Dictator DICTAMAT Move Installation and operating instructions

Imprint

Dictator Technik GmbH

Gutenbergstraße 9

86356 Neusäß

Germany

Telephone: +49 821 24673 0

Fax: +49 821 24673 90

E-mail: [email protected]

Internet: www.dictator.de

Contents

Translated User Manual MultiMove drive system MultiControl control system Version 2020-07 page 3 ׀35

1How to Read this User Manual ......................................................................5

1.1 Target group.....................................................................................................5

1.2 Conventions......................................................................................................5

1.2.1 Symbols and signal words................................................................................5

1.2.2 Format ..............................................................................................................6

1.2.3 Terms and abbreviations ..................................................................................6

1.3 Contents and structure of the manual...............................................................8

1.3.1 Integral parts of the user manual......................................................................8

1.3.2 Referenced documents.....................................................................................8

2The Operating System....................................................................................9

2.1 Components included.......................................................................................9

2.2 Main components ...........................................................................................10

2.3 Mode of operation and functioning..................................................................11

2.4 Safety systems ...............................................................................................11

2.5 Explanation of the device’s marking ...............................................................11

3Safety.............................................................................................................13

3.1 How to act in case of an emergency...............................................................13

3.2 Intended use...................................................................................................14

3.3 Foreseeable use.............................................................................................14

3.4 Responsibilities of the machine builder...........................................................15

3.4.1 Technical demands.........................................................................................15

3.4.2 Demands on the user information for the operator of the machine.................16

3.5 Demands on the qualification of the personnel...............................................17

3.5.1 Who may what?..............................................................................................17

3.5.2 Definitions of the required skills......................................................................17

3.6 Personal protective equipment .......................................................................18

3.7 Conditions of the surroundings.......................................................................18

4Technical Data ..............................................................................................19

4.1 Dimensions and weights.................................................................................19

4.2 Electrical system.............................................................................................19

5In-House Transport, Unpacking ..................................................................20

5.1 Safety .............................................................................................................20

5.2 Transporting and unpacking the drive system ................................................20

6Mounting, Installation...................................................................................21

6.1 Dimensions and fixing.....................................................................................21

6.2 Safety .............................................................................................................22

Contents

Translated User Manual MultiMove drive system MultiControl control system Version 2020-07 page 4 ׀35

6.3 Mounting of the operating system...................................................................24

7Troubleshooting ...........................................................................................29

8Maintenance..................................................................................................30

8.1 Safety .............................................................................................................30

8.2 Inspection and maintenance plan ...................................................................32

8.2.1 Checking of cables, wires and connections....................................................33

8.3 Wear parts, spares .........................................................................................34

8.3.1 Safety-related wear parts, spares...................................................................34

8.3.2 Other wear parts, spares ................................................................................34

9Proper Disposal ............................................................................................35

9.1 Safety .............................................................................................................35

9.2 Proper disposal...............................................................................................35

How to Read this User Manual

Translated User Manual MultiMove drive system MultiControl control system Version 2020-07 page 5 ׀35

1How to Read this User Manual

1.1 Target group

This user manual contains all information necessary for the personnel of the

engine builder to be able to transport, mount and install the product according

to regulations.

Furthermore, this user manual contains information for the operator of the

machine into which this product is integrated.

For the requirements regarding the qualification of the personnel, see 3.5

Responsibilities of the machine builder.

1.2 Conventions

1.2.1 Symbols and signal words

Label

Meaning

Calls your attention to the handling and effects of safety

information.

WARNING

Indicates a dangerous situation that can result in severe

injury or death if not avoided.

ATTENTION

Indicates a dangerous situation which can result in a slight

to medium severe injury if not avoided.

NOTE:

Points to possible material damage and other important

information in connection with the operating system.

How to Read this User Manual

Translated User Manual MultiMove drive system MultiControl control system Version 2020-07 page 6 of 35

1.2.2 Format

Operation modes, operating elements, control inputs and cross references

are written in italics.

Control signals and parameters are written in Courier fonts.

<KEYS> on operating elements or the keypad of the display which have to

be pressed for input, are written in capital letters and put in squared

brackets.

