Deltec CADD-Prizm PCSII 6101 User manual

32

T

E

C

H

N

I

C

A

L

M

A

N

U

A

L

C

A

D

D

-

P

r

i

z

m

®

P

C

S

I

I

A

M

B

U

L

A

T

O

R

Y

I

N

F

U

S

I

O

N

P

U

M

P

MODEL 6101

Deltec

31

For detailed instructions, specifications, warnings, warranties and additional information on operat-

ing CADD®pumps, please refer to the Operator’s Manual supplied with the product. If you have

additional comments or questions concerning the operation of CADD®pumps, please call this num-

ber: (800) 426-2448. Our staff is available to help you 24 hours a day with the programming and

operation of CADD®pump infusion systems.

The issue date of this Technical Manual is included for the user’s information. In the event one year

has elapsed between the issue date and product use, the user should contact Deltec, Inc. to see if a

later revision of this manual is available.

Issue Date: July 2003

33

Table of Contents

1. Introduction ............................................. 1

Limited Warranty ........................................... 1

Exposure to Radiation or Magnetic Resonance

Imaging (MRI) ............................................... 1

2. CADD-Prizm®PCS II Pump ..................... 2

Delivery Modes .............................................. 2

Specifications (Nominal) ................................ 5

3. Batteries ................................................... 8

Battery Compatibility ..................................... 8

DURACELL®Alkaline Battery Life ................ 8

ULTRALIFE®Lithium Battery Life ................ 8

4. Construction .......................................... 10

5. Theory of Operation .............................. 11

Keyboard Circuitry ...................................... 11

Data Memory EEPROM .............................. 11

Battery Backed RAM ................................... 11

Time Base Circuitry ...................................... 11

LCD Circuitry .............................................. 11

LED Status Indicators .................................. 12

Flash PROM Technology ............................. 12

Gate Array Circuitry .................................... 12

Audible Alarm Circuitry ............................... 12

Watchdog Timer Circuit .............................. 12

Motor Driver/Motor Watchdog Circuit ....... 12

Power Circuitry ............................................ 13

Voltage Reference Circuit ............................. 13

Pumping Mechanism .................................... 13

Pumping Characteristics ............................... 14

Air Detector ................................................. 15

Upstream Occlusion Sensor .......................... 15

6. Safety Features and Fault Detection ....... 16

Hardware Safety Features ............................ 16

Watchdog Timer Circuit .............................. 16

Motor Driver/Motor Watchdog Circuit ....... 17

Cassette ‘Type’ Sensor Circuit ...................... 17

Latch/Lock Sensor Circuit ............................ 17

Voltage Detector Circuit .............................. 17

Software Safety Features .............................. 18

7. Hardware and Software Fault Detection .. 19

Overview ...................................................... 19

Order of Error Code Events ......................... 19

8. Cleaning and Inspection Procedures ....... 20

Inspection Recommendation ........................ 20

Cleaning ....................................................... 20

Visual Inspection .......................................... 20

Mechanical Inspection .................................. 21

9. Testing Procedures ................................. 22

Functional Testing ........................................ 22

Air Detector Test (if Applicable)................... 25

Occlusion Tests ............................................ 25

Accuracy Testing .......................................... 27

Cleaning and Functional Testing Checklist ... 30

1

1 Introduction

The Technical Manual is intended to provide

a basic, but limited, understanding of the me-

chanical and electrical operation of the Deltec

CADD-Prizm®PCS II Computerized Ambulatory

Drug Delivery pump to persons familiar with this

device. The CADD-Prizm®PCS II Operator’s

Manual should be used in conjunction with this

publication for complete information.

This manual also outlines cleaning and func-

tional testing procedures that can be performed

on the CADD-Prizm®PCS II pump.

This technical manual is applicable to the

CADD-Prizm®PCS II pump only.

IMPORTANT NOTICE:

CADD-Prizm®PCS II pump operations and

safety features are based on a microcomputer

design. Inadequate servicing or tampering with

the safety features of the pump may seriously

affect performance and safety.

For that reason, ALL SERVICING AND

REPAIR OF THE CADD-Prizm®PCS II

PUMP MUST BE PERFORMED BY DELTEC

OR ITS AUTHORIZED AGENTS.

The manufacturer’s warranty agreement shall

become null and void if the pump is not used

in accordance with the Operator’s Manual and

Instructions for Use for the pump accessories;

or, the pump is serviced by persons other than

Deltec or those authorized by Deltec.

Limited Warranty

The limited warranty associated with the

CADD-Prizm®PCS II pump can be found in the

product literature supplied with the product

when originally purchased, which is incorpo-

rated herein by reference. DELTEC SPECIFI-

CALLY DISCLAIMS ANY OTHER WAR-

RANTY, WHETHER EXPRESS, IMPLIED OR

STATUTORY, INCLUDING, WITHOUT

LIMITATION, ANY IMPLIED WARRANTY

OF MERCHANTABILITY OR FITNESS FOR

USE. Deltec further disclaims responsibility for

the suitability of the system for a particular

medical treatment or for any medical compli-

cations resulting from the use of the system.

The manufacturer shall not be responsible for

any incidental damages or consequential

damages to property, loss of profits, or loss of

use caused by any defect or malfunction of the

system.

If you wish to receive additional information

about the extent of the warranty on these prod-

ucts, please contact your Deltec representative or

call Customer Service at (800) 426-2448.

All recommendations, information and litera-

ture supplied by Deltec with respect to the

CADD®product line are believed to be accu-

rate and reliable, but do not constitute warran-

ties. No agent, representative, or employee of

Deltec has authority to bind Deltec to any

representation or warranty, expressed or

implied.

Exposure to Radiation or Magnetic

Resonance Imaging (MRI)

CAUTIONS:

(1) The pump SHOULD NOT BE

DIRECTLY IRRADIATED by therapeutic

levels of ionizing radiation because of the

risk of permanent damage to the pump’s

electronic circuitry. The best procedure to

follow is to remove the pump from the

patient during therapeutic radiation sessions

or diagnostic levels of radiographic and

fluoroscopic radiation. If the pump must

remain in the vicinity during a diagnostic or

therapy session, it should be shielded, and

its ability to function properly should be

confirmed following treatment.

(2) Magnetic fields produced by magnetic

resonance imaging (MRI) equipment may

adversely affect the operation of the pump.

Remove the pump from the patient during

MRI procedures and keep it at a safe

distance from magnetic energy.

2

2 CADD-Prizm

®

Pump

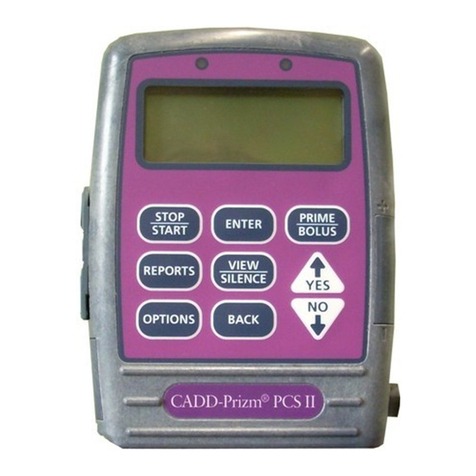

Figure 1. Front and back views of the CADD-Prizm®PCS II pump.

Rear View

Delivery Modes

The Deltec CADD-Prizm®PCS II pump

provides measured drug therapy to patients.

CADD-Prizm®PCS II pumps are indicated for

intravenous, intra-arterial, subcutaneous,

intraperitoneal, epidural space or subarachnoid

space infusion. Epidural administration is

limited to short-term infusion of anesthetics

and either long- or short-term infusion of

analgesics. Subarachnoid administration is

limited to short-term infusion of analgesics.

