diapath DPH 35 User manual

DPH 35

Flotation bath

User Manual

1

Manufacturer:

Diapath S.p.A.

Via Savol ini,71

24057 Martinengo (BG) Italy

Tel. (+39)0363.986.411

Fax (+39)0363.948.000

www. iapath.com

info@ iapath.com

2

Manual information

It is forbi en partly or in full to mo ify this manual in absence of any explicit authorization.

Information containe in this manual are subject to changes without prior notice.

Diapath S.p.A. has one as much as possible to assure the accuracy of this manual.

However, in case something seems to be wrong or not clear, please contact Diapath S.p.A or the

istributor.

Diapath a opts continuously a evelopment policy an reserves the right to make changes an

improvements to any pro uct escribe in this manual without prior notice. In no case Diapath will be

consi ere responsible for possible losses of ata or earnings or for any other atum.

Manual revision: Rev. 05

Date: 26

th

April 2016

3

Preface

Destination of use

DPH 35 is a flotation bath an it is compose of a removable tank in glass an a regulate resistance.

The flotation bath has been projecte to optimize the collection proce ures of histological sections obtaine

with the microtome.

The DPH 35 facilitate the sections flotation an isposition in or er to a here perfectly to the sli e.

In this instrument there is the possibility to set up the maximum an minimum level of the set point, the

water temperature, the minimum time in which the relay 1 is off, the relay status in case of anomalies, the

offset an the hysteresis regulation.

This manual escribes DPH35 operation, safety information an maintenance.

The first section eals with “Safety Information”, in which are escribe the a opte symbols, the

instructions an precautions.

The following section “Specifics an Installation” contains all information concerning the installation place

features an mo alities.

In the “Maintenance” section there are information about cleaning perio ic requirements, isinfection an

system controls. The maintenance is very important; for this reason we suggest to rea , un erstan an

follow them carefully.

The users might be a equately traine about its use an they might respect all safety requirements an the

instrument use limits.

The instrument maintenance concerning the electronic parts shoul be performe only by traine an

authorize staff of Diapath S.p.A.

The instrument has been projecte accor ing to the ex D.lgs. 332/00 of 8 September 2000 “ irective

actuation 98/79/CE of 27 October 1998 accor ing to iagnostic in vitro evices irective”.

4

Quality control

Diapath S.p.A. a optes quality management system ISO 9001(*) an ISO 13485(*) to project, make an

improve the technical-scientific solution for the customer in me ical an iagnostic in vitro systems, assuring

high quality services with the help of an highly qualifie an motivate staff to contribute to the

improvement of Diapath S.p.A. pro ucts.

Diapath S.p.A. constantly looks for customer’s satisfaction, tries to perceive their expectations an to treat

the customer without any iscrimination. Diapath S.p.A. assures the application of normative requirements.

Quality assurance of ata furnishe by Diapath S.p.A. is obtaine through these activities:

•Use only reference material

•Execution of proofs of the whole pro uction

•Correlation of ifferent results

The internal quality control foresees to monitor the most ifficult passages of an analytic process so as to

verify their stability, to assure that quality parameters estimate uring the vali ation or check of the

metho are vali also for real instruments an that they won’t get worse in the course of the time.

Diapath S.p.A. tests its own pro ucts in accor ance with some internal proce ures, to re uce possibility of

anomalies uring the operation.

To i entify an to fin out its own instruments, Diapath S.p.A. uses some internal proce ures in which we

can fin pro uction recor ing, assembling recor ing, tests recor ing, serial number or batch co e an

configuration recor ing.

(*)

In the applicable e ition

5

Safety information

Mentione agreement an graphic symbols

Danger - The anger instructions signal situations that might cause eath or serious

lesions.

Caution - The caution instructions signal situations that might cause physical

lesions to people or amages to things.

Heated surface – Heate surface instructions signal surfaces that get hot

uring use. Risk of burns, avoi irect contact.

Instructions of anger

Never isassemble, mo ify or repair the instrument without written authorization by

Diapath

S.p.A.

