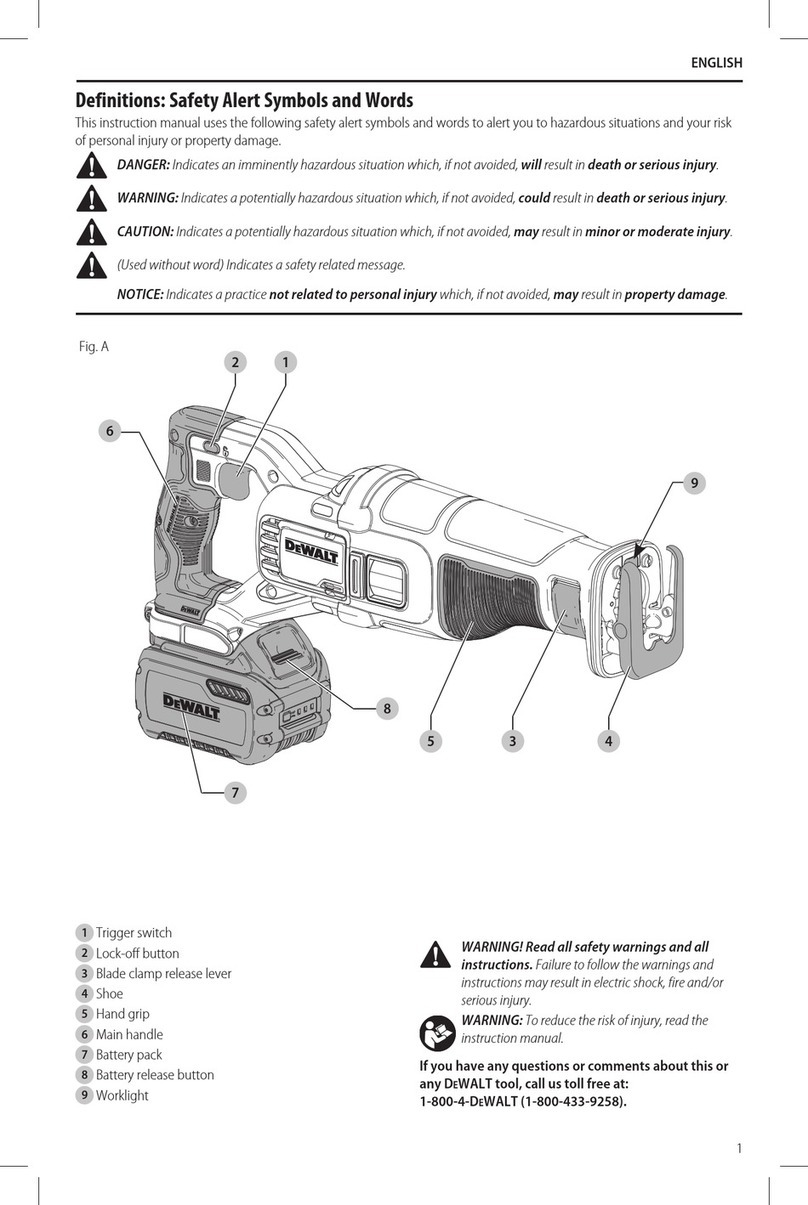

9

ENGLISH

MITRE SAW DW715

Congratulations!

You have chosen a DEWALT tool. Years of experience, thorough product

development and innovation make DEWALT one of the most reliable

partners for professional power tool users.

Technical data

DW715

573,1WtupnirewoP

503mmretemaidedalB

25.4mmerobedalB

nimdeepsedalb.xaM

-1

4,000

Max. cross-cut capacity 90° mm

441mm°54yticapacertim.xaM

99

190

72

133

72

134

72

190

47

mm°09tucfohtped.xaM

Max. depth of bevel cross-cut 45° mm

°05tfel)snoitisop.xam(ertiM

right

tfel)snoitisop.xam(leveB

right

0° mitre

Resulting width at max. height 85 mm mm

Resulting height at max. width 203 mm mm

45° mitre left

Resulting width at max. height 85 mm mm

Resulting height at max. width 142 mm mm

45° mitre right

Resulting width at max. height 85 mm mm

Resulting height at max. width 144 mm mm

45° bevel left

Resulting width at max. height 56 mm mm

Resulting height at max. width 203 mm mm

gkthgieW

The following symbols are used throughout this manual:

Denotes risk of personal injury, loss of life or damage to the

tool in case of non-observance of the instructions in this

manual.

