Deitz Pharmafill TC3 User manual

Model TC3 Electronic Counter

Operation Manual

Rev 2022-03-08 Pharmafill Model TC3 User Manual

Deitz Company Inc. TC3 User Manual Page I

CONTENTS

1. General Illustrations...................................................................................pgs II thru XI

2. Safety Reminder.............................................................................................................1

3. Introduction....................................................................................................................2

4. Specifications.................................................................................................................4

5. Installation and Commissioning

5.1. Unpacking ..........................................................................................................5

5.2. Connect Electric, Compressed Air and Blower Air ............................................6

5.3. Systems Check ....................................................................................................8

6. General Information

6.1. Standard Features And Capabilities....................................................................9

7. Controls

7.1. Control Panel Components................................................................................11

7.2. Operator Interface Display Panel (HMI) - Overview........................................13

7.3. Run Mode..........................................................................................................14

7.4. Speed Ajustment................................................................................................16

7.5. Menu 1. Adjust Settings....................................................................................17

7.6. Menu 2. Fill One ...............................................................................................19

7.7. Menu 3. Index One............................................................................................21

7.8. Menu 4. Half-step Index....................................................................................22

7.9. Menu 5. Check Count........................................................................................23

7.10. Menu 6. Technician Only..................................................................................25

7.11. Counting Sensor................................................................................................27

8. Counting and Filling

8.1. Product Guide Adjustments...............................................................................29

8.2. Bottle Gating Cylinder Positioning...................................................................33

8.3. Bottle Sensor Positioning..................................................................................35

8.4. Testing To Establish Parameters.......................................................................36

8.5. First - Use Check Count Mode..........................................................................36

8.6. Second - Use Fill One Mode.............................................................................36

8.7. Last - Use Run Mode.........................................................................................36

8.8. Summary ...........................................................................................................37

9. Breakdown, Cleaning and Buildup

9.1. Breakdown of Remove-To-Clean Contact Parts (Summary)............................38

9.2. Breakdown of Remove-To-Clean Contact Parts (Illustrated)...........................40

9.3. Buildup of Remove-To-Clean Contact Parts (Summary) .................................47

9.4. Clean-In-Place Contact Areas ...........................................................................49

9.5. Cleaning Non-Contact Areas.............................................................................49

9.6. Cleaning Recommendations..............................................................................49

10. Technical Information

10.1. Principle of Operation.......................................................................................51

10.2. Cycle of Operation ............................................................................................52

10.3. Troubleshooting.................................................................................................53

10.4. Index of Technical Notes/Drawings..................................................................55

(Technical Notes/Drawings Begin After Last Page)