An inappropriate use of the instrument can provoke electric shock, burning, fire an

other risks.

Biohazar of parts involve in the process.

Insert the plug of the instrument into a groun e power socket.

Instructions of caution

Do not place the instrument in liqui , nor put it in a position where it coul fall into liqui .

If the instrument gets wet, isconnect the power cable before touching it.

Use the instrument only for purposes escribe in this manual.

6

Do not use the instrument if it oesn’t work properly or if it has been amage .

Do not let the instrument or its flexible cable comes into contact with surfaces which are

too hot to touch.

Do not place anything on the instrument

Do not rop or put anything into any instrument opening.

Safety training

All the operators must be traine to use the instrument safely.

After such training the operators must have un erstoo that:

•The instrument must be connecte to a groun e power socket.

•The instrument must be connecte to a voltage source in accor ance with electrical ata label.

•The use of the instrument ifferently from Diapath instructions might compromise protections

supplie by the instrument.

•Operators must keep han s away from heating parts.

•Operators must consult the safety ata sheets for the han ling an safe isposal of the instrument

Compliance with safety rules

All regulations relate to safety, local co es an instructions that appear in the manual or on the instrument

must be carefully observe to ensure personal safety an to prevent amages to both the instrument an to

the equipment connecte to it. If the instrument is incorrectly use , the protection provi e might be

compromise .

7

Definition of a opte symbols

See the user manual

Electrical shocks risk

Disposal

Disconnect the power cable

before the maintenance

In vitro iagnostic me ical

evice

Built in

Manufacturer

Danger

European Community

approval mark

Rea carefully the manual before

instrument starting

8

Storage an han ling

For a correct conservation an functioning of the instrument, all the instructions provi e in this manual

concerning the maintenance an the installation shall be respecte . Also the showe below environmental

requirements shall be respecte .

The flotation bath can work with 80% relative humi ity con itions for temperatures up to 31°C with a linear

ecrease up to 50% at the temperature of 40°C. Voltage variation can’t excee +/-10% the nominal value.

Storage an transportation temperature range from +5°C to +40°C

Storage humi ity 80%

Working temperature range from +5°C to +40°C

9

Contents

MANUAL INFORMATION ...........................................................................................................................2

PREFACE .................................................................................................................................................3

Destination of use ........................................................................................................................3

QUALITY CONTROL ..................................................................................................................................4

SAFETY INFORMATION ............................................................................................................................5

DEFINITION OF ADOPTED SYMBOLS ........................................................................................................7

STORING AND HANDLING ........................................................................................................................8

1 INSTRUMENT PLACEMENT AND INSTALLATION ................................................................................... 10

1.1 Unpacking ........................................................................................................................... 10

1.2 Setting up before installation ................................................................................................ 10

1.3 Startup ............................................................................................................................... 10

2 OPERATIVE PROCEDURE .................................................................................................................... 11

2.1 Har ware theory an functionality ........................................................................................ 11

2.1.1 Type of liqui ................................................................................................................... 11

2.1.2 Instrument starting up ...................................................................................................... 11

2.1.3 Operator control before use .............................................................................................. 11

2.1.4 Heate areas .................................................................................................................... 11

2.1.5 Thermoregulator functioning ............................................................................................. 11

2.1.6 Set point .......................................................................................................................... 12

2.1.7 Stan by .......................................................................................................................... 12

2.1.8 Turning off proce ure ....................................................................................................... 12

3 PERFORMANCES AND LIMITATIONS ................................................................................................... 13

4 SPECIFICS AND INSTALLATION .......................................................................................................... 14

5 PREVENTIVE MAINTENANCE ............................................................................................................... 15

5.1 DPH 35 cleaning ................................................................................................................... 15

5.2 Glass tank isinfection .......................................................................................................... 15

5.3 Fuses replacement ................................................................................................................ 15

6 TROUBLESHOOTING .......................................................................................................................... 16

6.1 Parts supplie by Diapath ...................................................................................................... 16

6.2 Spare parts list ..................................................................................................................... 16

7 WEEE DIRECTIVES ............................................................................................................................. 17

7.1 Uninstallation an isposal .................................................................................................... 17

7.2 Diapath instrument guarantee ............................................................................................... 18

10

1

Instrument placement an installation

The instrument must be place an installe only by Diapath S.p.A. staff.