Denotes risk of electric shock.

Safety instructions

When using stationary power tools, always observe the safety

regulations applicable in your country to reduce the risk of fire,

electric shock and personal injury.

Read all of this manual carefully before operating the tool.

Save this manual for future reference.

General

1 Keep work area clean

Cluttered areas and benches can cause accidents.

2 Consider work area environment

Do not expose the tool to rain. Do not use the tool in damp or wet

conditions. Keep the work area well lit (250 - 300 Lux). Do not use the

tool where there is a risk of causing fire or explosion, e.g. in the

presence of flammable liquids and gases.

3 Keep children away

Do not allow children, visitors or animals to come near the work area or

to touch the tool or the mains cable.

4 Dress properly

Do not wear loose clothing or jewellery, as these can be caught in

moving parts. Wear protective hair covering to keep long hair out of the

way. When working outdoors, preferably wear suitable gloves and

non-slip footwear.

5 Personal protection

Always use safety glasses. Use a face or dust mask whenever the

operations may produce dust or flying particles. If these particles might

be considerably hot, also wear a heat-resistant apron. Wear ear

protection at all times. Wear a safety helmet at all times.

6 Guard against electric shock

Prevent body contact with earthed or grounded surfaces (e.g. pipes,

radiators, cookers and refrigerators). When using the tool under

extreme conditions (e.g. high humidity, when metal swarf is being

produced, etc.), electric safety can be improved by inserting an

isolating transformer or a (FI) earth-leakage circuit-breaker.

7 Do not overreach

Keep proper footing and balance at all times.

8 Stay alert

Watch what you are doing. Use common sense. Do not operate the

tool when you are tired.

9 Secure workpiece

Use clamps or a vice to hold the workpiece. It is safer and it frees both

hands to operate the tool.

10 Connect dust extraction equipment

If devices are provided for the connection of dust extraction and

collection facilities, ensure that these are connected and properly used.

11 Remove adjusting keys and wrenches

Always check that adjusting keys and wrenches are removed from the

tool before operating the tool.

12 Extension cables

Before use, inspect the extension cable and replace if damaged.

When using the tool outdoors, only use extension cables intended for

outdoor use and marked accordingly.

13 Use appropriate tool

The intended use is described in this instruction manual. Do not force

small tools or attachments to do the job of a heavy-duty tool. The tool

will do the job better and safer at the rate for which it was intended.

Do not force the tool.

Warning! The use of any accessory or attachment or performance of

any operation with this tool other than those recommended in this

instruction manual may present a risk of personal injury.

14 Check for damaged parts

Before use, carefully check the tool and mains cable for damage.

Check for misalignment and seizure of moving parts, breakage of

parts, damage to guards and switches and any other conditions that

may affect its operation.

Ensure that the tool will operate properly and perform its intended

function. Do not use the tool if any part is damaged or defective.

Do not use the tool if the switch does not turn it on and off. Have any

damaged or defective parts replaced by an authorised DEWALT repair

agent. Never attempt any repairs yourself.

15 Unplug tool

Switch off and wait for the tool to come to a complete standstill before

leaving it unattended. Unplug the tool when not in use, before changing

any parts of the tools, accessories or attachments and before servicing.

16 Avoid unintentional starting

Be sure that the tool is switched off before plugging in.

17 Do not abuse cord

Never pull the cord to disconnect from the socket. Keep the cord away

from heat, oil and sharp edges.

50°

0-48°

0-3°

203

56

19.0