Delixi CDW3 Series User manual

User's Manual

Air Circuit Breaker

CDW3

series

Safety notice:

This use manual is specially made for electrician.

Make sure the end user has this user manual.

Read and strictly abide this use manual before use.

Sign

Delixi provide “three guarantee service”within 36 months warranty from

manufacture date for the manufacture defect under normal storage,

maintenance and storage condition.

CONTENT

1

About CDW3 01

Secondary circuit wiring diagram 29-30

Open 01

About breaker 01

4

Debugging CDW3 31

Know the nameplate 01

iTR326 series electronic trip unit 31-34

Size and weight 01

Protection characteristics

(

general)

35-36

Breaker structure 02

Menu 37

Debugging operation 03

iTR326A operation 38-39

iTR326H operation 40-41

2

Carry CDW3 04

Carry requirement 04

5

Functions 42

Carry way 04

Technical parameter 42-43

Know the accessory 44-48

3

Installation CDW3 05

Tool 05

6

Maintenance 49

Installation requirements 05

Working conditions 49

Installation way 05-06

Maintenance procedures 49

Recommend Size of user busbar 07

Maintenance operations 49

Size for 1600N&H 08-11

Troubleshooting 50

Size for 2000N&H 12-13

Order replacement parts 50

Size for 500N&H 14-15

Size for 3200N&H 16-17

7

Appendix 51

Size for 4000N&H 18-21

Trip curve 51

Size for 6300N 22-23

Model selection table 52

Accessory installation 24-26

Configuration table 53

Accessory size 27-28

1

Open

Wooden box

CDW3 Screw Power

converter

Doorframe Interphase

partition

User's

Manual

About breaker

Draw-out

Fixed

Know the nameplate

Please read the nameplate and data plate information carefully before installation

1

Rated current 9 Applicability

(quarantine)

2

Rated insulation voltage

10 date of manufacture

3

Rated impulse withstand

voltage

11 Rated voltage

4

Rated frequency 12 Ultimate short circuit

breaking capacity

5

Maximum short circuit

delay time

13 Operating short circuit

breaking capacity

6

Category 14 Rated short-time

withstand current

7

Applicability(IT) 15 Certification mark

8

Factory code

Size and weight

Type 1600N&H 2000N&H 2500N&H 3200N&H 4000N&H 6300N

3P 4P 3P 4P 3P 4P 3P 4P 3P 4P 3P 4P

Draw-out

Size(mm)

322*288*

330

322*358*

330

436*405*

425

436*500*

425

436*465*

425

436*580*

425

436*465*

425

436*580*

425

439*441*

428.6

439*556*

428.6

436*843*

498

436*958*

498

Draw-out

Weight(kg) 33.5&34

40&41 73&73.6

85&85.5

84&84.3

102.9&10

3.3 93&93.8

114&115

77&78 94&95 233 271.8

Fixed

Size(mm)

301*276*

229

301*346*

229

397*364*

327

397*459*

327

397*428*

327

397*543*

327

397*428*

327

397*543*

327

352*422*

329.5

352*537*

329.5 / /

Fixed

Weight(kg) 13.6&14

16.5&17

41&41.4

51.5&52

48.6&48.9

59.7&60.1

53&53.4

67&68 41&42 51&52 / /

*

Dimension relationship: height * width * depth *6300N-3P size is use with 5000A, 3P-6300A size is 6300N-4P size, and 4P-6300A has no such product

About CDW3

1

2

3

4

5

6

7

8

9

10

11 13 14 12

15

2

Breaker structure

Drawer seat

(schematic diagram, subject to the configuration table)

1 Padlock lock handle 5 Rocker storage 9 Bundle collet

2 Separation, test and connection

position indication 6 Rocker 10 Handling handle

3 Rocker socket 7 Pull out the handle 11 Arc chute cover

4 Three position locking device

unlocking button 8 Door interlock

*

The picture shows that 1600AF drawer shaking mechanism is placed vertically on the right side, 2000AF-

6300AF drawer shaking mechanism is placed horizontally on the front bottom

Circuit breaker body

(schematic diagram, subject to the configuration table)

