Derbi GP1 125-250 c.c. Instruction manual

GP1125-250 c.c.

WORKSHOP MANUAL

1

DERBI - NACIONAL MOTOR, S.A.U., manufacturer of DERBI motorcycles and mopeds, has produced this

manual with the aim of documenting and simplifying as much as possible the work you need to do to in dis-

mantling and assembling the GP1 125/250 c.c.

The intention is to provide as much assistance as possible to mechanics working for our brand’s dealers and

sub-dealers.

Due to its constant commitment to improving its products, DERBI - NACIONAL MOTOR, S.A.U. Sociedad

Unipersonal reserves the right to introduce any modifications it deems fit, without prior warning.

All the information included in this manual is based on the latest data available at the time of its publication.

The drawings and photographs in this manual are for reference purposes only, and may therefore not be

exactly the same as the corresponding parts of the current model itself.

NACIONAL MOTOR, S.A.U.

3

INTRODUCTION

GENERAL INFORMATION

GENERAL TECHNICAL DATA

RECOMMENDED TOOLS

PERIODIC MAINTENANCE

DISMANTLING

SEAT SIDE TRIM

COWLING

COWLING BOTTOM COVER

WATER-OIL TANK COVER

SIDE COVERS

SHIELD INNER COVER

BATTERY COVER

PETROL TANK COVER

HELMET CARRIER

FOOTRESTS

SIDE COVERS

SHIELD

ENGINE

EXHAUST ASSY - REMOVAL

REMOVAL OF THE WNGINE FROM THE VEHICLE

AUTOMATIC TRANSMISSION

AIR DUCT

REMOVING THE DRIVEN PULLEY SHOFT BEARING

REFFITING THE DRIVEN PULLEY SHOFT BEARING

BAFFLE ROLLER

REMOVING THE DRIVEN PULLEY

INSTEPTING THE CLUTCH DRUM

REMOVING THE CLUTCH

INSPECTING THE CLUTCH

PIN RETAINING COLLAR

REMOVING THE DRIVEN HALF-PULLEY BEARING

INSPECTING THE DRIVEN FIRED HALF-PULLEY

INSPECTING THE DRIVEN SUDING HALF-PULLEY

REFITTING THE DRIVEN HALF-PULLEY BEARING

REFITTING THE DRIVEN PULLEY

INSPECTING THE CLUTCH SPRING

Pág. 1

Pág. 8

Pág. 9

Pág. 30

Pág. 40

Pág. 64

Pág. 64

Pàg. 65

Pág. 65

Pág. 65

Pág. 66

Pág. 66

Pág. 66

Pág. 67

Pág. 68

Pág. 68

Pág. 68

Pág. 69

Pág. 69

Pág. 71

Pág. 71

Pág. 72

Pág. 72

Pág. 73

Pág. 73

Pág. 73

Pág. 74

Pág. 76

Pág. 76

Pág. 77

Pág. 77

Pág. 78

Pág. 78

Pág. 80

Pág. 81

4

REFITTING THE CLUTCH

REFITTING THE DRIVEN PULLEY

DRIVE-VELT

REMOVING THE DRIVING PULLEY

INSPECTING THE ROLLERS CASE

REFTTING THE DRIVING PULLEY

REFITTING THE TRANSMISSION COVER

END GEAR

REMOVING THE WHEEL AXLE

REMOVING THE HUB BEARING

REMOVING THE WHEEL ASXLE BEARING

REMOVING THE DRIVEN PULLEY SHAFT BEARING

INSPECTING THE HUB SHAFT

INSPECTING THE HUB COVER

REFITTING THE WHEEL AXLE BEARING

REFITTING THE HUB COVER BEARING

REFITTING THE HUB BEARING

REFITTING THE HUB COVER

FLYWHEEL COVER

REMOVING THE STATOR

FLYWHEEL AND STARTING

REMOVING FLYWHEEL MAGNETO

