Contents

Preface ............................................................................................................................................................... 6

Safety information .............................................................................................................................................. 8

Compliance with safety rules ............................................................................................................................... 9

1 Packing instructions ................................................................................................................................ 10

2 Giotto stainer components...................................................................................................................... 18

2.1 Instrument overview ............................................................................................................................ 18

2.2 Instrument rear part............................................................................................................................. 19

2.3 Instrument features ............................................................................................................................. 19

2. Packing list .......................................................................................................................................... 20

2.5 Accessories .......................................................................................................................................... 20

2.6 Technical data ..................................................................................................................................... 21

2.7 Reagent reservoir ................................................................................................................................. 22

2.7.1 Loading and replacement of reagents ................................................................................................ 22

2.8 Water reservoir .................................................................................................................................... 22

2.8.1 Loading and replacement of water reservoirs ...................................................................................... 23

Instrument setting .................................................................................................................................. 24

3.1 Placement and installation .................................................................................................................... 2

3.1.1 Requirements dor the installation ...................................................................................................... 2

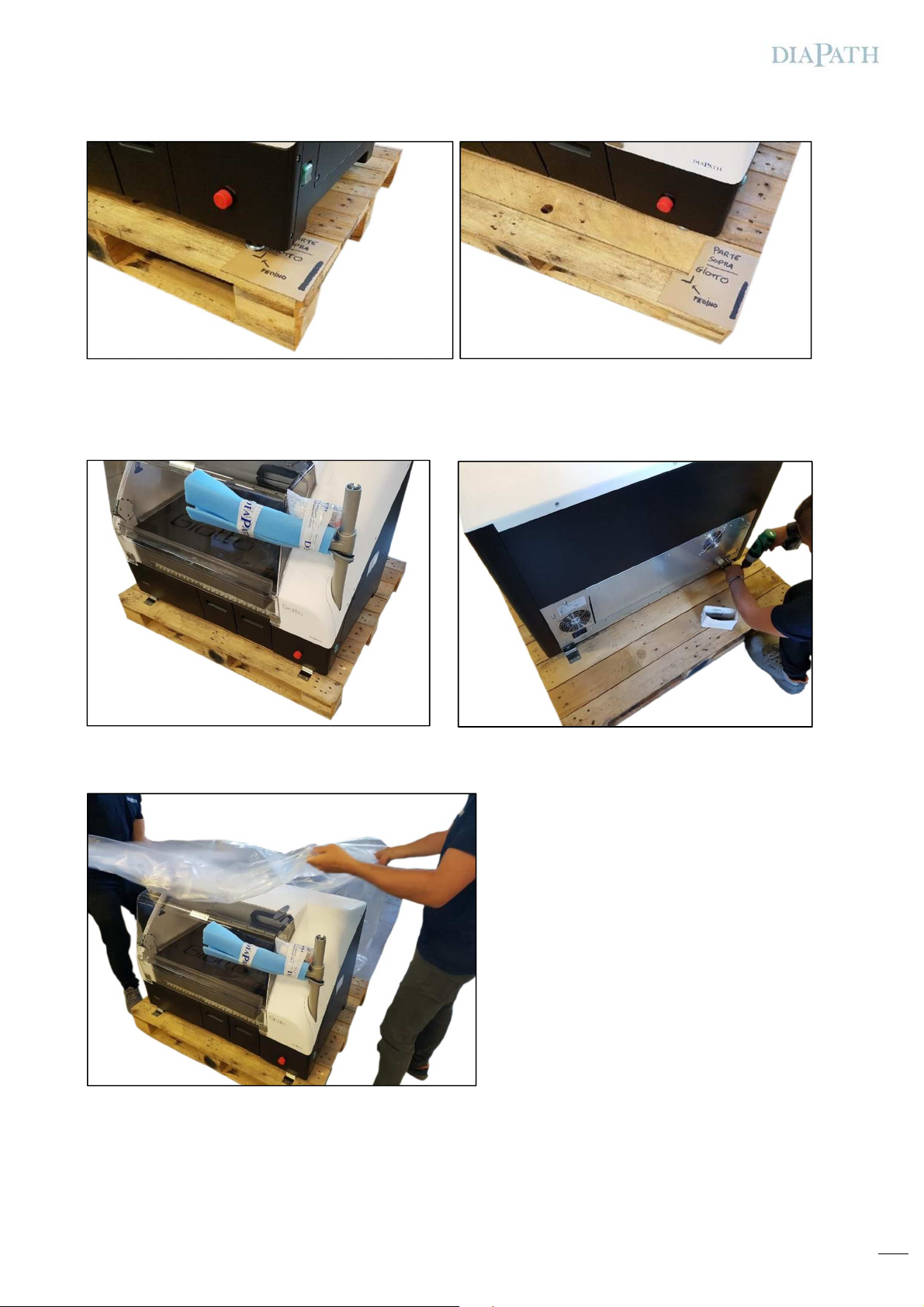

3.1.2 Unpacking ....................................................................................................................................... 2

3.1.3 Re-packing ...................................................................................................................................... 25

3.1. Checks before the use ...................................................................................................................... 25

3.1.5 Requirements for connections ........................................................................................................... 25

3.2 Water connection ................................................................................................................................. 26

3.3 Air drainpipe assembly .......................................................................................................................... 28

3. Instrument level................................................................................................................................... 28

3.5 Electrical connection ............................................................................................................................. 29

3.5.1 P

ROCEDURES BEFORE THE USE

.................................................................................................................. 30

3.6 Instrument starting .............................................................................................................................. 30

3.7 Check list before the start up ................................................................................................................ 30

3.8 Alarm system ....................................................................................................................................... 31

3.9 Transport ............................................................................................................................................ 31

3.10 Quick installation guide ......................................................................................................................... 31

