DiamaPro Systems SVX2-A User manual

OWNER’S MANUAL

SVX2-A

INDUSTRIAL VACUUM

USER & MAINTENANCE BOOK

SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE

1. INTRODUCTION

This user and maintenance manual will set out the guidelines and proce-

dures that must be followed by those operating this equipment in order to

guarantee:

• Operators’ safety

• Correct use of the machine

• Optimum performance

IT IS NECESSARY THAT THE AUTHORIZED PERSON-

NEL AND MACHINE OPERATOR HAVE READ AND

UNDERSTOOD THE MANUAL BEFORE USING THE

MACHINE.

Due to the importance of this information, we recommend that the opera-

tor:

• Always keeps this manual close at hand for easy consultation

• Keeps the manual in a safe place in order to prevent loss or damage

• Asks the manufacturer/supplier for a replacement copy in case of loss or

damage

• Supplies this manual and the manufacturer’s details together with the

machine if it is sold to a third party

IF THE PURCHASED VACUUM CLEANER IS DIAMA-

PRO AUTHORIZED, THE TECHNICAL PLATE AT-

TACHED TO THE ENGINE HAS A SERIAL NUMBER

THAT IS USED FOR REQUESTING A COPY OF THE

CERTIFICATE IF THIS IS DETERIORATED OR LOST.

The manufacturer reserves the right to update its products and manuals

and is not required to provide updated versions of the them.

2. WARRANTY

The vacuum cleaners manufactured by DiamaPro have been fully inspect-

ed to guarantee correct electrical, pneumatic and mechanical function.

The vacuum cleaners are covered by a 12-month warranty. All defective

parts of the machine are covered by warranty but this does not include

parts damaged during shipping, handling or use nor does it cover parts

damaged by normal wear and tear.

Repairs can be carried out by an authorized service center or directly by

DiamaPro.

To request your warranty service you MUST send a written request to the

dealer or directly to the manufacturer including the manufacturing details

that can be found on a plate tted inside your machine together with a

copy of the invoice.

The warranty is valid under the following conditions:

• Improper use of the machine or total or partial failure to comply with the

contents of this manual

• Any part of the vacuum cleaner is altered or modied in any way

• Incorrect electrical installation

• If the laws in the country of use are not respected

• Inadequate maintenance

• The machine has not undergone routine maintenance as specied in this

manual

• Use of spare parts that are not produced by DiamaPro or not specically

indicated for the model in use

• Partial or total failure to comply with the instructions given in this manual

3. UNINTENDED USE

• Never suck up cigarette butts that have not been properly put out and/or

any other ammable materials

• Never suck up substances that may explode in contact with the air

• Never operate in environments where explosive gases and/or gases from

toxic chemical products are present in the air

• Check the suitability of the cartridge lter before sucking up toxic sub-

stances

• Disconnect from the power outlet before accessing any electrical compo-

nents of the machine

• Do not modify the machine in any way

• Do not use the machine in a way that does not comply with the require-

ments of this manual

4. MACHINE DATA

4.1 TECHNICAL DATA PLATE

Every DiamaPro machine carries a registration plate showing essential

details that are necessary when contacting the supplier/manufacturer for

advice, suggestions or information on spare parts. The following details are

included on the plate:

• Manufacturer

• Model

• Supply voltage

• Installed rated power

• CE symbol (built in compliance with Machinery Directive 2006/42/EEC)

4.2 TESTING

All DiamaPro machines are tested before packaging and delivery in order

to ensure the correct function of each component. An accurate electrical

safety test is carried out in compliance with specic electric safety stan-

dards related to:

• Ground continuity test

• Insulation resistance test between every phase and the ground

• Dielectric test

• Measurement of dispersed current

• Measurement of power and absorbed current (acceptable dierence of

+/-10% of rated value)

• Measurement of maximum depression and air exhaust values (tolerance

of +/-15% based on temperature values and humidity of environment)

• Measurement of maximum air absorption

4.3 SAFETY DEVICE

The vacuum cleaner has been manufactured in compliance with all legal

standards for the operator’s safety.

• All metal components are grounded to eliminate shock or electrostatic

discharge, including the exible suction hose that is properly grounded.

Also in this regard the choice of a suitable exible suction hose allows to

eliminate this risk on the hose length that goes from the use area to the

vacuum cleaner.

