Delta-T Devices GP1 User manual

Irrigation Control

Using Soil Moisture Sensors

Quick Start Guide

Version2c

Delta-T Devices Ltd

© 2010 Delta-T Devices Ltd Page 2

Overview

Potential benefits of sensor control

Reduced water use

Compact plants

Fewer weeds

Reduced labour for watering, pruning and weeding

Plants are less soft so establish more reliably

More fruit and flowers, less vegetative growth

Irrigation Timer

GP1

Solenoid

Valve

Moisture

Content

Timer control

Sensor control

© 2010 Delta-T Devices Ltd Page 3

This guide explains how to adapt timer-based irrigation control systems to include

soil moisture sensing using the

GP1

irrigation monitor and

SM300

soil moisture

sensor. The instructions are particularly directed at container-grown plants, but can

be applied to other shallow-rooting crops in free-draining compost or soil.

System Requirements

Check through this list carefully to make sure your system is

compatible:

Overhead or drip irrigation

- Capillary, sand bed or flood and drain systems switch off too slowly for

accurate moisture control

Reasonably uniform irrigation system

- The Coefficient of Uniformity (CU) should be > 80% for you to get the most

benefit from the system (otherwise you will have to routinely over-water to

prevent the less irrigated plants from drying out).

Plant pots, grow bags, mineral wool slabs etc. > 0.8 litre volume

- The SM300 can be set to control

irrigation in smaller pots but it may

be difficult to insert with sufficient

distance (~2cm) from the edge of

the pot.

The timer-based irrigation system

controls irrigation by solenoid

valves

- The relay cannot be used for direct

pump control

If you plan to control irrigation for a

mixed bed, the plants must have

similar water requirements.

© 2010 Delta-T Devices Ltd Page 4

Preparation

You need to assemble the following equipment:

Item

Accessories / notes

GP1

Mounting kit (GP1-MP1)

Serial cable, small screwdriver and PC software on

CD (included with GP1)

SM300

Logger cable (SMSC/sw-05)

Extension cables may be required (see section 1.1)

Note that the SM300 includes a built-in temperature

sensor but this can only provide soil / substrate

temperature readings when the SM300 is fully buried.

Cable to solenoid

Round cross-section 2-core wire

3-way

connector

block

You will need to put the connector block into a

sealed box if connecting to the solenoid valve in a

wet area.

Tape and/or cable ties

For keeping wires tidy and preventing accidents.

These may also be helpful:

SM300 + HH2

Useful for checking range of moisture contents

during set up and adjustment. Note that the HH2

does not display readings from the SM300 temperature

sensor.

You will also need access to the following:

Tools

Wire cutters & wire strippers…

An electrical multi-meter with audible short circuit

warning is also very useful.

Ladder

If some of the wiring will run overhead.

Portable computer

with Windows 98, XP,

Vista or 7

For configuring the GP1.

It is even more convenient to do this with an iPAQ

(see section 7), but check for compatibility.

© 2010 Delta-T Devices Ltd Page 5

Installation

1Install the SM300

1.1 Plan cable runs

Locate the solenoid valve that controls the bed irrigation.

Plan where to splice into the cable to the valve, and then

consider where it makes sense to mount the GP1.

Depending on available extension cables, this will then

determine the general location for the SM300.

1.2 Choose a location for the SM300

If there’s more than one type of plant within the bed,

choose a variety that uses more water.

Choose a representative plant i.e.

- Not in the outside row

- Moderate growth

- Foliage won’t shed water unduly

- No voids in the growing media

Check the water content of potential control plants using an SM300 and HH2 if

available, otherwise by lifting the pots or feeling the compost. Avoid plants that

appear to be unusually dry or wet.

1.3 Insert SM300 into pot / soil

Screw the cable onto the sensor (attach the extension cable first if you are using

one, otherwise directly attach the logger cable which terminates in bare wires).

Make sure the connectors halves are clean and aligned before pushing together,

then push them fully home and tighten to maintain the seal.

Insert the SM300 into the pot as close to the centre as

reasonably possible –see illustration above. Once inserted,

don’t joggle the sensor as this will create air gaps around the

measurement rods. You may find it useful to tape the cable to

the side of the pot.