Upstream Occlusion Sensor

⁄¤‹

Œ„´

ÅÍÎ

hkj

CADD-Prizm

®

PCSII

Display

Power jack

Keypad

Data In/Out jack

Air Detector

Port Cover

Air Detector

(optional)

Indicator Lights

Amber Green

2000-03-07 D. Zurn

«Prizm Rear 3/4 (dark BW)»

Cassette

Polemount

Bracket Recess

Cassette lock

Cassette latch

Battery

compartment

Front View

3

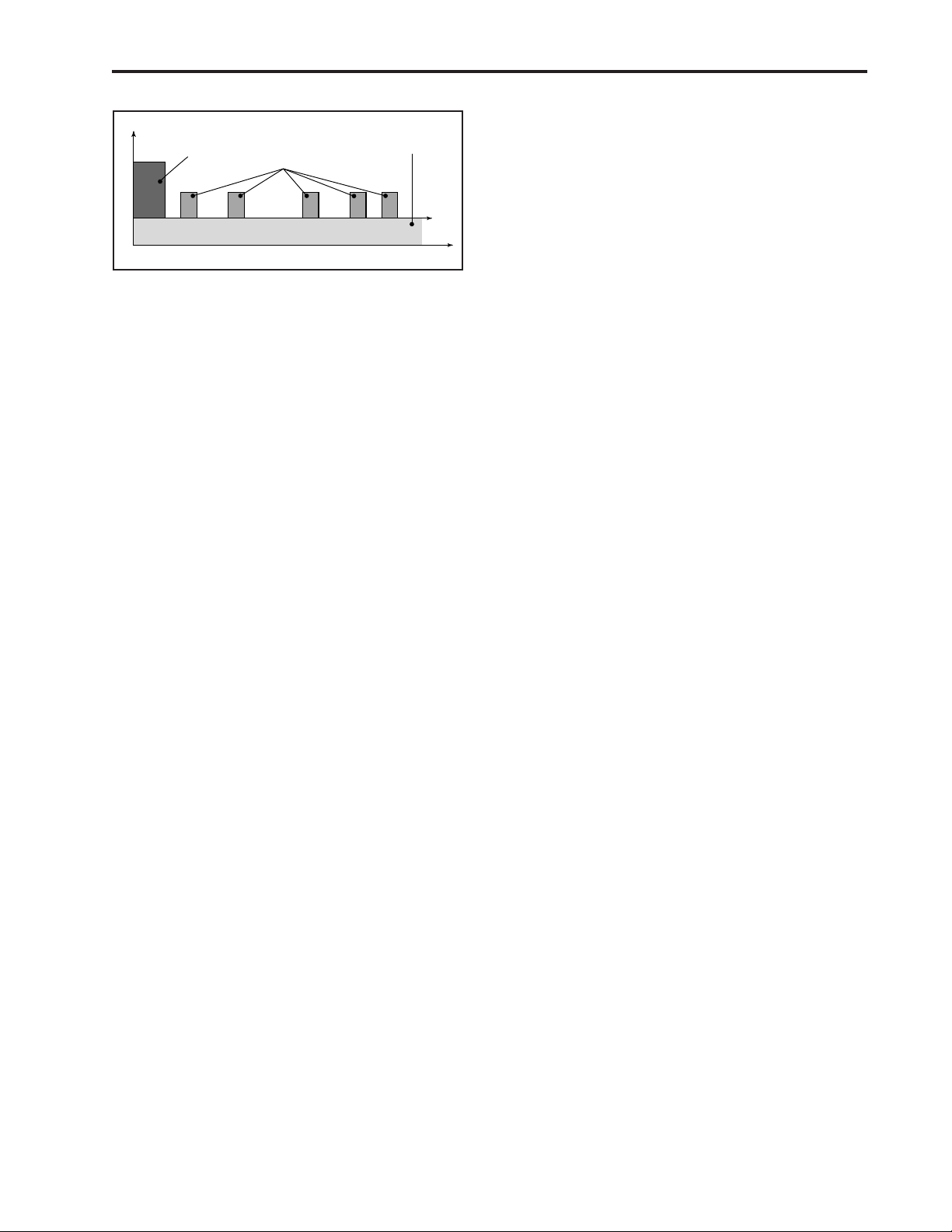

Figure 2. PCA mode delivery profile.

Clinician Bolus

(used here as a loading dose)

Demand Doses

Continuous Rate

Time

Dosage

PCA Delivery Profile

The PCA (patient-controlled analgesia) delivery

mode is used for therapies that require a

continuous rate of infusion, patient-controlled

demand doses or both, such as patient-

controlled analgesia.

4

Table 1. PCA delivery mode: continuous rate scroll ranges.

Units Starting Increment Maximum

Milliliters 0.10 0.10 30.00

Milligrams & 10% of Mg only: Values between 0.01 and 0.5: 0.01 Concentration

Micrograms concentration Mcg only: Values between 0.1 and 0.5: 0.1 x 30

Values between 0.5 and 100: 0.1

Values between 100 and 1000: 1.0

Values greater than 1000: 10.0

Continuous Rate Scroll Ranges

Concentration

mg/ml

Demand Dose

increment max.

Clinician Bolus

increment max.

Milligrams

0.1 0.01 0.99 0.01 2

0.2 0.02 1.98 0.02 4

0.3 0.03 2.97 0.03 6

0.4 0.04 3.96 0.04 8

0.5 0.05 4.95 0.05 10

10.05 9.9 0.05 20

20.10 19.8 0.10 40

30.15 29.7 0.15 60

40.20 39.6 0.20 80

50.25 49.5 0.25 100

60.30 59.4 0.30 120

70.35 69.3 0.35 140

80.40 79.2 0.40 160

90.45 89.1 0.45 180

10 0.50 99.0 0.50 200

11 0.55 108.9 0.55 220

12 0.60 118.8 0.60 240

13 0.65 128.7 0.65 260

14 0.70 138.6 0.70 280

15 0.75 148.5 0.75 300

20 1.00 198.0 1.00 400

25 1.25 247.5 1.25 500

30 1.50 297.0 1.50 600

35 1.75 346.5 1.75 700

40 2.00 396.0 2.00 800

45 2.25 445.5 2.25 900

50 2.50 495.0 2.50 1000

55 2.75 544.5 2.75 1100

60 3.00 594.0 3.00 1200

65 3.25 643.5 3.25 1300

70 3.50 693.0 3.50 1400

75 3.75 742.5 3.75 1500

80 4.00 792.0 4.00 1600

85 4.25 841.5 4.25 1700

90 4.50 891.0 4.50 1800

95 4.75 940.5 4.75 1900

100 5.00 990.0 5.00 2000

Table 3. Demand dose, clinician bolus scroll ranges, micrograms

Demand Dose Clinician Bolus

increment max. increment max.

0.05 9.9* 0.05 20

Milliliters

Table 4. PCA delivery mode: Demand dose, clinician

bolus scroll ranges, milliliters

*The maximum Demand Dose is 20 with software revision E or

higher.

Table 2. Demand dose, clinician bolus scroll ranges,

milligrams

Demand Dose

increment max.

Clinician Bolus

increment max.