• The brakes tted onto the anterior pivoting casters safely x the machine

in its place of use where there may be a risk of movement due to uneven

oor surfaces or other particular working conditions.

BEFORE USING THE MACHINE CHECK THAT THE

MACHINE HAS NOT SUFFERED ANY SHOCKS OR

DAMAGES DURING THE TRANSPORT THAT CAN

AFFECT THE OPERATION OF THE ABOVE DEVICES

5. PERFORMANCE TOLERANCES

The performance of the turbine may vary by 15% based on the tempera-

ture and air humidity.

The safety valves are calibrated based on the amperage of the turbine.

6. SAFETY PROVISIONS

• Carefully read the instructions in this manual before starting, using,

servicing or operating the vacuum cleaner

• Check that the vacuum cleaner hasn’t been damaged in any way

• Never turn on the machine if it is faulty or if you suspect it is faulty

• Check that the switch isn’t worn or damaged

• Do not approach the suction intake of the machine with unfastened or

broken garments that could easily be sucked into the machine

• Check that the lters are present and ecient

• Make sure that the lters are installed correctly and in full working order,

always observing the regulations in force in the workplace

• Do not carry out repairs without the manufacturer’s authorization

• Never use gasoline, solvents or other ammable liquids for cleaning;

only proper detergents should be used for cleaning

• Never move the machine by pulling the power cable or exible hose

• Never direct the opening of the machine or the exible tube towards

people or animals

• Protect the machine from the rain

• Check that the machine is connected to a power source with the correct

voltage indicated on the registration plate

• Make sure that the power cable has no wear or damage. If replacing the

cable, always replace it with another of the same specications as the orig-

inal one: cables that are not approved or of inferior quality may overheat

and cause serious injury to the user

• Make sure that the machine is connected to an appropriate power source

in full working order (check the presence of a fully functional grounding

socket)

• Repairs must only be carried out by authorized personnel and only when

the machine is turned o and disconnected from the power source

• Never allow unauthorized personnel to use the machine

• Make sure that all safety devices are in full working order before turning

on the machine

• Never cover the vacuum cleaner during use

7. INSTALLATION

7.1 DELIVERY AND HANDLING

All machines are carefully tested and checked by DiamaPro before

delivery. The machine is transported inside a protective box or wrapped

in a protective lm that allows the courier to see the item during transport

and is securely xed to a pallet. If any part of the machine is not intact or

has been damaged during transport, le an immediate complaint with the

courier. Parts that have been damaged or broken due to incorrect transport

or handling of the machine will not be recognized by the manufacturer’s

warranty. The machine must be lifted and moved using a forklift truck in

accordance with the relevant safety regulations in force in the workplace

7.2 CHECK THE PROPER ELECTRICAL

CONNECTION

Connect the industrial plug to the power cable and connect the plug to a

socket that has the same amp rating and is protected by a line-isolating

switch; in the case of the three-phase vacuum cleaner, it is necessary to

check before use that the motor rotates in the correct direction (clockwise)

as shown by the die-cast indicator on the turbine; if rotation occurs in an

anti-clockwise direction, it is necessary to disconnect the machine from

the power source, invert one of the three phase cables inside the plug and

check again for correct rotation

8. PERIODICAL MAINTENANCE

Maintenance and cleaning operations must ALWAYS be carried out when

the vacuum is turned o and disconnected from the power source. No

particular measures must be taken for the maintenance, cleaning or lubri-

cation of the suction unit. However, it is important to remember that correct

use and servicing are essential if the safety and eciency of the vacuum

are to be guaranteed.

To ensure regular and constant operation and to prevent the warranty from

becoming void, always use genuine DiamaPro spare parts when repairs

are needed.

8.1 BEFORE TURNING ON AND TURNING OFF

EVERY DAY

• Visually check that the suction hose has not been damaged in any way (it

must not be damaged, torn, crushed)

• Check that the electrical switches are in full working order and are not

damaged in any way

• Check the level of waste inside the main barrel N.B. Empty the main

barrel if you are using an DiamaPro model empty the main barrel

• Check that the suction hose has not been damaged in any way

• Check that the motor head is correctly positioned on the lter chamber

and that the latter is correctly placed on the main barrel

• If the vacuum cleaner is moved, ensure that the power voltage of the play

in this new location corresponds to the one on the technical data plate

8.2 AT EVERY 200 HOURS OF OPERATION

• Check the condition of the primary lter: it must not have tears, holes or

other damage: in this case replace it (see 14.)