INSPECTING THE FLYWHEEL COMPONENTS

REFITTING THE FLYWHEEL MAGNETO

REFITTING THE STATOR MOTOR

CYLINDER ASSY AND TIMING SYSTEM

REMOVING THE ROCKER ARMS COVER

REMOVING THE CAMSHAFT

REMOVING THE CYLINDER HEAD

REMOVING THE VALVES

REMOVING THE CYLINDER - PISTON ASSY

INSPECTING THE SMALL END

INSPECTING THE WRIST PIN

INSPECTING THE PISTON

INSPECTING THE CYLINDER

Pág. 82

Pág. 85

Pàg. 85

Pág. 86

Pág. 87

Pág. 88

Pág. 89

Pág. 90

Pág. 90

Pág. 92

Pág. 92

Pág. 92

Pág. 93

Pág. 93

Pág. 95

Pág. 95

Pág. 95

Pág. 96

Pág. 97

Pág. 97

Pág. 98

Pág. 99

Pág. 101

Pág. 101

Pág. 102

Pág. 103

Pág. 103

Pág. 105

Pág. 105

Pág. 106

Pág. 106

Pág. 107

Pág. 107

Pág. 107

Pág. 110

5

INSPECTING THE PISTON RING

REMOVING THE PISTON RING

CHOOSING THE GASKET

COMPRESSION RATIO VERSION 250

REFITTING THE PISTON RINGS

REFITTING THE CYLINDER

INSPECTING THE CYLINDER HEAD

INSPECTING THE TIMING SYSTEM COMPONENTS

INSPECTING THE VALVE SEALINGS

INSPECTING THE VALVE HOUSINGS

INSPECTING THE VALVES

INSPECTING THE SPRINGS AND HALF-CONES

REFITTING THE VALVES

INSPECTING THE CAMSHAFT

REFITTING THE TIMING SYSTEM COMPONENTS

REFITTING THE ROCKER - ARMS COVER

REFITTING THE INTAKE MANIFOLD

REFITTING THE TIMING SYSTEM COMPONENTS

CRANKCASE - CRANKSHAFT

INSPECTING THE CRANSHFT ALIGNMENT

INSPECTING THE CRANKCASE HALVES

INSPECTING THE CRANKSHAFT PLAIN BEARING

REFITTING THE CRANKCASE HALVES

LUBRICATION

OIL PRESSURE CHACK

OIL PUMP

INSPECTION

REFITTING

REMOVING THE OIL - SUMP

INSPECTING THE BY-PASS VALVE

REFITTING THE OIL SUMP

SAS VALVE

INSPECTING THE CUT-OFF

FUEL SUPPLY

REFITTING THE CARBURETTOR

LEVEL CHECK

INSPECTING THE VALVE AND NEEDLE

INSPECTING THE AUTOMATIC CHOCKE DEVICE

Pág. 111

Pág. 112

Pág. 113

Pág. 115

Pág. 116

Pág. 116

Pág. 117

Pág. 117

Pág. 118

Pág. 118

Pág. 118

Pág. 120

Pág. 120

Pág. 121

Pág. 122

Pág. 128

Pág. 128

Pág. 128

Pág. 129

Pág. 133

Pág. 134

Pág. 135

Pág. 137

Pág. 139

Pág. 140

Pág. 143

Pág. 144

Pág. 145

Pág. 145

Pág. 146

Pág. 146

Pág. 147

Pág. 148

Pág. 149

Pág. 159

Pág. 164

Pág. 166

Pág. 169

6

FORK, SHOCK ABSORBER. ENGINE SUPPORT AND STAND

DISMANTLING FRONT SUSPENSION

INSPECTING THE FRONT FORKS

DISMANTLING

INSPECTION

SWING-ARM

CHECKING THE SWINING ARM

EXHAUST BRACKET

OVERHAUL

REFITTING

CENTRE - STAND

FRONT WHEEL AND BRAKES

REAR WHEEL 125 C.C.

REAR WHEEL 250 C.C.

DISMANTLING

INSPECTING THE FRONT WHEEL

DISMANTLING THE FRONT DISCK CALLIPER

ASSEMBLING THE FRONT WHEEL

REAR WHEEL AND BRAKES

REAR WHEEL 125 C.C.

REAR WHEEL 250 C.C.

DISMANTLING

DISMANTLING THE REAR DISCK CALLIPER

INSPECTING THE REAR WHEEL

RIFTTING THE REAR WHEEL

CIRCUITO DE REFRIGERACIÓN

CIRCUIT DIAGRAM 250 C.C.

CIRCUIT DIAGRAM 150 C.C.