1.2.3 Terms and abbreviations

Term / Abbreviation

Explanation

Driving medium

Toothed belt/chain/toothed rack

Dead-man operation

(control system without

latch)

The sliding element moves only when a key

(OPEN/CLOSE) is being pressed. As soon as the key is

released, the movement will stop according to EN 12453.

Operating system

Operator including the control system and driving medium

for the horizontal movement of sliding elements

Sliding elements

All horizontally moved masses such as e.g. doors,

windows, blinds, etc.

Impulse operation

A single and short pressing of the key will start the

movement of the sliding element.

Emergency service

The emergency service can be activated to keep the

sliding element in operative condition when the safety

devices have broken down. The sliding element moves

only when a key (OPEN/CLOSE) is being pressed. As

soon as the key is released, the movement will stop

according to EN 12453. All safety devices are ignored.

Teach-in run

Determining of the final positions. Only necessary for initial

operation.

Dynamic run

Learning of the forces, acceleration values and speeds.

Necessary for initial operation and after modifications of

the installation.

Reference run

Seeking the physical limit stop CLOSE as a reference for

positions and distances. Necessary after a power cut.

Emergency-STOP

Stopping and reversing the sliding element when the

safety devices recognize an obstacle or when the input

"EMERGENCY-STOP" is being activated.

How to Read this User Manual

Translated User Manual MultiMove drive system MultiControl control system Version 2020-07 page 7 ׀35