1 Arc chute 7 Closing button 13 SWT Fault trip contact

2 XF Closing coil 8 Opening button 14 SWT/2 Fault trip contact or Remote

reset

3 OF Auxiliary contact 9 L Opening lock 15 MN Under-voltage release

4 PF Prepare closing contact 10 iTR

Electronic trip unit 16 MX Release

5 Energy storage handle 11 D-Side plate 17 D-Secondary terminal box

6 MCH Electric operating mechanism 12 F-Side plate 18 F-Secondary terminal box

8

11

10

9

1

7

2

3

4

5

6

1

3

4

5

6

7

8

18

17

16

15

14

13

9

12

10

11

2

About CDW3

3

Debugging operation

Opening and closing operation of circuit breaker

1. If there is undervoltage release, it must be powered first

2. First watch the indication window to determine whether the circuit breaker is in the opening state. If it

is closed, press the opening button directly

3. Shake the energy storage handle downward for 7-8 times to store energy, hear the "click" sound, and

watch whether the "energy storage" indicator window is in the "energy storage" state

4. Press the closing button to close the circuit breaker

5. Press the opening button to open the circuit breaker

6. If it is necessary to switch on again, "energy storage" is required“

Drawer seat operation

1. When the circuit breaker is in the connection position, the indicator indicates "connection", pull out the

rocker from the rocker storage and insert it into the rocker slot

2. Rotate the rocker anticlockwise to move the circuit breaker from the "connection" position to the "test"

position, and the indicator indicates "test", and the unlocking button of the three position locking

device pops up, and the rocker cannot be shaken again

3. Press the unlocking button of the three position locking device, continue to shake the rocker

anticlockwise to "separation" position, indicator indication "separation", the unlocking button of the

three position locking device pops up, and the rocker cannot be shaken again

4. Pull out the draw out handle of drawer seat and draw out the circuit breaker body

5. When installing the circuit breaker body, first pull out the draw out handle of the drawer base, place

the circuit breaker body on the draw out handle, push the circuit breaker body into the drawer base,

and push the draw out handle into the drawer base for locking

6. Press the unlocking button of the three position locking device, rotate the rocker clockwise to "test"

position, indicator indication "test, the unlocking button of the three position locking device pops up,

and the rocker cannot be shaken again

7. Press the unlocking button of the three position locking device, continue to shake the rocker clockwise

to "connect" position, indicator indicates "connect", the unlocking button of the three position locking

device pops up, and the rocker cannot be shaken again

About CDW3

Closing button

Open

ing button

Reset button

Window(O/I)

O

I

ETU

Three position locking

device unlocking button

Rocker storage

Energy storage handle

Window(Reday)

Separation, test and connection position indication

R

ocker

4

Carry requirement

Severe collision shall be avoided as

far as possible

Do not reverse or roll the circuit

breaker

Handle with care

Heavy bus terminal of circuit breaker

Please carry it as shown in the right figure

Transportation environment temperature: - 25 ℃ ~ 55 ℃, relative humidity: no

more than 90% (at 25 ℃)

Carry way

When carrying the drawer type circuit breaker body together,

pay attention to check the drawer type circuit breaker body

The circuit breaker can be handled only when it is in the

"connected" position with the drawer base

Pay attention to check whether the circuit breaker is in "off"

state before handling the circuit breaker

The handling of fixed circuit breaker is the same as that of drawer circuit breaker

Carrying drawer seat

Insert the pull hook into the handle of the drawer seat of the circuit breaker as

shown in the figure, and then lift the drawer seat

Carry CDW3

5

Tool

Installation requirements

The installation position shall be vertical, and the inclination in each

direction shall not exceed 5 °

The main circuit, undervoltage release and primary coil of power transformer of the circuit

breaker are class IV, and the auxiliary circuit and control circuit are class III

Installation way

2. Install drawer base and body

Installation CDW3

S

crewdriver

(

-

)

S

crewdriver

(+)

S

crewdriver

(+)