Rev 2022-03-08 Pharmafill Model TC3 User Manual

Deitz Company Inc. TC3 User Manual Page II

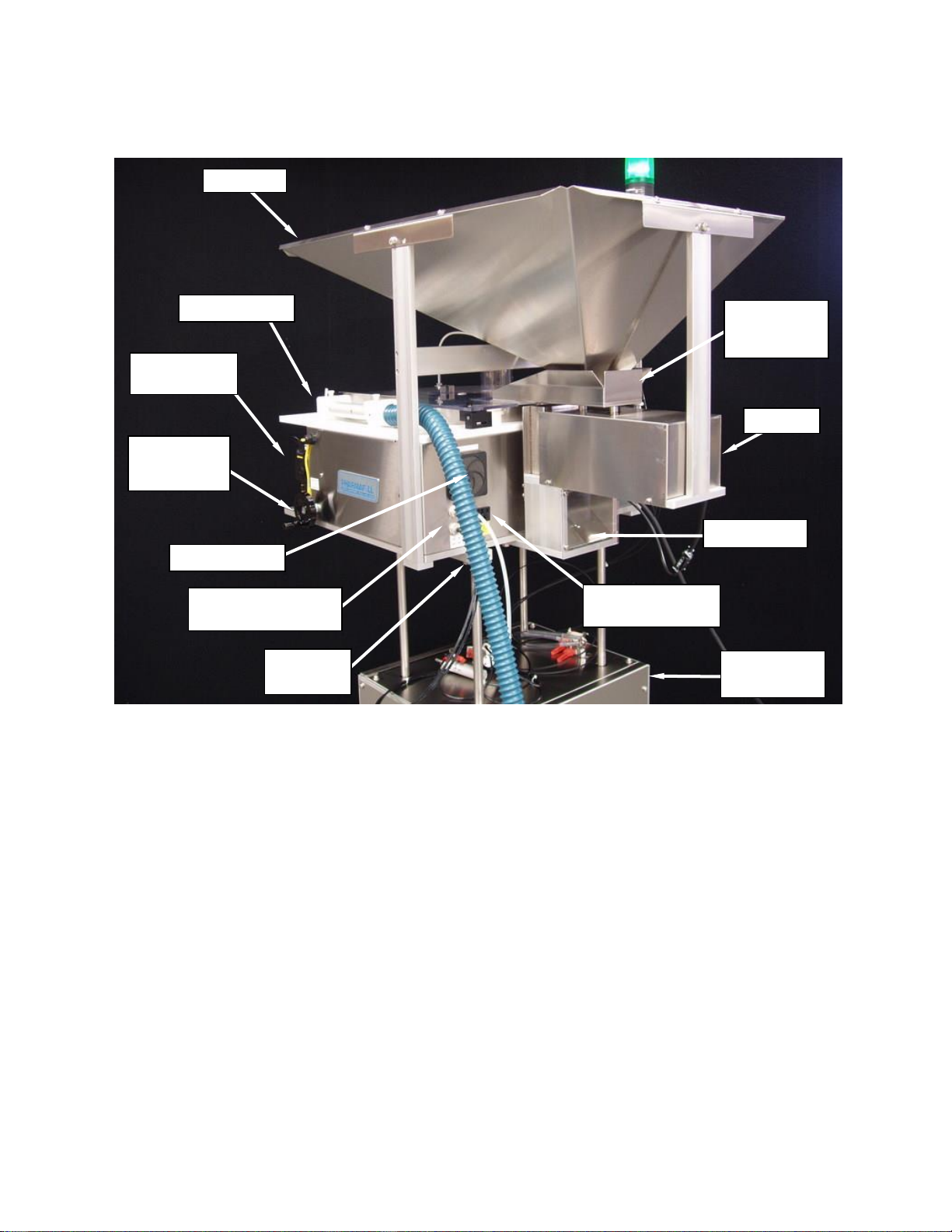

Section 1 - GENERAL ILLUSTRATIONS

1.1 - Front View

CONTROL

PANEL

AUTO-FEED

SENSOR

CABLE

DUST

COVER

HOLDER

PRODUCT

GUIDES

AIR

MANIFOLD

SUPPLY

SENSOR

BACKUP

SENSOR

START

SENSOR

RIM

BAND

RIM

DUST

COVER

GATING CYLINDERS

HOPPER

HOPPER

DOOR

STACK LIGHT

COUNTING

HEAD

Rev 2022-03-08 Pharmafill Model TC3 User Manual

Deitz Company Inc. TC3 User Manual Page III

1.2 - Overhead View

PRODUCT GUIDE

(LONG, POINTED)

GLASS DISC

(UNDER CENTER HUB)

AUTO-FEED

SENSOR

AIR

MANIFOLD

ADJUSTABLE

GUIDE

BLOCK

DISPLAY

PANEL

RUN

CONTROL

SWITCHES

S

DEFLECTOR

ARM

FLOW

GUIDE

AIR

NOZZLES

AIR GUIDE

ASSEMBLY

PRODUCT

GUIDE PLATE

GUIDE CHUTE

CENTER HUB

Rev 2022-03-08 Pharmafill Model TC3 User Manual

Deitz Company Inc. TC3 User Manual Page IV

1.3 - Counting Head

CENTERING

WHEEL

TRAP (CLOSED)

DIVIDER

FLAG

GUIDE CHUTE

CLEAR COVER

COUNTING

SENSOR

TRAP (OPEN)

CLEAR HEAD

COVER

FUNNEL

TRAP FLAG

COUNTING

WINDOW

Rev 2022-03-08 Pharmafill Model TC3 User Manual

Deitz Company Inc. TC3 User Manual Page V

1.4 - Power Switches

COMPONENT

FUSES ARE

BEHIND THIS

PANEL

MAIN POWER

DISCONNECT

SWITCH

START BUTTON

EMERGENCY

STOP BUTTON

(TWIST RELEASE)

Rev 2022-03-08 Pharmafill Model TC3 User Manual

Deitz Company Inc. TC3 User Manual Page VI

1.5 - Right Side Rear

BLOWER

POWER OUTLET

FEEDER

BLOWER

AIR HOSE

HOPPER

AIR MANIFOLD

HEAD

CENTERING

WHEEL

COUNTING

SENSOR

FEEDER PAN

(SIEVE

INSIDE)

COMPRESSED

AIR CONNECTIONS

CHIP CHUTE

LIFT

PLATFORM

COOLING FAN

Rev 2022-03-08 Pharmafill Model TC3 User Manual

Deitz Company Inc. TC3 User Manual Page VII

1.6 -Left Side Rear

CHIP CHUTE

(CLEAR COVER)

