DEC DEClaser 5100 User manual

DEClaser5100Printer

ServiceGuide

Order Number: EK–LNX09–SV. A01

Digital Equipment Corporation

Maynard, Massachusetts

First Printing, April 1994

Digital Equipment Corporation makes no representations that the use of its products in the

manner described in this publication will not infringe on existing or future patent rights, nor do

the descriptions contained in this publication imply the granting of licenses to make, use, or sell

equipment or software in accordance with the description.

© Digital Equipment Corporation 1994/Digital Equipment Corporation.

Printed in USA

The following are trademarks of Digital Equipment Corporation: DECdirect, DEClaser,

PrintServer, ReGIS, VAX DOCUMENT, and the DIGITAL logo are trademarks of Digital

Equipment Corporation.

ITC Souvenir is a registered trademark of International Typeface Corporation.

PCL and LaserJet are registered trademarks of the Hewlett-Packard Company.

Microsoft is a registered trademark of Microsoft Corporation

WordPerfect is a registered trademark of WordPerfect Corporation

PostScript is a registered trademark of Adobe Systems, Inc.

Tektronix is a registered trademark of Tektronix, Inc.

All other trademarks and registered trademarks are the property of their respective holders.

The postpaid Reader’s Comments forms at the end of this document request your critical

evaluation to assist in preparing future documentation.

S2312

This document was prepared using VAX DOCUMENT Version 2.1.

