Drawout Breakers

5.1 GENERAL

Drawout breakersare manufactured in six different styles,

identified in Table2 bythemounting codelettersNone,

A,

8,

C,

D&

F.

The"no-letter"models areusedin GeneralElectri

e's

AKDSwitchgear. CodeAbreakerswerelaterintroducedwilti

AKD-5 Switchgear and feature closed-door drawout opera·

tion.Code

Band

Fbreakers provideanalternateclosed-door

drawout arrangement with the stationary element furnished

as a preassembled "substructure." Code C breakers are

exclusively

for

AKD-6 Switchgear; they employ the Code A

drawout mechanism but have finger-type primary studs in-

stead

of

tubular. Code D breakers were introduced wilti lhe

AKD-8 Switchgear and feature the Code 8 closed-door

drawoutmechanism.The construction andoperation of each

of these drawoutstyles is covered underrespectiveheadings

in the following text.

NOTE:

The

Code

Band

Code Fdrawout t)pesare

mutually interchangeable.

The

"

no

-letter

,"

Code

A.

Code C and Code D drawout types are mutually

noninterchangeable. Before attempting to insert a

breaker, verily that the breaker model matches the

compartment.

The Code

B,

D,and F breakers areidentical exceptfor lhe

following:

a. Position indication label.This label is mounted

on

the

sides of the breaker's deepescutcheonand indicates

the DISCONNECTED, TEST, and CONNECTED posi-

tions.The Code D breaker label ind

ic

ates the proper

position only inAKD 8 switchgear. The Code

Band

F

breakerIabels indicateproperly onlyinAKR

Su

bstru

c-

tures.

b.

Trip device. Code D and F breakers are factory sup-

plied with Micro-Versa

Tr

ip programmers. Code B

breakersaresupplied

with

SST

or

ECS programmers.

(A SST/ECS to

Mic

ro-Versa Trip conversion kit is

available).

c. Appearance. Code D and F breake

rs

use a different

color scheme on their deep escutcheons and labels.

Also,theyhavea differentlyshaped manual operating

hand

le

.