FEEDER

POWER

CORD

MAIN AC IN

POWER

CORD

STACKLIGHT

CABLE

AUTO-FEED

SENSOR

CABLE

FEEDER

SENSOR

FIBER OPTIC

CABLES

Rev 2022-03-08 Pharmafill Model TC3 User Manual

Deitz Company Inc. TC3 User Manual Page VIII

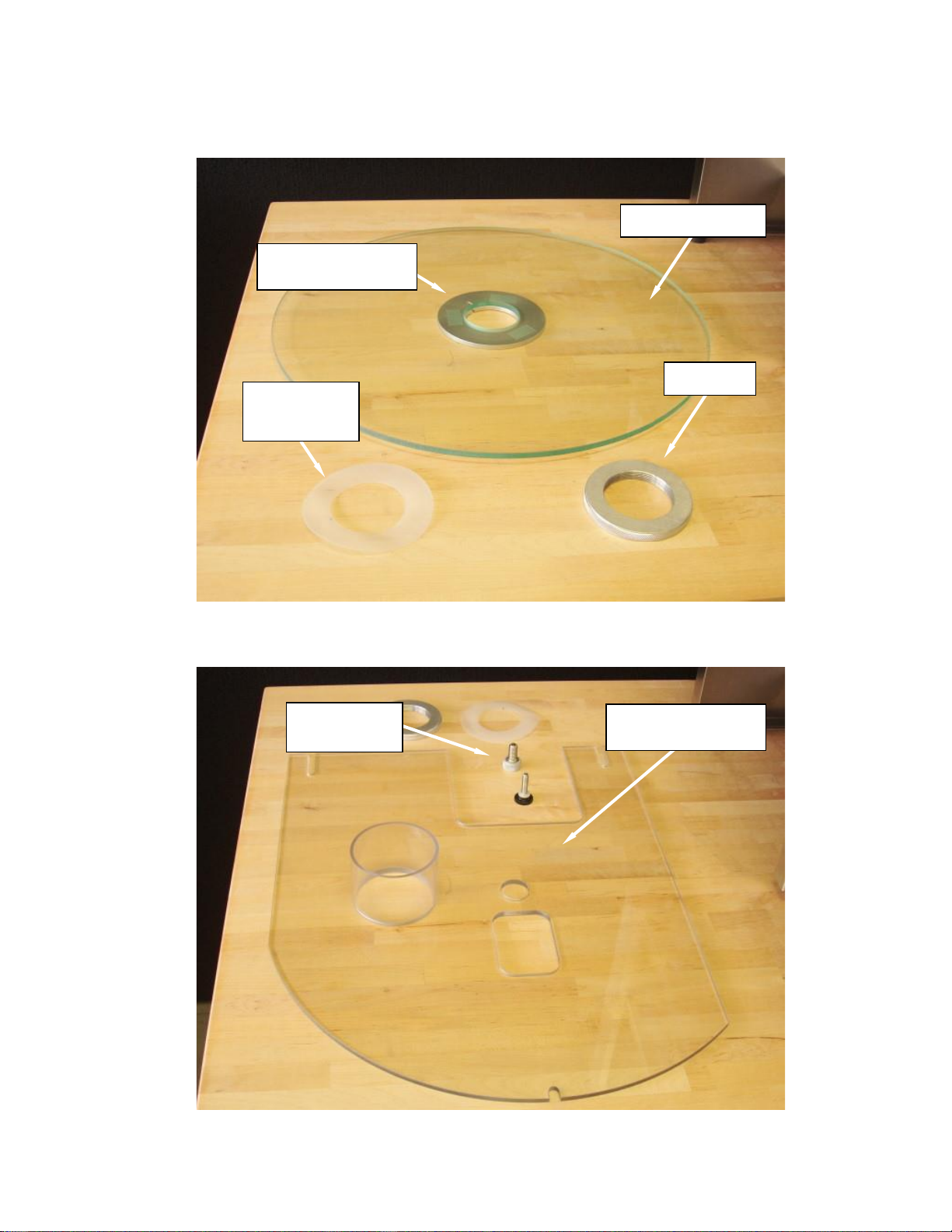

1.7 - Glass Disc, Ring Nut, Washer

1.8 - Clear Rim Cover, Center Hub Knob

GLASS DISC (20”)

DISC SUPPORT RING

(BONDED TO DISC)

