2

Contents

Contents..........................................................................................................................................2

Chapter 1 Operation screen.................................................................................................................4

Displaying or Exiting VPanel ...........................................................................................................5

What is VPanel? ....................................................................................................................................................................................5

Displaying VPanel................................................................................................................................................................................5

Display of VPanel in the Tasktray....................................................................................................................................................6

Exiting VPanel .......................................................................................................................................................................................6

Overview of VPanel Window...........................................................................................................7

Top Window...........................................................................................................................................................................................7

Description of SETTINGS Window .................................................................................................8

"Settings" Tab........................................................................................................................................................................................8

"Override" Tab.......................................................................................................................................................................................9

"Maintenance" Tab ........................................................................................................................................................................... 10

"Mail" Tab............................................................................................................................................................................................. 11

"Manual correction" Dialog........................................................................................................................................................... 12

"Tool management" Dialog .......................................................................................................................................................... 13

"Tool registration" Dialog .............................................................................................................................................................. 14

Chapter 2 Cutting................................................................................................................................15

How to Use / Read the Built-in Panel............................................................................................16

How to Use / Read the Built-in Panel......................................................................................................................................... 16

Colors and Statuses of Signal LED Lamp and Operation Button..................................................................................... 16

Power On / Off...............................................................................................................................17

Turn On the Power Switch............................................................................................................................................................. 17

Turn O the Power Switch.............................................................................................................................................................17

Getting Ready to Cutting...............................................................................................................18

Preparation of Workpieces (Usable Workpieces) .................................................................................................................. 18

Preparation for Tool (Size of Tool That Can Be Used) ........................................................................................................... 18

Preparation for Supply of Compressed Air (Setting the Regulator)............................................................................... 18

Starting Cutting .............................................................................................................................19

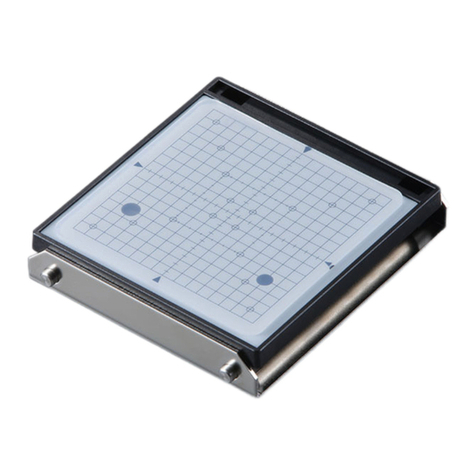

STEP1: Attaching the Workpiece ................................................................................................................................................ 19

STEP2 : Attaching a Tool................................................................................................................................................................. 22

STEP3 : Outputting Cutting Data................................................................................................................................................ 23

Stopping the Output of Cutting Data....................................................................................................................................... 24

Removing Milling Data in Standby from the Output List .................................................................................................. 24

Chapter 3 Maintenance ......................................................................................................................25

Precautions about Maintenance....................................................................................................26

Important Notes on Care and Maintenance........................................................................................................................... 26

Daily Maintenance.........................................................................................................................27

Cleaning after Cutting Operation Ends.................................................................................................................................... 27

Periodic Maintenance....................................................................................................................28

Spindle Run-in (Warm-up) ............................................................................................................................................................ 28

Correction of Milling Machine ..................................................................................................................................................... 29

Care and Storage Methods of Detection Pin and Automatic Correction Jig .............................................................. 30

Retightening the Collet.................................................................................................................................................................. 31

Care and Maintenance of the Regulator .................................................................................................................................. 33

Replacing the Collet ........................................................................................................................................................................ 34

Cleaning the Inside and Applying Grease............................................................................................................................... 35

Replacing of the Spindle Unit ...................................................................................................................................................... 38