Deif AGC 150 User manual

AGC 150 Engine drive

Operator's manual

4189341305C

1. Introduction

1.1 Symbols for hazard statements......................................................................................................................................................................................... 3

1.2 About the operator's manual...............................................................................................................................................................................................3

1.3 Warnings and safety.................................................................................................................................................................................................................4

1.4 Legal information....................................................................................................................................................................................................................... 4

2. About the AGC 150 Engine drive

2.1 Display, buttons and LEDs.....................................................................................................................................................................................................5

2.2 Display settings..........................................................................................................................................................................................................................6

2.3 Mimic function.............................................................................................................................................................................................................................6

2.4 Running modes........................................................................................................................................................................................................................... 7

3. Menus

3.1 Menu structure.............................................................................................................................................................................................................................8

3.2 Parameters menu...................................................................................................................................................................................................................... 8

3.2.1 Menu numbers.................................................................................................................................................................................................................... 9

3.2.2 The jump to parameter function...............................................................................................................................................................................9

3.3 View menu...................................................................................................................................................................................................................................10

3.3.1 Display views.....................................................................................................................................................................................................................10

3.3.2 Display text........................................................................................................................................................................................................................ 10

3.4 Status text....................................................................................................................................................................................................................................11

3.5 Service view...............................................................................................................................................................................................................................12

3.6 Engine shortcuts..................................................................................................................................................................................................................... 13

3.6.1 PID configuration............................................................................................................................................................................................................. 13

3.6.2 ECU Diagnose and Force Regeneration.............................................................................................................................................................13

3.7 General shortcuts................................................................................................................................................................................................................... 14

3.8 Exhaust after-treatment (Tier 4/Stage V)...............................................................................................................................................................14

4. Alarm handling and log list

4.1 Alarm handling...........................................................................................................................................................................................................................18

4.2 Logs menu...................................................................................................................................................................................................................................19

Operator's manual 4189341305C EN Page 2 of 19

1. Introduction

1.1 Symbols for hazard statements

DANGER!

This shows dangerous situations.

If the guidelines are not followed, these situations will result in death, serious personal injury, and equipment

damage or destruction.

WARNING

This shows potentially dangerous situations.

If the guidelines are not followed, these situations could result in death, serious personal injury, and equipment

damage or destruction.

CAUTION

This shows low level risk situation.

If the guidelines are not followed, these situations could result in minor or moderate injury.

NOTICE

This shows an important notice

Make sure to read this information.

1.2 About the operator's manual

This document gives the necessary information to operate the controller.

CAUTION

Installation errors

Read this document before working with the controller. Failure to do this may result in human injury or damage

to the equipment.

Intended users of the operator's manual

The operator's manual is for the operator that uses the controller regularly.

The manual describes the LEDs, buttons and screens on the controller, alarm handling, and the logs menu.

Operator's manual 4189341305C EN Page 3 of 19

1.3 Warnings and safety

Factory settings

The controller is delivered pre-programmed from the factory with a set of default settings. These settings are based on

typical values and may not be correct for your system. You must therefore check all parameters before using the controller.

Data security

To minimise the risk of data security breaches:

• As far as possible, avoid exposing controllers and controller networks to public networks and the Internet.

• Use additional security layers like a VPN for remote access, and install firewall mechanisms.

• Restrict access to authorised persons.

1.4 Legal information

Legal information

Third party equipment

DEIF takes no responsibility for the installation or operation of any third party equipment, including the engine. Contact the

engine company if you have any doubt about how to install or operate the engine.

Warranty

NOTICE

Warranty

The controller is not to be opened by unauthorised personnel. If opened anyway, the warranty will be lost.

Disclaimer

DEIF A/S reserves the right to change any of the contents of this document without prior notice.

The English version of this document always contains the most recent and up-to-date information about the product. DEIF

does not take responsibility for the accuracy of translations, and translations might not be updated at the same time as the

English document. If there is a discrepancy, the English version prevails.

Copyright

© Copyright DEIF A/S. All rights reserved.

Software version

This document is based on the AGC 150 software version 1.16.

Operator's manual 4189341305C EN Page 4 of 19

2. About the AGC 150 Engine drive

2.1 Display, buttons and LEDs

No. Name Function

1 Power Green: The controller power is ON.

The controller power is OFF.

2 Display screen

Resolution: 240 x 128 px.

Viewing area: 88.50 x 51.40 mm.

Six lines, each with 25 characters.