CLEAR

PLASTIC

WASHER

RING NUT

CLEAR RIM DUST

COVER

CENTER HUB

KNOB

Rev 2022-03-08 Pharmafill Model TC3 User Manual

Deitz Company Inc. TC3 User Manual Page IX

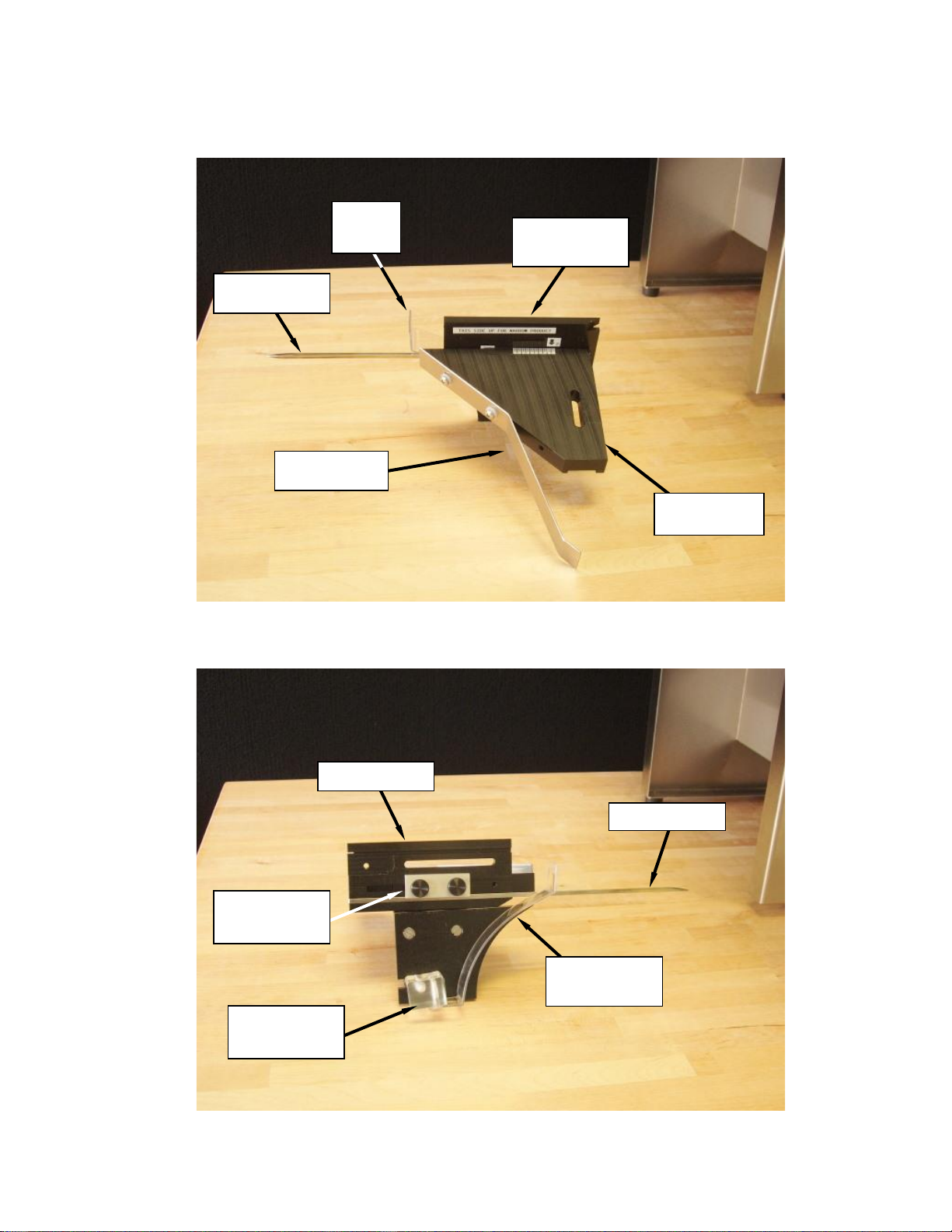

1.9 - Guide Block Assembly (Left Side)

1.10 - Guide Block Assembly (Right Side)