• Check that the technical data plate is legible and not damaged in any

way: contact the manufacturer for a replacement if necessary

PERFORM THE FOLLOWING OPERATIONS AT

EVERY 10 HOURS OF OPERATION IF THE VACUUM

CLEANER IS AN DIAMAPRO MODEL

9. PRODUCT DISPOSAL

Dispose of the machine and any accessories according to the legislation of

the country. To avoid aecting the environment or your health or the health

of others it is recommended to separate the machine from other waste,

and if necessary properly recycle it.

10. TECHNICAL DATA

MODEL

CODE

CERTIFICATE

MOTORS

VOLTAGE

FILTER CLEANING

FILTRATION CLASS

USEFUL CAPACITY

CFM*

WATERLIFT

DIMENSIONS

INLET DIMENSION

TANK DIAMETER

WEIGHT

SOUND PRESSURE LEVEL (ISO 11201)

SVX2A

110V-60HZ

CE

2

110V-60 HZ

AUTOMATIC

HEPA

INFINITY BAGS

220

88 IN

31X25X54IN

2 IN

18 IN

218 LBS

<78

*Theoretical

I

0

1

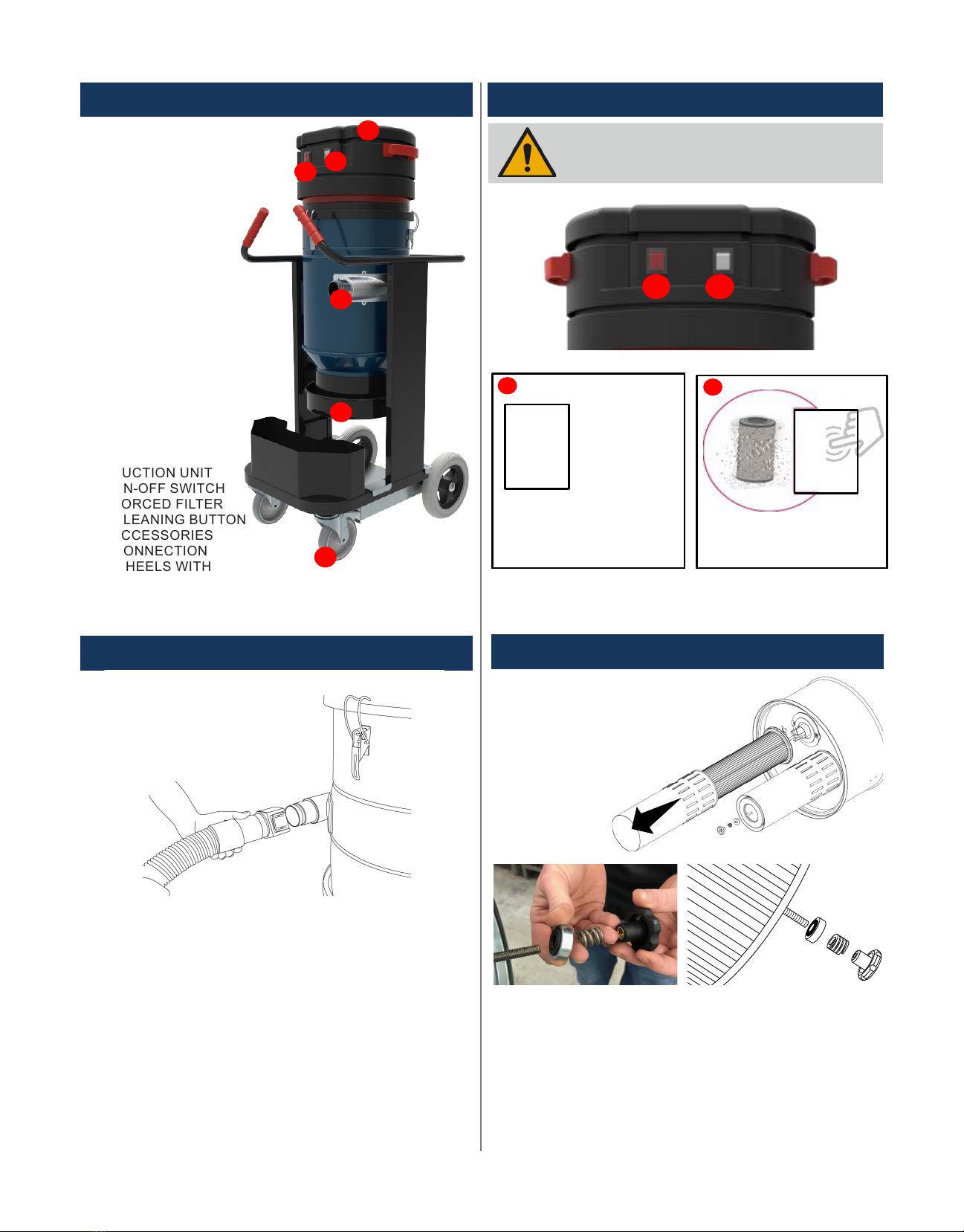

11. DESCRIPTION

1. SUCTION UNIT

2. ON-OFF SWITCH

3. FORCED FILTER

CLEANING BUTTON

4. ACCESSORIES

CONNECTION

5. WHEELS WITH

BRAKE

6. BAG

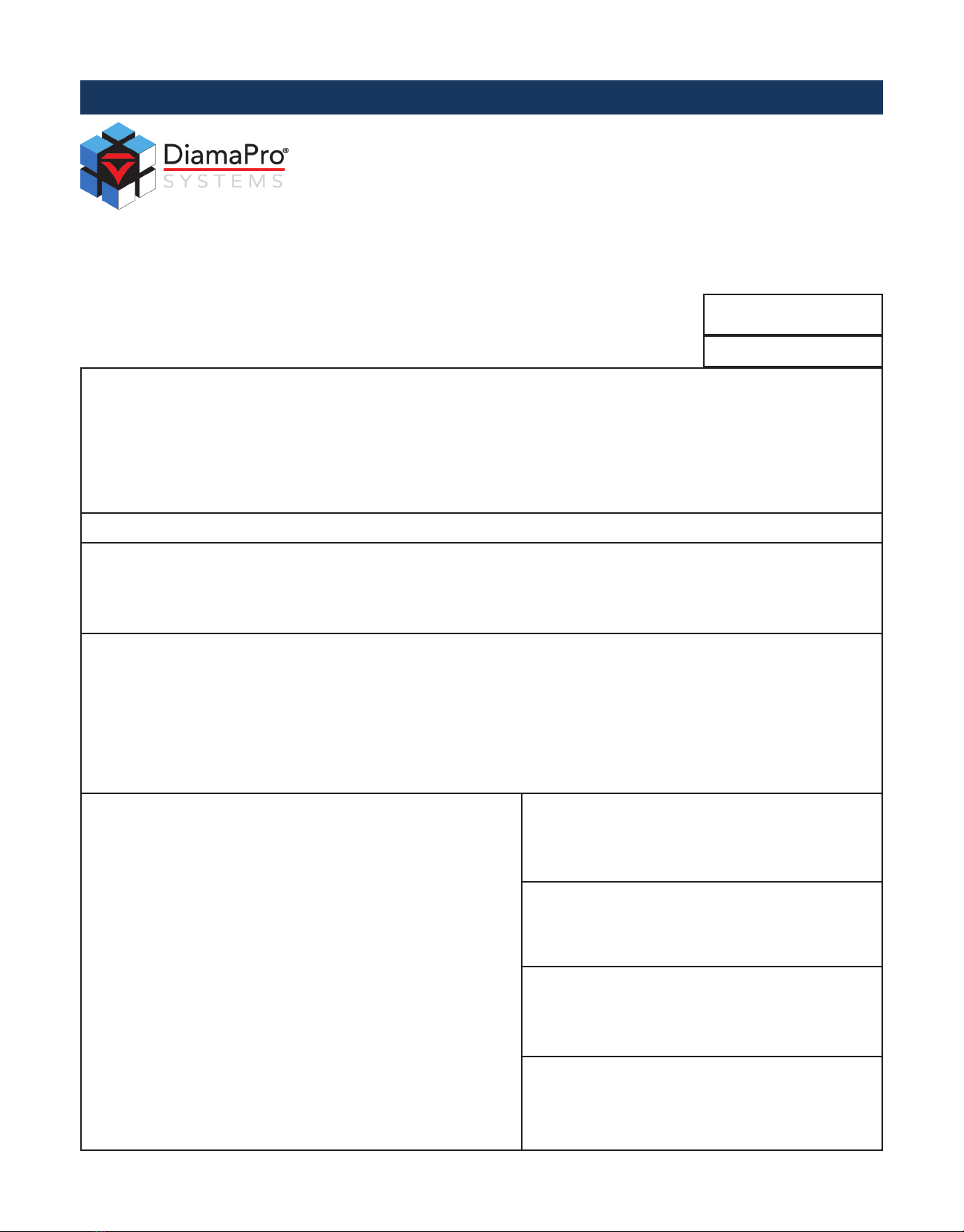

12. MOUNTING OF PARTS

Depending on the specic needs of the client, the vacuum cleaner may

include accessories that are not normally supplied in the standard version.

It is necessary to select the suction hose and accessories that are appro-

priate for the type of material that must be sucked into the cleaner.

The machine is now ready for use.

Connect one end of the exible hose to the desired accessory and the

other with the quick coupling nozzle mounted on the lter chamber. (See

the accessories sheet)