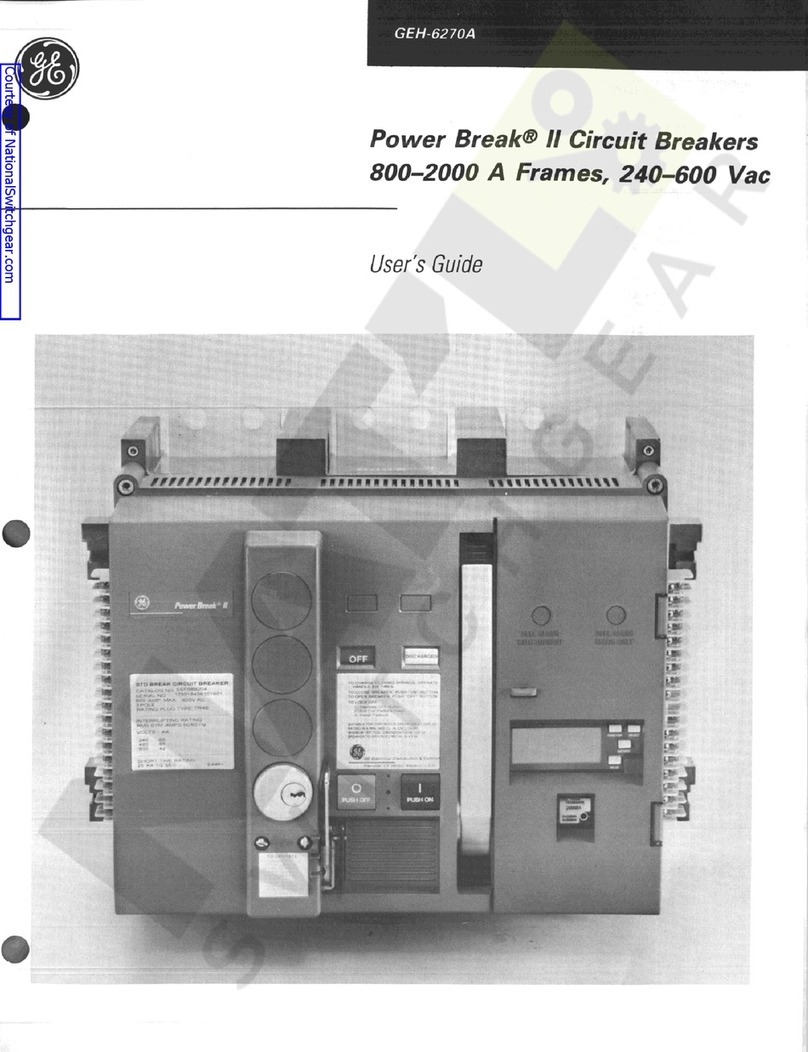

5.2

NO

CODE

LETTER (AKO SWITCHGEAR)

(Fig. 1)

These "no-letter" AKR-75/100 models are replacements

fortheir

AK

-75and AK-100 predecessors inAKD switchgear.

The

racking

mechanism

is

breaker-mounted

and

the

breakers are bolted

to

a roller-mounted tray in

an

arrange-

mentsimilarto the BType(see Section 5.4). Inaddition

to

the

characteristics

lis

ted in Table

1,

the

AKD

drawout has the

following unique aspects:

1. There are three (3) distinctdrawout positions-CON-

NECTED, TEST and WITHDRAWN.

2..

Racking travel occurs only between the CONNECTED

position and apointjustshort

of

reaching the TEST position.

3.

The compartment door must

be

open during racking.

5.2.1 BREAKER INSERTION

1. Prior to lifting a breakerto its intended compartment

location, observe the following precautions:

a.

Check the compartment

to

insure that

it

is free

of

foreign objects.

b. Verify that the breaker is the

correct

type

for

that

compartment.

c. Insure that the

breaker

is OPEN.

d.

Apply

a thin, fresh

coat

of

D50HD38 /ubricant to the

breaker

's primary disconnects.

e. Insure that the racking cams

on

the breaker are

correctly

posit

i

oned

for initial engagement with the

pins

in the compartment.

To

do

this, insertthe rack-

ing

handle

and

rotate

it

fully clockwise.

f.

If

a compartment contains a keylock,

it

will

not

ac-

cept

the AKA-75/100 replacement breakers as re-

ceived.

The

AKA

drawout mechanism differs from

that

of

its predecessor

AK

model, causing the

AKA

breaker to mechanically interfere with the keylock

during breaker insertion.

To

remedy this

it

will be

necessaryta relocate the keylock using

new

mount·

ing hardware included as a modification kit. So

al

-

tered, the compartment

accepts

both

AK

and

AKA

types.

2. Using a suitable lifting mechanism and spreader rig,

position lifting hooks at the cutout notches in the top wrap-

around frames

of

thebreaker. Exercise care to avoid damage

to the control wiring.

3. Open the compartment.door. Keeping the rollout tray

positioned insidethe compartment, raise the breaker above

the elevation of the tray.

4. Depressthetestpositionstoplever and pull thetrayall

the way out to its WITHDRAWN position.

5.

Lower the breaker over

!he

tray until

it

is about one-

half inch above the two dowel pins

on

the tray. Push the

breaker back into the compartment until the rear bottom

flange of the breaker rests against the guides behind the

dowel pins.

6.

Slowly lower and guide the breaker onto the tray so

the holes in the rear flange fit overthe two dowel pins. When

correctlypositioned

on

thedowelpins, the breaker's rear and

side bottom flanges will rest firmly

on

the

tray.

7.

Securethe breakerto the traybyinserting and tighten·

ing two-

-%

inch hex-headscrews into thefrontholes

of

itsside

flanges.

8.

If

the breakeris a manually operated type, push it into

the compartment until the TEST position stop engages,

preven

ti

ng

further travel. The breaker is now

in

the TEST

position.

6

Courtesy of NationalSwitchgear.com