Wrench

6

3. Bus installation

Drawer type, fixed type is the same

Note: vertical wiring is limited to 1600AF/4000AF

4. Safe distance

Safe distance

(mm)

Draw-out Fixed

A B A B

Insulation 0 10 0 0

Metal 0 10 0 0

Live conductor 30 60 100 60

Installation CDW3

7

Recommend Size of user busbar

Reference table of wiring busbar specifications under different temperatures

Allowable maximum temperature of busbar: 100 ℃

Busbar material is bare copper

Frame

(AF)

Rated

current

(A)

Ambient temperature +40℃ Ambient temperature +50℃ Ambient temperature +60℃

5mm busbar 10mm busbar 5mm busbar 10mm busbar 5mm busbar 10mm busbar

Pieces

Size Pieces

Size Pieces

Size Pieces

Size Pieces

Size Pieces

Size

1600

400

2 30*5

1 30*10

2 30*5

1 30*10

2 30*5

1 30*10

630

2 40*5

1 40*10

2 40*5

1 40*10

2 40*5

1 40*10

800

2 50*5

1 50*10

2 50*5

1 50*10

2 50*5

1 50*10

1000

3 50*5

2 40*10

3 50*5

2 40*10

3 50*5

2 40*10

1250

4 40*5

2 40*10

4 50*5

2 50*10

4 50*5

2 50*10

1600

4 50*5

2 50*10

4 50*5

2 50*10

4 50*5

2 50*10

2000

630

2 40*5

1 40*10

2 50*5

1 50*10

2 60*5

1 60*10

800

2 50*5

1 50*10

2 50*5

1 50*10

2 60*5

1 60*10

1000

3 50*5

2 40*10

3 50*5

2 40*10

3 60*5

2 50*10

1250

3 60*5

2 50*10

3 60*5

2 50*10

3 60*5

2 50*10

1600

4 60*5

2 60*10

4 60*5

2 60*10

4 60*5

2 60*10

2000

6 60*5

3 60*10

6 60*5

3 60*10

6 60*5

3 60*10

2500

630

2 40*5

1 40*10

2 50*5

1 50*10

2 60*5

1 60*10

800

2 50*5

1 50*10

2 50*5

1 50*10

2 60*5

1 60*10

1000

2 60*5

1 60*10

3 60*5

2 50*10

3 60*5

2 50*10

1250

2 80*5

2 40*10

3 60*5

2 50*10

3 60*5

2 50*10

1600

2 100*5

1 100*10

2 100*5

1 100*10

2 100*5

1 100*10

2000

4 100*5

2 100*10

4 100*5

2 100*10

4 100*5

2 100*10

2500

4 100*5

2 100*10

4 100*5

2 100*10

4 100*5

2 100*10

3200

2000

4 100*5

2 100*10

4 100*5

2 100*10

4 100*5

2 100*10

2500

4 100*5

2 100*10

4 100*5

2 100*10

4 100*5

2 100*10

3200

8 100*5

4 100*10

8 100*5

4 100*10

8 100*5

4 100*10

4000

630

2 40*5

1 40*10

2 50*5

1 50*10

2 60*5

1 60*10

800

2 50*5

1 50*10

2 50*5

1 50*10

2 60*5

1 60*10

1000

2 60*5

1 60*10

3 60*5

2 50*10

3 60*5

2 50*10

1250

2 80*5

2 40*10

3 60*5

2 50*10

3 60*5

2 50*10

1600

2 100*5

1 100*10

2 100*5

1 100*10

2 100*5

1 100*10

2000

4 100*5

2 100*10

4 100*5

2 100*10

4 100*5

2 100*10

2500

4 100*5

2 100*10

4 100*5

2 100*10

4 100*5

2 100*10

3200

8 100*5

4 100*10

8 100*5

4 100*10

8 100*5

4 100*10

4000

5 100*10

5 100*10

6 100*10

6300

4000

5 100*10

5 100*10

6 100*10

5000

7 100*10

7 100*10

8 100*10

6300

8 100*10

8 100*10

Note 1: the data in the above table are obtained from test and theoretical calculation, but as a guide, it can not replace industrial

