Deif IMD 100 Use and care manual

IMD 100 Integration manual 4189360015 Rev. G

www.deif.com/wind-power Page 2 of 243

Disclaimer

The contents of this document are subject to revision without notice. DEIF A/S shall have no liability for any

error or damages of any kind resulting from the use of this document.

The English version of this document is the original language, and always takes precedence if there is any

discrepancy with a translation of the document.

Trademarks

DEIF

DEIF is a registered trademark of DEIF A/S

CAN®

CAN is registered trademark of Robert Bosch GmbH

CiA®

CiA is a registered trademark of CAN in Automation e. V.

CANopen®

CANopen is a registered trademark of CAN in Automation e. V.

All trademarks mentioned in this document are the properties of their respective owners.

Copyright

© Copyright DEIF A/S. All rights reserved.

IMD 100 Integration manual 4189360015 Rev. G Contents

www.deif.com/wind-power Page 3 of 243

Contents

1. Introduction...................................................................................................................... 9

1.1 Conventions....................................................................................................................10

2. Safety precautions ........................................................................................................ 11

2.1 Mechanical work.............................................................................................................11

2.2 Electrical work................................................................................................................11

2.3 Thermal precautions......................................................................................................13

3. Avoiding damage to the IMD ........................................................................................ 14

3.1 Connecting the safe energy...........................................................................................14

3.2 Switching mains ON and OFF........................................................................................14

3.3 Overloading the ballast resistor....................................................................................14

3.4 Connecting the mains with overvoltage .......................................................................14

4. Mechanical integration.................................................................................................. 15

4.1 Integrating the IMD in a cabinet.....................................................................................15

4.1.1 Environmental requirements .................................................................................15

4.1.2 Temperature considerations..................................................................................15

4.1.3 Mounting of the IMD in the cabinet........................................................................19

5. Electrical HW connections and requirements............................................................. 22

5.1 Shielding and EMC.........................................................................................................27

5.2 Power connections (X1).................................................................................................28

5.2.1 Motor connections requirements...........................................................................30

5.2.2 Mains supply connections requirements................................................................33

5.2.3 Safe energy connection requirements...................................................................34

5.2.4 Ballast resistor requirements.................................................................................35

5.3 Peripheral and temperature connections (X2, X3, X4, X5)...........................................36

5.3.1 Connecting the motor brake (X2) ..........................................................................37

5.3.2 Connecting the temperature sensors (X3, optional)...............................................37

5.3.3 Connecting the resolver (X4).................................................................................39

5.3.4 Connecting the SSI (X5), optional.........................................................................41

5.4 Communication..............................................................................................................44

5.4.1 Connecting the CAN bus (X6)...............................................................................44

5.5 Connecting 24V, digital and safety I/O (X7, X8, X9)......................................................46

5.5.1 Connecting digital inputs (X9) ...............................................................................47

5.5.2 Connecting safety I/O and digital outputs (X8) ......................................................49

5.5.3 Connecting 24V (X7).............................................................................................52

IMD 100 Integration manual 4189360015 Rev. G Contents

www.deif.com/wind-power Page 4 of 243

6. Functions description................................................................................................... 55

6.1 IMD states .......................................................................................................................55

6.2 Internal flags...................................................................................................................61

6.3 Safe energy monitoring..................................................................................................62

6.4 Brake control..................................................................................................................63

6.4.1 Brake engagement (Brake output OFF) ................................................................64

6.4.2 Brake disengagement (Brake output ON)..............................................................65

7. Communication ............................................................................................................. 66

7.1 CAN/CANopen interface.................................................................................................66

7.1.1 CANopen network structure and management......................................................66

7.1.2 CAN proprietary Interface......................................................................................67

7.1.3 CANopen interface................................................................................................69

7.2 Serial data interface .......................................................................................................78

8. IMD configuration.......................................................................................................... 79

8.1 Prerequisites...................................................................................................................79

8.1.1 Hardware..............................................................................................................79

8.1.2 Software................................................................................................................79

8.2 Safety ..............................................................................................................................80

8.3 Turning the power on.....................................................................................................80

