&RQWHQWV ,QWHUQDWLRQDO(QJOLVK

MICROMASTER 420 Reference Manual

viii Issue A1

/LVWRI7DEOHV

Table 2-1 Current Limit and Overload.....................................................................................................8

Table 2-2 Measured Current Monitoring Accuracy.................................................................................9

Table 2-3 Trip Levels............................................................................................................................11

Table 2-4 Maximum Cable Lengths......................................................................................................23

Table 2-5 Derating with Switching Frequencies....................................................................................25

Table 2-6 Cubicle Calculations.............................................................................................................26

Table 2-7 BiCo Connections (r0019 to r0054)......................................................................................31

Table 2-8 BiCo Connections (r0055 to r1119)......................................................................................32

Table 2-9 BiCo Connections (r1170 to r2050)......................................................................................33

Table 2-10 BiCo connections (r2053 to r2294).......................................................................................34

Table 2-11 Acoustic Test Results...........................................................................................................35

Table 2-12 Single Phase 230V Connection............................................................................................36

Table 2-13 Three Phase 230V Connection.............................................................................................36

Table 2-14 Three Phase 400V Connection.............................................................................................37

Table 3-1 Defined Task ID....................................................................................................................47

Table 3-2 Defined Reply ID ..................................................................................................................47

Table 3-3 Defined Error Values for Reply ID = Task cannot be executed ............................................48

Table 3-4 PZD Area Structure..............................................................................................................51

Table 3-5 Inverter Control Word (STW)................................................................................................52

Table 3-6 Inverter Status Word (PZD)..................................................................................................53

Table 3-7 Practical Examples...............................................................................................................54

Table 3-8 Comparison Table (MICROMASTER 420/Earlier MICROMASTER)....................................58

Table 3-9 Assignment of the PROFIBUS SUB-D socket connector .....................................................63

Table 3-10 Maximum Cable Lengths for Data Transfer Rates................................................................63

Table 3-11 Order Numbers for Connectors and Cables .........................................................................63

Table 3-12 Technical data......................................................................................................................64

Table 3-13 PROFIBUS Ordering information..........................................................................................64

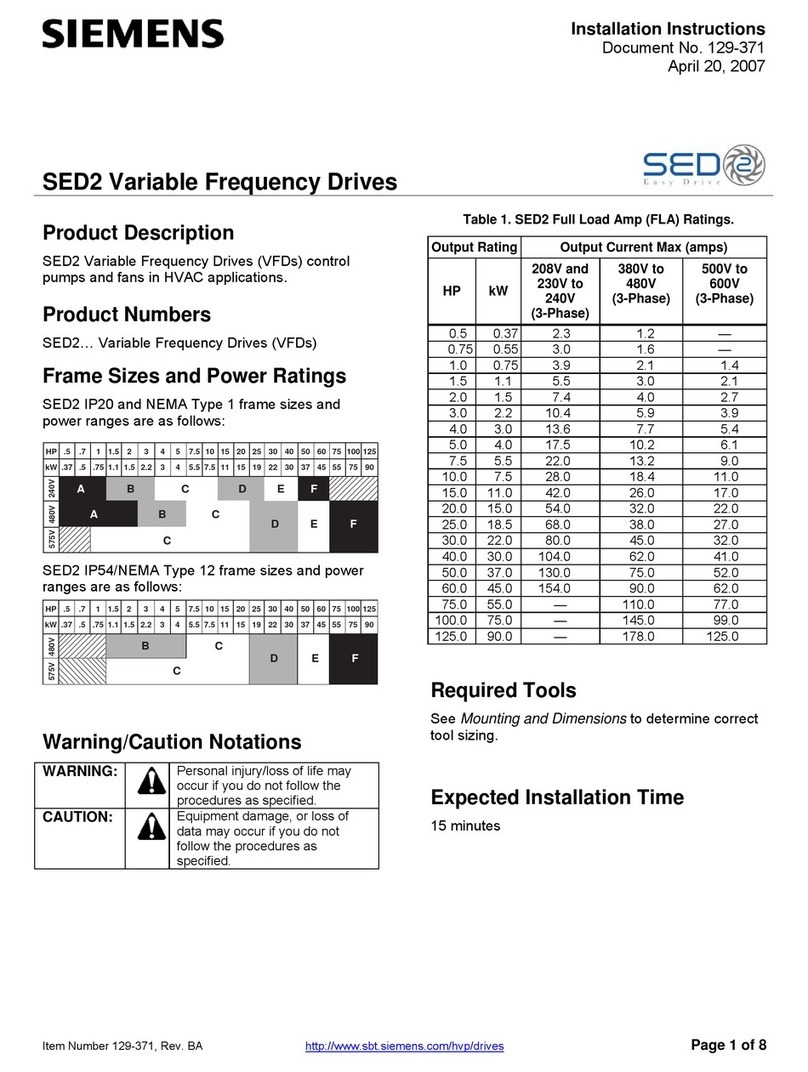

Table 4-1 Recommended Fuses (230 V Single-phase)........................................................................69

Table 4-2 Recommended Fuses (230 V Three-phase) ........................................................................69

Table 4-3 Recommended Fuses (380 V – 480 V) ................................................................................70

Table 4-4 Recommended Circuit Breakers (230 V Single-phase)........................................................71

Table 4-5 Recommended Circuit Breakers (230 V Three-phase).........................................................71

Table 4-6 Recommended Circuit Breakers 380 V – 480 V)..................................................................72

Table 5-1 Inverter conditions indicated by the LEDs on the SDP.........................................................76