Micrograms

Concentration

mcg/ml

10.05 9.9 0.05 20

20.10 19.8 0.10 40

30.15 29.7 0.15 60

40.20 39.6 0.20 80

50.25 49.5 0.25 100

60.30 59.4 0.30 120

70.35 69.3 0.35 140

80.40 79.2 0.40 160

90.45 89.1 0.45 180

10 0.50 99.0 0.50 200

11 0.55 108.9 0.55 220

12 0.60 118.8 0.60 240

13 0.65 128.7 0.65 260

14 0.70 138.6 0.70 280

15 0.75 148.5 0.75 300

20 1.00 198.0 1.00 400

25 1.25 247.5 1.25 500

30 1.50 297.0 1.50 600

35 1.75 346.5 1.75 700

40 2.00 396.0 2.00 800

45 2.25 445.5 2.25 900

50 2.50 495.0 2.50 1000

55 2.75 544.5 2.75 1100

60 3.00 594.0 3.00 1200

65 3.25 643.5 3.25 1300

70 3.50 693.0 3.50 1400

75 3.75 742.5 3.75 1500

80 4.00 792.0 4.00 1600

85 4.25 841.5 4.25 1700

90 4.50 891.0 4.50 1800

95 4.75 940.5 4.75 1900

100 5.00 990.0 5.00 2000

200 10.00 1980.0 10.00 4000

300 15.00 2970.0 15.00 6000

400 20.00 3960.0 20.00 8000

500 25.00 4950.0 25.00 10000

5

Specifications (Nominal)

General Pump Specifications

Resolution

Medication Cassette Reservoir or CADD®

Administration Set, 0.050 ml per pump

stroke nominal

Size

4.4 cm x 10.4 cm x 14.1 cm [1.7 in. x 4.1

in. x 5.6 in.] excluding cassette or other

accessories

Weight

568 g [20 oz.] including 9 volt battery and

empty 100 ml Medication Cassette Reser-

voir, excluding other accessories

Pump Alarms

Low battery power; depleted battery

power; external power source low, faulty,

depleted; pump stopped; pump fault; low

reservoir volume; high delivery pressure;

air in line; Air Detector faulty or detached

(only with the use of the optional Air

Detector); Air Detector Port Cover de-

tached; delivery too slow; key stuck;

cassette detached or unlocked; print fail-

ure, epidural cassette not used.

Bolus Volume at Occlusion Alarm Pressure

0.050 ml resolution administration sets/

Medication Cassette Reservoirs: <0.25 ml

Power Sources

9 volt alkaline or lithium battery such as

DURACELL®Alkaline MN 1604 or

ULTRALIFE®Lithium U9VL; CADD®

External Power Source (EPS) Power Pack

reorder number 21-3801; AC Adapter.

The expected life of a 9 volt battery is 12

hours at 100 ml/hour, or approximately 5

days at 10 ml/day (nominal). This estimate

is based on laboratory tests conducted at

room temperature using a new battery.

Actual battery life will vary depending on

the brand of battery, shelf life, temperature

conditions, delivery rate, and frequency of

screen display, backlighting and printing. It

is recommended that a new 9 volt battery be

kept available for replacement if necessary.

An internal battery powers the clock.

When it is depleted, it cannot reliably

* If programmed to be part of pump programming screens in Biomed Toolbox.

maintain the clock time. This battery must

be replaced by the manufacturer. The

internal battery has an expected life of 5

years.

System Operating Temperature

+2°C to 40°C (36°F to 104°F)

System Storage Temperature

-20°C to 60°C (-4°F to 140°F)

Power Pack Charging Temperature

+10°C to 35°C (50°F to 95°F)

System DeliveryAccuracy

±6% (nominal)

System Definition

System is defined as a CADD-Prizm®pump

with an attached Medication Cassette

Reservoir and CADD®Extension Set with

integral anti-siphon valve, or an attached

CADD®Administration Set with integral

or add-on anti-siphon valve.

Delivery Specifications

Reservoir Volume

1 to 9999 or Not In Use; programmable in

1 ml increments, displayed in 0.1 ml

increments.

Default: 1 ml

Units*

Milliliters (ml), milligrams (mg), micro-

grams (mcg).

Default: milligrams

Concentration

Mg/ml:

0.1 to 0.5 mg/ml in increments of 0.1

1 to 15 mg/ml in increments of 1 mg/ml

20 to 100 mg/ml in increments of 5 mg/ml

Default: 100 mg/ml

Mcg/ml:

1 to 15 mcg/ml in increments of 1 mcg/ml

15 to 95 mcg/ml in increments of 5 mcg/ml

100 to 500 mcg/ml in increments of 100

mcg/ml. Default: 500 mcg/ml

Continuous Rate

0to30 ml/hr (or the mg or mcg equivalent).

Default: 0 mg/hr (See Table 1 for Scroll

ranges)

6

Demand Dose

0 to 9.9 ml*

Delivery rate (Continuous Rate + Demand

Dose): programmable from 40 to 125 ml/hr.

Default: 0 ml (See Table 2, 3 & 4 for Scroll

ranges)

*The Maximum Demand Dose is 20 with

software revision E or higher.

Demand Dose Lockout

5 minutes to 24 hours in the following

increments:

•1minute for values between 1 and 20

minutes

•5minutes between 20 minutes and 24

hours

Default: 5 min

Set Delivery Limit

0.5 ml to 1000 ml (or the mg or mcg

equivalent), or “No Limit”:

0.01 from 0.01 to 0.1

0.1 from 0.1 to 100

1.0 from 100 to 1000

10.0 from 1000 to 10000

100.0 from 10000 to 100000

1000.0 from 100000 and up

Default: 0.5 ml or mcg or mg equivalent

Given

0 to 99999.99 in 0.01 unit increments.

Clinician Bolus

0.1 ml to 20.00 ml (or mg or mcg equivalent)

Delivery rate (Continuous Rate + Clinician

Bolus): 125 ml/hr nominal (See tables 2, 3

& 4 for Scroll ranges)

High Pressure Alarm

18 ±9 psi [1.24 ±0.62 bar]

Air Detector Alarm

Single bubble greater than 0.100 ml

Options Specifications

Lock Level

LL0, LL1, LL2. Default: LL2

Epidural Mode

On or Off. Default: Off

Units*

Milliliters (ml), milligrams (mg), micro-

grams (mcg).

Default: milligrams

Time

00:00 to 23:59

Air Detector

Turned On or Turned Off. Default: On

Biomed Toolbox Specifications

Custom Concentrations

All individual mg or mcg concentration

settings may be enabled or disabled (at

least one concentration must be enabled).

Default: All On

Program Limits*

Maximum program limits may be pro-

grammed for Demand Dose, Continuous

Rate, and Clinician Bolus.

Default: maximum program limits.

Dosing Limit*

Delivery Limit, a Maximum Doses per

Hour, or neither. Default: Neither

Key Beeps

On or Off. Default: On

Res Vol Trip Point

1 to 999 ml in increments of 1 ml, or

“Standard.” Default: Standard

Res Vol Empty Alarm*

Single or Insistent alarm. Default: Single

Pump Stopped Alarm*

Beep or Two-tone alarm. Default: Beep

AutoLock

Not In Use, LL1 Key/Code, LL2 Key/Code,

LL1 No Key or LL2 No Key. Default: Not

In Use

PM (Preventive Maintenance) Reminder

1 to 24 months in 1 month increments, or

“Not In Use.” Default: Not In Use

Custom Lock Level Code

001 to 899 (excluding preset code) in

increments of 1. Default: 061

Units Selection*

Program units to appear in the Program-

ming Units screens. Default: All Program-

ming Units

Units Location

Options, Program or Biomed Toolbox.

Default: Programming screens

* If programmed to be part of Options settings in the Biomed Toolbox.

7

Defaulting the Lock Level Code & Clinician

Bolus Code

The standard Lock Level Code (061) can be

changed to a customized code using the

Biomed Toolbox Custom Lock Code feature.

See the Operator’s Manual supplied with the

pump for instructions on customizing the Lock

Level Code. If it becomes necessary to change a

customized code back to the standard Lock

Level Code, do the following:

1. Press the OPTIONS key until the Lock Level

screen appears.

2. Press the ENTER key twice.

3. Scroll to 911.

4. Press the OPTIONS key.

Compatible Reservoirs and

Administration Sets

•50-ml or 100-ml Medication Cassette reser-

voir, used with the CADD®extension set

with anti-siphon valve.