8.4 Configuring general parameters ...................................................................................81

8.4.1 Configuring the general servo fields......................................................................81

8.4.2 Configuring motor data..........................................................................................88

8.4.3 Configuring the safety run fields............................................................................95

8.4.4 Configuring the CAN bus.......................................................................................97

8.4.5 Configuring the safe energy test............................................................................97

8.4.6 Configuring pre-heating.........................................................................................99

8.4.7 Configuring virtual limit switches .........................................................................100

8.4.8 Configuring manual operation.............................................................................100

8.4.9 Configuring input-output logic..............................................................................101

8.5 Configuring the control parameters data....................................................................103

8.5.1 General PID parameters .....................................................................................103

8.5.2 Configuring speed parameters............................................................................106

8.5.3 Configuring current parameters...........................................................................110

8.5.4 Configuring magnetic field weakening parameters..............................................112

8.5.5 Configuring position parameters..........................................................................113

8.6 Configuring async. motor parameters and resolver offset .......................................113

8.6.1 Configuring resolver offset ..................................................................................113

IMD 100 Integration manual 4189360015 Rev. G Contents

www.deif.com/wind-power Page 5 of 243

8.6.2 Configuring additional motor parameters.............................................................118

8.6.3 Configuring volt/freq control for async. motor......................................................119

8.7 Configuring SE charger parameters (option) .............................................................120

8.7.1 Charger configuration management....................................................................120

8.7.2 Configuring the charger with a script...................................................................120

8.7.3 Configuring the charger manually........................................................................122

9. Operational procedures.............................................................................................. 129

9.1 Brake test......................................................................................................................129

9.1.1 Prerequisites.......................................................................................................129

9.1.2 Activation............................................................................................................129

9.1.3 Operation............................................................................................................129

9.1.4 Deactivation........................................................................................................129

9.2 Changing actual position value (Pos. preset) ............................................................130

9.2.1 Prerequisites.......................................................................................................130

9.2.2 Activation............................................................................................................131

9.2.3 Operation............................................................................................................131

9.2.4 Deactivation........................................................................................................131

9.3 Disconnecting AC mains from DC-link (Mains, disconnect) .....................................131

9.3.1 Prerequisites.......................................................................................................132

9.3.2 Activation............................................................................................................132

9.3.3 Operation............................................................................................................133

9.3.4 Deactivation........................................................................................................133

9.4 Enabling the power module.........................................................................................133

9.5 Forcing speed zero.......................................................................................................134

9.5.1 Prerequisites.......................................................................................................135

9.5.2 Activation............................................................................................................135

9.5.3 Operation............................................................................................................135

9.5.4 Deactivation........................................................................................................135

9.6 Manual operation..........................................................................................................136

9.6.1 Reg. 0x01 bit 23 (SCI state) set to OK ................................................................136

9.6.2 Reg. 0x01 bit 23 (SCI state) set to Not OK (safety chain tripped)........................137

9.7 Manual operation 360...................................................................................................138

9.7.1 Prerequisites.......................................................................................................138

9.7.2 Activation............................................................................................................138

9.7.3 Operation............................................................................................................138

9.7.4 Deactivation........................................................................................................138

9.8 Manually activating the fan..........................................................................................139

9.8.1 Prerequisites.......................................................................................................139

IMD 100 Integration manual 4189360015 Rev. G Contents

www.deif.com/wind-power Page 6 of 243

9.8.2 Activation............................................................................................................139

9.8.3 Operation............................................................................................................139

9.8.4 Deactivation........................................................................................................139

9.9 Manually initiating a Safety run...................................................................................140

9.9.1 Prerequisites.......................................................................................................140

9.9.2 Activation............................................................................................................140

9.9.3 Operation............................................................................................................141

9.9.4 Deactivation........................................................................................................141

9.10 Normal operation..........................................................................................................141

9.10.1 Prerequisites.....................................................................................................141

9.10.2 Activation..........................................................................................................141

9.10.3 Operation..........................................................................................................141

9.10.4 Deactivation......................................................................................................141

9.11 Pre-heating the motor ..................................................................................................141

9.11.1 Prerequisites.....................................................................................................141

9.11.2 Activation..........................................................................................................142

9.11.3 Operation..........................................................................................................142

9.11.4 Deactivation......................................................................................................142

9.12 Restarting the IMD (by communication).....................................................................142

9.12.1 Prerequisites.....................................................................................................143

9.12.2 Activation..........................................................................................................143

9.12.3 Operation..........................................................................................................145

9.12.4 Deactivation......................................................................................................145

9.13 Safe energy (ultra-capacitors only) discharging........................................................145

9.13.1 Prerequisites.....................................................................................................145

9.13.2 Activation..........................................................................................................145

9.13.3 Operation..........................................................................................................146

9.13.4 Deactivation......................................................................................................146

9.14 Tripping safety-chain outputs .....................................................................................147

9.14.1 Prerequisites.....................................................................................................147

