9

ENGLISH

Important Safety Instructions for All

Battery Chargers

WARNING: Read all safety warnings, instructions,

and cautionary markings for the battery pack,

charger and product. Failure to follow the

warnings and instructions may result in electric

shock, fire and/or seriousinjury.

• DO NOT attempt to charge the battery pack with

any chargers other than a DeWALT charger. DeWALT

chargers and battery packs are specifically designed to

worktogether.

• These chargers are not intended for any uses other

than charging DeWALT rechargeable battery packs.

Charging other types of battery packs may cause them to

overheat and burst, resulting in personal injury, property

damage, fire, electric shock orelectrocution.

• Do not expose the charger to rain orsnow.

• Do not allow water or any liquid to entercharger.

• Pull by the plug rather than the cord when

disconnecting the charger. This will reduce the risk of

damage to the electric plug andcord.

• Make sure that the cord is located so that it will not

be stepped on, tripped over or otherwise subjected to

damage orstress.

• Do not use an extension cord unless it is absolutely

necessary. Use of improper extension cord could result in

risk of fire, electric shock orelectrocution.

• When operating a charger outdoors, always provide

a dry location and use an extension cord suitable

for outdoor use. Use of a cord suitable for outdoor use

reduces the risk of electricshock.

• An extension cord must have adequate wire size

(AWG or American Wire Gauge) for safety. The smaller

the gauge number of the wire, the heavier the cord and

thus the greater its capacity. An undersized cord will

cause a drop in line voltage resulting in loss of power and

overheating. The following table shows the correct size

to use depending on total length of all extension cords

The RBRC® Seal

Please take your spent battery packs to

an authorized DeWALT service center or

to your local retailer for recycling. In some

areas, it is illegal to place spent battery

packs in the trash. You may also contact your local recycling

center for information on where to drop off the spent

battery pack. Do not place in curbside recycling. For more

information visit www.call2recycle.org. or call the toll free

number in the RBRC®Seal.

RBRC® is a registered trademark of Call 2Recycle,Inc.

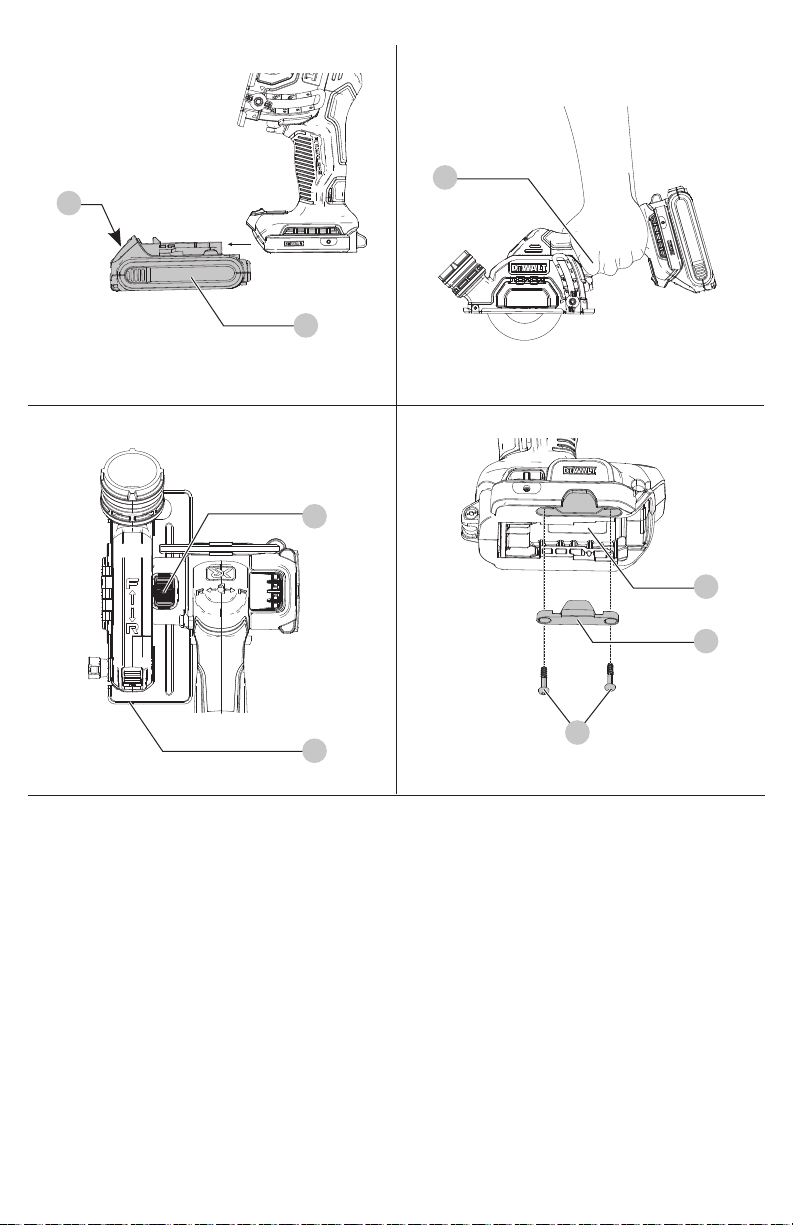

Shipping the DeWALT FLEXVOLT® Battery Pack

The DeWALT FLEXVOLT® battery pack has a battery cap that

should be used when shipping the batterypack.

Attach the cap to the battery pack to ready it for shipping.