PRODUCT

GUIDE

GUIDE BLOCK

SHIELD

CLEAR CHUTE

COVER

CHUTE COVER

MOUNTING

BLOCK

PRODUCT

GUIDE PLATE

GUIDE

BLOCK

GUIDE PLATE

GUIDE PLATE

CLAMPING

BLOCK

CLEAR

CHUTE

COVER

FLOW GUIDE

Rev 2022-03-08 Pharmafill Model TC3 User Manual

Deitz Company Inc. TC3 User Manual Page X

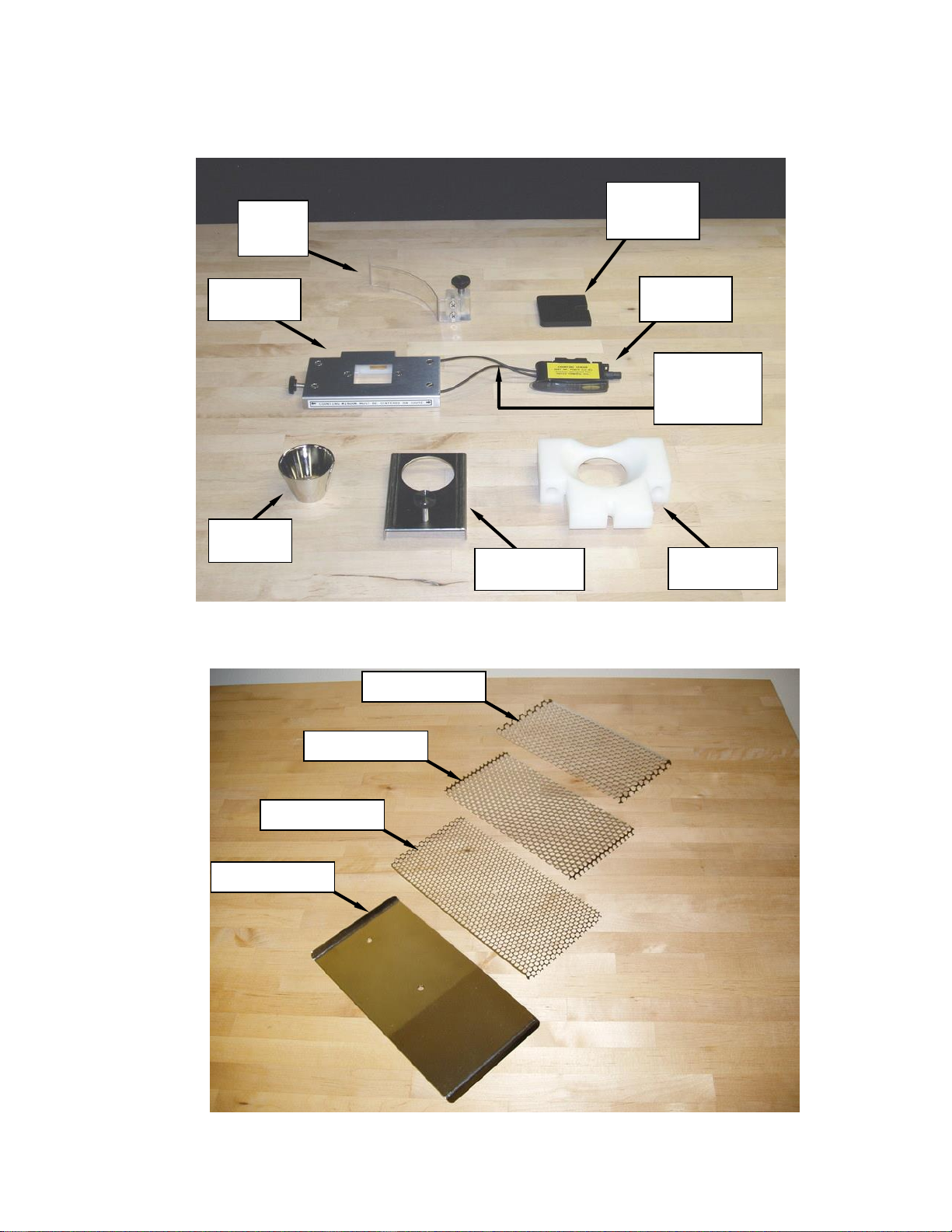

1.11 - Center Hub, Deflector Arm, Auto-Feed Sensor

1.12 - Counting Head Breakdown Parts

DEFLECTOR

ARM

CENTER HUB

SENSOR

TARGET

AUTO-FEED

SENSOR

TRAP

FLAG

DIVIDER

FLAG

SIDE

BLOCK

CLEAR COVER

CENTER BLOCK

BACK PLATE

SIDE

BLOCK

DEFLECTOR

SPRING

Rev 2022-03-08 Pharmafill Model TC3 User Manual

Deitz Company Inc. TC3 User Manual Page XI

1.13 - Counting Head Breakdown Parts (Cont’d)

1.14 –Feeder Chute Sieves

FUNNEL

BLOCK

BLOCK

FUNNEL

(4 SIZES)

SOLID SIEVE

.156” HOLES

.188 HOLES

.250 HOLES

CLEAR

CHUTE

COVER

COUNTING

WINDOW

COUNTING

SENSOR

COUNTING

SENSOR

COVER

COUNTING

SENSOR

FIBER OPTIC

CABLES

FUNNEL

HOLDER

BLOCK

Rev 2022-03-08 Pharmafill Model TC3 User Manual

Deitz Company Inc. TC3 User Manual Page 1

Section 2 - SAFETY REMINDER

Warning

This machine contains moving parts and

operates automatically. This may present a

hazard to personnel.

Never operate this machine with any covers or guards removed or any guard switches or

safety devices removed or bypassed.

Only people who have been correctly trained should operate or clean this machine.

Only people who are correctly qualified and trained should carry out maintenance,

installation or any other service work.

Never clean or service the machine without

isolating the electrical supply and isolating the

air supply.

Always test for the presence of voltage before touching or working on electrical

components.

Note that there might be other requirements that could apply.

Refer to the manuals supplied by the component manufacturers for further safety

instructions.

Rev 2022-03-08 Pharmafill Model TC3 User Manual

Deitz Company Inc. TC3 User Manual Page 2

Section 3 - INTRODUCTION

Thank you for purchasing a Pharmafill Model TC3 Automatic Pill Counter. We at Deitz

Company hope you will find that the Model TC3 meets or exceeds your expectations and

requirements for an affordable, reliable and innovative addition to your packaging operation.

Pharmafill products are designed and manufactured by Deitz Company Inc., in Wall, NJ, USA.

We have manufactured machinery for the bottle filling industry since 1966 and started our

Pharmafill line in 1993. We are a small (but growing) family-owned business that emphasizes

quality, innovation and superior customer service.

If you have any questions or comments, please contact us by phone or visit our website. Chances

are someone whose last name is Deitz will handle your inquiry personally.

Deitz Company Inc.

PO Box 1108

1750 Route 34

Wall, NJ, USA 07719

Tel 732-681-0200

Fax 732-681-8468

Web site deitzco.com or

pharmafill.com

The operation manual is designed to make it easier for you to know the machine and to make use

of its intended range of operation. It contains important instructions on how to operate the

machine safely, adequately and economically. Observing these instructions helps to avoid risks,

to reduce cost for repair work and machine downtime, and enhances the machine’s operational

reliability and lifetime.