9.14.2 Activation..........................................................................................................147

9.14.3 Operation..........................................................................................................147

9.14.4 Deactivation......................................................................................................147

9.15 Turning the power to the IMD on.................................................................................148

9.16 Updating Firmware.......................................................................................................148

9.16.1 Updating firmware with the Service USB connector method..............................149

9.16.2 Updating firmware with method

154

9.16.3 Updating firmware through CANopen................................................................164

IMD 100 Integration manual 4189360015 Rev. G Contents

www.deif.com/wind-power Page 7 of 243

9.17 Using digital inputs and outputs.................................................................................165

9.17.1 Digital outputs...................................................................................................165

9.17.2 Digital inputs .....................................................................................................166

9.18 Using SSI Encoder to determine blade position ........................................................167

9.18.1 Retrieving position from single-turn encoder .....................................................167

9.18.2 Retrieving position multi-turn encoder...............................................................167

10. Units conversion ......................................................................................................... 170

10.1 Converting position values..........................................................................................170

10.2 Converting voltage units to volts................................................................................170

10.3 Converting temperature values...................................................................................170

10.3.1 Converting power module temperature (T-igbt).................................................170

10.3.2 Converting motor temperature (T-motor, KTY 84 sensor)..................................172

10.3.3 Converting motor temperature (T-motor, Pt100 sensor)....................................176

10.3.4 Converting temperature Pt100 sensor (Pt1 to Pt4)............................................179

10.3.5 Converting (internal) air temperature (T-air)......................................................182

10.4 Converting current values ...........................................................................................185

10.4.1 Converting current raw values to Ampere .........................................................185

10.4.2 Converting Ampere to current raw values .........................................................185

10.5 Converting speed values.............................................................................................186

10.5.1 Converting speed values from raw values to RPM............................................186

10.5.2 Converting speed values from RPM to raw values............................................186

10.6 Converting torque values ............................................................................................186

10.6.1 Converting torque raw values to Nm .................................................................187

10.6.2 Converting Torque Nm to raw values................................................................187

11. Protection and errors description.............................................................................. 188

11.1 Voltage protection and errors......................................................................................188

11.1.1 Overvoltage error..............................................................................................188

11.1.2 Under voltage error...........................................................................................188

12. Errors and warnings.................................................................................................... 189

12.1 Error list........................................................................................................................189

12.1.1 Charger (option) errors......................................................................................191

12.2 Warning list...................................................................................................................192

12.2.1 Charger (option) warnings.................................................................................193

12.3 Errors log......................................................................................................................193

13. Parameter description................................................................................................. 196

13.1 Parameter types ...........................................................................................................196

IMD 100 Integration manual 4189360015 Rev. G Contents

www.deif.com/wind-power Page 8 of 243

13.2 Parameter bit mapping.................................................................................................197

13.2.1 User options (01)...............................................................................................197

13.2.2 User state (02)..................................................................................................199

13.2.3 User demand (03).............................................................................................201

13.2.4 Drive status (40)................................................................................................202

13.2.5 Device mode (51)..............................................................................................204

13.2.6 Device option (5A).............................................................................................204

13.2.7 Errors/warnings (8F) .........................................................................................206

13.2.8 Logic Out block (98)..........................................................................................207

13.2.9 Logic in block (9B).............................................................................................208

13.2.10 User motor options (A4)..................................................................................209

13.2.11 Logic in/out block state (D8)............................................................................209

13.3 Parameter list................................................................................................................211

13.3.1 Charger parameters..........................................................................................228

13.3.2 Error history parameters....................................................................................231

14. Revision history........................................................................................................... 236

15. Product user documentation...................................................................................... 239

16. Glossary....................................................................................................................... 242

16.1 Terms and abbreviations.............................................................................................242

16.2 Units..............................................................................................................................243

IMD 100 Integration manual 4189360015 Rev. G Introduction

www.deif.com/wind-power Page 9 of 243

1. Introduction

This document describes the IMD 100 in details to enable the integration of the IMD in a pitch system.

It is intended for customers R&D personnel, who will integrate the IMD in the pitch system. All aspects

of the integration are included in this manual:

•Mechanical integration:

oMechanical specifications and requirements

oDescription of mechanical installation options

oSpace requirements

•Electrical requirements:

oDescription of electrical connections

oRequirements for all electrical interfaces

•Configuration

oConfiguration of the IMD for a specific system using the IMD Manager

oCreation of a configuration file for use in production

•Operation control and monitoring

oCommunication

oOperational states

oInput and output states

oMonitoring parameters

oWarnings

oErrors

oInterpretation of numeric representation unitsconversion

•Starting the IMD in the laboratory for the first time

Read instructions

Read the IMD 100 function description(document no. 4189360013) in order to understand

the functions of the IMD. Description of the functions is not repeated in this manual.

