4. Disassembly and Assembly Procedures

4.2 Assembly Procedures:

Take a interface board, LED driver board and some

cables, connect the LVDS cables to the connectors

of the interface board. Take the interface board close

to the power board, then connect the power board

with the interface board, connect the LED driver

board with the power board. Turn over the interface

board, LED driver board and locate them into the

hooks of the bracket chassis base. Use a Philips-

head screwdriver to tighten 4 screws for locking the

interface board and LED driver board.

(No.8~11 screw size=M3x7.5, Torque=7~8kgfxcm)

Take a AC board and a cable, connect the cable to

the AC board, then locate the AC board into the

bracket as the following picture shown.

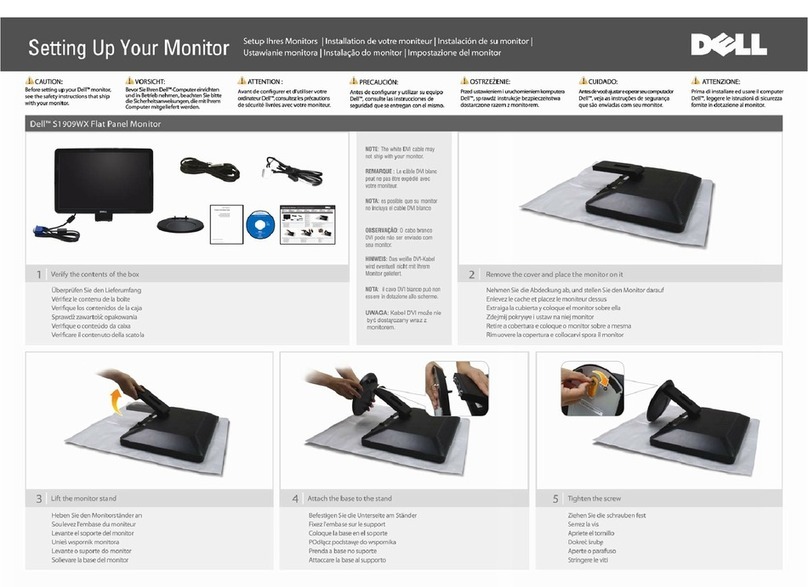

Place a bracket chassis base on a protective

cushion, then stick two Silicon sheets on the

positions as the picture below shown.

S2

Turn over the bracket chassis base. Connect cable

to the a Stand LED board, then locate the stand LED

board to the correct position. Use a

two screws for locking the

stand LED board. Use a

two screws for locking the AC power outlet.

Philips-head

screwdriver to tighten

Philips-head screwdriver to

tighten

(No.1~2 screw size=M3x4.5, Torque=7~8kgfxcm,

No.3~4 screw size=M3x10, Torque=6~8kgfxcm)

S5

13

S1

10

9

8

11

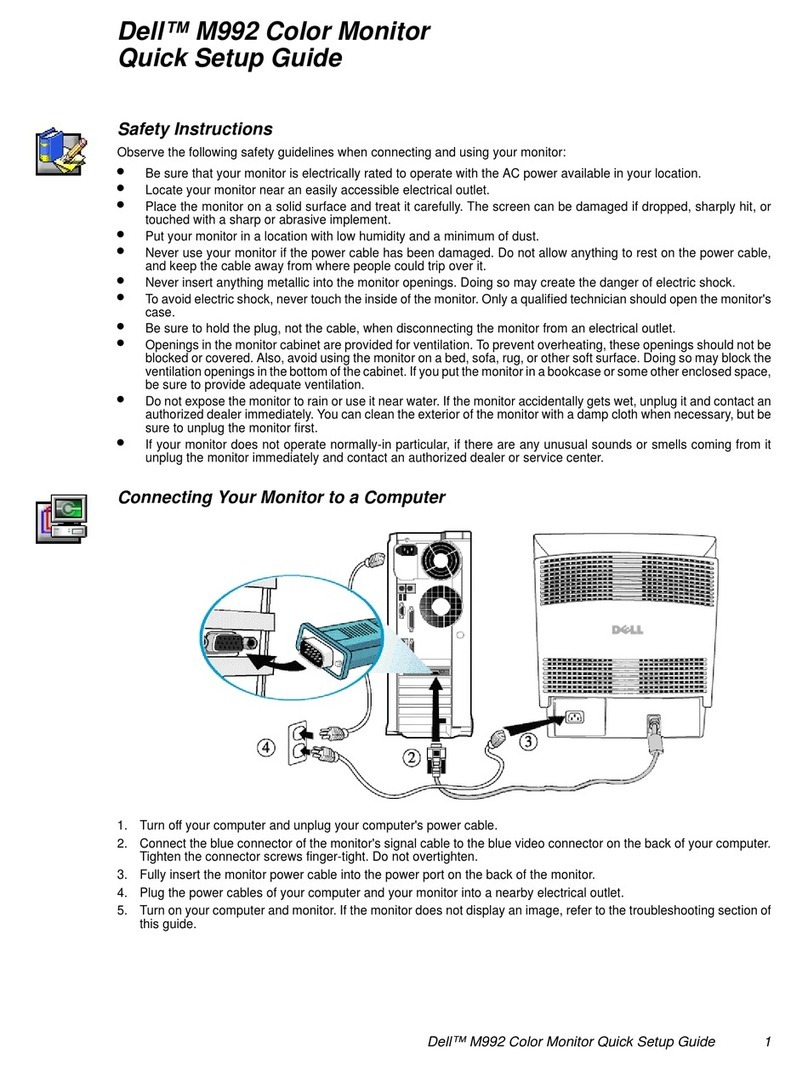

Take a power board, Connect the cable to the

it into

the correct position. Use a Philips-head screwdriver to

tighten 7 screws for locking the power board and AC

board, then Insert a piece of mylar tape to the hooks of

bracket to cover the power board.

power

board, then turn over the power board and locate

(No.1 screw size=M4x8, Torque=7~8kgfxcm;

No.2~7 screw size=M3x7.5, Torque=7~8kgfxcm;

S4

S3

1

6

24

7

5

3

1

2

3

4