Contents

Preface ..................................................... xi

1 Physical and Functional Description

1.1 Product and Servicing Safety Notes ....................... 1–1

1.2 Physical Description................................... 1–2

1.3 Cassettes ........................................... 1–12

1.4 Optional Feeders . . ................................... 1–14

1.5 Memory Options . . ................................... 1–18

1.5.1 Optional Hard Disk ................................ 1–18

1.5.2 Expansion Memory ................................ 1–18

1.6 Ethernet Network Board ............................... 1–19

1.7 Font (PCMCIA) Cartridges . . ........................... 1–20

1.8 Resolution/Graphics Enhancements Option Board . . .......... 1–21

2 Technical Description

2.1 Print Engine Control .................................. 2–2

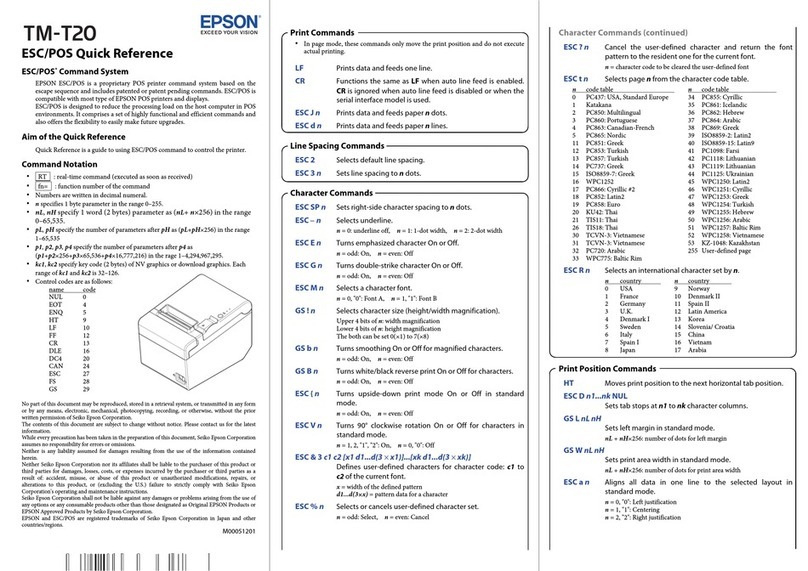

2.1.1 Video Controller Board and SmartPage ................. 2–4

2.1.2 Print Engine Modes ................................ 2–6

2.1.3 Low-voltage Power Supply Assembly ................... 2–8

2.1.4 Fusing Heater Control . . . ........................... 2–9

2.1.5 Fusing Malfunction ................................ 2–10

2.1.6 Interlocks ........................................ 2–12

2.2 Paper Feeding System ................................. 2–12

2.2.1 Size Sensing Cassettes . . . ........................... 2–14

2.3 Xerographic Process ................................... 2–15

2.3.1 Primary Charging Process ........................... 2–16

2.3.2 Exposure Process .................................. 2–16

2.3.3 Development Process ............................... 2–17

2.3.4 Transfer Process................................... 2–17

2.3.5 Separation Process ................................. 2–18

2.3.6 Print Drum Cleaning Process......................... 2–18

iii

2.3.7 Fusing Process .................................... 2–18

2.4 Scanner ............................................ 2–20

2.5 HVPSA............................................. 2–22

2.5.1 EP-ED Cartridge . . ................................ 2–24

3 Operating the Control Panel

3.1 Control Panel Description .............................. 3–2

3.2 Control Panel Operation ............................... 3–4

3.2.1 Online and Paused Messages . ........................ 3–4

3.2.2 Key Menu Modes . . ................................ 3–6

4 Test Patterns and Miscellaneous Procedures

4.1 About the Test Page . . . ................................ 4–2

4.2 About the Menu Guide . ................................ 4–3

4.3 About the Demo Pages . ................................ 4–4

4.4 About the Print PS or PCL Menus Pages. . . ................ 4–5

4.5 About the PCL Fonts and PostScript Fonts Lists............. 4–6

4.6 About the PostScript Error Report ........................ 4–7

4.7 Engine Board Test Pattern.............................. 4–8

4.8 Locking and Unlocking the Set-Up Menu . . ................ 4–9

4.9 Adjusting the Leading Edge Registration. . . ................ 4–10

4.10 Reading the Page Count ............................... 4–11

4.11 Formatting the Optional Disk . . . ........................ 4–12

5 Start FIP and Total Call Concept

5.1 Preliminary Information ............................... 5–2

5.2 Start FIP . . . ........................................ 5–2

5.3 Total Call Concept (TCC) Procedure....................... 5–5

5.3.1 200K Maintenance Procedure ........................ 5–7

6 Power and Control Panel FIPs

6.1 Bad Power or Control Panel FIPs ........................ 6–2

6.2 Optional Equipment Non-Error FIPs ...................... 6–5

6.3 Insert or Remove Cartridge ............................ 6–7

6.4 Load Env (Value)..................................... 6–8

6.5 Load Front or Manual Feed ............................. 6–9

6.6 Load LCIT (Value).................................... 6–10

6.7 Load or Install Inter (Value) ............................ 6–11

6.8 Memory Overflow or Print Overrun ....................... 6–12

iv

6.9 No Toner Cart or Toner Low . ........................... 6–13

6.10 Printer Open ........................................ 6–14

6.11 All Hard Disk Errors .................................. 6–15

6.12 50 ERROR .......................................... 6–16

6.13 51 or 52 ERROR . . ................................... 6–17

6.14 57 ERROR ......................................... 6–18

6.15 58 ERROR ......................................... 6–19

6.16 68 Service .......................................... 6–20

6.17 Print Engine Wiring Diagrams .......................... 6–20

6.17.1 Envelope Feeder and LCIT Wiring diagrams . . . .......... 6–25

7 FIPs for Fixing Paper Jams

7.1 Types of Jams ....................................... 7–2

7.2 Identifying the Location of the Jam ....................... 7–2

7.3 Paper Feed Area Jams ................................ 7–4

7.4 Fusing and Delivery Area Jams .......................... 7–6

7.5 Phantom Jams ....................................... 7–6

8 FIPs For Fixing Image Defects

8.1 Image Defects Lookup ................................. 8–2

8.2 Light or Faint Images ................................. 8–3

8.3 Blank or White Prints ................................. 8–4

8.4 Black or Too Dark Prints ............................... 8–5

8.5 In-line Vertical Dots ................................... 8–5

8.6 Dirt on Back of Page .................................. 8–6

