Page 7

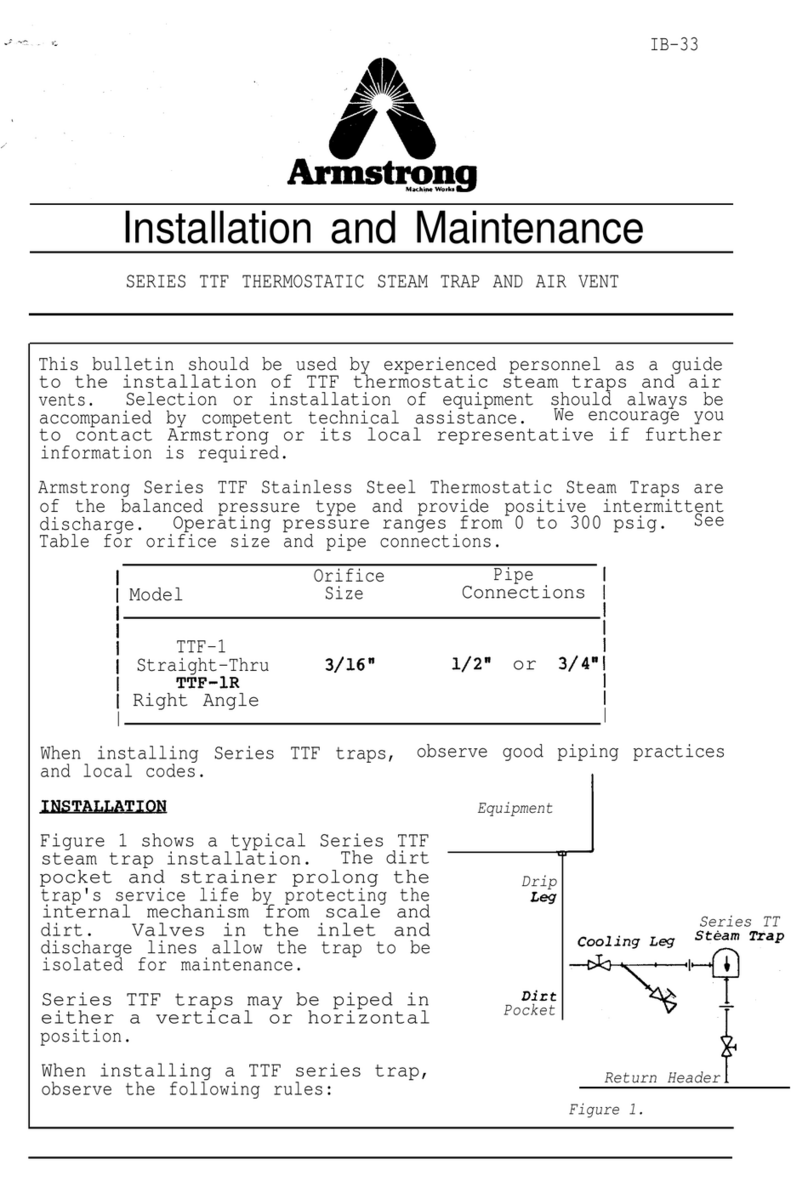

Measure the refractory thickness with a measuring

tape. Confirm that this distance matches the length

of the straight portion of the HRW Refractory Well as

shown.

(If the HRW well is too short, the thermocouple will

contact it during thermocouple insertion, causing it to

break. If the HRW well is too long, there is an

increased possibility of breakage due to thermal

shock)

If there is a discrepancy of more than

0.5in (12 mm) on the above

measurements, DO NOT install the

thermocouple until the discrepancy

is resolved. (see below)

Resolving Dimensional Problems.

Carefully measure the nozzle and refractory dimensions and compare them to the dimensions on the front cover of

this manual. Dimensional discrepancies are commonly caused by the following conditions:

1. Nozzle inner diameter is not as specified – If the nozzle I.D. is too small, the hard insulating rings will

not fit. These rings can be cut down to size. This is best done in a lathe with a tapered arbor to fit the center

hole. Use a dust collector when cutting these rings to avoid breathing the dust.

2. Nozzle height is not as specified – If the nozzle is too tall, the thermocouple will not extend all the way

into the vessel and may report erroneously low temperatures. If the nozzle is too short, the thermocouple

may contact the bottom of the refractory well causing it to break. (See Note “4”, below). Contact Delta

Controls to arrange for a thermocouple correctly sized for the installation.

3. Incorrectly specified thermocouple dimensions – The design intent is for the thermocouple element tip

to be positioned even with the refractory hot face, and for the HRW Refractory Well to extend approximately

1 inch (2.5 cm) past the refractory hot face. If these conditions are not met, the result may be inaccurate

measurement and/or breakage due to mechanical interference or thermal shock. Contact Delta Controls

to arrange for a thermocouple that is correctly sized for the installation.

4. Refractory has entered the base of the nozzle –The top surface of the refractory should be even with

the inside surface of the vessel shell. If it is not, the HRW Refractory Well will not rest at the proper position

and may cause it to be broken when the thermocouple is inserted into the nozzle. If there is refractory

material inside the base of the nozzle, it must be removed to restore a flat surface that is even with the

inner surface of the vessel shell.

5. Refractory is not installed at the specified thickness – If the overall refractory is thicker than specified,

the thermocouple will not extend all the way into the vessel and may report erroneously low temperatures.

Thickness

Thickness

Note: The HRW Refractory Well is intended to

protrude approximately 1in (25 mm) beyond the