3 Navigation Move the selector up, down, left and right on the screen.

4 OK Go to the menu system.

Confirm the selection on the screen.

5 Back Go to the previous page.

6 AUTO mode The controller automatically starts and stops the engine.

No operator actions are needed.

7 Silence horn Stops an alarm horn (if configured) and enters the alarm menu.

8 Shortcut menu Access jump to parameter, running mode, test and lamp test.

9

mode

The controller cannot automatically start and stop the engine.

The operator can start and stop the engine manually from the display.

10 Engine

Green: There is running feedback or an external signal.

Green flashing: The engine is getting ready.

Red: The engine is not running, or there is no running feedback.

11 Stop Stops the engine if or manual mode is selected.

12 Start Starts the engine if or manual is selected.

Operator's manual 4189341305C EN Page 5 of 19

2.2 Display settings

To adjust for ambient lighting, configure the display settings.

Parameters > Basic settings > Controller settings > Display > Display control

Parameter Text Range Default

9151 Backlight dimmer 0 to 15 * 12

9152 Green LEDs dimmer 1 to 15 * 15

9153 Red LEDs dimmer 1 to 15 * 15

9154 Contrast level to 0

9155 Sleep mode timer 1 to 1800 s 60 s

9156 Enable mode timer) OFF

ON ON

9157 Alarm Jump OFF

ON ON

9158 Engineering units Bar/Celsius

PSI/Fahrenheit Bar/Celsius

NOTE * Low numbers are minimum brightness and high numbers are maximum brightness.

2.3 Mimic function

With the mimic function you can select how the control buttons and LEDs are shown on the controller's display.

Parameters > Basic settings > Controller settings > Display > LED mimic

Parameter no. Item Range

6082 LED mimic

Standard with genset

Standard

Guided with genset

Guided

Standard

The control buttons and LEDs are shown.

If you stop the engine, the engine symbol is not shown.

Standard with genset

The control buttons and LEDs are shown.

If you the stop the engine, the engine symbol is shown in red.

Operator's manual 4189341305C EN Page 6 of 19

Guided

Active control buttons and LEDs are shown, inactive are not shown.

Example: The AGC 150 Engine drive is in mode, and the

engine is not operating. Only the start button is shown, as this is

the only possible action.

Guided with genset

Active control buttons, LEDs and the engine symbol are shown,

inactive are not shown.

Example: AGC 150 is in mode. The engine is not

operating. The only possible action is to start the engine, and so

only the start button and the red engine symbol are shown.

2.4 Running modes

The controller has three different running modes, a block mode and a test mode. Push the Shortcut button and select

Running Modes to see the running modes and block mode. To select the test mode, push the Shortcut button and

select Start Test.

Mode Description

AUTO The controller automatically starts and stops the engine.

The controller cannot automatically start and stop the engine. The operator can start these sequences using

the buttons on the controller, Modbus commands or the digital inputs.

MANUAL The operator can use the digital increase/decrease inputs (if they are configured) and the Start and Stop

buttons. When the engine starts in manual mode, it will start without subsequent regulation.

BLOCK The controller cannot start a sequence, for example the start sequence. Select the block mode when you do

maintenance work on the engine.

Test The test sequence will start when you select the test mode.

NOTE The engine will shut down if you select the block mode while the engine is operating.

Operator's manual 4189341305C EN Page 7 of 19

3. Menus

3.1 Menu structure

The controller has two menu systems, which can be used without password entry:

•The View menu system: Shows the operating status and values. The system has 20 configurable windows, that can be

entered with the arrow buttons.

•The Parameters menu system: The operator can see the controller's parameters. A password is necessary to change

the parameter settings.

3.2 Parameters menu

You can configure the controller in the parameters menu and you can also find information, which is not available in the

view menu. From the view menu, push the button to find the parameters menu. Use the and buttons to find

the different parameters and select with the button.

Parameters menu example

This is an example of how to change the running detection type.

Operator's manual 4189341305C EN Page 8 of 19

3.2.1 Menu numbers

Each parameter has a menu number. You can find the number in the upper right corner on the display screen.

You can also find the menu number with the utility software:

1. Select Parameters from the vertical toolbar on the left.

2. Set the view mode to list. The view mode can be found in the left corner of the screen.

3. The menu numbers are in the Channel column.

3.2.2 The jump to parameter function

If you know the menu number for a parameter, you can use the jump to parameter function to go directly to the parameter.

On the controller:

1. From the view menu, push the Shortcut button to see the jump to parameter function:

2. Use the and buttons to go to Jump to parameter and push the button.

3. Use the and buttons to change the numbers, and push the button to save. Use the and buttons to

move to the next number.