References are made in this manual to IMD 100 Installation instructions, IMD Manager

Installation instructions, IMD Manager user manual and IMD 100 Datasheet. Have these at

hand while reading this manual.

IMD 100 Integration manual 4189360015 Rev. G Introduction

www.deif.com/wind-power Page 10 of 243

1.1 Conventions

The following conventions are used in this document:

Used in document

Description

Monotype font

Used when describing a path or text input in a machine human interface

Used to illustrate a space and Enter characters

A yellow symbol that illustrates hazard type (this symbol is an example for

general hazard). There are different types such as electrical, chemical and so

on.

Danger!

A signal word used to indicate an imminently hazardous situation, which if not

avoided, will result in death or serious injury. (ISO 3864)

Warning!

A signal word used to indicate an imminently hazardous situation, which if not

avoided, could result in death or serious injury. (ISO 3864)

Caution!

A signal word used to indicate a potentially hazardous situation, which if not

avoided, could result in minor or moderate injury. (ISO 3864)

A blue symbol that illustrates a need for mandatory action. In this example

read instructions. Other types of blue symbols exist and always indicate

mandatory action.

A symbol used to draw attention to extra information or an action that is not

mandatory

Current

IMD

When the IMD is mentioned, it means the IMD 100 series

Binary description

In binary descriptions the first bit is bit zero

IMD 100 Integration manual 4189360015 Rev. G Safety precautions

www.deif.com/wind-power Page 11 of 243

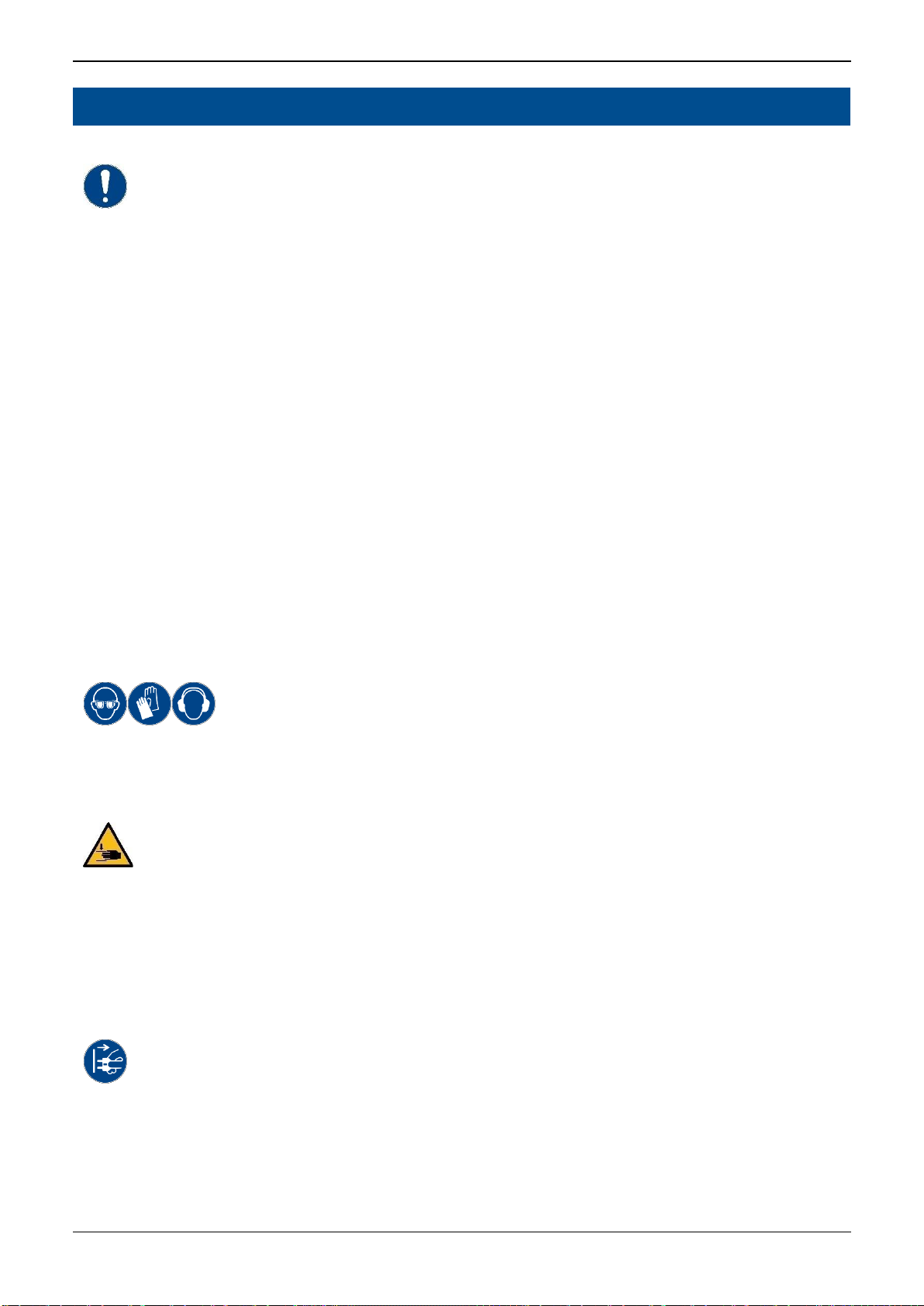

2. Safety precautions

Attention

The permitted environmental conditions must be observed.

EN 60204, and relevant local regulations must be observed.

Power supply of protection class I and of protection degree IP20. Do not use outside or in

wet or damp rooms.

The equipment must be installed, operated and used for its intended function as described

by the manufacturer. If this requirement is ignored, safety protection provided by the

equipment may be impaired.

In the event of a fault we recommend that you return the unit to the manufacturer.

Company policy and local regulations regarding PPE must always be followed, regardless

whether the PPE is shown in this manual or not.

2.1 Mechanical work

2.2 Electrical work

Use eye, hand and hearing protection

Use protection for eyes, hand and hearing, if the mounting holes for bolts and

heat sink need to be made.

Caution!

Risk of hand injury.

The IMD is heavy. Be careful with your hands when mounting the IMD in the cabinet.

Disconnect power

Ensure that all power is disconnected when working with the IMD, except for during testing,

commissioning and service.

IMD 100 Integration manual 4189360015 Rev. G Safety precautions

www.deif.com/wind-power Page 12 of 243

Caution!

Risk of electrical shock from touch current if the protective earth is removed when the IMD

is energized.

Do not remove the protective earth is removed when the IMD is energized.

Danger!

Risk of burns and electrical shock from short circuit, electrical arc and uninsulated wires.

Live work is not permitted, except for during test, verification, commissioning, and service.

Observe local regulation when working with electrical components.

Danger!

Risk of burns and electrical shock from short circuit, electrical arc and uninsulated wires.

Commissioning and maintenance work on this device may only be carried out by a qualified

electrician.

When the IMD has been powered, there is a risk of stored energy even when the power is

disconnected. Wait 5 minutes after the power is disconnected and verify zero energy

according to company procedures on the outputs before performing any work.

