Contents

1 General information ..................................................................................................................................................... 3

2 Product description ....................................................................................................................................................... 3

3 Technical data ................................................................................................................................................................ 3

4 Safety instructions ........................................................................................................................................................ 4

5 Scanner description....................................................................................................................................................... 5

5.1 Scanner components............................................................................................................................................... 5

5.1.1 Rear view..................................................................................................................................................... 5

5.1.2 Front view.................................................................................................................................................... 5

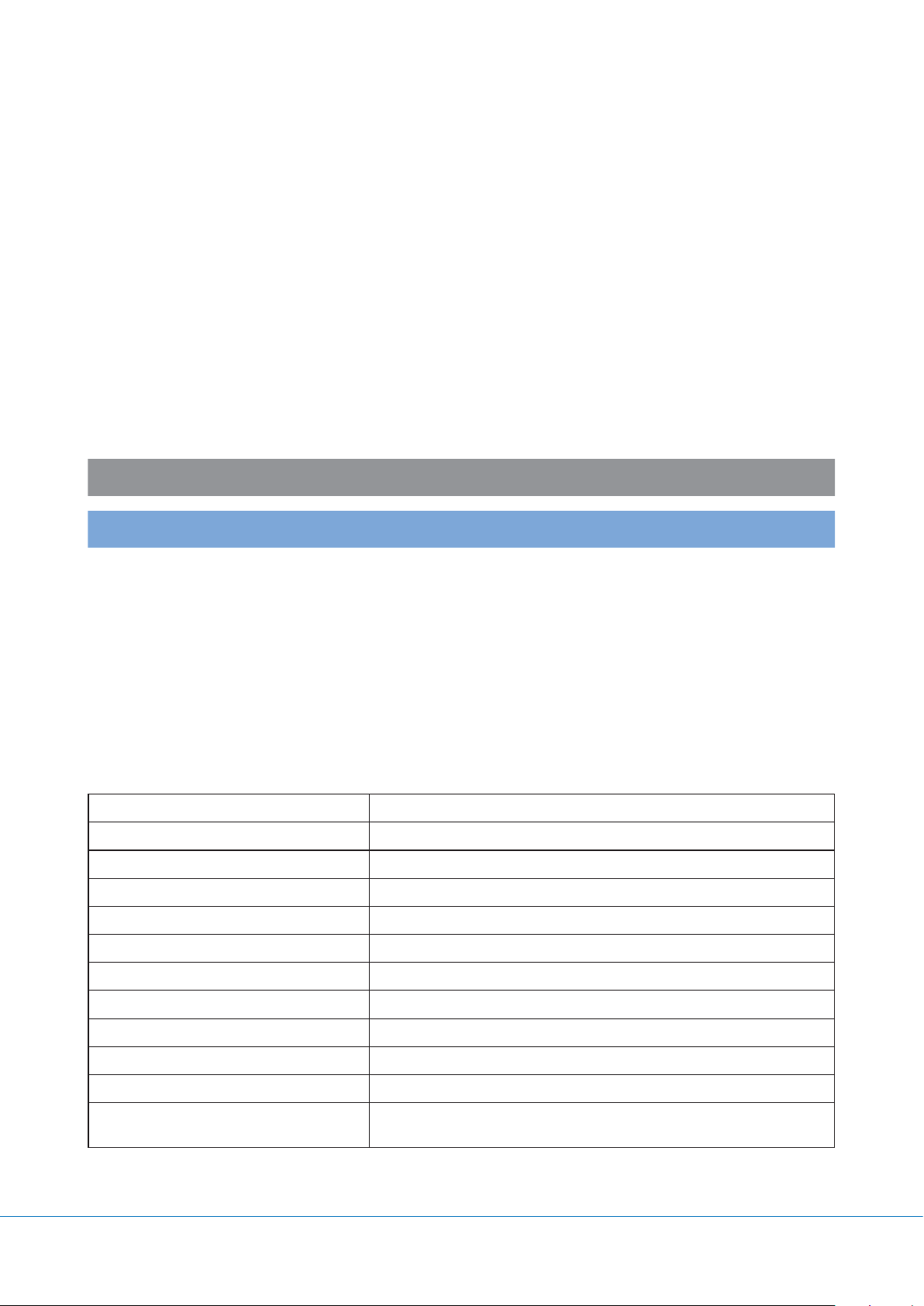

5.1.3 Interior view................................................................................................................................................. 6

5.2 Operation of orthoX®scan....................................................................................................................................... 6

5.3 Model holder .......................................................................................................................................................... 6

6 Placing model in the 3D model scanner orthoX®scan ................................................................................................ 7