1.1 Unpacking

Unpack instrument parts taking care to not amage them. The instrument has been teste before the

shipping.

Make sure about any serious amage to the packaging an to the instrument ue to the transport. In case

of amages, please contact Diapath or the local istributor.

1.2 Setting up before installation

Before the installation, please verify that electrical supply sources are set accor ing to the ata supplie by

the manufacturer (see instrument specifics).

Place the instrument on a plane surface an able to support the pro uct weight (see instrument specifics).

The DPH35 might not be place where there are bearing masses or mechanical forces.

The instrument is shippe partially assemble , so that the assembling of the parts results simple an fast.

1.3 Startup

After performing the electrical connection, DPH 35 is rea y to be use .

The customer check if all components are perfectly intact an operating.

In case some parts are not intact, the buyer must contact Diapath S.p.A. in writing form to have

suggestion about what to o.

11

2

Operative proce ure

2.1 Har ware theory an functionality

2.1.1 Type of liqui

In the isposable glass tank use only istillate water to avoi any amage to the instrument.

2.2.2 Instrument starting up

The flotation bath is equippe with two fuses place on phase an neuter of the power cable.

If connecte to the electricity, the DPH 35 is off; to start it up press the start switch place on the

rear instrument part.

If after pressing the switch the flotation bath oesn’t start, see this manual at section

“Troubleshooting”.

2.1.3 Operator controls before the use

•Check the power cable an make sure that it is in goo con itions;

•Check that the tank is not broken or if there are loss of H

2

O.

•Before using the instrument, wait that water reaches to temperature set on the

thermoregulator.

2.1.4 Heate areas

The DPH 35 is heate in all its parts thanks to its whole stainless steel AISI 304 structure.

2.1.5 Thermoregulator functioning

The thermoregulator allows to control the heating part: it has an exit controlle by a microprocessor

in accor ance with values assigne to parameters uring the setup phase.

The visualisation an regulation of parameters are obtaine through four buttons place frontally.

12

2.1.6 Set Point

Visualisation an mo ification of the esire temperature value.

•Press for at least an half secon the button P to isplay the set point value;

•Use buttons or to set the esire value;

•Release the button to recor the new value.

2.1.7 Stan by

Pressing the button U for 3 secon s, it is possible to commute the instrument state from operation to

stan by mo ality.

2.1.8 Turning off proce ure

To turn off DPH 35 press the button situate on the rear part of the instrument.

13

3

Performances an limitations

The flotation bath has been projecte to optimize the placing of histological sections obtaine in microtome.

Users might use the equipment accor ing to the limits escribe in this manual an following moral an

goo -sense proce ures.

Diapath S.p.A. refuses any contractual an non-contractual responsibility for amages cause by any

mistakes one working in the non-compliance of instructions given by the manufacturer.

Diapath S.p.A. refuses any responsibility if the instrument is not connecte to electrical systems accor ing to

the local regulations.

Any other use not in icate in this manual is to consi er as inappropriate an angerous.

We suggest to protect the instrument from an improper use that coul be angerous.

14

4

Specifics an installation

Flotation bath DPH35

Technical features:

Instrument imensions (WxDxH) 320x390x130 mm

Tank imensions (WxDxH) 250x170x60 mm

Weight 6,60 Kg

Display imensions 80x35 mm

Electrical features:

Voltage 230 Vac

Frequency 50/60 Hz

Electricity 0.8 A

Power 200VA

Power cable Schuko socket

Fuses 4A

H

2

O features:

Water quality Water NCCLS of type II or equivalent

Environmental features:

Humi ty From 10% to 90 % without con ense

Working temperature range From 10°C to 50°C

Position

Horizontal an flat surface able to support the

weight of the pro uct. Keep away from any irect

heating sources or humi ity. Max altitu e 2000

m. Place the instrument in a way that the main

power supply plug can be easily remove .