The operation instructions are to be supplemented by further instructions due to existing national

regulations on accident prevention and environmental protection.

If used in compliance with the instructions contained in this manual and provided that safety

devices are regularly maintained and properly working, this machine is not dangerous to the

operator.

This manual is to be kept accessible to all operators using this machine and it is assumed that

before use the operator will read fully, and understand this manual and will follow instruction

stated within.

Rev 2022-03-08 Pharmafill Model TC3 User Manual

Deitz Company Inc. TC3 User Manual Page 3

Section 3 –INTRODUCTION (Cont’d)

As this machine may be used in the packaging of hazardous substances the operator should be

aware of the precautions required for these substances.

In addition to the operating instructions and the binding regulations on accident prevention valid

in the country where the machine is being used and at its operational site, the recognized

technical rules on safe and proper working have to be observed as well.

These operating instructions and the information contained therein have been compiled with due

care and attention. However, DEITZ COMPANY does not take any responsibility for misprints,

translation errors or other errors and any damages resulting there from.

DEITZ COMPANY retains the right to make changes in the described products to improve

functionality, reliability and design. The measurements or data shown on schematics, sketches

and photos are not binding. They are for description purposes.

The information and drawings found in the operation manual are the intellectual property of

DEITZ COMPANY and may not be copied or given to third parties.

LEGAL NOTICE: DEITZ COMPANYTM, PHARMAFILLTM and any graphic representations of

the same are legal trademarks of Deitz Company Inc. and may not be used by others without

specific written permission from Deitz Company.

Rev 2022-03-08 Pharmafill Model TC3 User Manual

Deitz Company Inc. TC3 User Manual Page 4

Section 4 –SPECIFICATIONS

(Also see technical information at end of manual)

GENERAL

Model TC3 Automatic Pill Counter

Description Fully Automatic Electronic Counting Filler

Type AD1115

Product Capability Most solid oral dose tablets, capsules and caplets.

Maximum width or diameter: 0.9 inch (22 mm)

Maximum length: 0.9 inch (22 mm)

Maximum height: 0.4 inch (10 mm)

Maximum Counting Rate Typical coated tablet, diameter .25 inch: 2500-3000 per minute

Typical capsule, size 00: 1000-1500 per minute

Maximum Filling Rate 50-60 bottle per minute

Accuracy Typically 99.99% (1 error per 10,000 pills) at optimal conditions

INPUTS

Voltage 110 VAC 1

Cycles 50/60 HZ

Phase 1

Amperage 6.0A peak

Compressed Air 80 PSI [550 kPa], consumes less than 1.0 CFM [28 LPM]

AIR MUST BE FREE OF WATER VAPOR AND OIL

Room Humidity 85% RH non-condensing

DIMENSIONS

Floor foot print 25” wide x 37” deep [62cm X 94cm]

Hopper height Variable from 61” to 70” [155cm to 178cm] 2

Overall height Variable from 75” to 84” [191cm to 214cm]

Bottle height Up to 10”[25cm] 3

Weight 300 lbs [136 Kg]

OTHER

Hopper Capacity 1.9 cu. ft [.054 m3], or 2.8 cu. ft [.079 m3] with 6” extension

Glass Disc Float Glass 20” diam. X 1/4" thickness [50 cm x 6 mm]

Construction Materials See Section 10 –Contact Compliance Document

Notes:

1. Other input voltages are available as factory options if specified at the time of order

2. May be adjusted further by adjusting or modifying leveling feet.

3. Bottle height based on 34” [86cm] high conveyor surface.

Rev 2022-03-08 Pharmafill Model TC3 User Manual

Deitz Company Inc. TC3 User Manual Page 5

Section 5 - INSTALLATION AND COMMISSIONING

5.1 - Unpacking

❑Carefully remove the cardboard cover from the pallet.

❑Remove all packing materials any additional boxes that may be inside.

❑Remove the threaded rods, washers and nuts that hold the machine to the pallet.

❑Remove the machine from the pallet and position on the floor.

❑Remove any shrink-wrap, bubble wrap and/or protective cardboard inserts.

❑Inspect all supplied equipment for damage.

❑If any damage is present please notify DEITZ COMPANY immediately.

❑VERY IMPORTANT: Refer to Section 9: “Cleaning – Breakdown and Buildup” to

remove the last of the packing material and for cleaning prior to first use. DO NOT

attempt to operate the machine before all packing material is removed.

❑Connect compressed air, electrical power and then test. See the procedure on the

following pages.