8.7 Vertical Black Lines ................................... 8–7

8.8 Black Smudged Vertical Bands .......................... 8–7

8.9 Black Smudged Horizontal Bands ........................ 8–7

8.10 Blank or White Spots ................................. 8–8

8.11 Vertical White Lines .................................. 8–8

8.12 Registration ......................................... 8–9

8.13 Fusing Failure ....................................... 8–10

8.14 Distorted Image or Missing BD Signal. . ................... 8–11

8.15 Repetitive Marks . ................................... 8–12

v

9 Removing and Replacing FRUs

9.1 Removing and Replacing FRUs . . ........................ 9–1

9.2 Assembly, Control panel ............................... 9–2

9.3 Assembly, Gear ...................................... 9–5

9.4 Assembly, High-Voltage Power Supply (HVPSA) ............. 9–7

9.5 Assembly, Low-Voltage Power Supply (LVPSA) .............. 9–8

9.6 Assembly, Optional Hard Disk Drive ..................... 9–11

9.7 Assembly, Paper Delivery .............................. 9–15

9.8 Assembly, Feed ...................................... 9–18

9.9 Assembly, Scanner . . . ................................ 9–21

9.10 Board, LCIT Controller ................................ 9–23

9.11 Board, Feed Controller ................................ 9–27

9.12 Board, DC Control . . . ................................ 9–29

9.12.1 Page Count Memory (NVRAM) ....................... 9–32

9.13 Board, Ethernet ..................................... 9–33

9.14 Board, SIMMs ....................................... 9–35

9.15 Board, Video Controller ................................ 9–37

9.16 Cage, Card . . ........................................ 9–39

9.17 Cartridge, EP-ED (toner) .............................. 9–40

9.18 Cover, Left-Side ...................................... 9–41

9.19 Cover, Right-Side ..................................... 9–43

9.20 Cover, Top Cover ..................................... 9–45

9.21 Door, Rear . . ........................................ 9–47

9.21.1 Rear Door Latch. . . ................................ 9–49

9.22 Door, Front and Guide Plate ............................ 9–50

9.22.1 Guide Plate ...................................... 9–52

9.23 Fan Exhaust ........................................ 9–54

9.24 Feeder, Envelope ..................................... 9–57

9.25 Fusing Unit ........................................ 9–59

9.26 Guide, HVPSA Contact Plate ............................ 9–60

9.27 Interconnect, HVPSA/Fuser ............................. 9–70

9.28 Motor, Main ........................................ 9–74

9.29 Motor, LCIT Pickup . . ................................ 9–75

9.30 Pad, Front Tray Separation ............................ 9–78

9.31 Roller Transfer ...................................... 9–79

9.32 Roller, Cassette Pickup ................................ 9–80

9.33 Roller, Front Tray Pickup .............................. 9–81

9.34 Roller, LCIT Pickup . . . ................................ 9–83

9.35 Sensor, Fusing Exit/Rear Door . . . ........................ 9–84

vi

10 FRU Part Numbers

10.1 Field Replaceable Units ................................ 10–1

A Key Menu Map, Features, and Values

A.1 Key Menu Map . . . ................................... A–1

A.2 Key Menu Messages................................... A–8

B General Information

B.1 Connecting to an Ethernet Network . . . ................... B–1

B.2 Connecting PC or IBM Compatible Systems ................ B–2

B.2.1 Configuring AUTOEXEC Files ........................ B–3

B.2.2 MS–DOS Drivers .................................. B–4

B.2.3 Windows and Windows NT Drivers . ................... B–4

B.3 Connecting the Printer to a Macintosh Computer . . .......... B–5

B.3.1 Macintosh Printer Driver . ........................... B–6

B.4 Connecting to OpenVMS VAX or ULTRIX Systems . .......... B–7

C DEClaser 5100 Specifications

C.1 Operating Requirements ............................... C–4

C.1.1 Space Requirements ................................ C–4

C.1.2 Environmental Requirements ........................ C–6

D Training, Documentation and Tools

D.1 Training . ........................................... D–1

D.2 Documentation Ordering Information . . ................... D–2

D.3 Tools . . . ........................................... D–3

Index

Figures

1–1 Front View ....................................... 1–2

1–2 Front Tray Open .................................. 1–4

1–3 Inside the Top Door ................................ 1–6

1–4 Rear Panel ....................................... 1–8

1–5 LCIT Interconnection ............................... 1–10

vii

1–6 Universal Cassette ................................ 1–12

1–7 LCIT . . . ........................................ 1–14

1–8 Envelope Feeder. . . ................................ 1–16

1–9 Ethernet Network Board ............................ 1–19

1–10 Font Cartridge Installation . . ........................ 1–20

2–1 Overall Block Diagram.............................. 2–3

2–2 Video Controller Block Diagram....................... 2–5

2–3 Print Engine Modes Timing Diagram . . ................ 2–7

2–4 LVPSA Diagram . . . ................................ 2–8

2–5 Fusing Temperature Chart. . . ........................ 2–9

2–6 Discharging C202 . . ................................ 2–10

2–7 Fusing Control Circuits ............................. 2–11

2–8 Interlock Diagram . ................................ 2–12