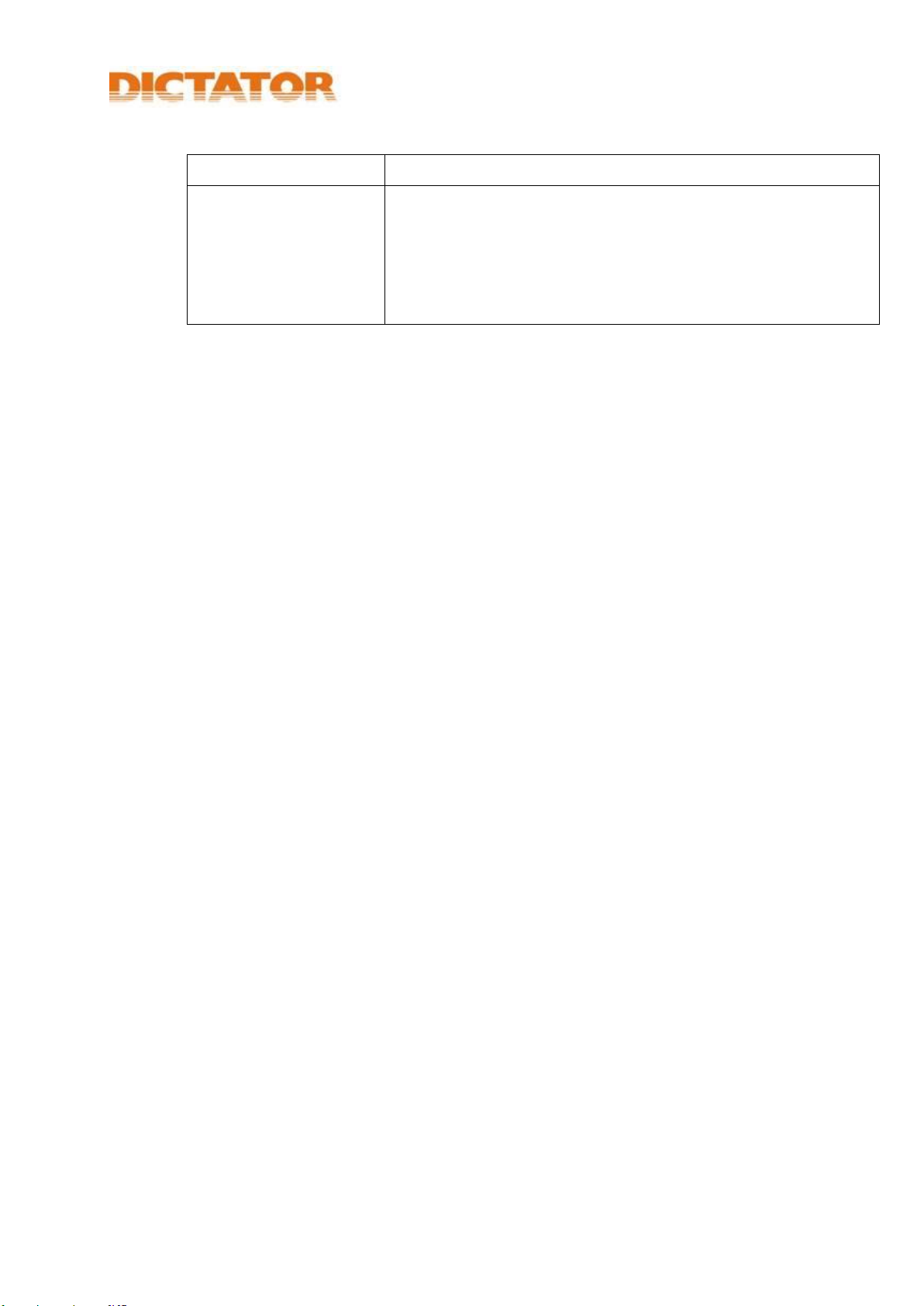

Term / Abbreviation

Explanation

Software-Emergency-

STOP

Stopping and reversing the sliding element when an

obstacle is detected by touching the sliding element (the

retardation or acceleration of the sliding element when

hitting the obstacle will exceeded or fall below the speed

learned during the dynamic run and the sliding element is

stopped and reversed).

How to Read this User Manual

Translated User Manual MultiMove drive system MultiControl control system Version 2020-07 page 8 of 35

1.3 Contents and structure of the manual

1.3.1 Integral parts of the user manual

This user manual consists of the following A4 lever arch files (loose-leaf):

Part

Contents

1

Brief instruction

2

Safety notices

3

General part

4

Customer-specific part (mounting, control system

and data of the installation)

1.3.2 Referenced documents

Data provided by the customer (questionnaire, drawings, functional description,

etc…), declarations of incorporation

The Operating System

Translated User Manual MultiMove drive system MultiControl control system Version 2020-07 page 9 ׀35

2The Operating System

2.1 Components included

NOTE:

Connection cables for the power supply of the control system and a main switch

possibly having to be installed, operating and safety elements form not part of

the standard components.

Operator with cable set to the control system

Standard mounting brackets

Idler pulley

Belt fixing device(s)

Driving medium (toothed belt, chain)

User manual

The Operating System

Translated User Manual MultiMove drive system MultiControl control system Version 2020-07 page 10 of 35