Rev 2022-03-08 Pharmafill Model TC3 User Manual

Deitz Company Inc. TC3 User Manual Page 6

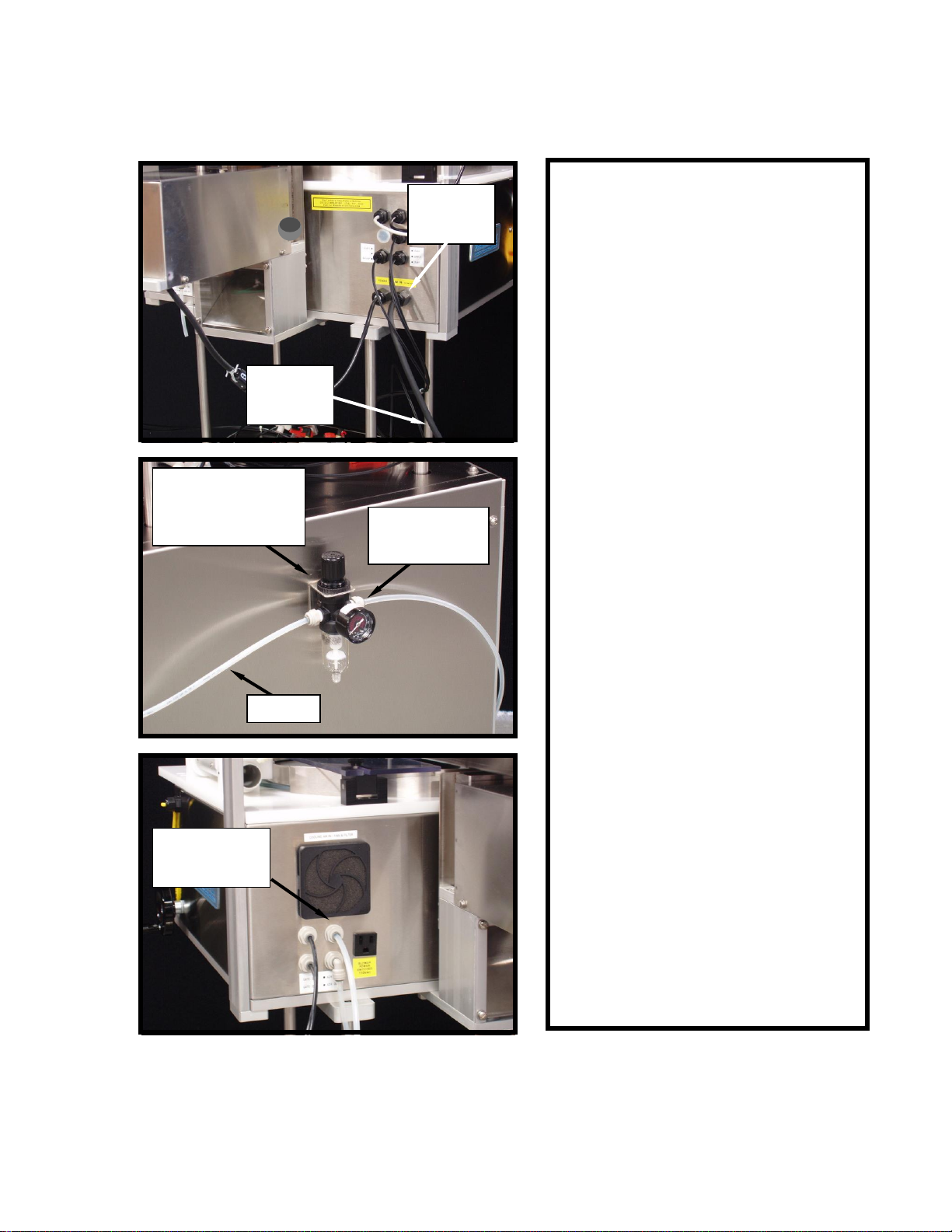

5.2 - Connect Electric, Compressed Air And Blower Air

1. Locate the main power cord at the

rear of the machine. Plug this into your

110 VAC 6A outlet.

2. Locate the compressed air filter-

regulator at the rear of the machine.

Attach the air line from your

compressor here.

3. Confirm that the air tube coming out

of the filter regulator is attached to the

machine as shown here.

4. Lift (to unlock) the knob on the

regulator and turn until the gage

indicates 80 PSI. Press the knob down

to lock.

MAIN

POWER

CORD

TO

110 VAC

OUTLET

COMPRESSED

AIR

FILTER-REGULATOR

(ADJUST TO 80 PSI)

COMPRESSED

AIR IN

1/4-NPT

TO TC3

COMPRESSED

AIR IN

FROM FILTER

Rev 2022-03-08 Pharmafill Model TC3 User Manual

Deitz Company Inc. TC3 User Manual Page 7

5.2 - Connect Electric, Compressed Air And Blower Air (Cont’d)

5. Locate the blower power cord and

the blower air hose at the rear of the

lift platform.

6. Plug the blower power cord from

the lift platform into the blower power

outlet on the back of the TC3.

7. Attach the blower air hose from the

lift platform to the 1-1/4” opening at

the rear of the air manifold tube.