WATER PUMP - OVERHAUL

ELECTRICAL SYSTEM

ELECTRICAL SYSTEM GP1 125-250 C.C.

CHECK CONNECTORS

INSPECTIONS STEPS

DIGITAL INSTRUMENTS UNIT

IGNITION

LIGHTS AND AUTOMATIC CHOKE

RECHARGING THE BATTERY AND STARTTING

Pág. 173

Pág. 175

Pág. 179

Pág. 179

Pág. 180

Pág. 181

Pág. 181

Pág. 182

Pág. 182

Pág. 183

Pág. 184

Pág. 185

Pág. 186

Pág. 186

Pág. 188

Pág. 194

Pág. 196

Pág. 197

Pág. 198

Pág. 198

Pág. 205

Pág. 205

Pág. 206

Pág. 207

Pág. 208

Pág. 218

Pág. 219

Pág. 220

Pág. 220

Pág. 221

Pág. 222

Pág. 223

7

SENSORS AND INDICATORS

TURN INDICATORS AND HORN

IGNITION CIRCUIT

SPARK PLUG

STATOR CHECK

VOLTAGE REGULATOR CHECK

FUSES

DISMANTLING THE BATTERY

BATTERY - INITIAL CHARGE

CAPACITY

INSPECTION THE CHARGING CONDITIONS

RECHARGING

CHARGING SYSTEM

TROUBLESHOOTING

ENGINE

REAR WHEEL TURNS WITH ENGINE TICKING OVER

DIFFICULTY STARTING

EXCESSIVE CONSUMPTION OF OIL/SMOKY EXHAUST

INSUFFICIENT LUBRICATION PRESSURE

THE ENGINE TENDS TO STOP AT MAX GAS OPENING

THE ENGINE TENDS TO STOP AT IDLE

HIGH CONSUMPTION

EXCESSIVELY NOISY WITH EXHAUST

SECONDARY AIR DEVICE ANOMALIES

TRANSMISSION AND BRAKES

INSUFFICIENT BRAKING

BRAKES OVERHEATING

VARIATIONS OR REFRAINED NOISINESS

BATTERY

FLASHING LICHTS NOT WORKING

HEARDENING STERRING

EXCESSIVE STEERING PLAY

NOIZY SUSPENSION

SUSPENSION OIL LEAKAGE

Pág. 224

Pág. 225

Pág. 226

Pág. 226

Pág. 227

Pág. 227

Pág. 230

Pág. 230

Pág. 232

Pág. 232

Pág. 233

Pág. 234

Pág. 235

Pág. 236

Pág. 237

Pág. 237

Pág. 238

Pág. 238

Pág. 239

Pág. 239

Pág. 240

Pág. 240

Pág. 240

Pág. 241

Pág. 241

Pág. 242

Pág. 242

Pág. 242

Pág. 243

Pág. 244

Pág. 244

Pág. 245

Pág. 245

8

REGULATIONS

This section describes the machine’s general safety and maintenance work rules.

SAFETY REGULATIONS

- In the event of having to carry out work on the engine while this is running, ensure that the area is well

ventilated, where possible using extractor fans. Never leave engines running in closed spaces. Exhaust gases

are poisonous.

Petrol is extremely inflammable and in certain conditions may explode. Smoking must not be allowed in the

work area, nor should there be naked flames or sparks.

MAINTENANCE REGULATIONS

- Use genuine DERBI spare parts and lubricants recommended by the manufacturer. Non-genuine or unau-

thorised parts may damage the engine.

Always use new gaskets and oil seals during re-assembly.

After dismantling, clean the components with solvents that are non-inflammable or with a high flammability

point. Lubricate all working surfaces before assembling, excluding tapered joints.

After assembly, check that all components have been correctly fitted and that they are functioning perfectly.

For dismantling, checking and assembly operations, use only tools with metric measurements. Metric screws,

nuts and bolts are not interchangeable with imperial measurement joining devices. Using unsuitable tools

and joining devices may damage the engine.

- In the case of work on the engine involving the electrical circuitry, check that electrical connections have

been correctly fitted.

N.B.

Indicates a note that gives key information to make the procedure easier and clearer.

ATTENTION

Indicates specific procedures that must be carried out to avoid damage to the machine.