Operator's manual 4189341305C EN Page 9 of 19

3.3 View menu

The view menu is shown when the controller is turned on, and you can see the operating status and values. The event and

alarms list will also be shown if an alarm is on.

1. Operating status

2. Values and information

3. Page number

The view menu has 20 different display views. Use the and buttons to select a view.

3.3.1 Display views

The controller has 20 different display views, and 5 of the views are pre-configured. You can configure the views with the

utility software.

Line View 1 View 2 View 3 View 4 View 5

1 0.0V Multi input 20 0.0 Aftertreatment EIC T. Coolant Serv1 0d 0h

2 MPU 0rpm Multi input 21 0.0 EIC Tier 4 Icons EIC T. Turbo Oil Serv2 0d 0h

3 - Multi input 22 0.0 - EIC T. Exh. Right -

4 [yyyy-mm-dd time] Multi input 23 0.0 - EIC T. Oil -

5 Run absolute 0 hrs - - EIC T. Fuel -

3.3.2 Display text

Configure the display views

You can configure the display views with the utility software:

1. Select the Configuration of the user views button in the toolbar.

2. In the pop-up window, select the display view to be changed.

Operator's manual 4189341305C EN Page 10 of 19

3. Select the display line you want to change.

4. In the pop-up window, select the text you want and click OK.

Display text

You can select five of the display texts for each display view.

3.4 Status text

Status text Condition

ACCESS LOCK The configurable input is activated, and the operator tries to activate one of the blocked

keys.

Aux. test ##.#V ####s The battery test is activated.

BLOCK Block mode is activated.

COOLING DOWN ###s Cooling-down period is activated.

DERATED TO #####kW Displays the ramp-down set point.

EXT. START ORDER There was an external engine start command.

EXT. STOP TIME ###s The extended stop timer is running.

FULL TEST Test mode is activated.

FULL TEST ###.#min Test mode is activated and test timer counting down.

IDLE RUN The Idle run function is active. The engine will not stop until a timer has expired.

IDLE RUN ###.#min The Idle run function is active. The engine will not stop until the timer has expired.

LOAD TEST Test mode is activated.

Operator's manual 4189341305C EN Page 11 of 19

Status text Condition

LOAD TEST ###.#min Test mode is activated and test timer counting down.

NOT POSSIBLE Unable to do the requested demand.

PROGRAMMING LANGUAGE Downloading the language file using the PC utility software.

RAMP FREEZED Stopped ramping (ramping frozen).

RAMP TO #####kW The power ramp is ramping in steps. The next step that is reached after the timer has

expired is displayed.

RAMPING Ramping up to the set point.

SHUTDOWN OVERRIDE The configurable input is active.

SIMPLE TEST Test mode is activated.

SIMPLE TEST ###.#min Test mode is activated and test timer counting down.

START PREPARE The start prepare relay is activated.

START RELAY OFF The start relay is deactivated during the start sequence.

START RELAY ON The start relay is activated.

3.5 Service view

You can use the service view to see the status of the controller. You can change the passwords in the service menu, but not

the other controller settings.

From the view menu, push the button and select Service View . Use the and buttons to go through the

parameters in the service view, and use the button to select the parameters.

Service view example

Operator's manual 4189341305C EN Page 12 of 19

3.6 Engine shortcuts

3.6.1 PID configuration

You can use the engine shortcuts menu to configure the PID set points.

On the controller

1. From the view menu, push the Shortcut button to see the menu.

2. Use the Up and Down buttons to go to Engine shortcuts menu, and push the button.

PID references

• Only active inputs are shown in the list.

• You can also see the values in the utility software. Select General Purpose PID from the left menu. There are a total of 2

reference values.

Manual regulation (up and down)

• Used for PID1.

• Not active during ramp up/down.

3.6.2 ECU Diagnose and Force Regeneration

You can activate ECU diagnose from the engine shortcuts menu. You can also use the menu to inhibit or force regeneration.

ECU Diagnose

Use ECU Diagnose to read ECU data without starting the engine.

To activate ECU diagnose on the controller:

1. Push the Shortcut button.

2. Select Engine shortcuts.

3. Select ECU Diagnose.

The diagnostics timer is activated when you select ECU Diagnose, and the controller starts to read the ECU data when the

diagnostic timer expires. To configure this timer, go to Parameters in the utility software and select parameter 6701.