BLOWER

POWER

CORD

BLOWER

AIR

HOSE

BLOWER

POWER

OUTLET

AIR

MANIFOLD

OPENING

BLOWER

AIR

HOSE

Rev 2022-03-08 Pharmafill Model TC3 User Manual

Deitz Company Inc. TC3 User Manual Page 8

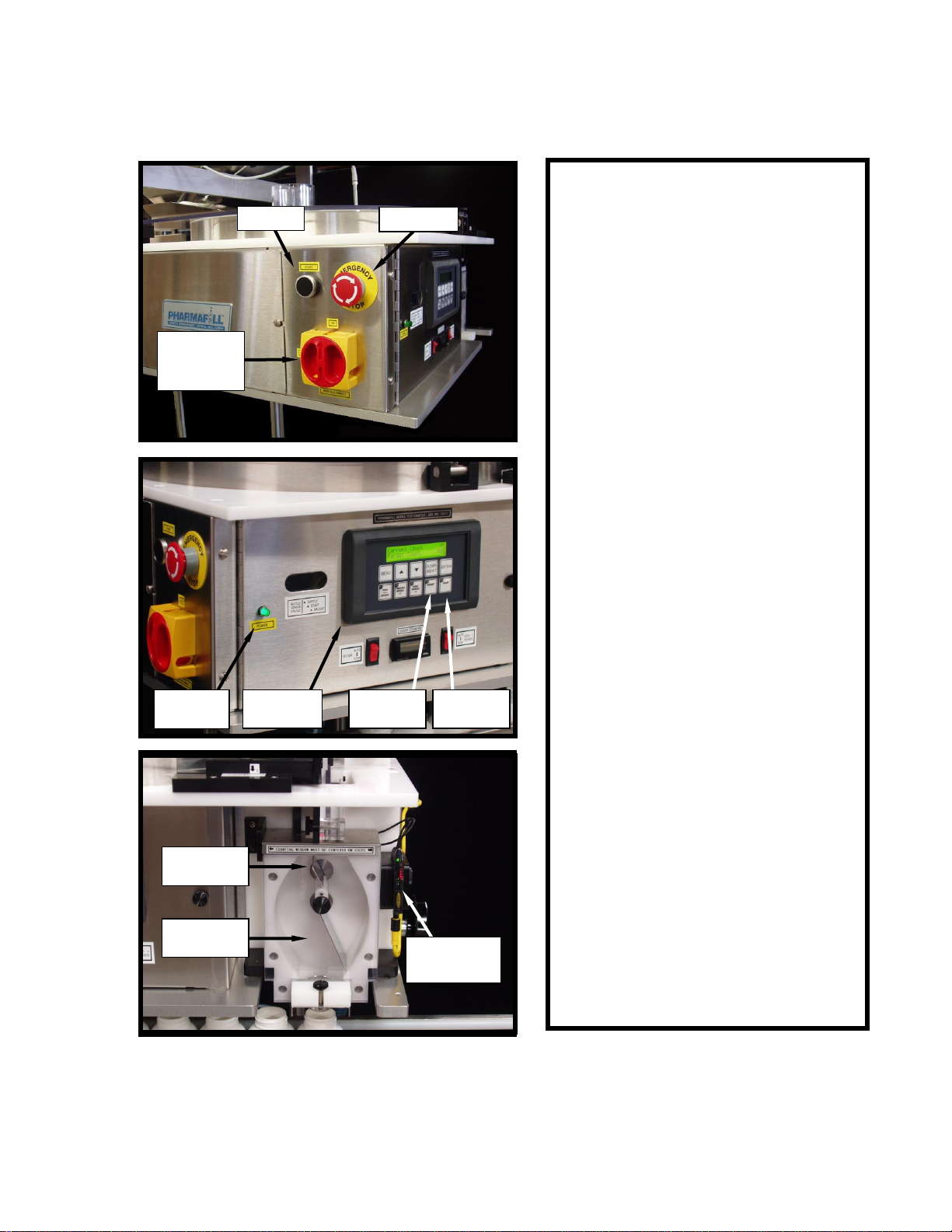

5.3- Systems Check

1. Turn on the Main Power Switch by

rotating it clockwise.

2. Twist and release the E-stop button.

3. Press the START button.

4. Confirm that the Control Panel

lights.

5. Confirm that the counting sensor

lights.

6. Press the RESET button several

times and confirm that the divider flag

flips back and forth smoothly and

quickly.

7. Press the TRAP button several

times and confirm that the trap flag

flips back and forth smoothly (but not

as quickly as the divider flag).

COUNTING

SENSOR

DIVIDER

FLAG

DISPLAY

PANEL

MAIN

POWER

SWITCH

START

E-STOP

POWER

LIGHT

TRAP

FLAG

RESET

BUTTON

TRAP

BUTTON

Table of contents

Other Deitz Cash Counter manuals

Popular Cash Counter manuals by other brands

Beckman Industrial

Beckman Industrial CIRCUITMATE UC10 Operator's manual

Baumer

Baumer NE230 operating instructions

Tektronix

Tektronix VX4101 user manual

Precision Digital Corporation

Precision Digital Corporation PROVU PD6300 Series instruction manual

Cashmaster

Cashmaster Sigma 170 user manual

Spectris

Spectris Particle Measuring Systems Ultra DI 50 Operation manual