WARNING

Indicates specific procedures that must be followed to avoid possible accidents to the person repairing the

machine.

GU O S

S GUOS

MAINTENANCE REGULATIONS

9

SPECIFICATIONS DESC. / QUANTITY

Maximum length

Maximum height

Length between axles

Handlebar width

Handlebar height

GP1 125 c.c.

GP1 250 c.c.

M434M

M237M

G

P1 12

5

c.c.

G

P1 2

50

c.c.

MACHINE ENGINE PREFIX FRAME PREFIX

VTHPS1A1A

VTHPT1A1A

DIMENSIONS AND WEIGHT

1930 mm.

1225 mm.

1375 mm.

705 mm.

1085 mm.

SPECIFICATIONS DESC. / QUANTITY

Engine type

Timing

Int. diameter per stroke (125)

Int. diameter per stroke (250)

Cubic capacity (125)

Cubic capacity (250)

Compression ratio (125)

ENGINE

57x 48,6mm

72 x 60 mm

124,015 cm3

244,290 cm3

12:1

Single cylinder four-stroke and four valve water-cooled

Single overhead cam driven by a chain on the left-hand

side; rockers with three arms and with threaded adjus-

ter.

10

SPECIFICATIONS DESC. / QUANTITY

ENGINE

Engine oil (125)

Engine oil (250)

Fuel tank

Rear hub oil

~ 1100 cc

~ 1200 cc

~ 11 L. with reservation of 2,7 L.)

250 cc

SPECIFICATIONS DESC. / QUANTITY

Transmission

TRANSMISSION

Automatic expandable pulley varistor with servosystem,

trapezoidal belt, self-ventilating dry automatic centrifu-

gal clutch, gear reducer and transmission compartment

with forced air circulation.

SPECIFICATIONS DESC. / QUANTITY

CAPACITIES

10,5-11,5: 1

CVEK-30

WVF 7G* 0 29

WVF-7S*

1650 ±50 r.p.m.

3,8 ± 07

Electric starter motor

11 kw (15CV)at 9700p.r.m.

16,18 Kw (22CV) at 8250 p.r.m.

Sponge-type damped eith a 50% for filters.

Oil - 50% unleaded petrol misture

Engine lubrication with geared twin-screw pump (inside the

oil sump) coomanded by chain and double paper net filter.

With depression pump and petrol through carburettor

Compresion ratio (250)

Keihin Carburettor (125 - 250)

Walbro Carburettor (125)

Walbro Carburettor (250)

Idle speed

Adjustment CO

Air filter

Starter system

Lubrication

Feeding

Max. power (crankshaft) 125cc

Max. power (crankshaft) 250cc

11

SPECIFICATIONS DESC. / QUANTITY

ELECTRICAL COMPONENTS

10°±1° at 2000 r.p.m. - 34°±1° at 6000 r.p.m.

CHAMPION RG4HC

CHAMPION RG4HC

12V-12Ah

N°1 15A / N°2 15A / N°3 15A

AC current

10° ± 1 at 2000g/min.

28° ± 1 at 6500 g/min.

Electronic with capacitive discharge (CDI) and variable

advance with separate HT coil.

SPECIFICATIONS DESC. / QUANTITY

FRAME AND SUSPENSIONS

100 mm

90/85 mm

Aluminium alloy Delta Box type

Hydraulic telescopic fotk with forward-shifted pin and

Ø 40 mm rods.

Engine functioning as swingarm pivoting on frame

through arm with two degrees of freedom. Pair of

double-acting hydraulic shock absorbers and coaxial

springs with preload adjustment.

SPECIFICATIONS DESC. / QUANTITY

BRAKES

Ø 240 disc with hydraulically operated dual opposed

piston caliper (lever at left end of handlebar).

Ø 245 mm disc with hydraulically operated dual piston

floating caliper (lever at right end of handlebar).

Ignition type

Ignition advance (before T.D.C) 125

Ignition advance

(

before T.D.C

)

Spark plug (125)

Spark plug (250)

Battery

Fuses

Generator

ELECTRICAL SYSTEM

Type

Front suspension

Front wheel max. travel

Rear suspension

Max. rear shock absorber travel

Brakes front

Brakes rear

12

Front wheel rim

Rear wheel rim

Front tyre

Rear tyre

Tyre pressure front wheel (cold)

Tyre pressure rear wheel (cold)

Tyre pressure rear/front wheel (driver and

passenger). (cold)

Aluminium alloy

In light alloy

120 / 70 x 14”

120 / 60 x 14”

1,9 bar

2,0 bar

2,0 / 2.2 bar

SPECIFICATIONS DESC. / QUANTITY

WHEELS AND TYRES

N.B.