13. USING THE VACUUM CLEANER

I - 3 Motors switch ON

O - Switch OFF

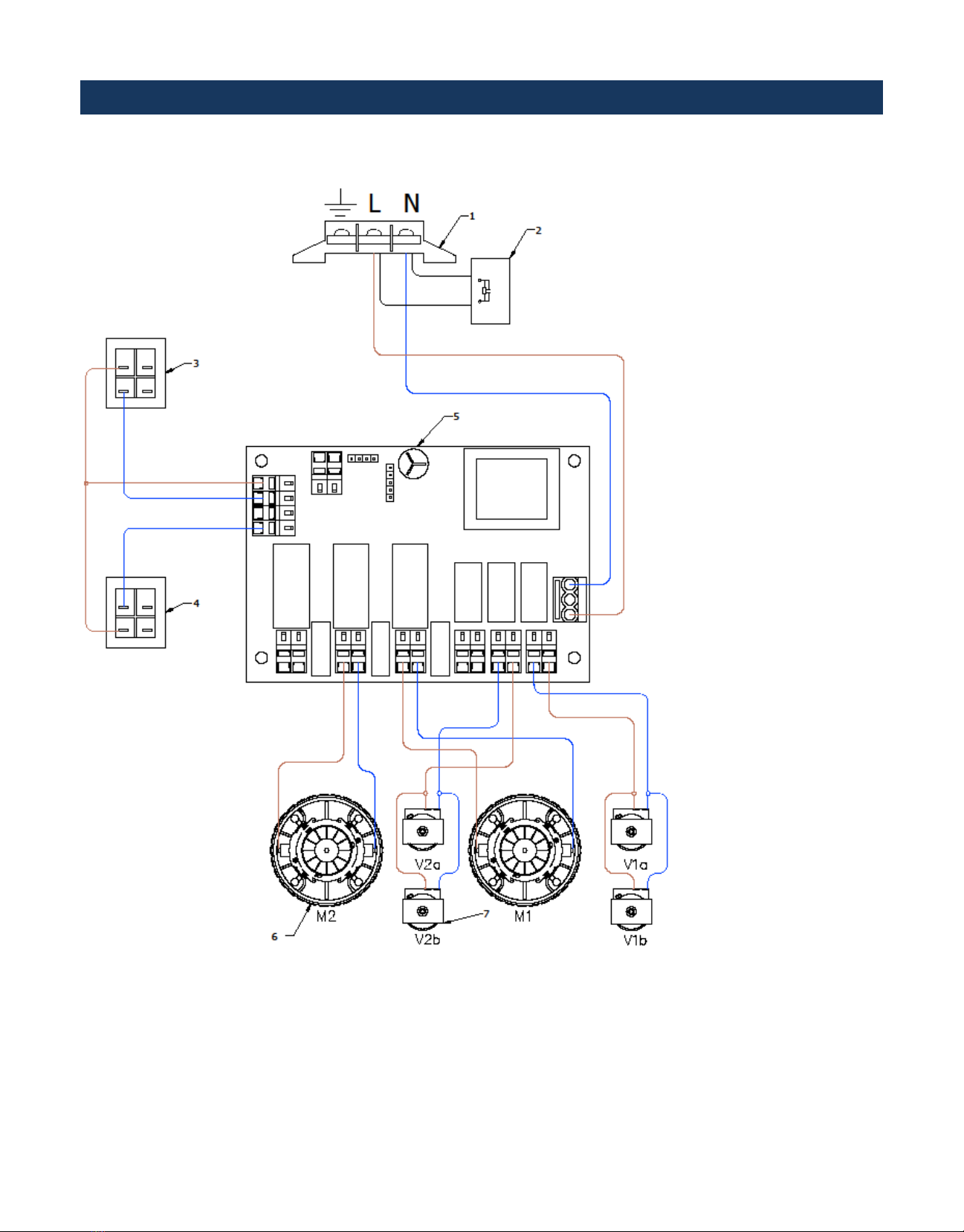

14. FILTER REPLACEMENT

Before switching ON the vacuum be sure the

container is empty

2

Push for forced lters

cleaning

1. Disconnect and lift the head.

2. Remove the lter’s cylindrical

steel protection

(unscrewing the screws on the

edge)

3. Unscrew the wing nut and

remove the spring and washer

4. Replace the lter with a proper

one for the vacuum cleaner

in use

5. Install the new lter according to

the label on the bottom of the lter

• Washer with rubber part facing

the base of the

lter

• Spring

• Plastic wing nut

6. Mount the cylindrical protection,

then reconnect the head on the

ltering chamber

1

2

3

4

5

6

1 2

15. TROUBLESHOOTING

You can thus solve any problem that may occur.

Motors do not start.

uNo electrical voltage. uCheck cables, plugs and socket.

Suction capacity decreases slowly.

uFilter, nozzle, suction hose or suction pipe may be blocked. uCheck, clean accessories. Clean lter.

Dust comes out during the vacuuming.

uFilter has not been fastened correctly or is defective. uCheck to see if lter is sitting properly; replace if required.

1 - Close the bag with two

distanced bands.

2 - Cut the strip between the

two bands.

3 - Pull the Innity Bag end to

make a new bag.

16. COLLECTION BAG USE

The dust and the particles are collected in a bag placed in the container under the hopper.

The Innity Bag system consists in a plastic tubular from which are obtained 20/30 bags of dierent weights and dimensions.

Once nished or damaged, the tubular must be replaced by a new rell.

The operations below described must be carried out when machine is turned o.

17. BAG REPLACEMENT

1- Cut the Innity Bag in

order to let it open.

2- Pull and rotate the re-

taining pins of the Innity

bag container in order to

unfasten them.

3- Remove the Innity Bag

container and any waste.

4- Insert the new Innity Bag

with the inner part facing

upwards.

5- Cut and remove the Innity

Bag closing bands.

7- Pull the outer part of

the bag to create a new

one.

8- Insert the container with

the Innity Bag.

9- Pull and rotate the retaining

pins and insert them into their

seats.

10- Pull the bag and place at

the edge the band to create

a new one. If necessary use

two bands.

6- Keep the inner part

of the bag inside the

container and pull it up

to the lower edge.