2–9 Xerographic Process ............................... 2–15

2–10 Scanning System Diagram . . . ........................ 2–21

2–11 HVPSA Control Circuit ............................. 2–23

2–12 EP-ED Cartridge . . ................................ 2–25

3–1 Control Panel ..................................... 3–2

3–2 Overall Key Menu Map ............................. 3–7

4–1 Test (Power Up) Page ............................... 4–2

4–2 Menu Guide ...................................... 4–3

4–3 Demo Page ....................................... 4–4

4–4 PostScript and PCL Settings Pages .................... 4–5

4–5 Font Lists........................................ 4–6

4–6 PostScript Error Report ............................. 4–7

4–7 Engine Board Test Pattern. . . ........................ 4–8

4–8 VR202 Registration Adjustment....................... 4–11

6–1 LVPSA Diagram . . . ................................ 6–4

6–2 Print Engine Wiring Diagram 1 ....................... 6–21

6–3 Print Engine Wiring Diagram 2 ....................... 6–22

6–4 Print Engine Wiring Diagram 3 ....................... 6–23

6–5 Print Engine Wiring Diagram 4 ....................... 6–24

6–6 Optional Envelope Feeder Wiring Diagram .............. 6–25

6–7 LCIT Wiring Diagram .............................. 6–26

7–1 Jam Areas ....................................... 7–3

8–1 Image Defects Directory ............................. 8–2

8–2 Roller Defect Ruler. ................................ 8–12

viii

A–1 Key Menu Map ................................... A–2

B–1 AppleTalk Network Connections . . . ................... B–5

B–2 EIA-232 and EIA-422 Cable/Adapter Configurations ....... B–8

C–1 Operating Space ................................... C–5

Tables

1–1 Front View ....................................... 1–3

1–2 Front Tray ....................................... 1–5

1–3 Inside the Top Door ................................ 1–7

1–4 Rear View ....................................... 1–9

1–5 LCIT Interconnection ............................... 1–11

1–6 Fixed and Universal Cassettes ........................ 1–13

1–7 LCIT ........................................... 1–15

1–8 Envelope Feeder................................... 1–17

2–1 Size Sensing Switches . . . ........................... 2–14

3–1 Control Panel . . ................................... 3–2

3–2 Indicators and Keys ................................ 3–3

3–3 Online and Paused Messages ......................... 3–4

5–1 Start FIP ........................................ 5–3

5–2 200K Maintenance Procedure ........................ 5–7

7–1 Types of jams . . ................................... 7–2

7–2 Jam Areas ....................................... 7–3

7–3 Feed Area Swap Lists . . . ........................... 7–5

10–1 FRUs ........................................... 10–1

B–1 Parallel Port AUTOEXEC.BAT Modifications . . .......... B–3

B–2 Serial Port AUTOEXEC.BAT Modifications .............. B–3

C–1 Printer Specifications ............................... C–1

D–1 Training ......................................... D–1

D–2 Documentation . ................................... D–2

D–3 Tools. ........................................... D–3

ix

Preface

This book is for Digital Service engineers to help them repair and service the

DEClaser 5100 printer. Before using this book, you must attend the specific

Digital Service training course and all other prerequisite training courses.

Section D.1 lists all recommended courses.

Conventions

The following conventions are used in this guide:

Convention Description

Note: Notes provide additional information.

Caution: Cautions contain information to prevent damage to the

equipment or software.

Warning: Warnings contain information to prevent personal injury.

On Line All control panel keys are represented by a box with the name of

the key inside the box.

Value When this symbol appears next to a control panel message,

it shows that a string of numbers normally accompanies the

message. For example, in the Parity=Value message, the value

can be one of five different words.

PRNT

A line over a signal name indicates that when the signal is

asserted, the signal is low.

How to Use this Guide

You can use this guide as a combined training document and for reference

information.

Use the table of contents or the fault isolation procedures (FIP)s to find the

section number of the information you need. The section header numbers (1.3,

2.3 and so on) are printed at the top of each page.

xi

• Chapter 1 identifies the significant external and internal components of the

standard printer and of the optional equipment.

• Chapter 2 describes the paper handling, electromechanical operation, and

the xerographic processes.

• Chapter 3 describes the control panel operation.

• Chapter 4 describes the test prints and several miscellaneous procedures.

• Chapter 5 contains the start FIP and the total call concept (TCC)

procedure.

• Chapter 6 contains FIPs for fixing power, control panel, and error message

malfunctions.

• Chapter 7 contains the paper jam FIPs.

• Chapter 8 contains the image defect FIPs.

• Chapter 9 contains procedures for removing and replacing field replaceable

units (FRU)s.

• Chapter 10 contains the FRU part numbers.

• Appendix A contains a map of the control panel key menus and a

glossary-style description of each feature and value.

• Appendix B contains information on how to connect and configure the

DEClaser 5100 printer.