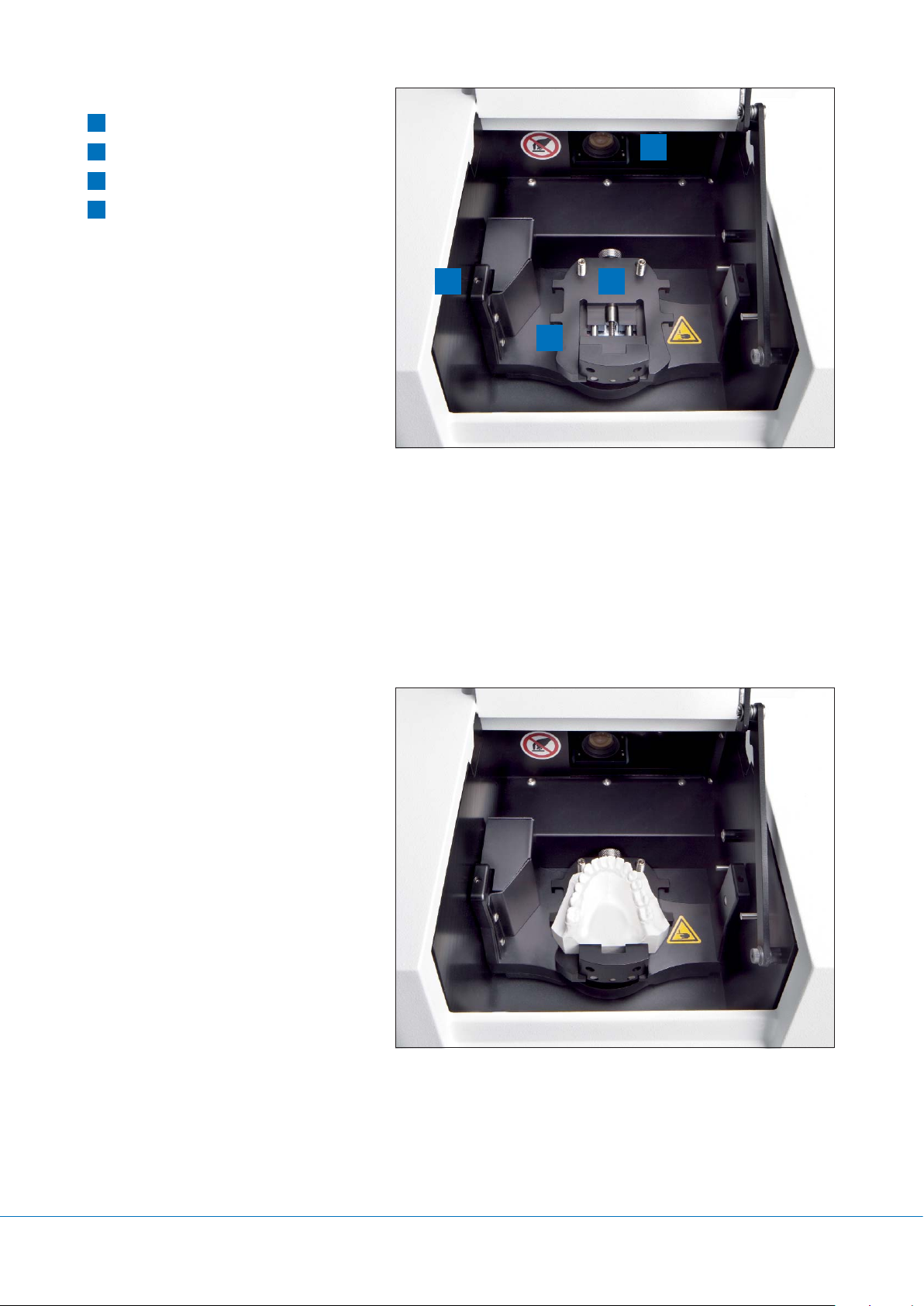

6.1 Securing model on model holder............................................................................................................................. 7

6.2 Placing the upper and the lower model in occlusion in the model holder................................................................. 7

6.3 Placing model holder in the orthoX®scan model scanner ......................................................................................... 7

7 Operating orthoX®scan scanner software .................................................................................................................. 8