IMD 100 Integration manual 4189360015 Rev. G Safety precautions

www.deif.com/wind-power Page 13 of 243

2.3 Thermal precautions

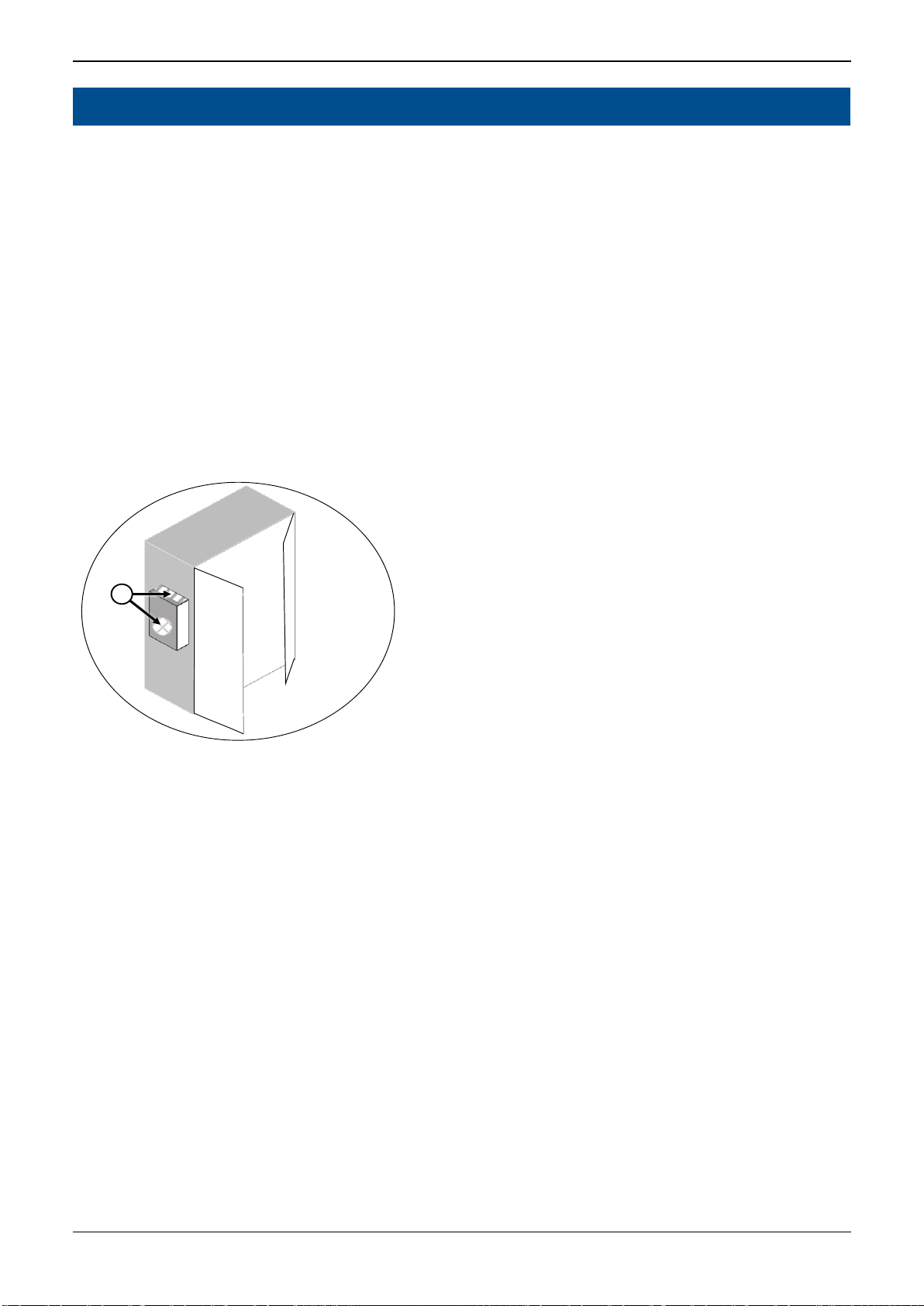

Figure 1 Hot surface areas

Info

During operation, the IMD can reach high surface temperatures. The temperature levels

depend on the ambient temperature inside and outside the cabinet.

Warning!

Risk of severe burns.

The heat sink of the IMD can reach high temperature.

Do not touch until the surface (see pos. 1 in Figure 1 on page 13 ) is cooled down.

Caution!

Risk of burns.

The sides of the IMD can reach medium high temperature.

Do not touch until the surface (see pos. 2 in Figure 1 on page 13 ) is cooled down.

2

1

IMD 100 Integration manual 4189360015 Rev. G Avoiding damage to the IMD

www.deif.com/wind-power Page 14 of 243

3. Avoiding damage to the IMD

Certain situations may result in product damage and should therefore be avoided by observing the

precautions described in this section. These situations are not likely to occur under normal use of the

IMD, but might occur in the lab or during service.

The situation list may not be comprehensive. Other, unknown situations that are not described in this

section could occur.

3.1 Connecting the safe energy

Possible damage: Damage to internal power components.

3.2 Switching mains ON and OFF

Possible damage: DC-link Pre-charge circuit damaged due to repeated MAINS ON and OFF

operations

How to avoid:

If the MAINS connections are switched ON and OFF more than once, wait 60 seconds

before switching ON after switch OFF.

3.3 Overloading the ballast resistor

Possible damage: Ballast circuit ((switch or resistor) damaged due to overload.

How to avoid:

•The ballast resistor value is adequate for the DC-link Vmax.

•Never use single pulse longer than 1 s during safe energy test.

•Wait 10 minutes (at 25ºC) if the IMD is restarted and the ballast resistor has been

loaded (hot)

3.4 Connecting the mains with overvoltage

Possible damage: Total damage to the IMD.

How to avoid:

The mains supply must never exceed the range specified in the Data sheet.

How to avoid:

If the safe energy was disconnected from the SE terminals, the mains supply must be

turned on before the safe energy is turned on.