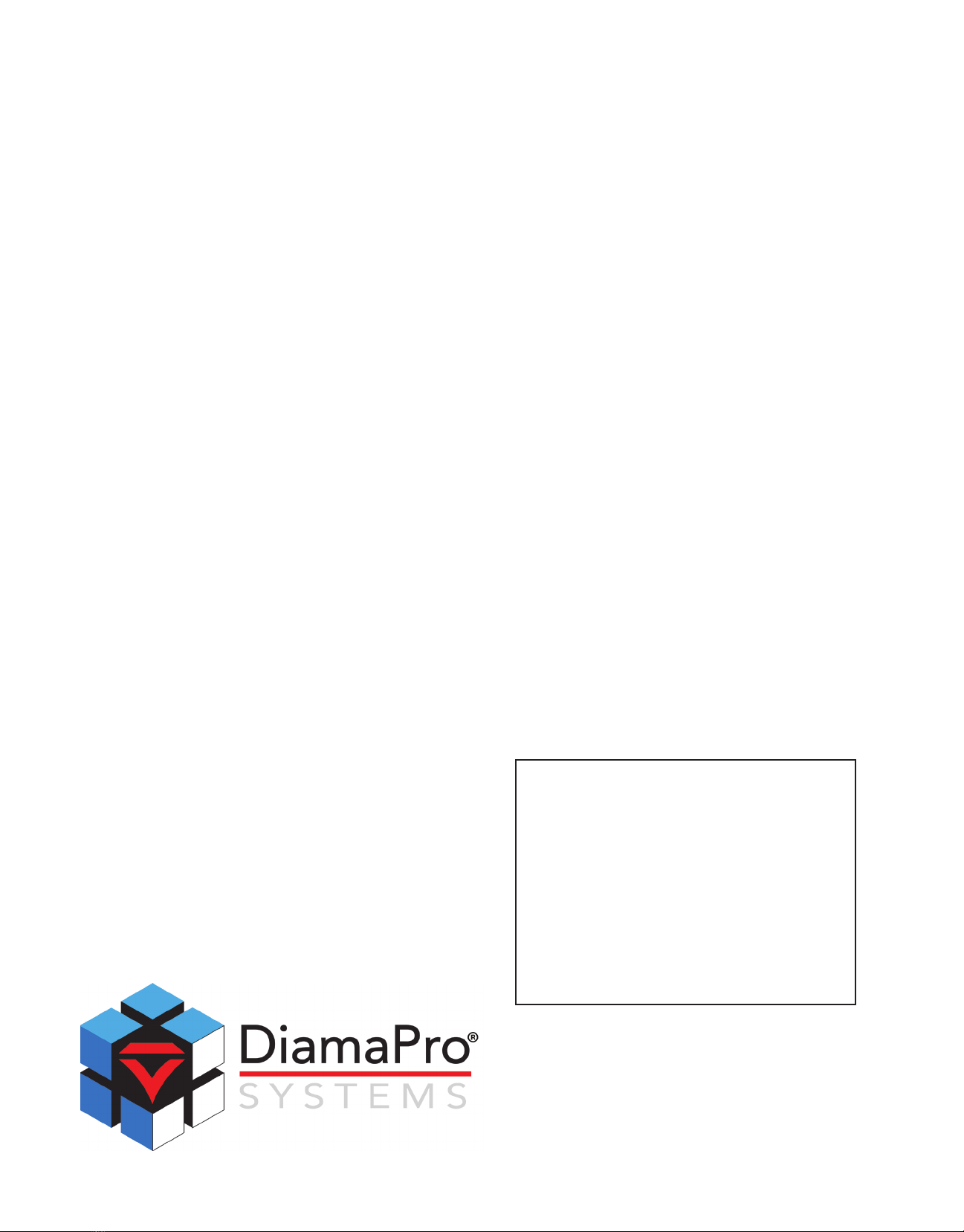

19. ELECTRIC DIAGRAM

1 - TERMINAL

2 - ANTI-DISORDER

3 - SWITCH (0-1)

4 - MOMENTARY SWITCH (NO)

5 - ELECTRONIC CARD

6 - MOTOR

7 - VIBRATOR

20. DECLARATION OF CONFORMITY

DiamaPro Systems

P.O. Box 19946

Charlotte, NC 28219

(404 ) 834-1162

UNDER OUR SOLE RESPONSIBILITY THAT THE PRODUCT

Model

Made In

Are in conformity with the undermentioned product’s specications:

and relative amendments

Harmonized norms:

The manufacturer declares that the technical le of the equipment is kept at:

This statement will expire automatically for:

1 - Changes to the equipment

2 - Non-compliance with instructions

contained in the user and maintenance

manual

SVX2-A

2018

2006/42/CE

CE Machinery Directive

2014/35/UE

CE Low Voltage Directive

2014/30/UE

CE EMC Directive

EN ISO 12100:2010

EN 60335-2-69

EN 55014-1:2006

DiamaPro Systems

P.O. Box 19946

Charlotte, NC 28219

(404 ) 834-1162

Name

Position

Date

Signature

DiamaPro Systems

P.O. Box 19946

Charlotte, NC 28219

(404 ) 834-1162

Dealer’s signature and stamp

Table of contents

Other DiamaPro Systems Vacuum Cleaner manuals

DiamaPro Systems

DiamaPro Systems SVX2+A User manual

DiamaPro Systems

DiamaPro Systems SVX3-A User manual

DiamaPro Systems

DiamaPro Systems TVX-A User manual

DiamaPro Systems

DiamaPro Systems WVX User manual

DiamaPro Systems

DiamaPro Systems SVX3-A User manual

DiamaPro Systems

DiamaPro Systems SVX2-M User manual

DiamaPro Systems

DiamaPro Systems WVX-P User manual