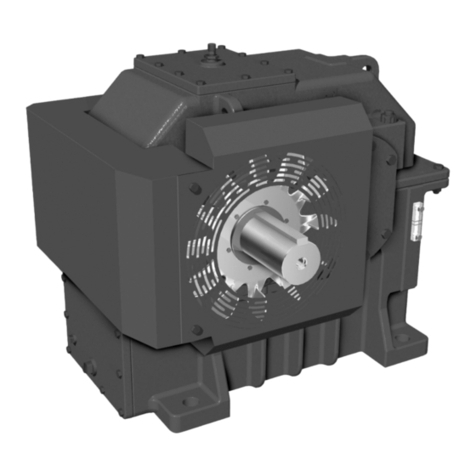

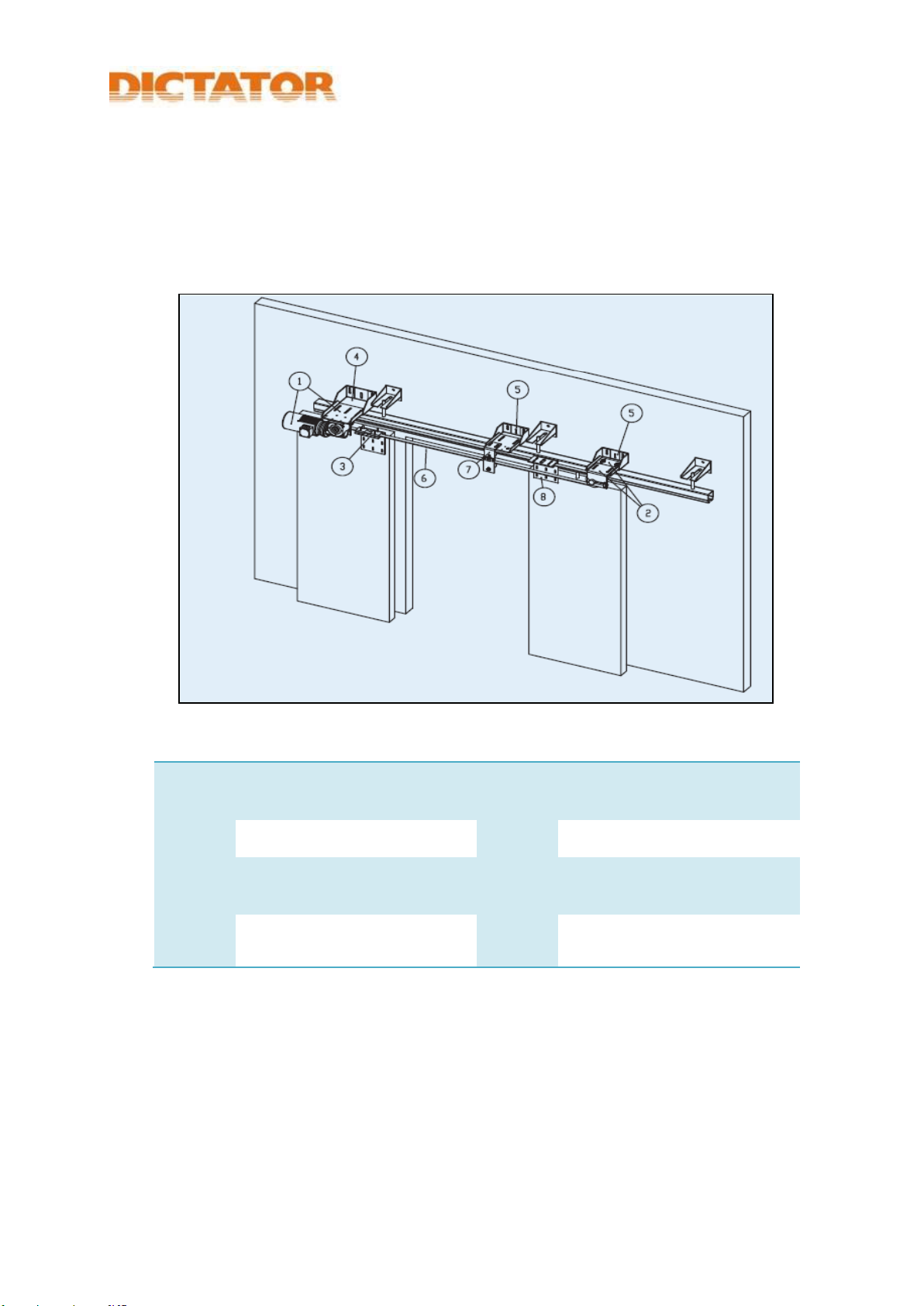

2.2 Main components

1

Door operator with

U-bracket

5

Wall bracket for idler pulley

(optional)

2

Idler pulley with U-bracket

6

Toothed belt

3

Belt fixing device

7

Supporting roller with

U- bracket (optional)

4

Wall bracket for door

operator (optional)

8

Belt fixing device for 2nd

door leaf (optional)

The Operating System

Translated User Manual MultiMove drive system MultiControl control system Version 2020-07 page 11 ׀35

2.3 Mode of operation and functioning

The operating system has been designed according to the newest European

standards and is controlled by two digital signal processors monitoring each other.

The centrepiece of the DICTAMAT Move operating system is the modular

structured gearbox which is absolutely smooth-running during a power failure, but

nevertheless meets all the demands of the relevant standards.

The position control is realized by an encoder with extremely high resolution. This

allows an absolutely exact positioning of the sliding element.

Usually the power is transmitted by a toothed belt, but it is also possible to use a

chain, rack, etc.

2.4 Safety systems

The operating system DICTAMAT Move meets the high safety demands of the EN

13241 standard, part 1 and its subordinated standards EN 12453 and EN ISO

13849-1. One of them being, that the sliding element stops after an extremely

short distance when having recognized an obstacle. In case of a power cut when

the element is moving, the short-term power supply of the electromagnetic brake

of the operator is backed up by supervised capacitors.