This converts the battery pack to three separate 20V

batteries. The three batteries have the Watt hour rating

labeled “Shipping” on the battery pack. If shipping without

• Contents of opened battery cells may cause

respiratory irritation. Provide fresh air. If symptoms

persist, seek medicalattention.

• Battery liquid may be flammable if exposed to spark

orflame.

• Never attempt to open the battery pack for any

reason. If the battery pack case is cracked or

damaged, do not insert into the charger. Do not crush,

drop or damage the battery pack. Do not use a battery pack

or charger that has received a sharp blow, been dropped,

run over or damaged in any way (e.g., pierced with a nail,

hit with a hammer, stepped on). Damaged battery packs

should be returned to the service center forrecycling.

Storage Recommendations

The best storage place is one that is cool and dry, away

from direct sunlight and excess heat or cold. Store the fully

charged battery pack out of thecharger.

Battery Pack Cleaning Instructions

Dirt and grease may be removed from the exterior of the

battery pack using a cloth or soft non‑metallic brush. Do not

use water or any cleaningsolutions.

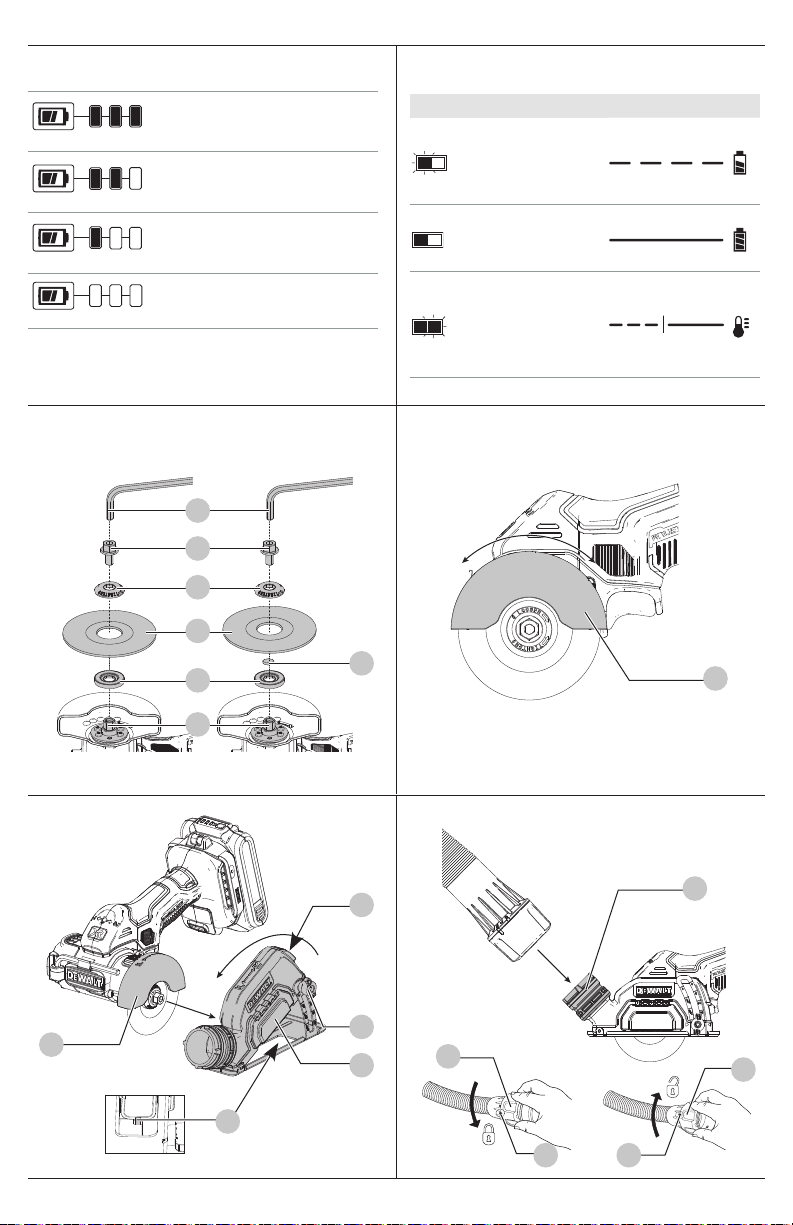

Fuel Gauge Battery Packs (Fig.B)

Some battery packs include a fuel gauge. When the fuel

gauge button is pressed and held, the LED lights will

indicate the approximate level of charge remaining. This

does not indicate tool functionality and is subject to

variation based on product components, temperature, and

end‑userapplication.

Transportation

WARNING: Fire hazard. Do not store, carry, or

transport the battery pack so that metal objects

can contact exposed battery terminals. For

example, do not place the battery pack in aprons,

pockets, tool boxes, product kit boxes, drawers, etc.,

with loose nails, screws, keys, coins, hand tools, etc.

When transporting individual battery packs, make

sure that the battery terminals are protected and well

insulated from materials that could contact them and

cause a short circuit. NOTE: Li‑ion battery packs should

not be put in checked baggage on airplanes and must

be properly protected from short circuits if they are in

carry‑onbaggage.

the cap or in a tool, the pack is one battery at the Watt hour

rating labeled“Use”.

Example battery pack label:

USE: 120 Wh SHIPPING: 3 x 40 Wh

In this example, the battery pack is three batteries with

40Watt hours each when using the cap. Otherwise, the

battery pack is one battery with 120Watthours.