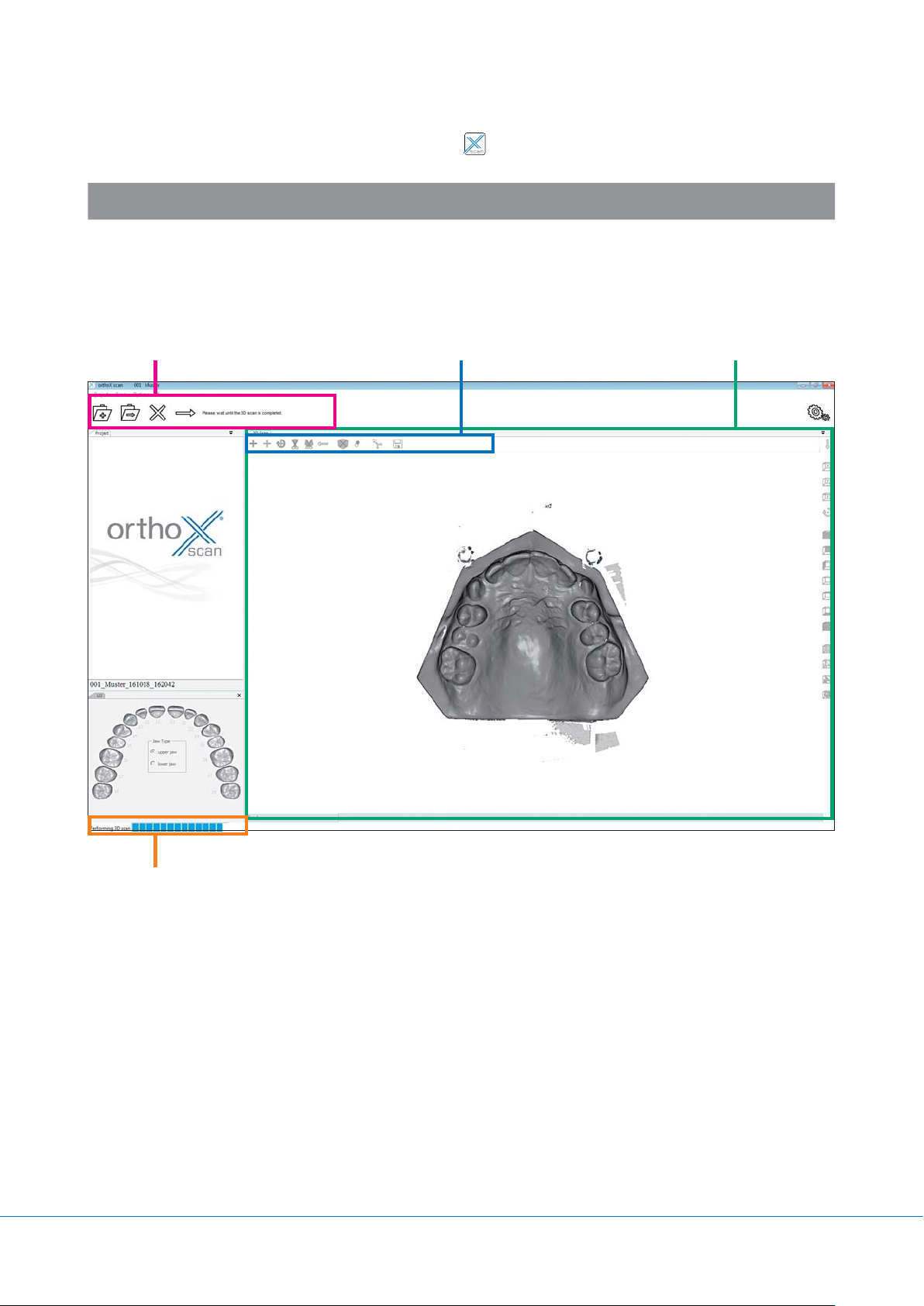

7.1 Program interface.................................................................................................................................................... 8

7.1.1 Explanation of icons in tool bar.................................................................................................................... 9

7.1.2 Explanation of icons in tool bar for re-scanning and articulation................................................................... 9

7.2 Selecting model to be scanned.............................................................................................................................. 10

7.3 Scanning model set............................................................................................................................................... 10

7.4 Re-scanning .......................................................................................................................................................... 17

7.5 Aligning maxilla and mandible manually................................................................................................................ 19

8 Options ........................................................................................................................................................................ 23

8.1 Matching .............................................................................................................................................................. 23

8.2 General................................................................................................................................................................. 24

8.3 Installation ............................................................................................................................................................ 25

8.4 Axis calibration...................................................................................................................................................... 25

9 Repair and maintenance............................................................................................................................................. 26

10 Malfunction and repair............................................................................................................................................... 26

11 Environment and disposal.......................................................................................................................................... 26

11.1 Packaging ............................................................................................................................................................. 26

11.2 Environment and disposal ..................................................................................................................................... 26

12 Quality information .................................................................................................................................................... 26

13 Explanation of symbols used on the label ................................................................................................................ 26

14 Conformity declaration............................................................................................................................................... 27

2