practical experience or temperature rise test

Note 2: it is recommended that the cross-sectional area of busbar specification selected by the user is not less than the cross-

sectional area in the table. 50 mm wide busbar is recommended for 400A of 1600AF

Bolt configuration

1600N&H 2000N&H 2500N&H 3200N&H 4000N&H 6300N

Bolt size M10 M12 M12 M12 M10 M12

Recommended torque 50N·m 95N·m 95N·m 95N·m 50N·m 95N·m

Drilling

size and installation torque of busbar

1600N&H 2000N&H 2500N&H 3200N&H 4000N&H 6300N

Drilling size of busbar ф11 ф13 ф13 ф13 ф11 ф13

Recommended torque 50N·m 95N·m 95N·m 95N·m 50N·m 95N·m

Installation CDW3

8

Size for 1600N&H

1600N&H Draw-out 3P&4P

Datum point

Horizontal fixation (on base plate or track) Vertical fixation (on backplane or rack)

Safe spacing Door opening size Rear panel opening size

Safe distance

(mm)

Draw-out

A B C

Insulation 0 10 0

Metal 0 10 0

Live conductor 30 60 30

Note 1: the schematic diagram of safety distance is schematic diagram, and the circuit breaker shall be subject to the real object

Note 2: the x-axis and Y-axis of the 3-pole circuit breaker are symmetrical to the front cover of the circuit breaker body

Installation CDW3

9

1600N&H Draw-out back connection Datum point

Horizontal back connection

Vertical back connection

Rear connection with extension terminal

Refer to "rear connection with extension terminal" for installation

1.4-pole center left or right extension terminal 2.3-pole intermediate expansion terminal 3.4-pole left or right extension

terminal 4.3-pole left or right extension terminal

Note: the x-axis and Y-axis of the 3-pole circuit breaker are symmetrical to the front cover of the circuit breaker body

Installation CDW3

10

1600N&H Fixed 3P&4P Datum point

Horizontal fixation (on base plate or track) Vertical fixation (on backplane or rack)

Safe spacing Door opening size Rear panel opening size

Safe distance

(mm)

Fixed

A B

Insulation 0 0

Metal 0 0

Live conductor 100 60

Note 1: the schematic diagram of safety distance is schematic diagram, and the circuit breaker shall be subject to the real object

Note 2: the x-axis and Y-axis of the 3-pole circuit breaker are symmetrical to the front cover of the circuit breaker body

Note 3: (*) the safety distance shall be considered to be 50mm when removing the arc extinguishing cover and 20mm when

removing the terminal block

Installation CDW3

11

1600N&H Fixed back connection Datum point

Horizontal back connection

Vertical back connection

Rear connection with extension terminal

Refer to "rear connection with extension terminal" for installation

1.4-pole center left or right extension terminal 2.3-pole intermediate expansion terminal 3.4-pole left or right extension

terminal 4.3-pole left or right extension terminal

Note: the x-axis and Y-axis of the 3-pole circuit breaker are symmetrical to the front cover of the circuit breaker body

Installation CDW3

12

Size for 2000N&H

2000N&H Draw-out 3P&4P

Fixed horizontally (on the base plate or track) * the distance of the mask protruding from the door frame is 5mm

Safe spacing Door opening size Bus size

Safe distance

(mm)

Draw-out

A B In(A) a(mm)

Insulation 0 0 630-800 10

Metal 0 0 1000-1600 15

Live conductor 100 60 2000 20

Note 1: the schematic diagram of safety distance is schematic diagram, and the circuit breaker shall be subject to the real object

Installation CDW3

13

2000N&H Fixed 3P&4P

Fixed horizontally (on the base plate or track) * the distance of the mask protruding from the door frame is 5mm

Safe spacing Door opening size Bus size

Safe distance

(mm)

Fixed

A B In(A) a(mm)

Insulation 0 0 630-800 10

Metal 0 0 1000-1600 15

Live conductor 100 60 2000 20

Note 1: the schematic diagram of safety distance is schematic diagram, and the circuit breaker shall be subject to the real object