Refer to the SM300 Quick Start Guide for more detail:

© 2010 Delta-T Devices Ltd Page 6

2Connect the GP1

2.1. Mount GP1 on post

Open the GP1 cover and attach to the

mounting plate using the 4 screws provided.

Then fix the mounting plate to a suitable post

either using cable ties, tape or U-bolts

(provided).

2.2. Connect cables to GP1

Pass the cable from the SM300 through the cable gland and connect to Channel 1

as shown (order for channel 1 is red, grey, white, black, green and blue):

Connect the cable for controlling the solenoid valve to the relay as shown (note the

colours of your cable will likely be different but the orientation of the connection is

unimportant). Don’t connect the other end to the solenoid valve at this stage.

Tighten the cable glands, replace the GP1 cover, secure all cables to the post and

tape carefully over any cable runs in walkways.

Refer to the GP1 Quick Start Guide if you want to connect the

SM300 temperature sensor or need more detailed instructions.

© 2010 Delta-T Devices Ltd Page 7

3Configure the GP1

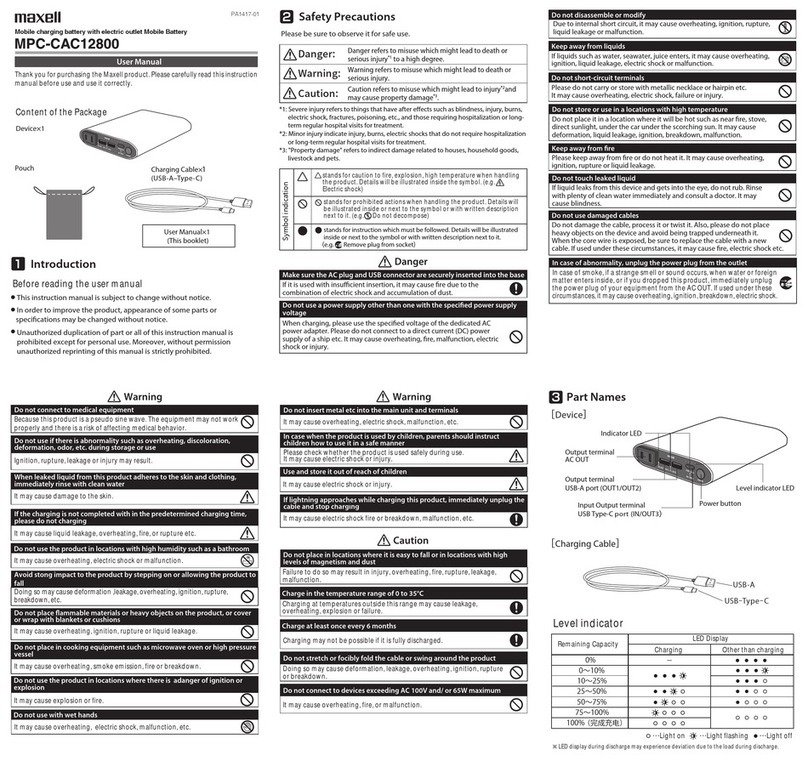

3.1. Connect laptop to GP1

These instructions assume you’ve already fully installed the DeltaLINK software - if

not, you should refer to the GP1 Quick Start Guide.

Connect your laptop to the GP1. Start DeltaLINK and select File, New,

Program….From the list choose Standard GP1 Program.

3.2. Set up the GP1 recording program

Double-click and select the

SM300 sensor type for

Channel 1. In this example the

SM300 moisture reading has

been labelled “Moisture1”.

Select Organic for the Soil

type unless you are using

John Innes compost.

Click on other channels if you

have more sensors to connect.

Set the recording interval.

Note: this also sets how often

the GP1 checks whether to

turn the irrigation ON.

