Table of contents

1Change logs...................................................................................................................2

2Important safety and grounding instructions..................................................................3

2.1 Safety and compliance........................................................................................3

2.2 Grounding instructions ........................................................................................3

3Before installation ..........................................................................................................4

3.1 Safety requirements ............................................................................................4

3.2 Recommended tools............................................................................................4

3.3 Important safety instructions ...............................................................................4

4Site preparation .............................................................................................................5

4.1 Power connection................................................................................................5

4.1.1 Circuit breaker rating and cable cross section......................................5

4.1.2 Required cable length...........................................................................6

4.2 LAN cabling.........................................................................................................7

4.3 Load-management connection............................................................................7

4.4 Load-management cabling..................................................................................7

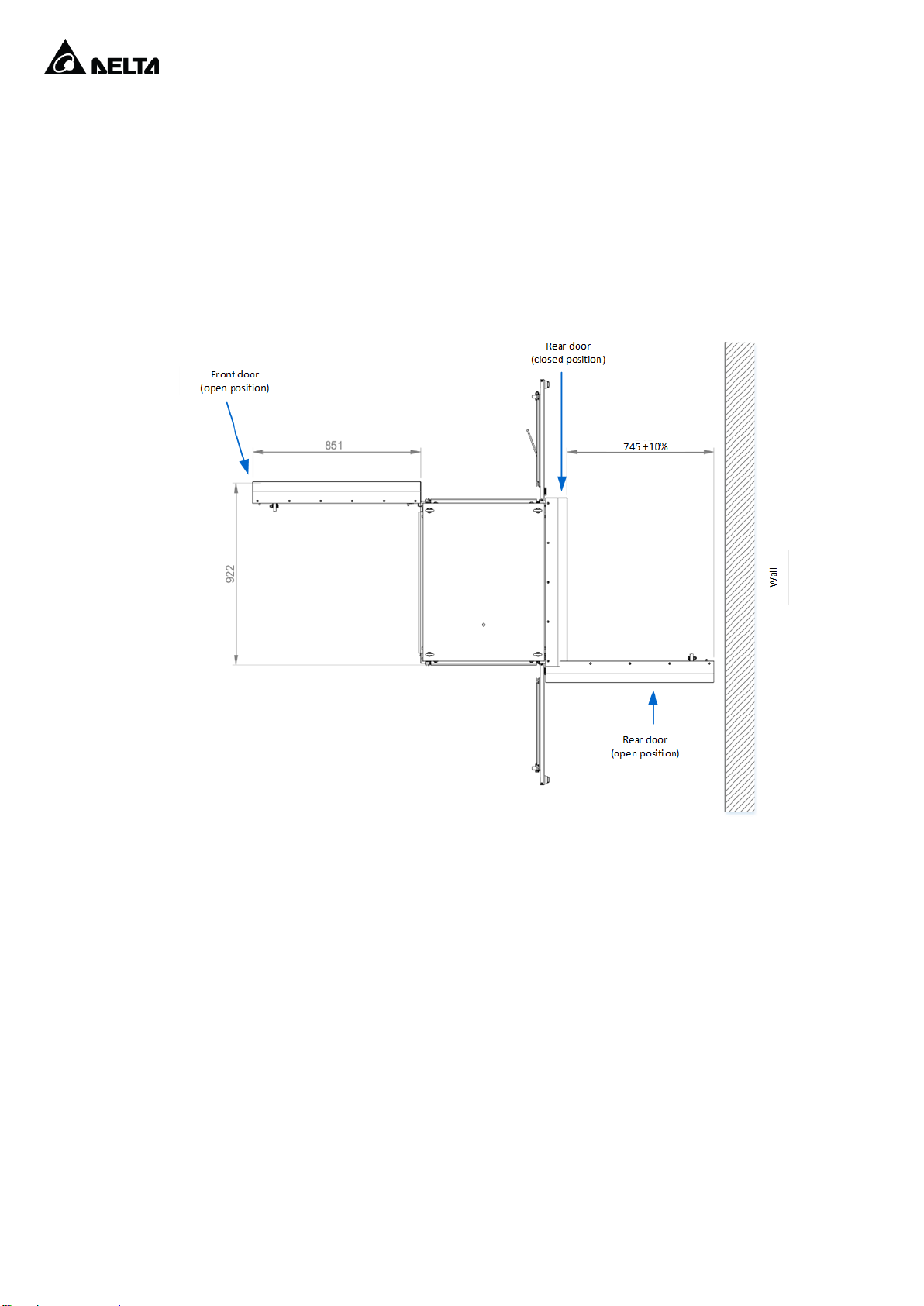

4.5 Required distances and dimensions ...................................................................8

4.5.1 Wall distance.........................................................................................8

4.5.2 Collision protection pole........................................................................9

4.5.3 Cable entry..........................................................................................10

5Preparing for the installation........................................................................................12

6Commissioning............................................................................................................17

7Load-management connection installation..................................................................18

8Application guidance lightning protection....................................................................21

9Network connection.....................................................................................................22

9.1 Sites with 1 EV Ultra Fast Charger....................................................................22

9.1.1 Ethernet connection............................................................................22

9.1.2 Wireless connection............................................................................23

9.2 Sites with more EV Ultra Fast Chargers............................................................24