CHECK AND ADJUST TYRE PRESSURE WITH TYRES AT AM-

BIENT TEMPERATURE. ADJUST PRESSURE ACCORDING TO

THE WEIGHT OF THE RIDER AND ACCESSORIES.

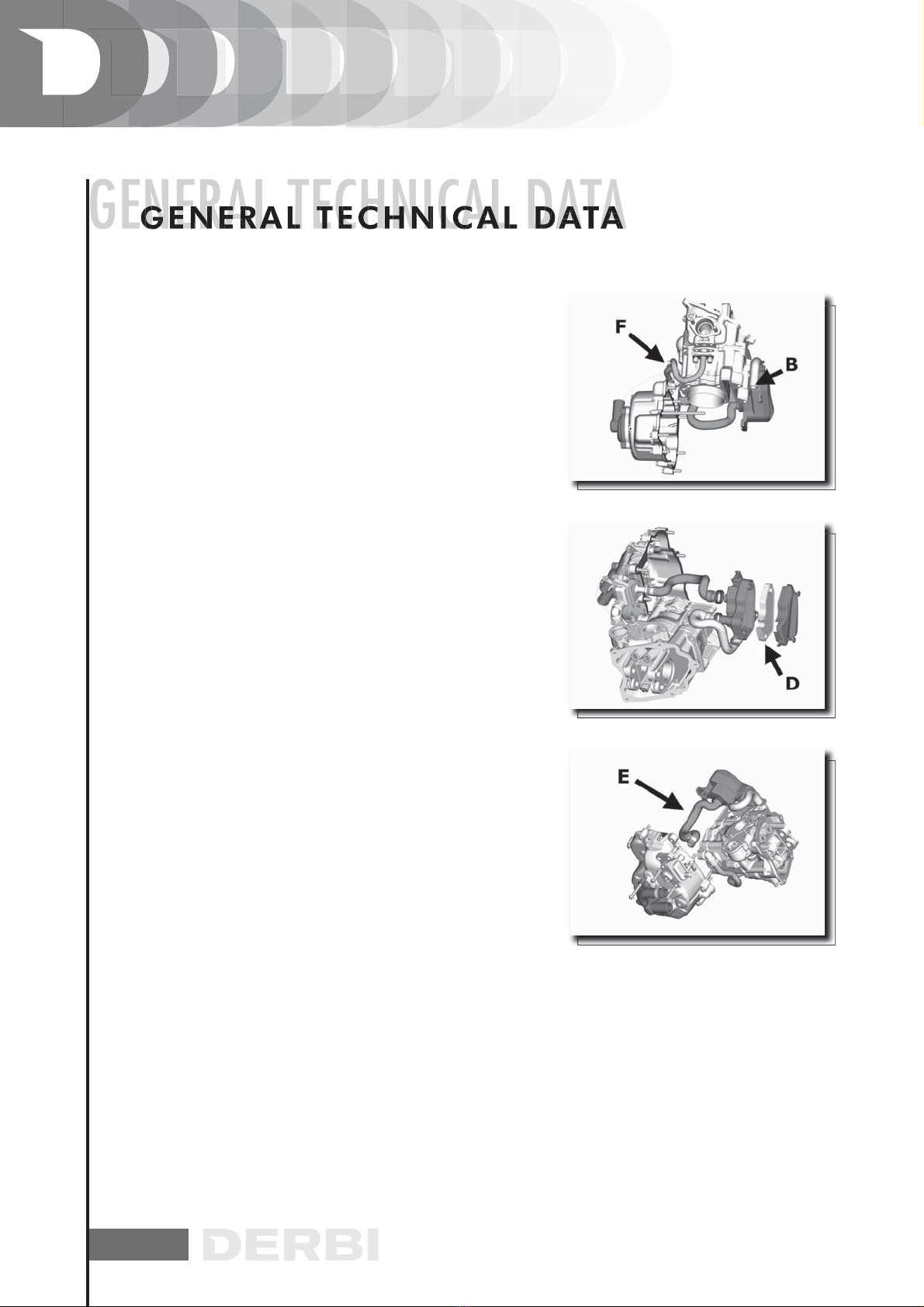

SECONDARY AIR

The working principie of the SAS for Leader 125 ce engines is

entirely similar to the SAS employed on 2-stroke engines.

