Table of Contents

Chapter 1 : Guide for Safe Operation....................................................................................5

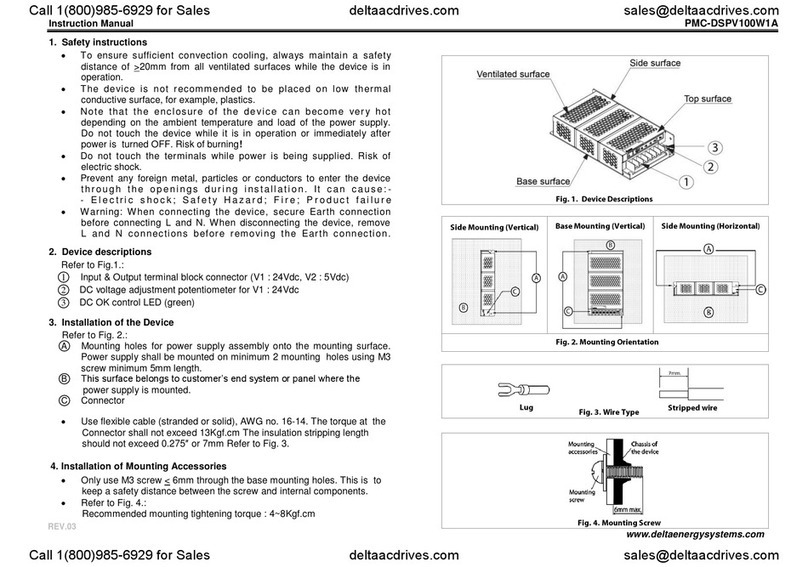

1.1 Safety Instructions ..................................................................................................5

1.1.1 Installation Instructions ................................................................................6

1.1.2 Instructions for Use ......................................................................................6

1.2 Nameplate Information............................................................................................7

1.3 Product Introduction ................................................................................................8

1.4 Functions & Features ..............................................................................................8

1.5 Dimensions ...........................................................................................................10

1.6 Design Capacities .................................................................................................11

Chapter 2 : Introduction .......................................................................................................12

2.1 Packing List...........................................................................................................12

2.2 Optional Accessories ............................................................................................14

2.3 Appearance...........................................................................................................14

2.4 Component Identification ......................................................................................15

2.5 Piping System .......................................................................................................17

Chapter 3 : Installation.........................................................................................................18

3.1 Installation Site......................................................................................................18

3.2 Space Reservation................................................................................................19

3.3 Handling ................................................................................................................20

3.4 Positioning.............................................................................................................21

3.4.1 Remove the Rack Door Panel ...................................................................21

3.4.2 Install CoolDoor Connect Duct ..................................................................22

3.4.3 Hang CoolDoor on Connect Duct ..............................................................23

3.5 Holing ....................................................................................................................24

3.6 Piping Installation Size..........................................................................................25

3.7 External Piping ......................................................................................................26

3.8 CoolDoor Water Side Installation Components ....................................................27

3.8.1 CoolDoor Control Ball Valve (Standard Accessory)...................................27

3.8.2 Pressure Independent Control Valve (Optional Accessory).......................29

3.8.3 Leakage Cut Off Valve (Optional Accessory).............................................30

3.8.4 Flow Meter (Optional Accessory)...............................................................31