars are used.

• Position the flexible hose with diameter of 45 mm (for passage of the power supply and command cables) in the relevant pilot holes

of the formwork. The piping must be connected to the plant management and handling station.

• Introduce concrete (RCK4 type) all around the metal pit up to ground level and successively connect the projecting part to the road

surface.

Warning: make sure that the concrete casting is vibrated using suitable equipment in away to adhere correctly to the walls of the metal

pit and that the same remains above the ground level by at least 20 mm (Fig. 7).

WARNING All piping must be positioned with full respect of regulations in force.