Note 2: (*) the safety distance shall be 110mm when removing the arc extinguishing cover and 20mm when removing the

terminal block

Installation CDW3

14

Size for 2500N&H

2500N&H Draw-out 3P&4P

Fixed horizontally (on the base plate or track) * the distance of the mask protruding from the door frame is 5mm

Safe spacing Door opening size Bus size

Safe distance

(mm)

Draw-out

A B In(A) a(mm)

Insulation 0 0 630-2500 20

Metal 0 0

Live conductor 100 60

Note 1: the schematic diagram of safety distance is schematic diagram, and the circuit breaker shall be subject to the real object

Installation CDW3

15

2500N&H Fixed 3P&4P

Fixed horizontally (on the base plate or track) * the distance of the mask protruding from the door frame is 5mm

Safe spacing Door opening size Bus size

Safe distance

(mm)

Fixed

A B In(A) a(mm)

Insulation 0 0 630-2000 20

Metal 0 0

Live conductor 100 60

Note 1: the schematic diagram of safety distance is schematic diagram, and the circuit breaker shall be subject to the real object

Note 2: (*) the safety distance shall be 110mm when removing the arc extinguishing cover and 20mm when removing the

terminal block

Installation CDW3

16

Size for 3200N&H

3200N&H Draw-out 3P&4P

Fixed horizontally (on the base plate or track) * the distance of the mask protruding from the door frame is 5mm

Safe spacing Door opening size Bus size

Safe distance

(mm)

Draw-out

A B In(A) a(mm)

Insulation 0 0 630-2500 20

Metal 0 0 3200 30

Live conductor 100 60

Note 1: the schematic diagram of safety distance is schematic diagram, and the circuit breaker shall be subject to the real object

Installation CDW3

17

3200N&H Fixed 3P&4P

Fixed horizontally (on the base plate or track) * the distance of the mask protruding from the door frame is 5mm

Safe spacing Door opening size Bus size

Safe distance

(mm)

Fixed

A B In(A) a(mm)

Insulation 0 0 2000-2500 20

Metal 0 0 3200 30

Live conductor 100 60

Note 1: the schematic diagram of safety distance is schematic diagram, and the circuit breaker shall be subject to the real object

Note 2: (*) the safety distance shall be 110mm when removing the arc extinguishing cover and 20mm when removing the