• Appendix C contains the printer specifications.

• Appendix D contains information about tools, training, and documentation.

xii

DSG-000172

Notes:

1

1

Physical and Functional Description

This chapter provides a physical and functional description of the DEClaser

5100 printer and of the optional printer equipment.

1.1 Product and Servicing Safety Notes

Note: The DEClaser 5100 printer complies with all United States government

safety regulations applicable to ozone gas emissions and laser beam light

exposure.

Laser Safety: The DEClaser 5100 printer complies with 21 CFR Chapter 1,

Subchapter J, as a Class 1 laser product under the U.S. Department of Health

and Human Services (DHHS) Radiation Performance Standard, according to

the Radiation Control for Health and Safety Act of 1968. The DEClaser 5100

printer does not emit hazardous light because the laser beam is totally enclosed

during all modes of customer operation and maintenance.

Warning: Use of controls or adjustment procedures other than those specified

in this manual could result in hazardous laser light exposure.

Physical and Functional Description 1–1

1.2 Physical Description

1.2 Physical Description

Figure 1–1 presents a view of the front and right side of the printer. The

names and functions of the items are described in Table 1–1.

Figure 1–1 Front View

DSG-000425

6

13

7

8

4

5

2

1–2 Physical and Functional Description

1.2 Physical Description

Table 1–1 Front View

!

Top door

and cover Lifts for access to the EP-ED cartridge or for clearing

paper jams. When closed, a plastic post pushes down the

linkage to the interlock switch. The switch connects the

+24VB power to the main motor and paper feed motor.

See Section 2.1.3 for additional information.

"

Face down tray

delivery stack Holds up to 250 sheets. This printer has no tray full or

job offset features.

#

Hot air exhaust The main fan blows the hot air from inside the printer

through this vent. Overheating might result if the vent

is blocked.

$

Power on/off switch Connects to the main LVPSA switch by a mechanical

linkage.

%

Font cartridge slot Holds up to two optional PCMCIA font cartridges. The

cartridges can be hot swapped (with power applied) but

the printer must be paused.

&

Control panel Consists of seven multipurpose keys, an alphanumeric

display panel, and indicators that light or flash to

show status conditions. See Chapter 3 for additional

information.

'

Internal paper cassette Holds up to 250 sheets of xerographic paper. Internal

cassettes are available in fixed or universal sizes. The

universal cassette can be configured to accommodate the

standard sized sheets listed in Table 2–1.

(

Cassette full/empty

indicator The mechanical indicator links to and moves with the

paper stack lifter inside the cassette.

Physical and Functional Description 1–3

1.2 Physical Description

Figure 1–2 shows the components that are accessible through the front tray of

the printer. Table 1–2 describes the components.

Figure 1–2 Front Tray Open

DSG-000863

12

3

4

1–4 Physical and Functional Description

1.2 Physical Description

Table 1–2 Front Tray

!

Envelope feeder

connector Connects the optional envelope feeder to the feed unit

controller. It is hidden by a panel when no envelope

feeder is installed. See Section 9.24 for envelope feeder

and panel installation.

"

Test print switch Use a suitable tool to press this switch. When pressed,

the DC control board feeds and prints one copy of the

engine board test pattern from the internal cassette only.

See Section 4.7 for additional information.

#

Adjustable paper

guides The adjustable guide is moved to hold the media against

the fixed guide. Image skewing, paper jams, or bad

image positioning can occur if the adjustable guide is too

loose or over-tightened.

$

Front tray

and door Shown in the open position. The tray accommodates

standard size cut sheets and envelopes. The tray is

monitored by the paper end and front tray paper sensor.

Physical and Functional Description 1–5

1.2 Physical Description

Figure 1–3 shows the inside components that are accessible through the top

door of the printer. Table 1–3 describes each component.