© 2010 Delta-T Devices Ltd Page 8

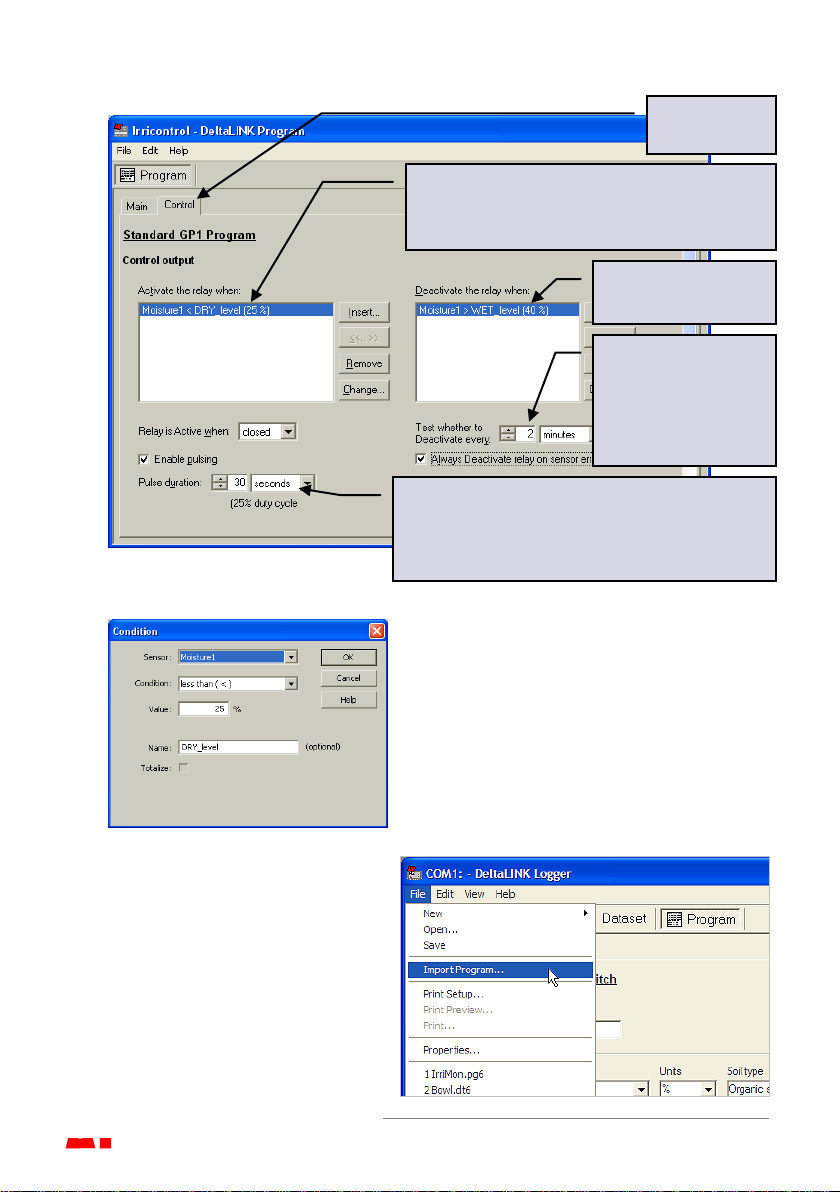

3.3. Set moisture control levels and pulse irrigation

3.4. Adjustable thresholds

When setting the control conditions, it is

useful to give a name to the threshold level

(“DRY_level” in this example). You will then

be able to adjust the thresholds later without

starting and stopping the program (this

feature requires DeltaLINK version 2.4 or

later).

3.5. Configure the GP1

Save the program and close the

program editor.

In the main DeltaLINK window,

select the Program view and click

on the Change button.

Select File, Import Program…,

and select the program file (.pg6)

that you have just saved.

Switch to the

Control tab.

Click on Insert... and select Moisture1 to

control irrigation ON with an appropriate

moisture threshold (see next section, 3.4).

Set the OFF

conditions similarly.

Set the GP1 to

check the OFF

conditions more

often than the

recording rate.

If Duty cycle < 100% the GP1 will pulse the

irrigation so that the compost has time to wet

up. In this example the irrigation would be

pulsed ON for 30 seconds every 2 minutes.

© 2010 Delta-T Devices Ltd Page 9

4Check the system

4.1. Check the SM300 readings and relay operation

In the main DeltaLINK window, select the Sensor view. Click on Read now and

check that the SM300 is giving sensible readings.

By withdrawing and re-inserting the SM300 partially from the soil/compost you can

simulate drying/wetting and check the relay operation as in this (rather artificial)

example.