The main differences are the following:

Secondary air enters directly into the exhaust duct on the

cylinder head, instead of entering through the exhaust pipe

as in two-stroke engines.

The reed valve found on 2-stroke engines is here replaced by

a membrane. The unit, indicated by an arrow in the figure, is

provided with a cut-off connected to the vacuum inlet on the

intake manifold to shut air intake during deceleraron, so to

prevent detonations in the silencer.

Air is sucked in through hole «A» and flowing through the

first filter is directed towards hole «B».

SECONDARY AIR

13

Flowing through the hole shown in the figure, the air reaches

the second filter, «B», At this point, the tiltered air enters the

membrane device, so to be channelled towards the head.

Flowing through a rigid pipe, flanged to the head, the se-

condary air reaches the exhaust duct thus providing oxygen

addition to the unburnt gases just before they enter the ca-

taiytic converter. The efficiency ofthe catalyzing process is

therefore increased.

El sistema de funcionamiento del SAS para motor Quasar

250 Euro 2 es totalmente similar al funcionamiento del siste-

ma SAS para motor 2T.

Las diferencias son las siguientes:

El aire secundario, en vez de entrar en el silenciador, como

sucede para el 2T entra directamente en el conducto de des-

carga sobre la culata.

14

The working principie ofthe SAS for Quasar 250 cc Euro 2

engines is entirely similar to the SAS employed on 2-stroke

engines. The main differences are the following:

Secondary air enters directly into the exhaust duct on the

cylinder head, instead of entering through the exhaust pipe

as in two-stroke engines.

The reed valve found on 2-stroke engines is here replaced

by a membrane.

Unit «A», shown in the figure, is provided with a cut-off con-

nected to the vacuum inlet on the intake manifold to shut air

inlet during deceleration, so to prevent detonations in the

silencer. Air is sucked in through hole «B» and flows inside

the duct into air-box «C» where it is filtered by filtering ele-

ment «D».

The filtered air now enters membrane device «A», through

duct «E» and is then guided towards the head.

Flowing through pipe «F», flanged to the head, secondary

air reaches the exhaust duct thus providing oxygen addition

to the unburnt gases just before they enter the catalytic con

verter.

The efficiency of the catalyzing process is therefore increa-

sed.

15

Depresione type

Printing on the body

Device CUT-OFF

Max. jet

Minimum jet

Max. air jet

Minimum air jet

Idle mixture adjusment screw initial opening

Conical pin

Emulsifier nozzle

Starter air jet

Starter jet

Starter device resistance

Venturi choke

Throttle valve

Choke maximum cone

CVEK30

CVK

Not present

105

35

70

130

2 ±1/4

Ø 2,450

Ø 2,8

Ø 1,5

42

~20

Ø 29

Ø 30,5

Ø 47

SPECIFICATION DESC. / QUANTITY

CARBURATTOR HEIHIN

Version 125

Type to depression

Printing on the body

Device CUT-OFF

Max jet

Minimum jet

Max air jet.

Minimum air jet

Gas valve spring

Idle mixture adjustment screw initial opening

Conical pin printing

Conical pin notches position from top

Emulsifier nozzle

Choke máximum cone

Starter air jet

Starter emulsifier jet

SPECIFICATION DESC. / QUANTITY

CARBURETTOR WALBRO

WVF-7G*

7G

Not present

108

36

115

100

100 gr

2 5/8 ± 1/2

51C

2

Ø 2,7

Ø 1,5

200

130

16

Starter jet

Starter pin diameter

Starter device resistance

Choke

Throttie valve

Choke máximum cone

SPECIFICATION DESC. / QUANTITY

CARBURADOR WALBRO

50

Ø 1,78

~ 40Q

Ø 29 (30,3x27,0)

