EtherCAT Communication Card: CMM-EC02/ CMM-EC03

CMM-EC02/ CMM-EC03 Operation Manual

Table of Contents

1. Introduction................................................................................................................................6

1.1 Network Functions and Specifications.....................................................................................6

1.2 Product Appearance..................................................................................................................7

1.2.1 Panel Cut Out Dimensions..............................................................................................7

1.2.2 Components ....................................................................................................................7

1.3 LED Indicators .........................................................................................................................8

1.4 RJ45 PIN Definition.................................................................................................................8

1.5 Application ...............................................................................................................................8

1.5.1 Applicable firmware version and supporting mode........................................................8

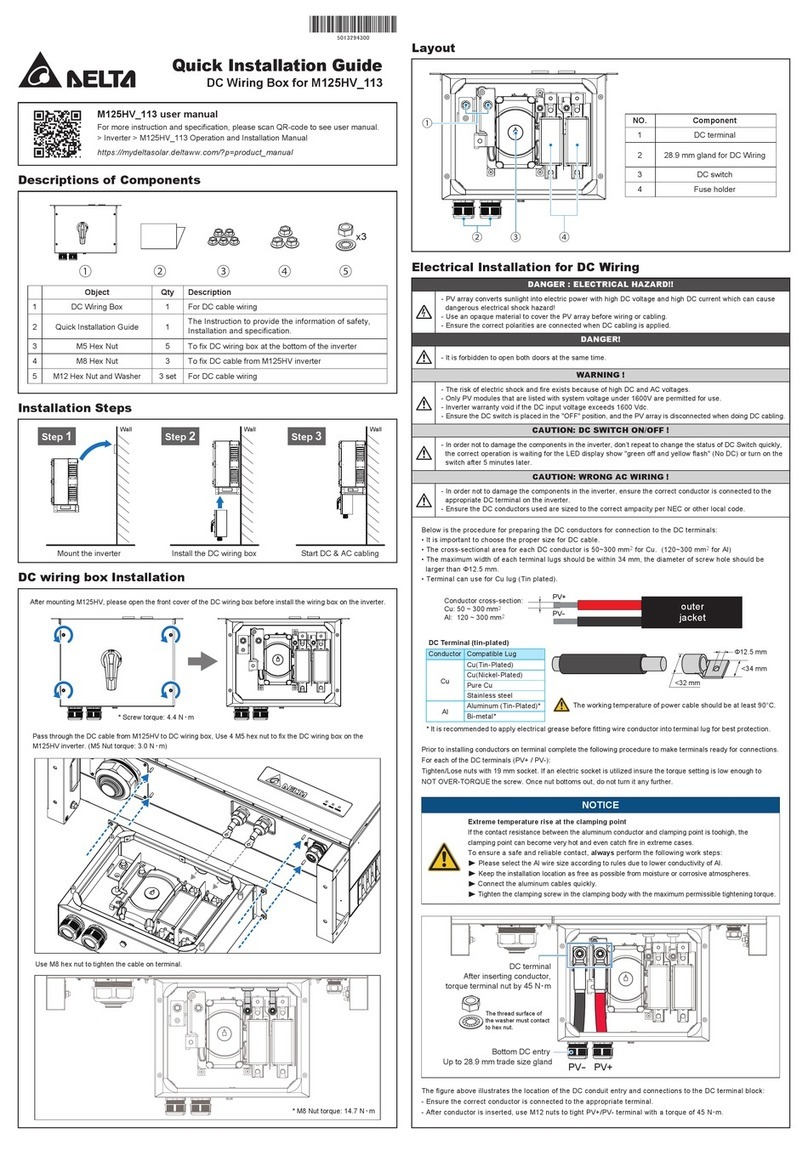

2. Installation and Wiring...............................................................................................................9

2.1 Mounting Position of Communication Card ............................................................................9

2.2 Install and Remove Option Cards ..........................................................................................10

2.2.1 Communication Cable and Grounding..........................................................................10

Communication Cable............................................................................................................10

Grounding............................................................................................................................... 11

2.2.2 MS300 Installation ........................................................................................................13

MS300 Mounting Position 1 (See Section 2.1 for Details on Mounting Position) Frame A-F13

2.2.3 MH300 Installation .......................................................................................................13

MH300 Mounting Position 1 (See Section 2.1 for Details) – Frame A – I ............................13

2.3 Network Connection .................................................................................................................17

2.4 MH300 / MS300 Drive Settings.............................................................................................17

2.5 ESI (EtherCAT Slave Information) ........................................................................................17

3. Introduction to EtherCAT.........................................................................................................18

3.1 Protocol ..................................................................................................................................18

3.2 EtherCAT State Machine........................................................................................................19

3.3 Dynamic Recognition ............................................................................................................20

4. System Setup ...........................................................................................................................21

4.1 Asynchronous.........................................................................................................................21

4.2 PDO mapping configuration ..................................................................................................22

4.2.1 Default PDO mapping configuration............................................................................22

4.2.2 Set PDO mapping .........................................................................................................23

5. CiA402 equipment regulation..................................................................................................24

5.1 CANopen over Ethernet (CoE) State Machine ......................................................................24

5.2 EtherCAT Operation Mode ....................................................................................................26

5.2.1 Velocity Mode...............................................................................................................26

6. Communication Warning / Fault Table....................................................................................28

6.1 Motor drive warning / fault table ...........................................................................................28

6.2 SDO Abort Code ....................................................................................................................29