Note: you should be able to hear the GP1 relay switching, but it may be

convenient to attach a multi-meter to the end of the control cable, so that you can

check the switching remotely.

When finished, click on Cancel to stop the readings, and if you have been

checking the readings by withdrawing the SM300, re-insert it in a new hole.

Moisture level () falls below set

level (25%), ON condition () is

triggered, and control relay ()

switches on.

Moisture level rises above 25%,

so ON condition is no longer

met, but irrigation will continue

until OFF condition is met.

Moisture level rises above 40%,

OFF condition () is met and

control relay () switches off.

© 2010 Delta-T Devices Ltd Page 10

5Connect the solenoid valve and start irrigation

5.1. Connect the solenoid valve

Turn off irrigation to the bed. Cut the cable from the irrigation timer to the solenoid

valve and splice in the cable from the GP1 control relay using the connector block

as shown below. You will need to mount the block in a small waterproof enclosure

if the connection is likely to get wet.

Note: cable colours are likely to be different from this illustration.

5.2. Adjust the irrigation timer

Adjust your irrigation timer to water for longer periods.

The SM300 and GP1 will prevent your irrigation system from over-watering, so you

can safely increase the irrigation times. The sensor control will attempt to switch

the irrigation ON soon after the moisture level falls below the lower threshold

(depending on the time set in the recording rate) so it is important that the timer

allows irrigation to start within a reasonable time.

If you are watering by drip irrigation you may want to adjust the timer to irrigate

continuously throughout the day, leaving all the control to the SM300 and GP1.

5.3. Start irrigation control

Connect your laptop to the GP1, start DeltaLINK, and in the main Logger view

click on Start.

Turn on your irrigation system.

Your irrigation system is now under sensor control

© 2010 Delta-T Devices Ltd Page 11

6Adjust the settings

6.1. Check recorded

data

Connect your laptop to

the GP1, start

DeltaLINK and select

Dataset. The GP1 will

automatically download

the stored data and

display the soil moisture

readings as a graph

(this example shows a

GP1 with 2 SM300s

and a temperature

sensor):

To save the data, select File, Save and enter a name for your data.

6.2. Adjust irrigation levels

If you want to adjust an

irrigation control level, in the

main Logger view click on

Change... and adjust the

threshold value in the

Program setting window that

opens up. Click OK to apply

the change.

7Pocket DeltaLINK

The GP1 can also be configured using the Pocket PC

version of DeltaLINK. This provides exactly the same

facilities for programming the logger and examining the

stored readings, but is even more convenient for field use.

Pocket DeltaLINK requires a pda running Pocket PC

version 4.2 or later and an RS232 serial port for

connection to the GP1.

Notes

Battery use: the GP1 battery can be changed quickly without losing program settings

or data, but no readings will be taken and no control of irrigation will occur while the

battery is removed.

A standard PP3 alkaline battery will power the GP1 and SM300 for more than 4 months

when recording at 30 minute intervals. Check the battery voltage from time to time in

DeltaLINK and replace when below 6 Volts. See the GP1 Quick Start Guide for

further detail.

Sealing: the SM300, GP1 and all connectors are sealed to an appropriate standard,

but to maintain this sealing you should:

Take care when attaching cables to ensure that the connectors are clean,

undamaged and properly aligned before pushing the parts together. Screw

together firmly to ensure the connection is water-tight.

Ensure that all cable glands and cover screws are fully tightened.

Where possible avoid placing the GP1 directly underneath irrigation nozzles.

Replace the GP1 desiccant bags annually.

Status LED: the GP1 LED flashes twice every 10 seconds when it is logging normally.

It will flash four times instead if it detects a problem.

Care and Safety

The rods of the SM300 are sharp in order to ease insertion. Take care and

follow handling precautions.

Avoid touching the rods or exposing them to other sources of static damage.

Keep the SM300 in its protective tube when not in use.

Do not pull the sensor out of the soil by its cable.

If you feel strong resistance when inserting the SM300 into soil, it is likely you

have encountered a stone or a root. Stop pushing and re-insert at a new

location.

Delta-T Devices Ltd

130 Low Road, Burwell

Cambridge CB25 0EJ

UK

This manual suits for next models

1

Table of contents

Other Delta-T Devices Accessories manuals