Figure 1–3 Inside the Top Door

DSG-000861

134

2

5

1–6 Physical and Functional Description

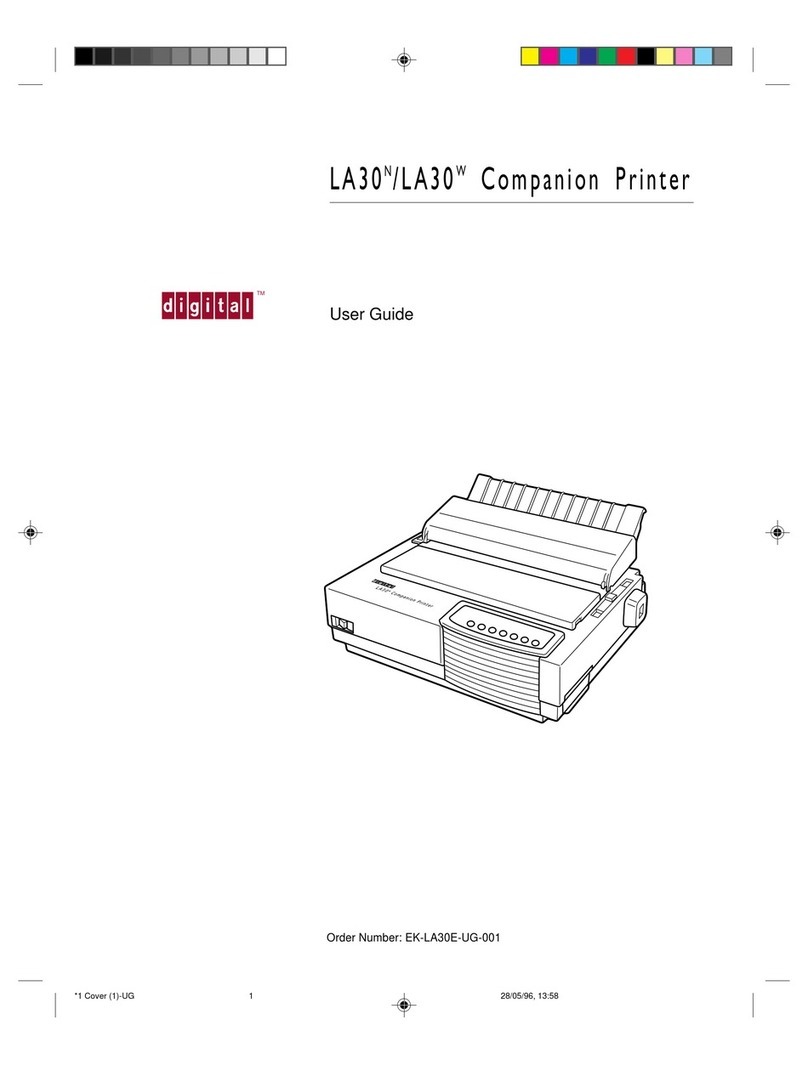

Other manuals for DEClaser 5100

2

Table of contents

Other DEC Printer manuals

Popular Printer manuals by other brands

Canon

Canon iP5000 - PIXMA Color Inkjet Printer quick start guide

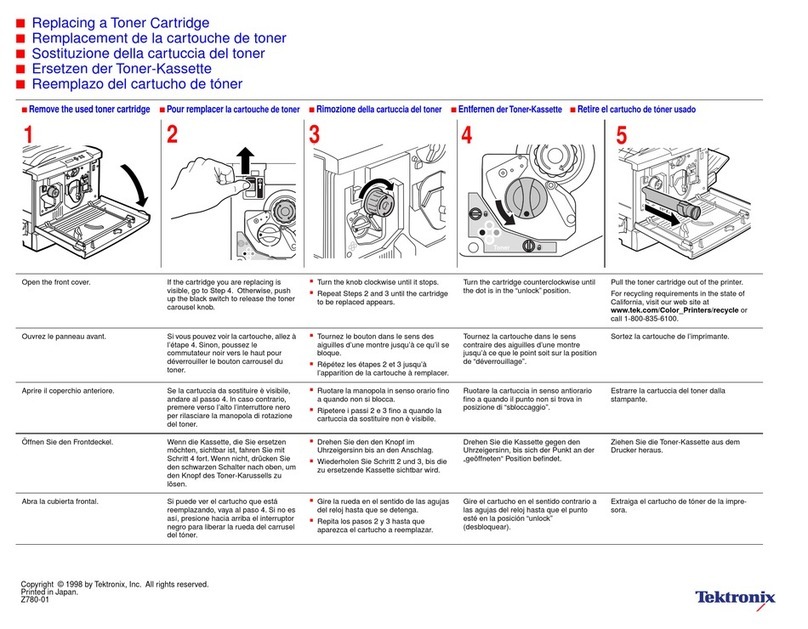

Tektronix

Tektronix Phaser 780 Color supplementary guide

Epson

Epson B-510DN - Business Color Ink Jet Printer Specifications

Philips

Philips CRYSTAL 660 - NETWORK Installation guidelines

Canon

Canon PIXMA MP620 series Getting started

Ricoh

Ricoh SG 7100DN installation guide