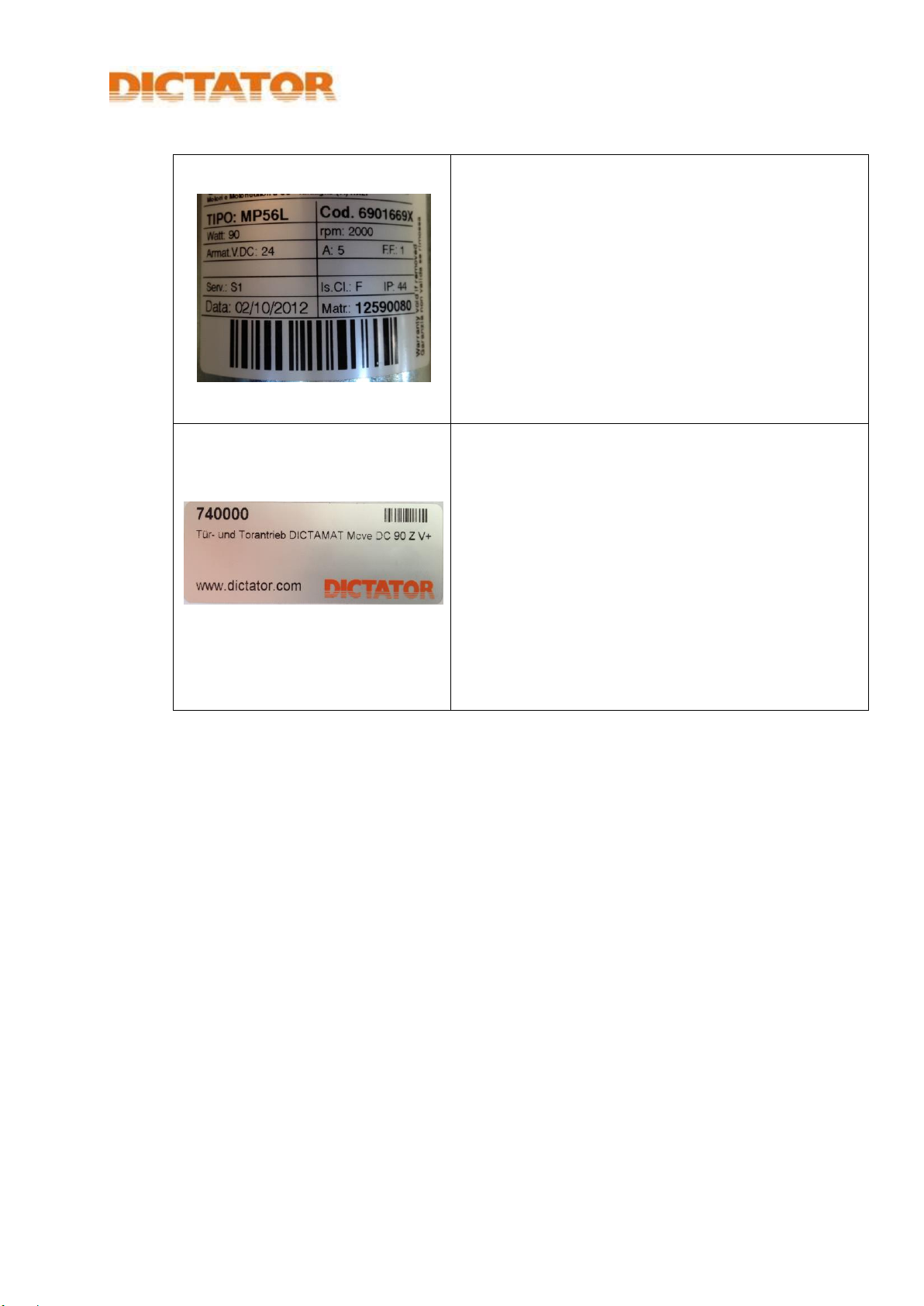

2.5 Explanation of the device’s marking

The Operating System

Translated User Manual MultiMove drive system MultiControl control system Version 2020-07 page 12 of 35

Rating plate of the motor

Rating plate with

motor rating

nominal speed rpm

voltage

type of protection

serial number

date of manufacture

Rating plate of the

operating system

Rating plate with

system number

system name*

*Structure of the system name:

name of the operator

tension

power

power transmission

dimensioning of the gearbox

Safety

Translated User Manual MultiMove drive system MultiControl control system Version 2020-07 page 13 ׀35

3Safety

The personnel of the machine builder has to carefully and completely read and

understand this user manual before they start to mount and put into operation

the operating system. This user manual contains all important information

necessary to prevent personal and material damage, to guarantee a trouble-

free operation and not to affect the environment.