terminal block

Installation CDW3

Table of contents

Other Delixi Circuit Breaker manuals

Popular Circuit Breaker manuals by other brands

Siemens

Siemens 3RV1.3 Series operating instructions

Abelko

Abelko IMSE UltraBase40 quick start guide

Block

Block ECONOMY SMART PC-FU/DC24 manual

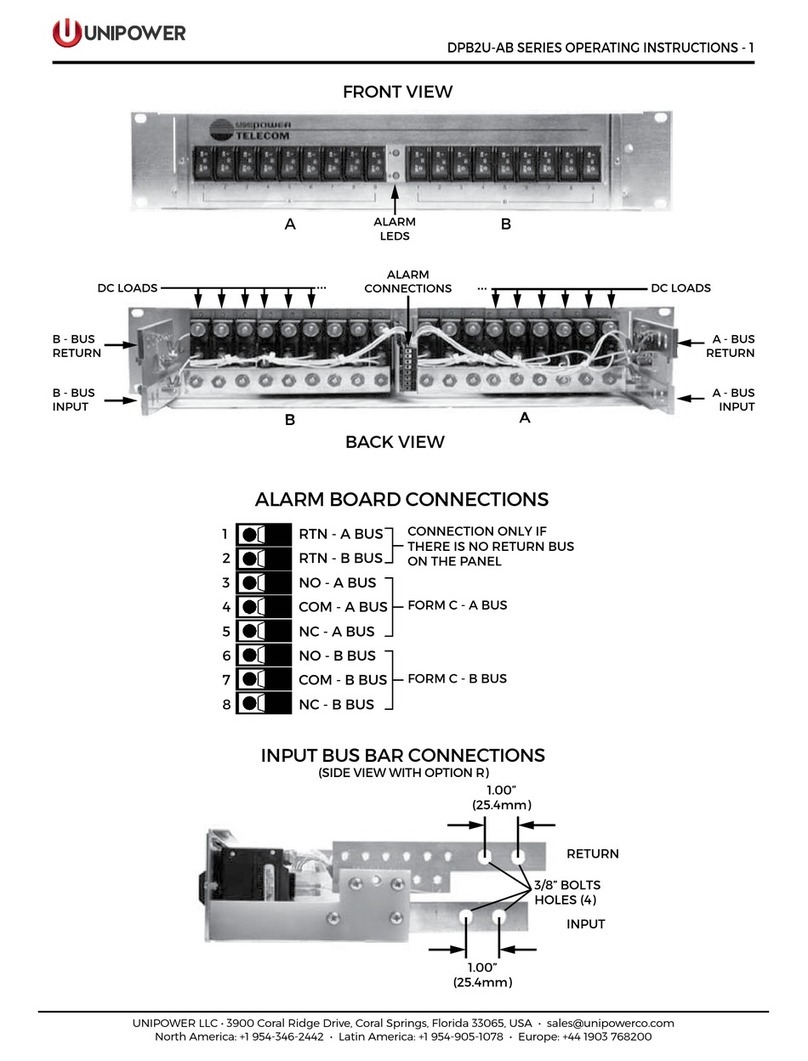

Unipower

Unipower DPB2U-AB SERIES operating instructions

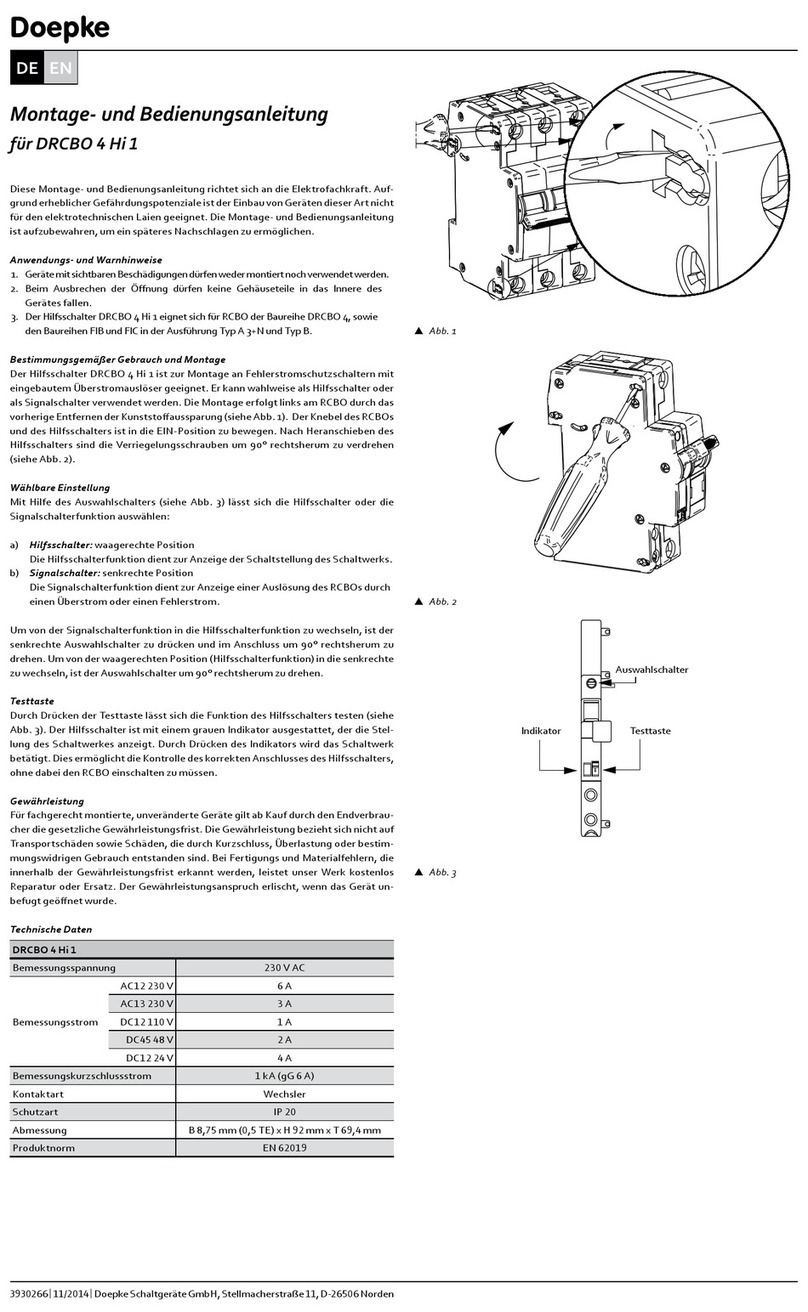

Doepke

Doepke DRCBO 4 Hi 1 Installation and operating manual

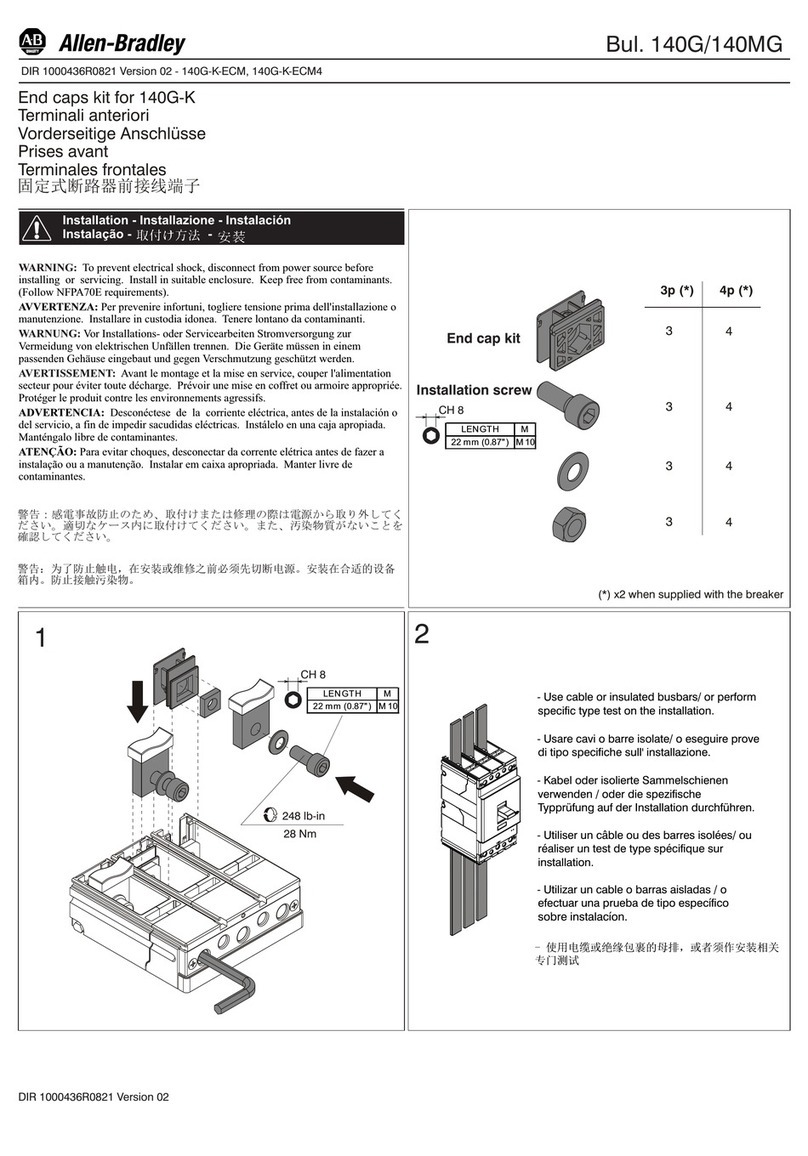

Allen-Bradley

Allen-Bradley 140G Series Installation