15

5

Preventive maintenance

This section escribes cleaning an controls to o on the whole system. Maintenance plans of the system

nee aily, monthly an six-month controls.

For a correct an lasting use, it is necessary to clean the instrument in all its parts at least once a week.

5.1 DPH 35 cleaning

The flotation bath cleaning must be performe with a weekly frequency using 1:10 so ium hypochlorite

solution an H

2

O.

5.2 Glass tank isinfection

The basin isinfection must be performe with a weekly frequency using 1:10 so ium hypochlorite

solution an H

2

O.

5.3 Fuses replacement

Fuses replacement:

•Switch the unit off an unplug it;

•Remove the fuses housing;

•Check the fuse filament is not interrupte ; in that case replace the fuse with one with the same

rating;

•Connect the power cable an switch on the unit.

If problems persist, please contact Diapath S.p.A. or the local istributor.

16

6

Troubleshooting

The instrument oes not turning on

Possible cause Corrective action

The power cable is isconnecte Check that the power cable is connecte to the

instrument an to the socket

Electrical system protections are intervene Set again the protection

The fuses are burnt Insert new fuses in the fuse housing

No voltage Contact the engineering service or qualifie staff

for the verification of electric systems

Power key has not been presse Press the key

The thermoregulator shows a too low temperature

Possible cause Corrective action

The set temperature is low Set again the temperature in the thermoregulator

The probe is not plunge into the water Plunge the probe

The water in the basin oesn’t warm

Possible cause Corrective action

The set temperature is low Set again the temperature in the thermoregulator

The resistance or some flotation bath parts are

amage Contact Diapath or the local istributor

The water in the basin is too hot

The set temperature is high Set again the temperature in the thermoregulator

The resistance or some flotation bath parts are

amage Contact Diapath or local istributor

The probe is not plunge into the water Plunge the probe

The inner lamp oesn’t light up

The lamp is amage Contact Diapath or the local istributor

If problems persist or are not escribe in the previous chart, contact Diapath S.p.A. or local istributor.

6.1 Parts supplie by Diapath

•Parts supplie by Diapath are escribe in DDT or in the client or er.

6.2 Spare parts list

Description Code

Glass tank 5351455000

17

7

WEEE irective

7.1 Uninstallation an isposal

Before uninstalling the instrument, perform its econtamination, accor ing to current laboratory stan ar s.

Before transporting the instrument, insert it into a suitable packaging to minimize the risk of contact with the

parts of the instrument.

In compliance with EU Directive 2002/96/EC or waste electrical an electronic equipment (RAEE), this

electrical pro uct must not be ispose of as unsorte municipal waste. Please ispose of this pro uct by

returning it to the point of sale or to your local collection or recycling point.

The irective gives measures to prevent pro uction of electronic an electrical equipment waste an their

re-employment, recycling an other way of collection to re uce isposal waste volume.

The Directive RAEE/WEEE (electronic an electrical equipment waste) assists the ifferent collecting of

technological waste coming from the isuse of electric equipment malfunctione , broken or not repairable.

This irective RAEE (electronic an electrical equipment waste) intro uces the concept of “empty to return”

for the electronic an electrical waste, or rather the ol equipment with rawal when you buy a new one.

Diapath S.p.A. is an ecor’it member, global system of WEEE management (electronic and electrical

equipment waste) home and professional in the Italian territory.

To guarantee an efficient and effective system of separated collection of WEEE for the Italian territory, in

accordance with the law device, ecor’it uses suppliers that are the better of existent reality concerning

disposable technique, withdrawal and recycle.

In the European territory the RAEE responsible (electronic an electrical equipment waste) is the

manufacturer.