•CADD®administration set with integral

anti-siphon valve, with or without bag spike

(allows use of flexible plastic bag or sterile

vial with injector)

•CADD®administration set with add on anti-

siphon valve and bag spike (allows for

gravity priming before attaching the add on

anti-siphon valve)

Remote Dose Cord

Deltec provides a Remote Dose Cord for the

PCA delivery mode. The push button switch is

a Single Pole Double Throw (SPDT). When the

Remote Dose Cord is attached to the pump,

the patient may press the Remote Dose button

to receive a Demand Dose. The clinician may

use the Remote Dose button to deliver a

clinician bolus. For easy access, the Remote

Dose cord may be fastened to the patient’s

clothing or bedsheet with the attached clip.

NOTE:

To detach the Remote Dose cord from the

pump, grasp the Remote Dose cord

connector and pull back using a straight,

steady motion. Do not twist or turn the

connector, or use any instrument to remove it.

For additional specifications refer to the

Operator’s Manual provided with the product.

Date Format

US Standard (mm/dd/yy) or European

Standard (dd/mm/yy). Default: U.S. Standard

Custom Main Display

Display:

•Res Vol or Continuous Rate

•Power Source Always or Low 9 volt

battery only

Default: Res Vol and Low 9V

Auto Review*

Select the automatic program review feature

during the pump’s power-up sequence.

Default: On

•Dose Counters (0 to 999 Given and/or

Attempted). Default: On

•Given. Default: On

•Doses Hour By Hour (up to 48 hours in

increments of 1 hour). Default: Off

•Patient Review. Default: Off

• Pain Scale (subjective pain scale rating of

0 to 10 in increments of 1). Default: On

•Pain Scale Log (0 to 500 entries).

Default: On

•Delivery Log (0 to 500 events). Default: Off

•Event Log (0 to 500 events). Default: Off

•New Patient Marker. Default: On

New Patient Marker*

Reports/No Clear, Power-up/No Clear,

Reports/Clear, Power-up/Clear

Default: Reports/No Clear

Air Detector Required

Required or Not Required. Default: Not

Required

Note: The CADD-DIPLOMAT®PC Communications System batch programming mode

must be used to change a customized code back to the standard lock level code with

CADD-Prizm®PCS II pumps with software revision E or higher.

8

Battery Compatibility

Recommended Batteries

Nine-volt alkaline or lithium batteries are

recommended for use in the CADD-Prizm®

pump. Carbon-zinc, mercury, nickel-cadmium,

or zinc-air 9-volt batteries should not be used.

Battery Life

The CADD-Prizm®pump has been designed to

provide optimal battery life. The expected

battery life in the CADD-Prizm®pump depends

on the following factors:

•Programmed delivery rate

•Operating temperatures

•Frequency of display backlighting

•Frequency of printing

•Battery type and brand

•Battery age

DURACELL®Alkaline Battery Life

The following tables may be used to predict

typical alkaline battery life at different delivery

rates when an alkaline battery is used in the

CADD-Prizm®pump. As expected, battery life

decreases as the delivery rate increases. These

tables are based on laboratory tests using fresh

DURACELL®alkaline batteries in CADD-Prizm®

pumps while the pumps were operating at room

temperature.

Actual battery life may be significantly shorter

depending on the operating temperature and

the storage conditions of the battery.

Battery life is shortened significantly at very

low operating temperatures. For example, at

0°C (32°F), an alkaline battery will yield

approximately 30% of its normal capacity.

Alkaline batteries do not need to be stored in a

refrigerator. After four years of storage at 21°C

3Batteries

(70°F), an alkaline battery retains approxi-

mately 86% of its original capacity. Battery life

will be shorter if the battery is stored above

room temperature. An alkaline battery stored at

43°C (110°F) will be down to approximately

80% of its capacity within one year.

Recommended storage conditions are 10°C to

25°C (50°F to 77°F) with no more than 65%

relative humidity noncondensing.

The following tables are based on laboratory

tests conducted at room temperature using fresh

DURACELL®alkaline batteries and a CADD®

administration set. Actual battery life will vary

depending on the brand of battery, battery shelf

life and temperature conditions.

ULTRALIFE®Lithium Battery Life

The following tables may be used to predict

typical lithium battery life at different delivery

rates when a lithium battery is used in the

CADD-Prizm®pump. As expected, battery life

decreases as the delivery rate increases. These

tables are based on laboratory tests using fresh

ULTRALIFE®lithium batteries in CADD-Prizm®

pumps while the pumps were operating at room

temperature.

Actual battery life may be significantly shorter

depending on the operating temperature and

the storage conditions of the battery. Lithium

battery life is dependent upon the temperature

and relative humidity of storage. Recommended

storage conditions are less than 20°C (68°F)

with a desiccant to ensure less than 10%

relative humidity.

The following tables are based on laboratory

tests conducted at room temperature using fresh

ULTRALIFE®lithium batteries and a CADD®

administration set. Actual battery life depends

upon the brand of battery selected, the

particular battery selected, battery shelf life,

and temperature conditions. Deltec’s testing

indicates a large variability in battery life.

9

Rate Life Volume

0.4 ml/hr 120 hrs 48 ml

10 ml/hr 86 hrs 860 ml

30 ml/hr 37 hrs 1110 ml

50 ml/hr 26 hrs 1300 ml

100 ml/hr 13 hrs 1300 ml

200 ml/hr 14 hrs 2800 ml

350 ml/hr 7 hrs 2450 ml

Rate Life Volume

0.4 ml/hr 212 hrs 85 ml

10 ml/hr 161 hrs 1610 ml

30 ml/hr 79 hrs 2370 ml

50 ml/hr 60 hrs 3000 ml

100 ml/hr 30 hrs 3000 ml

200 ml/hr 32 hrs 6400 ml

350 ml/hr 17 hrs 5950 ml

Table 4. 9-volt Alkaline-type batteries used with the CADD-Prizm®pump.

Table 5. 9-volt Lithium-type batteries used with the CADD-Prizm®pump.

Table 6. EPS System used with the CADD-Prizm®pump.

Continuous and PCA Delivery Battery Life (Max Delivery Rate PCA Mode 30 ml/hr)

Note: Results are without air detector.

Rate Life Volume

100 ml/hr 64 hrs 6400 ml

200 ml/hr 67 hrs 13400 ml

350 ml/hr 39 hrs 13650 ml

10

4Construction

The pump’s housing is made of a special high

impact plastic designed to reduce interference

from electromagnetic fields and to dissipate

electrostatic discharge. It is composed of two

sections: the base and cover housing. The

pump housing is sealed to ensure that the

pump is water resistant. The battery compart-

ment is not water resistant.

NOTE:

The CADD-Prizm®ambulatory infusion

pump is water resistant, but not waterproof.

The battery compartment is accessed through a

removable door on the side of the base hous-

ing. Within the battery compartment is space

for the battery and the two battery contacts.

The Medication Cassette reservoir or the

administration set is attached to the bottom of

the pump by inserting the two hooks on the

cassette into the mating hinge pins on the pump.

The pump and the reservoir or the administra-

tion set are then placed in an upright position

on a firm, flat surface. The reservoir or the

administration set can be latched in place by

inserting a coin in the slot on the pump’s

latching button, pushing the button in, and

turning the button one-quarter turn counter-

clockwise. The reservoir or the administration

set is locked into place by inserting a key into

the pump’s lock and turning the lock one-

quarter turn counterclockwise.

NOTE:

The cassette lock must be unlocked before

attempting to unlatch the disposable.

NOTE:

The Medication Cassette reservoir and the

administration set are intended for single

use only.