Operator's manual 4189341305C EN Page 13 of 19

Force Regeneration

To inhibit or force regeneration:

1. Push the Shortcut button.

2. Select Engine shortcuts.

3. Select Force Regeneration.

4. Select Inhibit or Force.

3.7 General shortcuts

You can see your configured shortcuts in the General shortcuts menu. If you have not configured a shortcut, then the menu

is empty. Use the shortcuts when the controller is in and manual mode.

More information

See General shortcuts in the AGC 150 Engine drive Designer's handbook for how to configure the general

shortcuts.

On the controller

1. From the view menu, push the Shortcut button to see the menu.

2. Use the Up and Down buttons to go to General shortcuts, and push the button.

3. Use the Up and Down buttons to go to select a shortcut.

3.8 Exhaust after-treatment 4/Stage

AGC 150 meets the Tier 4 V requirements. The user can use the display to monitor (and control) both the

engine, and the exhaust after-treatment system.

Operator's manual 4189341305C EN Page 14 of 19

After-treatment page

No. Referent Symbol Description

1 After-treatment status -

2 Engine emission system failure Emission failure or malfunction.

3 Diesel Particle Filter Regeneration is needed.

4 Page name -

5 Controller status -

6 Diesel Particle Filter Inhibit Regeneration is inhibited.

7 High temperature - Regeneration There is a high temperature and regeneration is in process.

8 HC burn-off Hydrocarbon accumulation that requires burn-off.

9 Engine emission system failure level Emission failure or malfunction, with the severity.

Operator's manual 4189341305C EN Page 15 of 19

No. Referent Symbol Description

10 Diesel Particle Filter level Regeneration needed, with the severity.

11 DEF level warning Low DEF level.

12 DEF shutdown DEF problem stops normal operation.

13 DEF level inducement

Mid-level inducement.

Severe inducement.

14 Diesel Exhaust Fluid DEF quality is low.

Engine dashboard

Operator's manual 4189341305C EN Page 16 of 19

No. Referent Symbol Description

1 Water in fuel There is water in the fuel.

2 Engine interface status An engine warning.

3 Page name - -

4 Controller status -

5 Engine interface status An engine shutdown.

6 Engine interface status An engine malfunction.

7 Cold start The engine is cold.

8 High engine coolant temperature The engine coolant temperature is high.

9 Low engine oil pressure The engine oil pressure is low.

10 Fuel filter clogging The fuel filter is blocked.

11 Air filter clogging The air filter is blocked.

12 LIMIT lamp Only for MTU engines.

13 Oil change The engine needs an oil change.

14 High engine oil temperature The engine oil temperature is high.

NOTE Grey symbols show that communication is available for the referent. An engine type might not support all of the

referents.

Operator's manual 4189341305C EN Page 17 of 19

4. Alarm handling and log list

4.1 Alarm handling

If the function Alarm Jump is on, the controller will automatically show the alarm list on the display screen when an alarm

occurs.

Service View > Display > Alarm Jump

Parameter Text Range Default

9157 Alarm Jump OFF

ON ON

Access the alarm list from the display unit

1. From the view menu, push the button.

2. Use the and buttons to go to the Alarm list.

3. Push the button to view the Alarm list.

4. Push the button to go back.

The alarm list contains both acknowledged and unacknowledged alarms that are active. An alarm is active, if you have not

cleared the alarm condition, which started the alarm. Once an alarm is acknowledged and you have cleared the alarm

condition, the alarm is removed from the alarm list. If there are no alarms, then the alarm list will show No alarms.

The display screen can show only one alarm at a time. The number of alarms is shown on the right at the bottom of the

screen.

Example of an unacknowledged alarm

To see the other alarms, use the and buttons to go through the list. To acknowledge an alarm, select the alarm and

push the button.

Access the alarm list with the utility Software

Select Alarms from the toolbar on the left.

Operator's manual 4189341305C EN Page 18 of 19

CAUTION

Caution

If an alarm is blocking an engine in AUTO mode from starting, the engine will automatically start if the condition

that triggered the alarm has gone and the alarm has been acknowledged.

4.2 Logs menu

These are the log sub-menus:

1. Event log: Shows up to 500 events.

2. Alarm log: Shows up to 500 alarms. Only the latest 100 alarms are shown on the display unit, while the remaining alarms

are shown in the utility software.