IMD 100 Integration manual 4189360015 Rev. G Mechanical integration

www.deif.com/wind-power Page 15 of 243

4. Mechanical integration

This section describes the mechanical aspects of the IMD. See IMD 100 Datasheet for physical

dimensions.

4.1 Integrating the IMD in a cabinet

4.1.1 Environmental requirements

The IMD must be mounted in a closed cabinet where the requirements for ingress protection of

components do not exceed IP 20.

The IMD heatsink is mounted through a hole in the cabinet and requirements for ingress protection

outside the cabinet do not exceed IP 55 (IP 54 for IMD 122 B).

When designing the pitch system, pay attention to IMD location in the hub, to avoid debris entering the

heatsink (1). Take the hub rotation into account, so that loose objects are not funnelled into the

heatsink.

IP 55

IP 20

1

Figure 2 Environmental requirements and considerations

For other environmental requirements, see IMD 100 Datasheet.

4.1.2 Temperature considerations

This section describes the considerations concerning temperature and ventilation when designing the

cabinet in which the IMD is placed, and the location of the cabinet.

4.1.2.1 Personal safety considerations

The heat sink (both in and out) can get hot depending on the ambient temperature and the activity of

pitching the blade. If there is a risk of people touching the back of the IMD (the heat sink outside the

cabinet) it is recommended to implement measures to protect personnel such as physical guards,

information, or any other means.