The keyboard, located on the front housing, is

composed of nine membrane switches and is

sealed against moisture. All of the keys contain

domes to provide a tactile feel when the key is

pressed. The keyboard keys are sensed by the

pump’s microprocessor.

The custom Liquid Crystal Display (LCD), also

located on the front housing, shows the pump

status and programmed settings. The dot

matrix display consists of 21 character col-

umns with 4 rows of characters, and is selected

by the pump’s microprocessor according to

status conditions and keyboard entries.

The microprocessor and other circuitry which

control the pump are located on two printed

circuit boards. The microprocessor board

contains the Central Processing Unit (CPU)

and its associated circuitry, motor driver

circuitry, and other miscellaneous circuitry.

The LCD board contains the Liquid Crystal

Display with its associated circuitry, and the

backlight module with its associated circuitry.

The pumping mechanism subassembly contains

the motor, gear train, camshaft, valves,

expulsor, sensing disk, infrared light source,

infrared detector, occlusion sensor, cassette

sensors, lock and latch. Via the motor driver

circuitry, the pump’s microprocessor controls

motor rotation.

Two external port connectors are utilized for

communication and external power input. One

of these connectors, the data in/out jack, is

used for attachment of the Remote Dose cord.

This enables the patient to use the Remote

Dose cord to begin a Demand Dose.

This jack can also be connected via an inter-

face cable to an external PC to view reports or

to a printer to print reports. The second port is

for external power connection. This port, the

power jack, can receive input from either an

AC adapter or the External Power Source

rechargeable power pack.

Connections between the printed circuit boards

are designed for ease of manufacturing and

serviceability. The keyboard is connected to the

microprocessor board via a flex circuit tail.

Flexible circuitry and discrete wires connect

the pumping mechanism, motor, and sensors to

the printed circuit boards.

11

5Theory of Operation

Keyboard Circuitry

The CADD-Prizm®PCS II pump is controlled

by a microprocessor. The actions of the micro-

processor are controlled by a program, which

is contained in the memory.

Commands are issued to the microprocessor

from the user via the nine keys on the key-

board and the Remote Dose cord. The keys on

the keyboard feed individually into the Gate

Array on the microprocessor board. A key

closure applies a ground to the associated

input of the Gate Array. Key debounce cir-

cuitry resident in the Gate Array provides a

clean output signal to the microprocessor for

the duration of the key closure. The micropro-

cessor reads keyboard status by accessing

special memory locations in the Gate Array.

The Remote Dose button consists of an SPDT

switch with its own dedicated input to the

microprocessor circuitry. The switch has a

common input line and two output signal

lines. The two signal lines are complementary

such that one line is always logic high and the

other is always low. When the Remote Dose

button is pressed, both signal lines change to the

alternate logic state. This redundancy prevents a

single line failure from starting a dose delivery.

Data Memory EEPROM

Many settings of the pump’s delivery and

record keeping parameters are stored by the

microprocessor in an Electrically Erasable

Programmable Read Only Memory

(EEPROM). Data to and from the memory is

presented serially. Whenever the microproces-

sor uses data from the EEPROM, the data is

checked for validity.

Battery Backed RAM

Additional settings of the pump’s delivery and

record keeping parameters are stored in a

battery backed Random Access Memory

(RAM). Battery backup is provided by two

printed circuit board-mounted lithium batter-

ies. These batteries are designed to provide a

minimum of five years of memory retention

during normal pump usage. Whenever the

microprocessor uses data from the RAM, the

data is checked for validity.

Time Base Circuitry

An accurate 3.6864 MHz timebase is provided

by a quartz crystal. The 3.6864 MHz signal is

connected to the microprocessor, where it is

frequency-divided to access the program

memory at a cycle rate of 921 kHz.

In addition, an accurate 32.768 kHz timebase

is provided by a second quartz crystal. The

32.768 kHz signal is used for the real time

clock.

LCD Circuitry

The high-impedance, low-power, special

drive signals for the liquid crystal display are

provided by the LCD-drivers. Each alpha or

numeric character on the LCD is formed by

darkening combinations of dots. Commands

to display dots are issued via data bus

commands to the LCD-drivers by the

microprocessor.

The LCD circuit also contains a power supply

which provides bias voltage to the LCD panel.

This voltage controls the relative brightness of

the characters. Additional circuitry allows the

microprocessor to disable the LCD when not

in use in order to conserve battery power.

A two brightness level LCD backlight is

provided to improve LCD viewing under low

light conditions. When the microprocessor

enables the LCD, it also enables the low

brightness backlight. Low brightness is used to

conserve battery power. If the AC adapter is

connected, the microprocessor will enable the

high brightness backlight since this does not

consume power from the battery.

The backlight automatically shuts off when the

LCD is turned off.

12

LED Status Indicators

An amber and a green Light Emitting Diode

(LED) are provided under the pump’s front

panel overlay to provide pump status to the

user. Under software control, the LEDs can

either flash at a low duty cycle or be on con-

tinuously. A flashing indicator typically indi-

cates a normal mode of operation and a steady

“on” indicator typically indicates a fault

condition.

Flash PROM Technology

Program memory for the pump is stored in

Flash Programmable Read Only Memory

(Flash PROM). This type of memory allows

modification of the contents without physically

removing the device from the circuit board.

Under certain circumstances, the program can

also be downloaded through the I/O port on

the side of the pump. Several layers of redun-

dancy in the programming system prevent

accidental erasing or modification of the

PROM.

Gate Array Circuitry

The Gate Array contains circuitry which

controls memory address decoding, keyboard

debounce, Light Emitting Diode (LED) indica-

tor status, LCD command buffering, Battery

Backed RAM interface, and miscellaneous

signal line buffering functions.

Audible Alarm Circuitry

Audible alarm circuitry consists of a piezo

electric disk and independent oscillator. The

disk flexes or bends in resonance with the

output of the oscillator. The piezo disk is

mounted to the pump housing to enhance

sound level. The oscillator which drives the

piezo disk is capable of providing two driving

frequencies. The low frequency is in the range

of 700 to 1500 Hz and the high frequency is in

the range of 1600 to 2500 Hz. The micropro-

cessor controls the audible alarm via control

lines from the Gate Array. When the micropro-

cessor selects both the low and high frequency

control lines, the audible alarm enters a warble

mode where it oscillates between the low and

high frequency sound at a rate of 0.8 and 2

Hz. Low battery voltage detection and watch-

dog timer circuitry also have the ability to

enable the audible alarm via the Gate Array.

Watchdog Timer Circuit

Watchdog timer circuitry is provided to moni-

tor the status of the microprocessor and

disable the motor and enable the audible alarm

if the microprocessor fails to function properly.

The microprocessor must strobe the watchdog

circuit at least once every second in order to

prevent the watchdog from performing its reset

function. The reset output from the watchdog

circuit is a pulse output. This acts to “jump

start” the microprocessor. This unique feature

allows the microprocessor to test the watchdog

circuit on every power-up. By setting a flag in

memory and not strobing the watchdog, the

microprocessor can force a watchdog time-out.

After being reset, the microprocessor checks

the status flag to see if this was a time-out test.

If so, the microprocessor continues normal

power-up activities. If the reset occurred when

the microprocessor was not expecting it, the

microprocessor traps the event, sounds the

audible alarm and displays an error message

on the LCD.

Motor Driver/Motor Watchdog

Circuit

Motor drive circuitry is composed of a series of

power FET transistors, passive components,

and two voltage comparators. Built into the

motor drive circuitry is an RC timer which

times how long the motor runs each time it is

turned on. If the motor runs for more than an

average of 4 seconds, the circuit will time out

and disable the motor. A unique feature of this

circuit is that control lines to and from the

microprocessor circuit allow the microproces-

sor to perform a complete functional test of the

motor drive circuit without running the motor.