4 Software functionalities .......................................................................................................................... 2

.1 User interface ...................................................................................................................................... 32

.1.1 Main screen ..................................................................................................................................... 32

.1.2 User authentication .......................................................................................................................... 32

.1.3 Key symbols .................................................................................................................................... 33

.1. Values introduction .......................................................................................................................... 33

5 Giotto setup ............................................................................................................................................. 4

5.1 General Setup ...................................................................................................................................... 3

5.1.1 Language, Time and date ................................................................................................................. 3

5.1.2 Oven ............................................................................................................................................... 35

5.1.3 Rinsing of water reservoirs ................................................................................................................ 35

5.1. Timings ........................................................................................................................................... 36

5.1.5 Racks .............................................................................................................................................. 36

5.1.6 Protocols ......................................................................................................................................... 37

5.1.7 Renewal of filter or staining kit .......................................................................................................... 38

5.1.8 Instrument switching off ................................................................................................................... 38

5.2 Roles and permissions management ...................................................................................................... 39

5.3 Reagent management .......................................................................................................................... 0

5.3.1 Add/modify reagent.......................................................................................................................... 0

5.3.2 Park setting ..................................................................................................................................... 0

5.3.3 Reservoirs setting ........................................................................................................................... 1

5. Create and modify staining protocols ..................................................................................................... 3

5. .1 Link the rack to the protocol ............................................................................................................ 5

5.5 S

3

Functionality .................................................................................................................................... 6

5.6 Scan of reagent level ............................................................................................................................ 8

5.6.1 Reagent refill and replacement .......................................................................................................... 9

5.7 Open drawer ....................................................................................................................................... 50

5.7.1 Drawer IN ....................................................................................................................................... 50

5.7.2 Rack loading .................................................................................................................................... 51

5.7.3 Loading of an unknown handle .......................................................................................................... 51

5.7. Drawer OUT .................................................................................................................................... 51

5.7.5 Door opening ................................................................................................................................... 51