AEROCET 531S Manual Page 2 AEROCET 531S-9800 Rev A.docx

Table of Contents

1. Introduction ........................................................................................................... 4

2. Setup ...................................................................................................................... 4

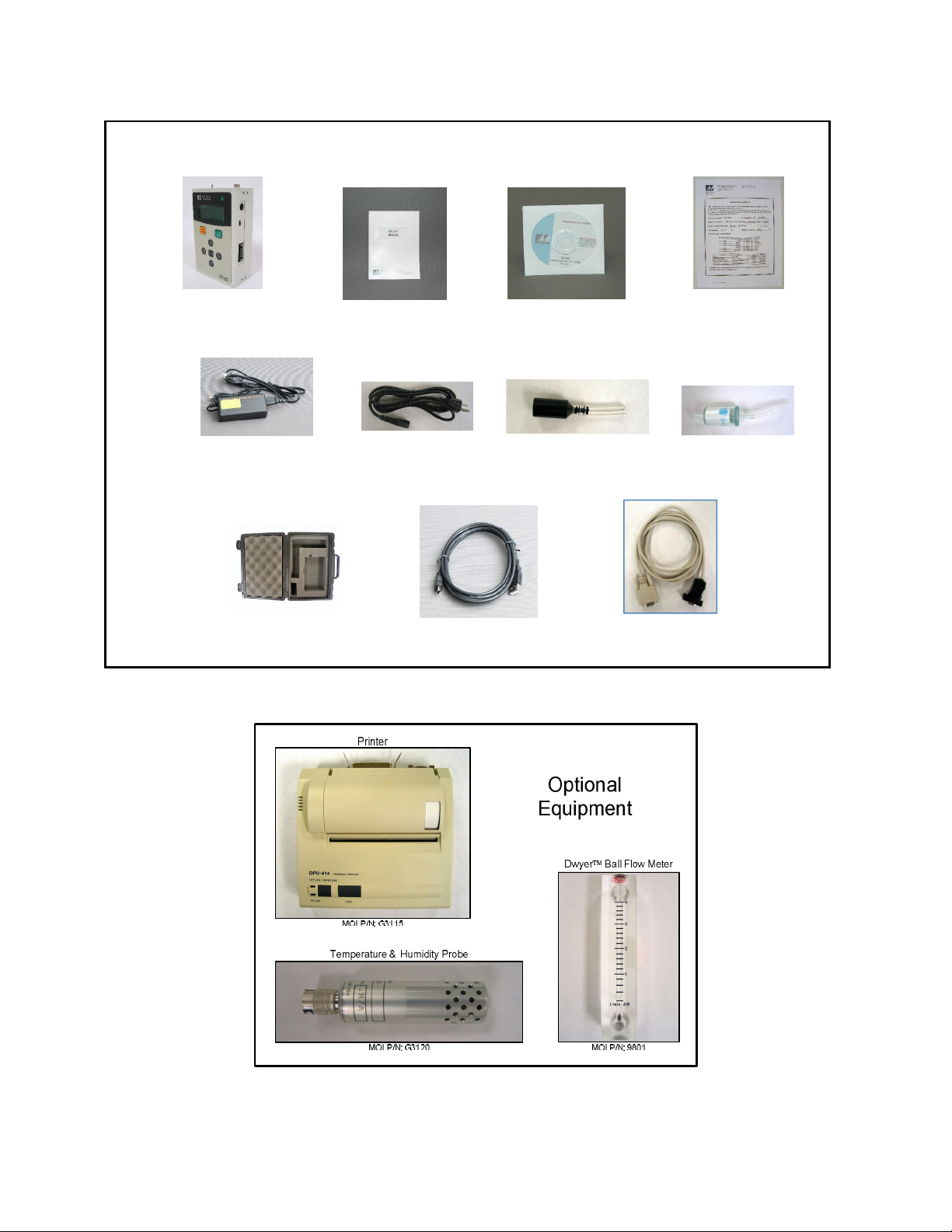

2.1. Unpacking ............................................................................................................................ 4

2.2. Layout .................................................................................................................................. 6

2.3. Default Settings .................................................................................................................... 7

2.4. Initial Operation .................................................................................................................... 7

3. User Interface ........................................................................................................ 7

4. Operation ............................................................................................................... 8

4.1. What’s New and Different ..................................................................................................... 8

4.2. About the Measurement ........................................................................................................ 8

4.3. Power Up.............................................................................................................................. 8

4.4. Operate Screen .................................................................................................................... 9

4.4.1. Sampling ...................................................................................................................... 10

4.4.2. Sample Status .............................................................................................................. 10

4.4.3. Sample History ............................................................................................................. 10

4.4.4. Warning / Error Messages ............................................................................................ 11

4.5. Sample Related Functions .................................................................................................. 11

4.5.1. Starting/Stopping .......................................................................................................... 11

4.5.2. Measurement Type ....................................................................................................... 11

4.5.3. Sample Mode ............................................................................................................... 11

4.5.4. Hold Time ..................................................................................................................... 11

4.5.5. Real-Time Serial Report ............................................................................................... 11

4.5.6. Sample Timing ............................................................................................................. 12

5. Menu Selections .................................................................................................. 12

5.1. Edit Menu Items .................................................................................................................. 12

5.2. SAMPLE SETUP Screen ...................................................................................................... 13

5.2.1. LOCATION Number....................................................................................................... 13

5.2.2. MEASURE ...................................................................................................................... 13

5.2.3. Sample MODE ............................................................................................................... 13

5.2.4. HOLD Time.................................................................................................................... 13

5.3. SETTINGS Screen .............................................................................................................. 14

5.3.1. VOLUME ........................................................................................................................ 14

5.3.2. TEMPERATURE .............................................................................................................. 14

5.4. SERIAL Screen .................................................................................................................. 15

5.4.1. REPORT ........................................................................................................................ 15

5.4.2. BAUD ............................................................................................................................ 15

5.4.3. SERIAL ........................................................................................................................ 15

5.5. RECALL DATA Screen ........................................................................................................ 16

5.6. PRINT DATA Screen .......................................................................................................... 16