The microprocessor performs this test function

every several minutes to assure its continued

functionality. An input from the watchdog

circuit prevents motor operation if the watch-

dog timer expires.

Rotation of the motor is sensed by the micro-

processor via an infrared-sensitive photo

13

detector. An infrared light source is mounted

so that its light beam illuminates the infrared

detector. An opaque flag is mounted concentri-

cally to the camshaft and rotates with it be-

tween the infrared light source and detector.

When the flag interrupts the light beam, the

output of the detector is sensed by the micro-

processor via an input port bit. Power to the

infrared LED light source is controlled by the

motor driver circuit and is off when the motor

is not running to conserve battery life.

In the microprocessor software, multiple

checks are made on motion of the camshaft.

When the motor is commanded to start, the

infrared sensor must show that half a revolu-

tion has occurred within five seconds and that

the motor has stopped when half a rotation

was completed. In addition, no camshaft

rotation can take place when the motor has

not been commanded to run.

Power Circuitry

Power for the pump is normally supplied by a

9-volt alkaline battery, 9-volt lithium battery,

or AC adapter. These types of batteries have a

fairly low internal resistance over their dis-

charge range, which will keep power supply

noise low. Other types of batteries, such as

carbon-zinc, exhibit high internal resistance,

especially near depletion. A voltage drop

across the internal resistance occurs when

current is drawn by the motor during pump

activations. This current is demanded in short

pulses when the motor is first turned on and

generates large spikes in the battery voltage.

This noise can cause the low battery detection

circuit to shut down the pump.

The motor driver circuit power is taken di-

rectly from the battery, but the microprocessor

and its associated circuitry requires closely

regulated and filtered 5-volt power which is

supplied from the micropower voltage regula-

tor. This regulator will supply 5-volt power

until its input voltage is approximately 5.3

volts. After that point, the output of the

regulator will follow the input voltage down.

Voltage Reference Circuit

A voltage reference circuit provides a constant

DC voltage to the microprocessor Analog to

Digital Converter (ADC). By reading this input

and comparing the value to a predetermined

range, the microprocessor can validate the

accuracy of the 5-volt power supply. Variations

in the 5-volt supply left undetected can result

in inaccuracy in the low battery alarm set

points and variations in other calculated values.

Table 12. CADD-Prizm®pump low battery conditions.

Voltage CADD®Pump Status

Trip Point*

>7.0V No alarm

6.4–7.0V* Transition to low battery

condition; battery low

message appears; 3 beeps

every 5 min.†

6.0–6.6V* Transition to depleted

battery condition; battery

depleted message appears;

continuous alarm††

5.25–5.95V Hardware reset occurs.

Pump continues to indicate

depleted battery condition.

*Voltage ranges are due to component

tolerances. Actual trip values are guaran-

teed to be non-overlapping.

† The pump emits 3 beeps every 5 minutes, and the

message “9 Volt Battery Low” appears on the pump’s

display, indicating that the battery power is low, but the

pump is operable.

†† The pump emits a continuous, variable-tone alarm,

and the message “9 Volt Battery Depleted” appears on

the display, the battery power is too low to operate the

pump, and pump operation has stopped.

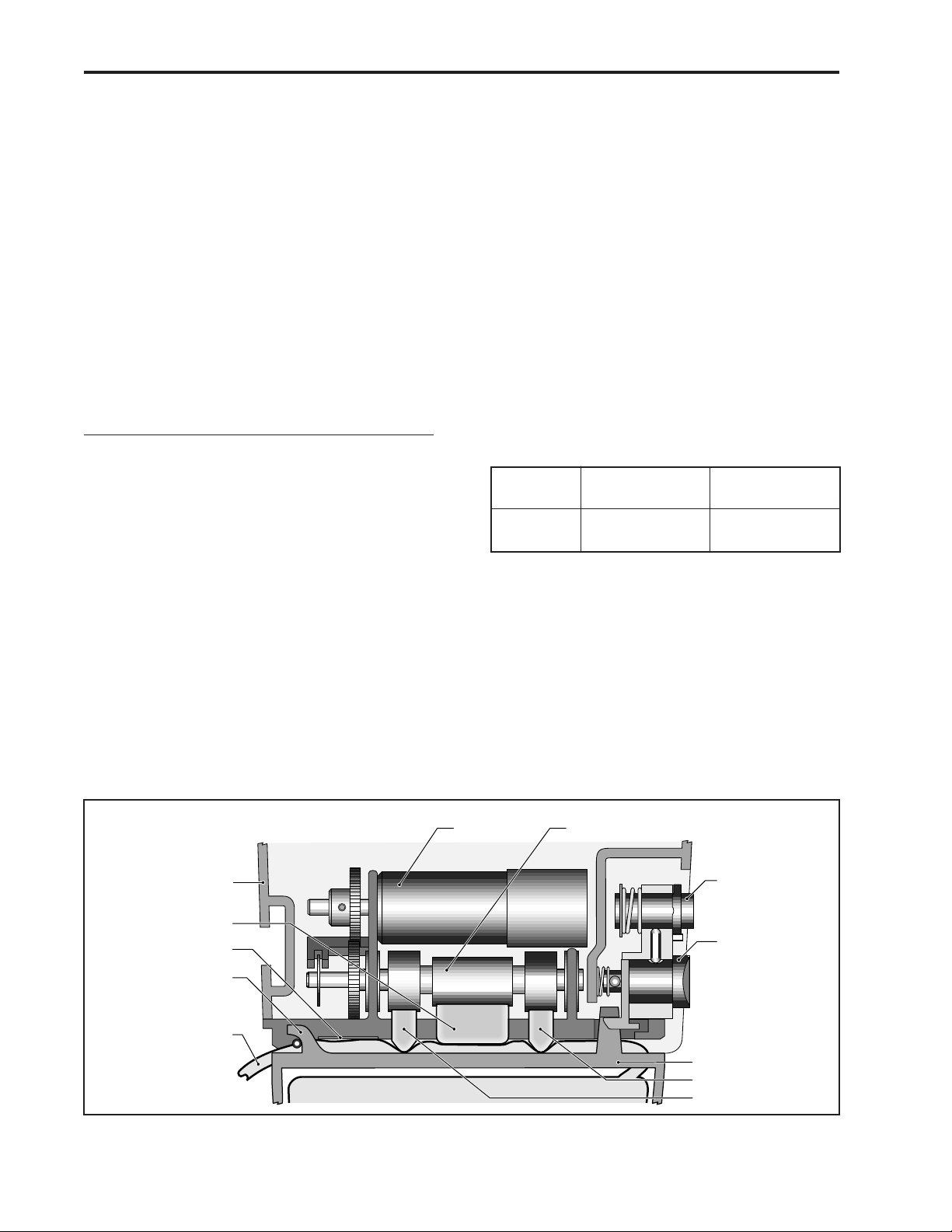

Pumping Mechanism

The pumping mechanism is linear peristaltic

with two active valves. Pumping occurs when

the expulsor presses on the reservoir pump

tubing in sequence with the inlet and outlet

valves. At rest, the outlet valve is pressing

down fully on the tubing and the expulsor and

inlet valve are retracted. (See Figure 7.)

14

When the microprocessor commands the mecha-

nism to pump, the camshaft begins to rotate,

thus controlling the following pump cycle:

1. The inlet valve closes.

2. In synchrony with the expulsor moving

down to compress the tubing, the outlet

valve opens, expelling 0.050 ml of fluid.

3. The outlet valve closes.

4. The inlet valve opens as the expulsor is

retracted, causing fluid from the reservoir to

again fill the pump tubing segment.

5. The camshaft rotation stops after half a

revolution and the cycle is completed.