3. Battery test log: Shows up to 52 tests, either Test OK or Test failed.

Access the log menu from the controller

1. From the view menu, push the button.

2. Use the and buttons to go to Logs.

3. Push the button to select Logs.

4. Select the log you want to see and push the button.

5. To leave the Log list, push the button.

Access the log list with the utility software

1. Select Logs from the left menu.

2. In the task bar, select Read logs .

3. Select the Log list you want to see.

Operator's manual 4189341305C EN Page 19 of 19

Other manuals for AGC 150

9

Table of contents

Other Deif DC Drive manuals

Popular DC Drive manuals by other brands

OEZ

OEZ RP-BC-CK30 Instructions for use

G-U

G-U ELTRAL K25 Installation and operating instructions

DoorHan

DoorHan SHAFT-50 Installation and operating manual

Leadshine

Leadshine CS3E-E Series user manual

SEW-Eurodrive

SEW-Eurodrive MOVIMOT MM D Series Compact operating instructions

Bosch

Bosch Rexroth MOBILEX GFT-W 30 Series operating instructions

Bosch

Bosch REXROTH AGK 20-80 instructions

Oerlikon

Oerlikon Fairfield Torque-Hub S40B Series Service manual

SureStep

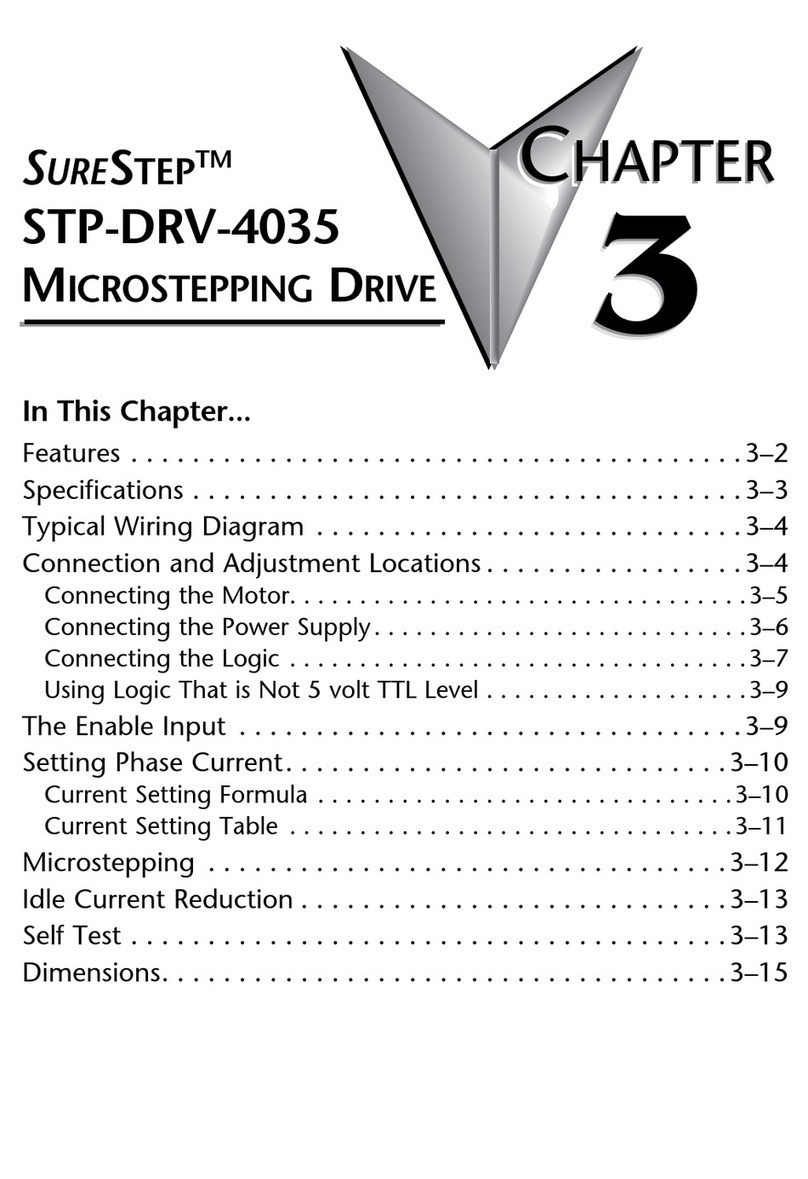

SureStep STP-DRV-4035 Wiring diagram

Pfeiffer Vacuum

Pfeiffer Vacuum TC 120 operating instructions

Siemens

Siemens SINAMICS S120 manual

Cole Parmer

Cole Parmer MasterFlex L/S Series operating manual