Ø 33

Ø 48,0

CARBURATTOR HEIHIN

Version 250

Depression type

Printing on the body

CUT-OFF device

Max jet

Minimum jet

Max air jet

Mínimum air jet

Idle mixture adjustment screw initial opening

Conical pin

Emulsifier nozzle

Starter air jet

Starter jet

Starter device resistance

Venturi choke

Throttie valve

Choke máximum cone

SPECIFICATION DESC. / QUANTITY

CVEK30

CVK

Present

100

38

70

115

2½ ± ¼

Ø 2,530

Ø 2,8

Ø 1,5

42

~ 20

Ø 29

Ø 30,5

Ø 47

17

CARBURATTOR WALBRO

Version 250

Depression type

Printing on the body

CUT-OFF device

Max jet

Minimum jet

Max air jet

Mínimum air jet

Gas valve spring

Idle mixture adjustment screw initial opening

Conical pin

Tacche dall’alto spillo cónico

Emulsitier nozzle

Choke máximum cone

Starter air jet

Starter emulsifier jet

Starter jet

Starter pin diameter

Starter device resistance

Choke

Throttie valve

Choke máximum cone

SPECIFICATION DESC. / QUANTITY

WVF-7S*

7S

Presente

118

34

150

31

120 gr

3±½

465

3

Ø 2,7

Ø 1,5

200

130

50

Ø 1,78

~ 40

Ø 29 (30,3x27,0)

Ø 33

Ø 48,0

* The identification letter can vary every time the carburettor is updated.

18

CHASSIS TIGHTENING TORQUES

1,7÷1,9

1,7÷1,9

4,5÷5,5

4,5÷5,5

7÷8

3÷4

3÷4

1,7÷1,9

1,7÷1,9

3÷3,5

6÷6,5

9÷13

0,8÷1

3÷4

1,7÷1,9

1÷1,3

1,7÷1,9

0,8÷1

1,7÷1,9

1,7÷1,9

0,35÷0,45

7÷8

1,5÷1,9

1÷1,2

3,5÷4

2,2÷2,5

11, 5÷12,5

2,7÷2,9

1,7÷1,9

1,7÷1,9

1÷1,2

1,7÷-1,9

0,8÷1

1,7÷2,2

0,4÷0,5

0,35÷0,45

0,8÷1

1,5÷1,9

0,1÷0,2

0,2÷0,35

DESCRIPTION TORQUES

(N.M)

17÷19

17÷19

45÷55

45÷55

70÷80

30÷40

30÷40

17÷-19

17÷19

30÷35

60÷65

90÷130

8 ÷ 10

30÷40

17÷19

10÷13

17÷19

8÷10

17÷19

17÷19

3,5÷4,5

70÷80

15÷19

10÷12

35÷40

22÷25

115÷125

27÷29

17÷19

17÷19

10÷12

17÷19

8÷10

17÷22

4÷5

3,5÷4,5

8÷10

15÷19

1÷2

2÷3,5

TORQUES

(M.KG)

.

.

.

.

.

.

.

SEALER

(•) Sellador the thread type locktite 243

M8X125 8.8 FRONT FRAME-CHASSIS SECUR.DEVICE

M8X125 8.8 SUBCHASSIS-CHASSIS SEC.DEVICE

M10x150 12.9 TOP SHOCK ABSOR.-CHASSIS SEC.DEVICE

M10x150 12.9 BOTTOM SHOCK ABSOR.-ENG. SEC.DEV.

M14x200 8.8 FRONT ENG. SUPPORT-CHASSIS SEC.DEV.

M10X150 8.8 REAR ENG.SUPP-FRONT ENG.SUPP. SEC.DEV.

M10X150 8.8 ENGINE-REAR SUPP. SEC.DEV.

M8X125 8.8 ENGINE SUPP. SILENTBLOC CLAMP SEC.DEV.

M8X125 8.8 SHOCK ABSORBER SUPP. SEC.DEV.

M8X125 12.9 SHOCK ABSOR. SUPP. TO CRANKCASE SEC.DEV.

M12X175 12.9 SHOCK ABSORBER SUPP. TO SUSP. ARM SEC.DEV. M12X175 12.9

M30,5X150 FORKS FLANGE SEC.DEV.

M6x100 HORN-CHASSIS SEC.DEV.

M10X150 8.8 STAND SEC.DEV.