Pumping Characteristics

If the fluid path to the patient becomes blocked,

the pump tubing will expand as pumping

occurs. When there has been an amount of

inflation corresponding to 124 ±62 kPa

(1.24 ±0.62 bar, 18 ±9 psi), the occlusion

analog sensor trips, whereupon the micropro-

cessor stops the pump mechanism and issues

visual and audible alarms. Thus the maximum

pressure which can be developed is 186 kPa

(1.86 bar, 27 psi).

To deliver the amount of drug specified by the

parameter settings, the pump’s microprocessor

causes the pump mechanism to deliver 0.05 ml

fluid “pulses” timed according to the desired

rate. At rates higher than 3 ml/hr, 2 pulses in

succession will be given. Thus, to deliver 20

ml/hr, for example, the microprocessor solves

these equations:

Mechanism activations per hr

=20 ml per hr/0.1 ml per activation

=20/0.1

=200

Time (seconds) between activations

=3600 sec per hr/number of activations per hr

=3600/200

=18

Rate Volume

(ml/hr) Resolution (ml)

Cassette or 0 - 3 0.050

Admin Set 3.1 - 125 0.100

The microprocessor uses its timer circuits to

accurately time the 18 seconds (in this ex-

ample) between mechanism activations. The

timebase accuracy is ultimately determined by

the 3.6864 MHz quartz crystal oscillator.

Figure 7. A simulated pumping mechanism in a CADD-Prizm®pump.

Lock Button

Latch Button

Pressure Plate

Inlet Valve

Outlet Valve

Pump Tubing

Cassette Hinge

Occlusion Sensor

Expulsor

Pump Housing

Camshaft

Motor

15

Air Detector

The air detector is designed to detect air in the

outlet tubing fluid path. The air detector is

detachable if not needed. The CADD-Prizm®

pump automatically detects the presence of the

air detector and will automatically turn the

sensor on when powered up in LL0.

When the optional air detector is installed, the

Biomed Toolbox feature allows the air detector

to be “required” or “not required.” When the air

detector is not required, it can be “turned on” or

“turned off” using the Options menu. When the

air detector is required, the option for turning

the air detector on or off will not be available.

When the air detector is turned on, the pump

will detect the presence of air in the outlet tubing

fluid path. If the air detector settings are “not

required” and “turned off,” it will default to

“turned on” each time the pump powers up in

Lock Level 0.

The air detector is compatible with all of the

reservoirs and sets indicated for use with the

CADD-Prizm®pump, and all pump accessories.

It is powered directly from the CADD-Prizm®

pump and no additional power is required.

Specifications

The air detector will alarm when it senses a

single air bubble greater than 100 microliters

(0.1 milliliters.)

Construction

The air detector housing is made of a special

high impact plastic and has a metalized film

coating on the inside surface to reduce interfer-

ence from electromagnetic fields. The air detector

is composed of a single base compartment with a

detachable door. It is sealed against the pump

housing to ensure the overall assembly is water

resistant. The air detector is mounted to the

pump housing with two screws, and electrically

connected with a ten pin connector.

Theory of Operation

The air detector consists of sensor electronics

and two ultrasonic transducers positioned on

opposite sides of the tubing. One transducer acts

as an acoustic transmitter and the other as an

acoustic receiver. Air detection occurs when air

in the fluid path causes a reduction in the signal

level to the receiver. When the signal is inter-

rupted for a preset length of time, the sensing

circuitry sends a signal to the microprocessor

indicating air in the fluid path. To maximize the

reliability of the system and to reduce false

alarms, the transmitted signal is swept over a

frequency range. This accommodates varying

resonance frequencies of the transducer and

reduces sensitivity to tubing tolerances and other

mechanical variations.

Upstream Occlusion Sensor

Theory of Operation

The upstream occlusion sensor is a strain

gauge device capable of detecting pressure

changes in the disposable tubing set. This is

accomplished by using a loading ball or sphere

located on the bottom of the pump. This

loading ball contacts the pump tubing when a

tubing set is attached to the pump. Under

normal operation, the pump tube pushes

outward and applies a specified force on the

sensor. When an upstream occlusion is present,

the upstream tubing collapses pulling away

from the sensor reducing the force on the

sensor. It is this change of the force that indi-

cates an upstream occlusion.

16

6Safety Features and

Fault Detection

Hardware Safety Features

Key hardware safety features include a watch-

dog timer circuit, motor driver and motor

watchdog circuits, cassette ‘type’ sensor circuit,

latch/lock sensor circuit, and a voltage detector

circuit. Each safety circuit performs a unique

function to insure the overall safety of the

device. (See Figure 8.)

Watchdog Timer Circuit

The microprocessor must send an appropriate

signal to the watchdog circuit at least once per

second. If the microprocessor does not, the

watchdog circuit will time out and shut down

the pump controller.

Watchdog timer circuitry is provided to monitor

the status of the microprocessor and disable

the motor and enable the audible alarm if the

microprocessor fails to function properly. The

microprocessor must strobe the watchdog

circuit at least once every second in order to

prevent the watchdog from performing its reset

function. The reset output from the watchdog

circuit is a pulse output. This acts to “jump

start” the microprocessor. This unique feature

allows the microprocessor to test the watchdog

circuit on every power-up. By setting a flag in

memory and not strobing the watchdog, the

microprocessor can force a watchdog time-out.

After being reset, the microprocessor checks

the status flag to see if this was a time-out test.

If so, the microprocessor continues normal

power-up activities. If the reset occurred when

the microprocessor was not expecting it, the

microprocessor traps the event, sounds the

audible alarm and displays an error message

on the LCD.