Carefully observe all safety advices and other advices, demands and

information given in this user manual.

Besides the advice in this manual, the generally accepted safety and

accident prevention regulations have to be followed.

Carefully keep this user manual during installation and initial operation

within striking distance of the machine.

Observing this user manual is the condition for a trouble-free operation and

the settlement of possible legal warranty claims. Defects due to not obeying

the user manual void any warranty claims. The manufacturer or distributor

will assume no liability for subsequent damages and for damages to

property or persons due to wrong operation or not obeying the safety notes.

The limit values given in the technical data must never be exceeded.

3.1 How to act in case of an emergency

(1) Should the situation arise, stop the movement:

Trip the EMERGENCY-STOP.

(2) Switch the machine to neutral:

Switch off the mains switch of the machine.

(3) Provide a safeguard to prevent the machine being reclosed

unintentionally.

(4) Request all people to leave the dangerous area.

(5) Secure the dangerous area.

(6) Inform the responsible superior.

(7) Rescue injured persons from the dangerous area if this is possible without

endangering yourself.

Safety

Translated User Manual MultiMove drive system MultiControl control system Version 2020-07 page 14 of 35

3.2 Intended use

The operating system has specially been designed for mounting on horizontally

moved sliding elements (without incline) and may only be used for such

applications. The weight and the dimensions must not exceed the values given

by the customer.

The operating system may only be mounted on sliding elements which

meet the relevant standards.

The control system may only be put into operation when the machine (the

complete installation) into which the operating system is integrated, meets

all legal demands.

The operating system may only then be used according to the intended use

when the machine builder has satisfied all demands regarding the safety

of the operating system that are still open, see 3.4 Responsibilities of the

machine builder.

when the machine (the complete installation) into which the operating

system is integrated, meets all the legal demands.

when all the protective devices which the machine builder has planned

together with the operating system, have been installed correctly and

function properly.

after the personnel of the user has received an initial training by the

engine builder.

Personnel who will have to use or work with/on the operating system has to

have the qualification necessary for the respective task, see 3.5

Qualification of the personnel requirements.

3.3 Foreseeable use

The operating system must not be altered or modified in any way. This

operating system may not or only after consulting be used on vertically moved

sliding elements (lifting gates, sectional doors). The operating system must not

be used on private garage doors, sectional doors and swiveling doors. The

limits (weight, dimensions) given by the customer must not be exceeded.

Safety

Translated User Manual MultiMove drive system MultiControl control system Version 2020-07 page 15 ׀35

3.4 Responsibilities of the machine builder

According to the Machinery Directive (2006/42/EG) the fitter who motorizes a

sliding element is subject to the same responsibilities as the machine builder

and therefore has to do the following:

Issue the technical documentation which has to include the documents

mentioned in the annex VII of the machinery directive.

Issue an EC declaration of conformity in accordance to annex II and attach it to

the machine.

According to article 16 of the machinery directive apply the CE label to the

automated sliding element.

3.4.1 Technical demands

Connection of the power supply of the control system and the possibly to

be installed main switch in accordance with the relevant standards by a

qualified electrical technician, including acceptance test and necessary

measurements.

In case of installations with a stationary mains connection, an all-phase

main circuit breaker with corresponding pre-fusing (fault current breaker,

overload protection) has to be provided.

Compliance with the maximum admissible parameters (mass, speed, travel

distances) specified in the technical data.

Control of the smooth operation of the sliding element before mounting the

door operator. It must be possible to move the sliding element with the

forces specified in the technical data of the operator.

The sliding element must have on both sides sufficiently strong mechanical

final stopping devices.

The noise emission of the operating system (without considering the

complete installation) is less than 70 dBa. After having installed the

operating system in the installation, a sound measurement has to be

performed. If necessary, suitable noise control measures have to be taken.

Installation of all necessary safety elements in accordance with DIN EN

12453 including the measurements of the force prescribed according to EN

12445.

Making sure there is a protective guard for moved or rotating parts of the

system (up to a height of 2.5 m above the floor).

