2.11.5.5 CONNECTION TO BASIC ETHERNET...................................................................40

2.11.5.6 CONNECTION TO COMPANY ETHERNET INFRASTRUCTURE.........................41

2.11.5.7 CONNECTION TO THE INTERNET........................................................................42

2.11.5.8 FIREWALL CONFIGURATION FOR INTERNET ACCESS....................................43

2.11.5.9 ETHERNET USED FOR THE DSE2610 REMOTE DISPLAY.................................44

2.11.6 MSC (MULTI-SET COMMUNICATIONS) LINK ..............................................................45

2.11.7 CAN PORT (REDUNDANT MSC)...................................................................................46

2.11.8 ECU PORT (J1939).........................................................................................................48

2.11.8.1 CAN SUPPORTED ENGINES.................................................................................48

2.11.8.2 CAN SUPPORTED AVRS .......................................................................................49

2.11.8.3 J1939-75 ..................................................................................................................50

2.11.8.4 CONFIGURABLE CAN............................................................................................51

2.11.9 DSENET®(EXPANSION MODULES).............................................................................52

2.11.9.1 DSENET® USED FOR MODBUS ENGINE CONNECTION ....................................53

2.12 SOUNDER ..........................................................................................................................54

2.12.1 ADDING AN EXTERNAL SOUNDER .............................................................................54

2.13 ACCUMULATED INSTRUMENTATION ............................................................................54

2.14 DIMENSIONS AND MOUNTING........................................................................................55

2.14.1 DIMENSIONS..................................................................................................................55

2.14.2 PANEL CUTOUT.............................................................................................................55

2.14.3 WEIGHT..........................................................................................................................55

2.14.4 FIXING CLIPS.................................................................................................................56

2.14.5 CABLE TIE FIXING POINTS...........................................................................................57

2.14.6 SILICON SEALING GASKET..........................................................................................57

2.15 APPLICABLE STANDARDS .............................................................................................58

2.15.1 ENCLOSURE CLASSIFICATIONS.................................................................................60

2.15.1.1 IP CLASSIFICATIONS.............................................................................................60

2.15.1.2 NEMA CLASSIFICATIONS......................................................................................60

3INSTALLATION.................................................................................................61

3.1 USER CONNECTIONS..........................................................................................................61

3.2 CONNECTION DESCRIPTIONS ...........................................................................................62

3.2.1 DC SUPPLY, E-STOP INPUT, DC OUTPUTS & CHARGE FAIL INPUT.......................62

3.2.2 ANALOGUE SENSOR INPUTS & CAN..........................................................................63

3.2.3 MPU, ECU, MSC & DSENET®........................................................................................64

3.2.4 OUTPUT C & D, & V1 (GENERATOR) VOLTAGE & FREQUENCY SENSING ............65

3.2.5 V2 (BUS) VOLTAGE & FREQUENCY SENSING...........................................................65

3.2.6 CURRENT TRANSFORMERS........................................................................................66

3.2.6.1 CT CONNECTIONS.................................................................................................67

3.2.7 DIGITAL INPUTS ............................................................................................................67

3.2.8 RS485..............................................................................................................................68

3.2.9 RS232..............................................................................................................................69

3.2.10 USB SLAVE (PC CONFIGURATION) CONNECTOR ....................................................70

3.2.11 USB HOST (DATA LOGGING) CONNECTOR...............................................................70

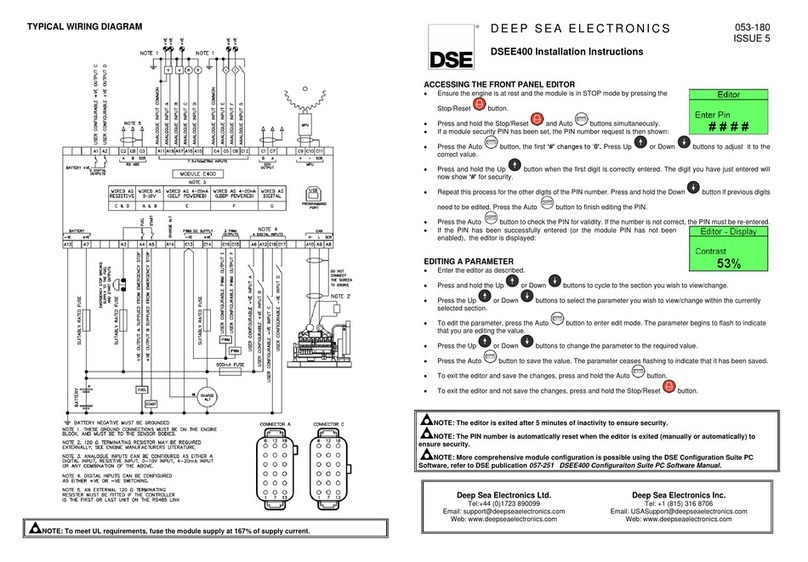

3.3 TYPICAL WIRING DIAGRAM................................................................................................71

3.3.1 3 PHASE 4 WIRE WITH RESTRICTED EARTH FAULT................................................72

3.3.2 EARTH SYSTEMS..........................................................................................................73

3.3.2.1 NEGATIVE EARTH..................................................................................................73

3.3.2.2 POSITIVE EARTH ...................................................................................................73

3.3.2.3 FLOATING EARTH..................................................................................................73

3.3.3 TYPICAL ARRANGEMENT OF DSENET®.....................................................................74

3.3.4 TYPICAL ARRANGEMENT OF MSC LINK ....................................................................75

3.4 ALTERNATE TOPOLOGY WIRING DIAGRAMS .................................................................76

3.4.1 SINGLE PHASE (L1 & N) 2 WIRE WITH RESTRICTED EARTH FAULT......................76

3.4.2 SINGLE PHASE (L1 & N) 2 WIRE WITHOUT EARTH FAULT ......................................77

3.4.3 SINGLE PHASE (L1 & L2) 3 WIRE WITH RESTRICTED EARTH FAULT.....................78

3.4.4 SINGLE PHASE (L1 & L2) 3 WIRE WITHOUT EARTH FAULT.....................................79

3.4.5 SINGLE PHASE (L1 & L3) 3 WIRE WITH RESTRICTED EARTH FAULT.....................80

3.4.6 SINGLE PHASE (L1 & L3) 3 WIRE WITHOUT EARTH FAULT.....................................81

3.4.7 2 PHASE (L1 & L2) 3 WIRE WITH RESTRICTED EARTH FAULT................................82