IMD 100 Integration manual 4189360015 Rev. G Mechanical integration

www.deif.com/wind-power Page 16 of 243

Figure 3 Risk of heat hazard

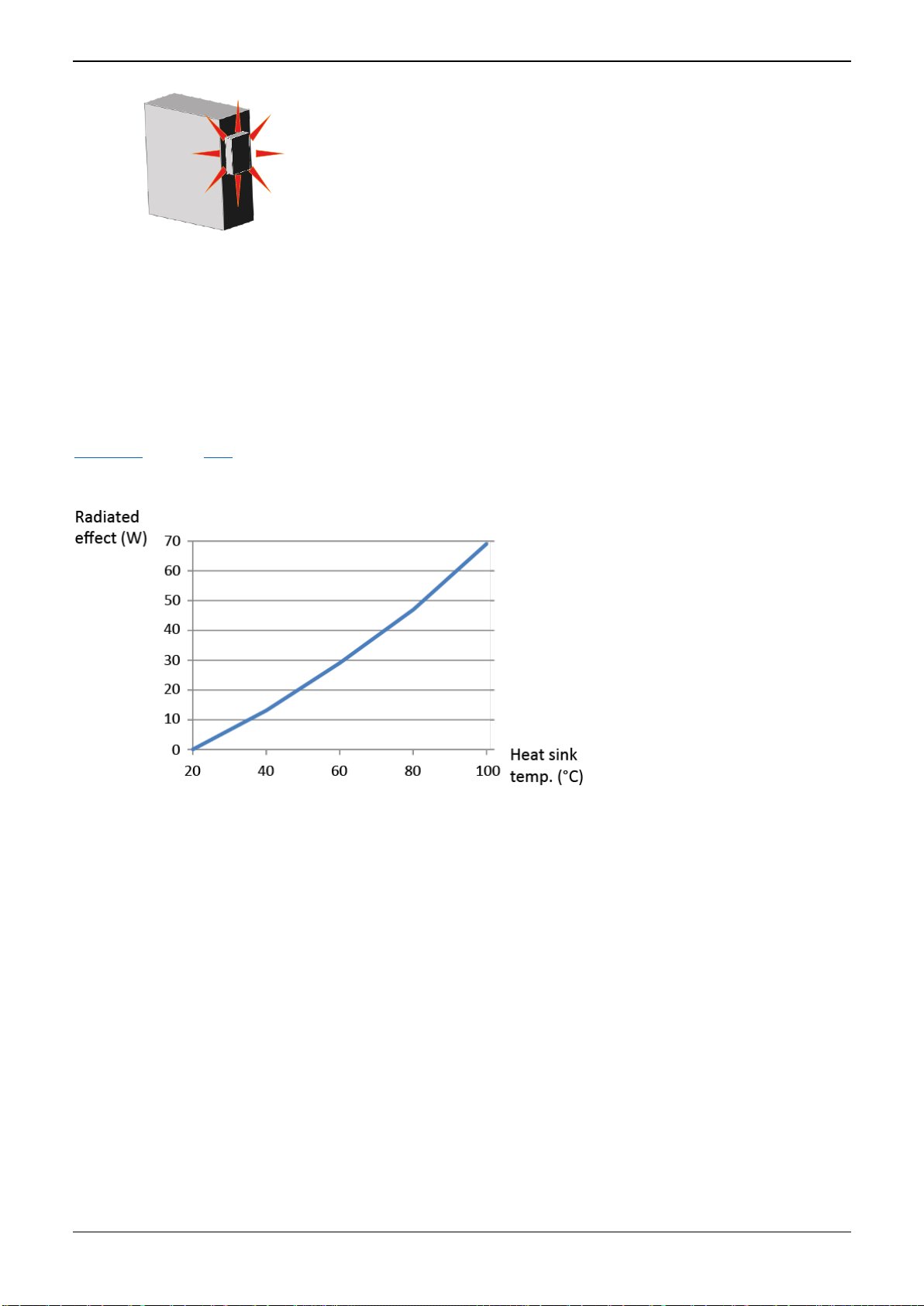

4.1.2.2 Cabinet cooling considerations

The ambient temperature range defined in the IMD 100 Datasheet must be maintained at all times.

This also applies inside the cabinet, where the IMD itself also contributes with heat radiation, mainly

because part of the heat sink is located inside the cabinet. The IMD shuts down the output drive at

90 ºC, thereby the heat sink temperature will never exceed 90 ºC.

IMD 122:

Figure 4 on page 16 shows the heat radiation of the IMD inside the cabinet as a function of the heat

sink temperature. At this temperature, the heat contribution from the IMD inside the cabinet is

approximately 69 W.

Figure 4 Radiated heat from the IMD inside the cabinet

IMD 100 Integration manual 4189360015 Rev. G Mechanical integration

www.deif.com/wind-power Page 17 of 243

IMD 135:

Figure 5 on page 17 shows the heat radiation of IMD 135 inside the cabinet as a function of the heat

sink temperature. At this temperature, the heat contribution from the IMD inside the cabinet is

approximately 81 W.

Figure 5 Radiated heat from the IMD inside the cabinet

4.1.2.3 Free space around the IMD

Outside the cabinet, keep free space around the IMD at least as shown in Figure 6 on page 17 (IMD

122 C), Figure 7 on page 18 (IMD 122 B) and Figure 8 on page 18 (IMD 135). There must be

adequate ventilation in this space.

Inside the cabinet, keep at least 20 mm free space from the sides of the IMD and 80 mm free space

from top and bottom of the IMD. There must be adequate ventilation in this space.

Figure 6 IMD 122 C free space requirements