Sufficient stability of the fixing points of the operator components.

Making sure that all parts provided on site (sliding element, rail, supply

lines) comply with the applicable standards.

Safety

Translated User Manual MultiMove drive system MultiControl control system Version 2020-07 page 16 of 35

3.4.2 Demands on the user information for the operator of the machine

It is the machine builder’s responsibility

to amend the information in this user manual according to the results of his

risk assessment and the safety measures taken by him

and to decide which of the information contained in this user manual is

relevant for the operator of the machine and has to be passed on to him.

Safety

Translated User Manual MultiMove drive system MultiControl control system Version 2020-07 page 17 ׀35

3.5 Demands on the qualification of the personnel

3.5.1 Who may what?

The operating system may only be built into the machine, connected and

put into operation by instructed and qualified persons.

Only a qualified electrical technician may work on the electrical system. If

there is no such person available, a specialist firm has to be charged

with the realization.

After its installation in the machine, only instructed persons may use the

operating system and only qualified persons may maintain it.

Only a qualified electrical technician may work on the electrical system. If

there is no such person available, a specialist firm has to be charged

with the realization.

3.5.2 Definitions of the required skills

Instructed person

As an instructed person is regarded somebody who has comprehensively

been instructed on the safe use of the machine by the machine builder or

the operator of the machine.

Qualified person

As a qualified person is regarded somebody who due to his relevant

technical (preparatory) training and/or due to his relevant experience can

recognize risks and prevent hazards which may occur during his work.

Qualified electrical technician

As a qualified electrical technician is regarded somebody who due to his

professional training, knowledge and experience and his knowledge of

relevant regulations can assess and perform the jobs assigned to him and

who independently can recognize possible risks.

Safety

Translated User Manual MultiMove drive system MultiControl control system Version 2020-07 page 18 of 35

3.6 Personal protective equipment

Always wear safety shoes according to EN ISO 20345, category S1 (A+FO+E)

when working with or on the operating system:

antistatic

oil and petrol resistant sole

energy absorption in the heel area

steel caps.

Always wear oil resistant work gloves according to EN 388 when performing

tasks which require a hand protection.

3.7 Conditions of the surroundings

Normal industrial surroundings, dry and dust-free

No hazardous surroundings

When outside operation, only underneath a cover provided by customer

Admissible operating temperatures for operation : -15° to +40 °C

Admissible operating temperatures during transport and storage:

-15° to +40 °C

Admissible air humidity: relative air humidity 20 –80 % non-condensing.

Technical Data

Translated User Manual MultiMove drive system MultiControl control system Version 2020-07 page 19 ׀35