M8Z125 8.8 FOOTREST SUPPORT-CHASSIS SEC.DEV.

M7x100 8.8 EXHAUST PIPE-CYLINDER SEC.DEV.

M8X125 8.8 SILENCER-SUSPENSION ARM SEC.DEV.

M6x100 8.8 STEERING LOCK-CHASSIS SEC.DEV.

M8x125 8.8 HANNDLEBARS-STEERING FORKS SEC. DEV.

M8x125 8.8 HANDLEBAR CLAMP SEC.DEV.

M5x80 8.8 COUNTERWEIGHT-HANDLEBAR SEC.DEV.

M14x150 FRONT WHEEL-FORKS SEC.DEV.

M8x125 FORK ARM LOCK SEC.DEV.

M6x100 10.9 BRAKE DISK-FRONT WHEEL SEC.DEV.

M10x150 8.8 FR. BRAKE CALLIPER-FORKS SEC.DEV.

M8X125 12.9 SUSP. ARM-ENGINE SEC. DEV.

M16X125 10.9 REAR HUB-ENGINE SEC.DEV.

M8X40 10.9 REAR WHEEL-HUB SEC.DEV.

M8X125 8.8 REAR CALLIPER SUPP.-CRANKCASE SEC.DEV.

M8X125 8.8 REAR CALLIPER-CALLIPER SUPP. SEC.DEV.

M6x100 10.9 BRAKE DISK-REAR HUB SEC. DEV.

M8x125 8.8 CLAMP-CHASSIS SEC.DEV.

M6x100 RADIATOR-CHASSIS SEC.DEV.

THERMOSTAT SWITCH-RADIADOR SEC.DEV.

M5X80 8.8 ELECT.FAN-CHASSIS SEC.DEV.

M5x80 VARIOUS METAL PARTS TO CHASSIS SEC.DEV

M6x100 VARIOUS METAL PARTS TO CHASSIS SEC.DEV.

M8x125 VARIOUS METAL PARTS TO CHASSIS SEC.DEV.

M5x80 VARIOUS PLASTIC PARTS TO CHASSIS SEC.DEV.

M6x100 VARIOUS PLASTIC PARTS TO CHASSIS SEC.DEV.

19

Screw clamping manifold to silencer

Screw clamping heat shield to silencer

Exhaust gas intake screw

Screw fixing silencer support arm to crankcase

Exhaust pipe/support bracket fixing screw.

Exhaust pipe/cylinder head fixing nut.

NAME TORQUE IN Nm

EXAUST PIPE

15,5 ÷ 18,5

5 ÷ 6

22 ÷ 26

33 ÷ 41

27 ÷ 30

16 ÷ 18

Hub oilexhaust cap

Oil filter unión on crankcase

Engine oil / net filter drainage cap

Oil filter

Oil pump cover screws

Screws fixing the oil pump to the crankcase

Oil pump control rim screw

Oil pump cover píate screws

Oil sump screws

Minimum oil pressure sensor

NAME TORQUE IN Nm

ENGINE - LUBRICATION

15 ÷ 17

27 ÷ 33

24 ÷ 30

4 ÷ 6

0,7 ÷ 0,9

5 ÷ 6

10 ÷ 14

4 ÷ 6

10 ÷ 14

12 ÷ 14

Spark plug

Cylinder head cover screw (1) (A)

Head fastening side screws

Start up mass screws

NAME TORQUE IN Nm

CYLINDER HEAD

12 ÷ 14

9 ÷ 11 + 180°

11 ÷ 13

7 ÷ 8,5

7 ÷ 8,5

M5 side screw fastening washers on cam

shaft (125 cc)

This manual suits for next models

2

Table of contents

Other Derbi Scooter manuals

Derbi

Derbi BOULEVARD 125 User manual

Derbi

Derbi GP1 OPEN User manual

Derbi

Derbi Variant Sport User manual

Derbi

Derbi GP1 125 E3 User manual

Derbi

Derbi ATLANTIS CITY 50 2T User manual

Derbi

Derbi Rambla 250 User manual

Derbi

Derbi GP1 2004 User manual

Derbi

Derbi Variant Sport User manual

Derbi

Derbi ATLANTIS 50 2004 User manual

Derbi

Derbi boulevard 125 4t Instruction manual