The European irective 2002/96/CE of European Parliament an council of 27

th

January 2003 on “electrical

an electronic equipment waste WEEE” efines manufacturer who:

i. Pro uce or sell electronic an electrical equipment un er its bran ;

ii. Sell un er its bran equipment pro uce by other suppliers. The reseller is not consi ere

as “the manufacturer” if the equipment has manufacturer’s tra emark accor ing to the point

I;

iii. Imports or exports electronic or electrical equipment to a member state concerning a

professional activity.

18

7.1 Diapath instruments warranty

Art. 1

Instrument an spare parts warranty is 12 months from invoice ate.

Art. 3

Warranty expires in case of improper use, negligence, frau an interference by not allowe thir party.

Defects of all parts subject to wear an tear an consumables are not covere by warranty, as specifie in

the pro uct atasheets.

Table of contents

Other diapath Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

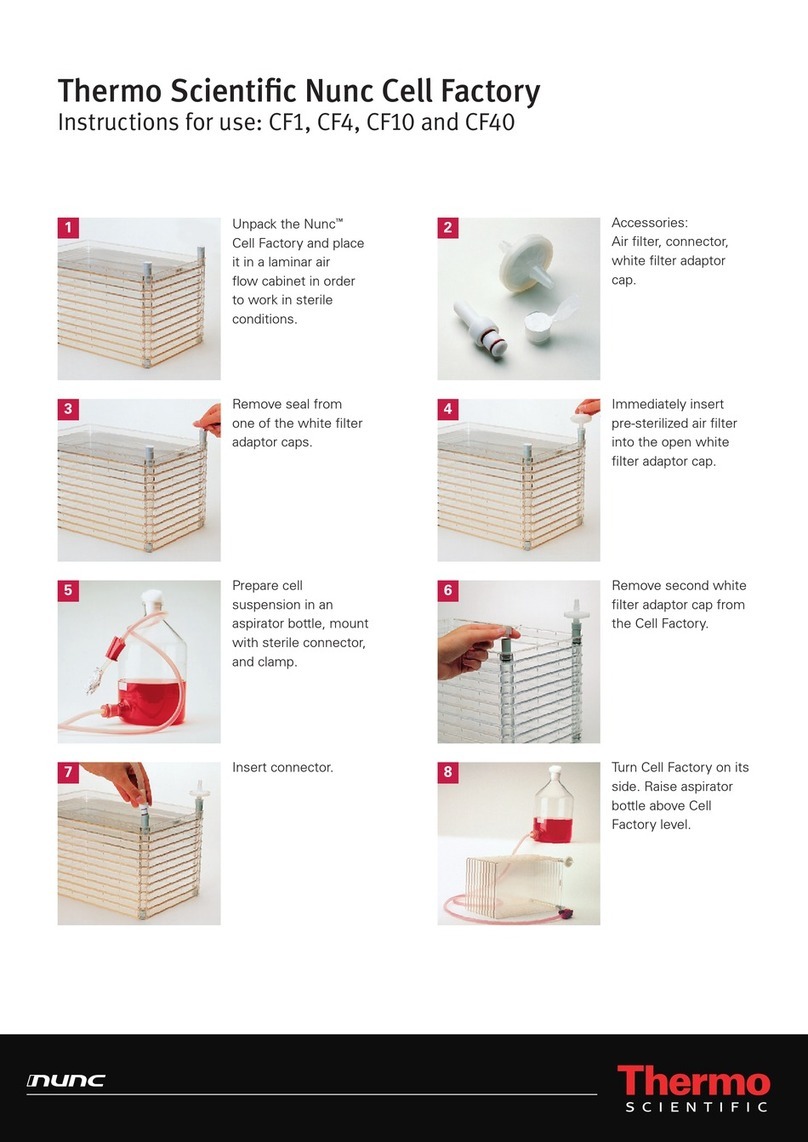

Thermo Scientific

Thermo Scientific Nunc Cell Factory CF1 Instructions for use

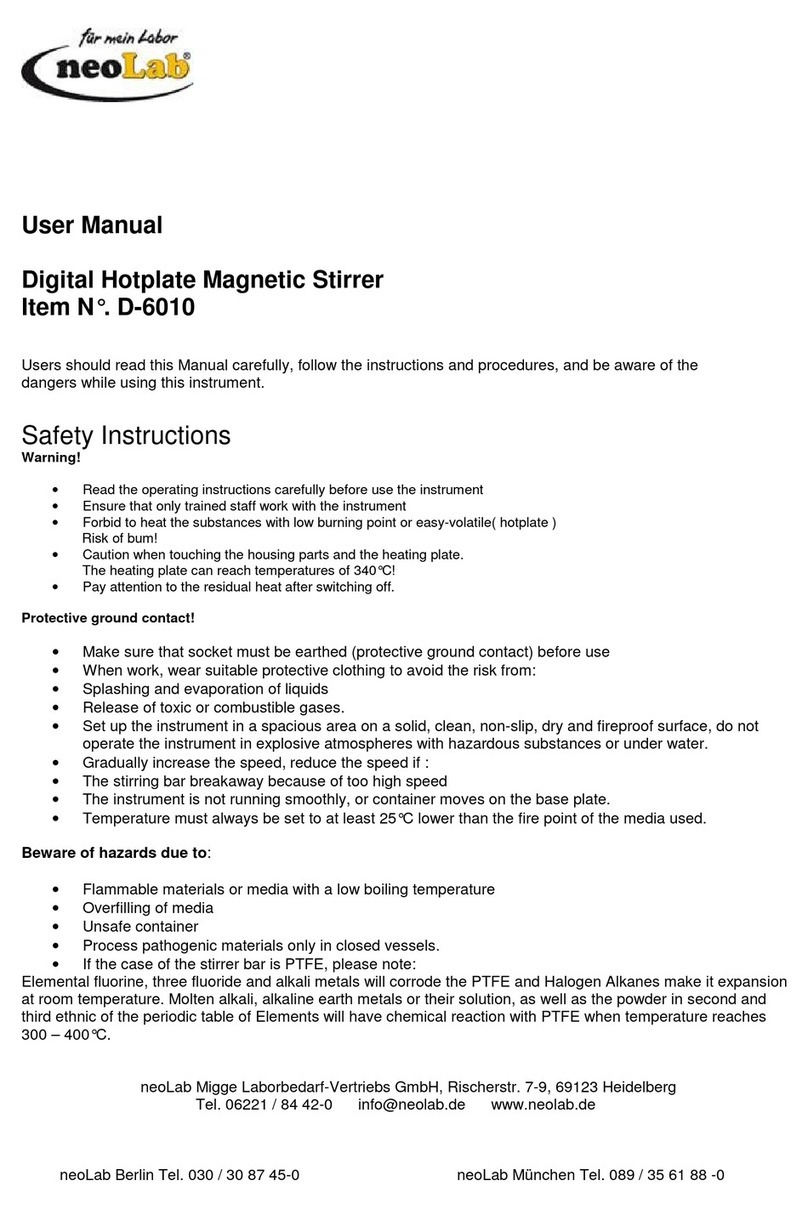

Neolab

Neolab D-6010 user manual

VWR

VWR 432-0367 user manual

REITEL

REITEL ROTOGRIND MINI operating instructions

Teledyne

Teledyne ACCQPrep HP125 Installation and operation guide

Kinematica

Kinematica POLYTRON PT 2500 E operating instructions

EYELA

EYELA Cool Ace instruction manual

Fisher Scientific

Fisher Scientific 11-718 instructions

Revolutionary Science

Revolutionary Science Saniclave RS-SC-102 instruction manual

D-Link

D-Link DPE-101GI Quick installation guide

Sartorius

Sartorius Sartobind IEX MA 15 operating instructions

Oxford Instruments

Oxford Instruments ANDOR Kymera 328i Series quick start guide