4Technical Data

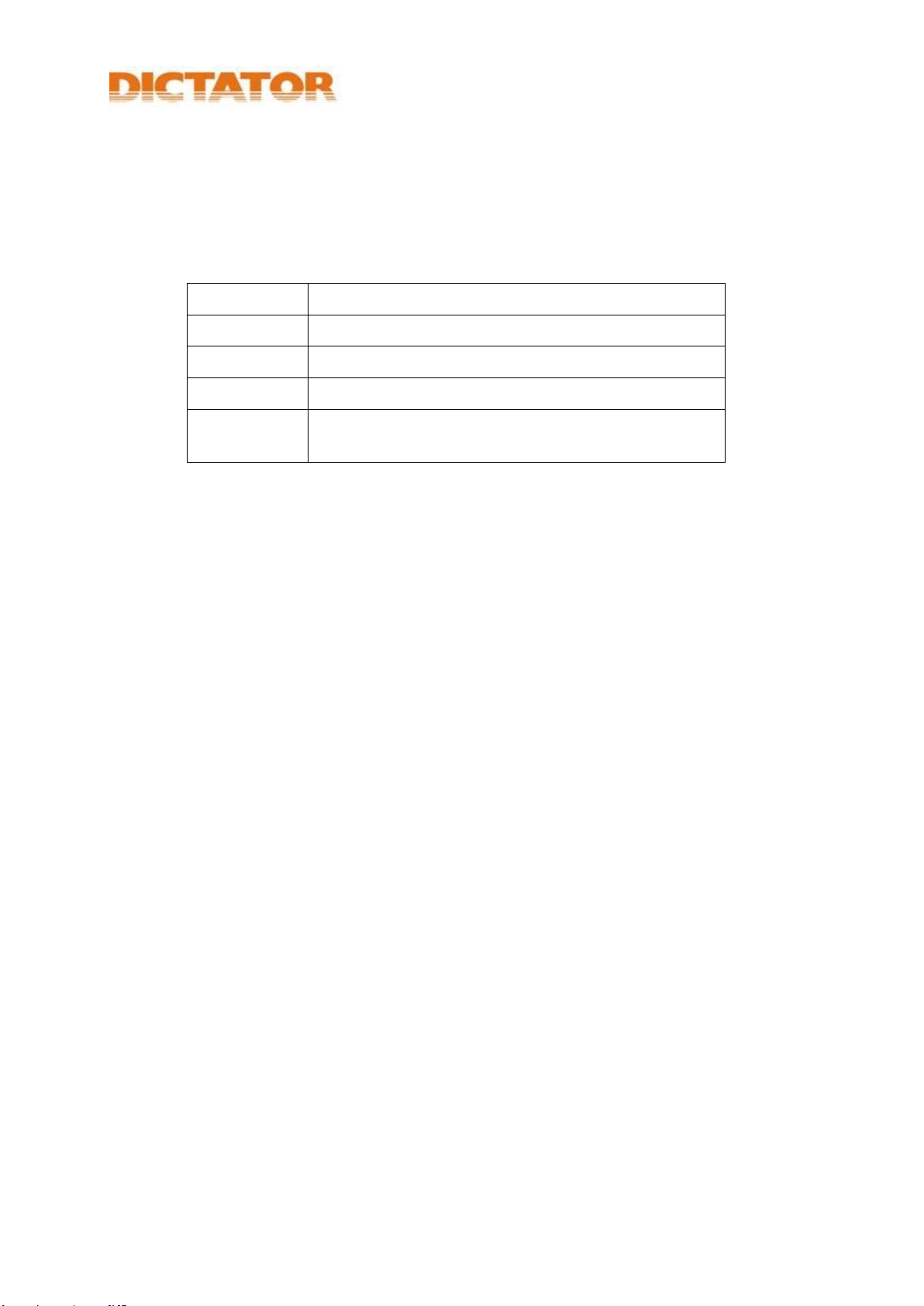

4.1 Dimensions and weights

Packed state

Dimensions (length x width x

height)

Control system + operator +

accessories

620 x 340 x 270 mm

Weight

max. approx. 30 kg

4.2 Electrical system

Rated input voltage

230 VAC, 50 –60 Hz

Power consumption

max. 6 A

Secondary output voltage

24 VDC or 28 VDC in case of a version with

emergency power

Secondary total load

max. 1 A per output, total max. 2 A

Emergency power capacity

28 VDC, 7 Ah

Output voltage of motor

230/400 VAC (3-phase) or 24 VDC

Power rating of motor

max. 0.37 kW AC / 200 W DC

IP rating

IP 54

Recommended fuse

protection

B 16 A

In-House Transport, Unpacking

Translated User Manual MultiMove drive system MultiControl control system Version 2020-07 page 20 of 35

5In-House Transport, Unpacking

5.1 Safety

WARNING

Squeezing hazard for hands and feet

The door operator can topple over and/or fall down during transport. This can

result in severe crushing injuries of hands and feet. There can be sharp edges on

the operator and the accessories. They can cause lacerations.

Wear work gloves.

Transport the door operator and the control system only with lifting and

transporting devices being sufficiently dimensioned.

5.2 Transporting and unpacking the drive system

(1) Use appropriate means of transport for transporting the door operator and

the control system (pallet truck).

(2) When opening the cardboard, don’t damage the operator. Use a knife with

a short blade.

(3) The electric cables must not be damaged during unpacking.

(4) Dispose properly of the packing material.

(5) Check if the unpacked parts are complete (components included).

(6) Check the unpacked parts for damages, especially the electrical cables.

(7) Lifting of the door operator: In three sides of the casing of the operator are

provided M10 threads. To these threads can be fixed suitable sling

devices (eyelets) to lift the operator.

(8) In case the door operator should be mounted at a higher height, we

recommend using a suitable hoisting platform.

Table of contents