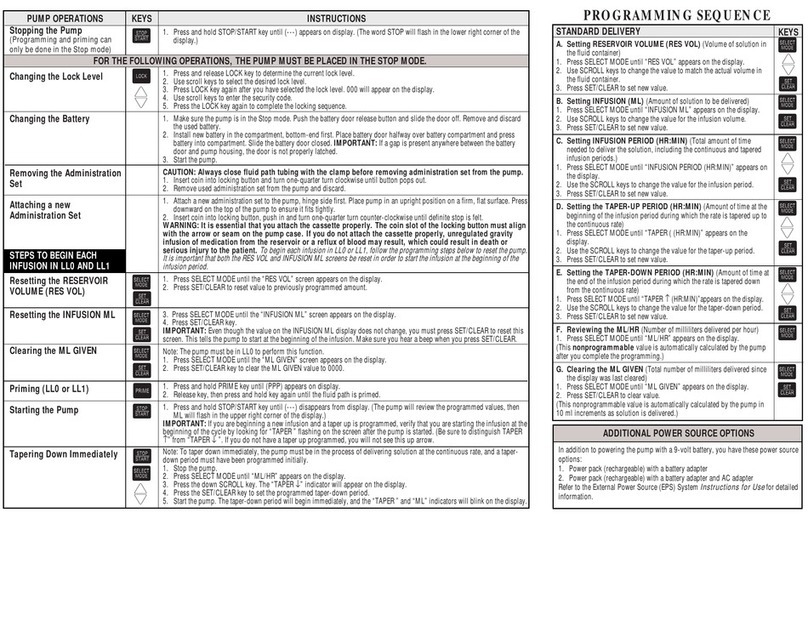

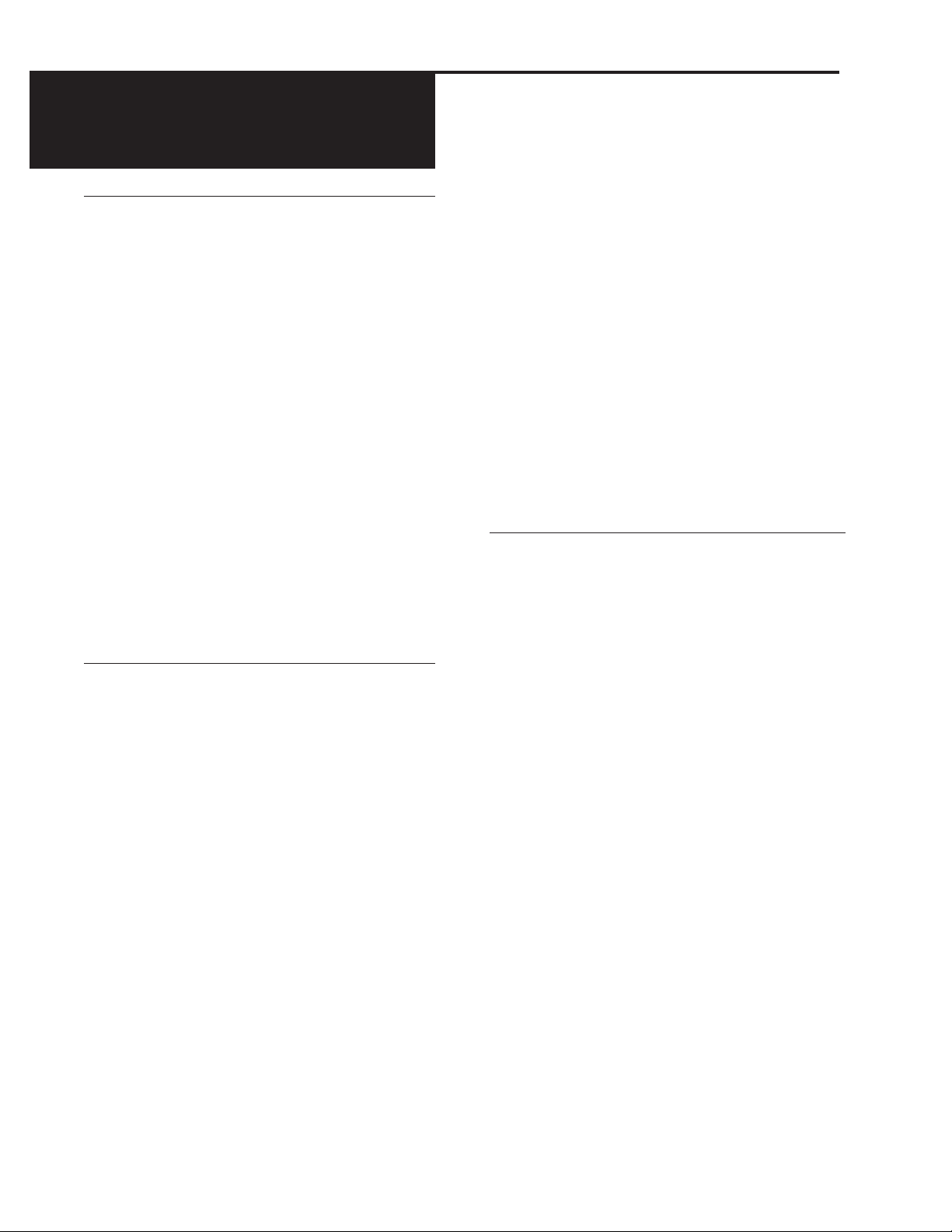

Figure 8. CADD-Prizm®pump hardware block diagram.

PROGRAM

MEMORY

MB

DATA

MEMORY

MB

LCD DISPLAY VOLTAGE

REFERENCE

MOTOR

DRIVER

WATCHDOG

REAL-TIME

CLOCK

CPU/IO/

GATE ARRAY

KEYBOARD

MOTOR

WATCHDOG

VOLTAGE

DETECTOR

SENSORS

AUDIBLE

ALARM

17

Motor Driver/Motor Watchdog Circuit

Motor drive circuitry is composed of a series of

power FET transistors, passive components,

and two voltage comparators. Built into the

motor drive circuitry is an RC timer which

times how long the motor runs each time it is

turned on. If the motor runs for more than an

average of 4 seconds, the circuit will time out

and disable the motor. A unique feature of this

circuit is that control lines to and from the

microprocessor circuit allow the microprocessor

to perform a complete functional test of the

motor drive circuit without running the motor.

The microprocessor performs this test function

every several minutes to assure its continued

functionality. An input from the watchdog

circuit prevents motor operation if the watch-

dog timer expires.

Cassette ‘Type’ Sensor Circuit

The cassette ‘Type’ sensor system consists of

three pins protruding from the button of the

pump mechanism that interface to the attached

administration set and associated circuitry.

Each type of administration set designed to

work with the CADD-Prizm®pump contains a

unique ‘code’ programmed into the set via

nubs molded into the plastic. When a set is

latched to the pump, the nubs press against the

pins in the pump mechanism in a pattern

unique to that set type. Optical detectors and

electronic circuitry on the circuit board encode

this pattern and report the information to the

microprocessor. This feature allows automatic

rate selection dependent on the type of set

attached. This system also acts as a safety

feature to detect a damaged or detached set.

If, during operation, the microprocessor

detects all pins extended, the pump will enable

audible and visual alarms and stop delivery.

Redundancy in the pattern prevents single fault

failures from causing over or under delivery of

fluid. Additional circuitry allows these sensors

to be turned on and off by the microprocessor

to conserve battery power. Additionally, control

of sensor power allows the microprocessor to

test the sensor inputs in both the powered and

unpowered states, thus allowing detection of

sensor fault conditions. Care should be taken

not to damage these sensor pins.

Latch/Lock Sensor Circuit

Latch and Lock sensors allow the microproces-

sor to detect the positions of the latch and lock

buttons. This prevents attempted fluid delivery

when the set is not correctly latched to the

pump. In addition, it allows the microprocessor

to stop fluid delivery and enable audible and

visual alarms if the set is unlatched during fluid

delivery. Opposing infrared transmitters and

receivers on both the latch and lock buttons

allow the microprocessor to detect their open

and closed positions. Additional circuitry

allows these sensors to be turned on and off by

the microprocessor to conserve battery power.

Additionally, control of sensor power allows

the microprocessor to test the sensor inputs in

both the powered and unpowered states, thus

allowing detection of sensor fault conditions.

Voltage Detector Circuit

Low voltage detection is performed by part of

the watchdog circuit and by the microprocessor

via software. Three low voltage levels are

detected. The first two levels are detected by

software and the third by hardware. The first

level to be reached is the Low Battery Warning

threshold which occurs when the battery

voltage decays to a nominal value of 6.8 volts.

An Analog to Digital Converter (ADC) built

into the microprocessor allows the micropro-

cessor, via software, to monitor the battery

voltage. At the Low Battery Warning thresh-

old, the microprocessor enables a periodic

series of beeps and displays a low battery

warning message on the LCD. As the battery

voltage reaches a nominal value of 6.3 volts,

the software disables delivery, places a battery

depleted message on the LCD, and enables a

constant two-tone audible alarm. When the

battery voltage decays to a nominal value of

5.6 volts, a hardware reset circuit is triggered

which places the microprocessor in reset. This

prevents ambiguous microprocessor operation

when the battery voltage continues to decay.

The hardware reset continues until the battery

is completely discharged or until it is removed.

Once the pump controller goes into low

battery shutdown, only replacing the old

battery with a fresh one will clear the condition.

Table of contents

Other Deltec Medical Equipment manuals

Popular Medical Equipment manuals by other brands

Drive DeVilbiss

Drive DeVilbiss 1025 Series Instruction guide

CeraGem

CeraGem MASTER V4 user manual

Stryker

Stryker ComfortGel 2850-000-016 Operation manual

Invacare

Invacare Propad Revolve V user manual

St. Jude Medical

St. Jude Medical Angio-Seal Evolution Instructions for use

Beurer

Beurer DM 20 Instructions for use