Note for IMD 122 C: The 100 mm indicated is recommended to enable easy replacement of the fan.

The minimum requirement due to temperature is 50 mm.

80 mm

80 mm

80 mm

20 mm

20 mm

25 mm

25 mm

Outside cabinet (back)

inside cabinet (front)

Heat sink

inside cabinet

80 mm

100 mm

IMD 100 Integration manual 4189360015 Rev. G Mechanical integration

www.deif.com/wind-power Page 18 of 243

Figure 7 IMD 122 B free space requirements

Figure 8 IMD 135 C free space requirements

Note for IMD 135: Consider the outside space (25 mm) around the IMD with regards to fan

replacement.

25 mm

80 mm

80 mm

20 mm

20 mm

25 mm

25 mm

Outside cabinet (back)

inside cabinet (front)

Heat sink

inside cabinet

80 mm

50 mm

80 mm

20 mm

20 mm

25 mm

25 mm

Outside cabinet (back)

inside cabinet (front)

Heat sink

inside cabinet

70 mm

136 mm

mm

80 mm

80 mm

IMD 100 Integration manual 4189360015 Rev. G Mechanical integration

www.deif.com/wind-power Page 19 of 243

4.1.3 Mounting of the IMD in the cabinet

A rectangle hole and 14/16 x 7 mm holes for M6 bolts must be made in the cabinet where the IMD is

to be mounted.

The holes for the bolts and heat sink are to be made according to the following drawing:

Figure 9 Cabinet cut-out drawing for IMD 122

Other manuals for IMD 100

3

This manual suits for next models

4

Table of contents

Other Deif DC Drive manuals

Popular DC Drive manuals by other brands

STG-BEIKIRCH

STG-BEIKIRCH M2 Series Technical information and operating instruction

Kinco

Kinco SV100 Series User Mannual

WITTUR

WITTUR Beamer 2 Series operating instructions

Oriental motor

Oriental motor Vextra PK264-E2.0A operating manual

KEBCO

KEBCO COMBIVERT F4-S instruction manual

Delta

Delta VFD-MS300 Series Quick setup instructions