DIG LEIT X Series User manual

1

LEIT® X and XRC Series

Ambient Powered

Irrigation Controllers

Instruction Manual

INSTRUCTION MANUAL

2

Table of ConTenTs

A. Introduction ……………………………………………………………………… 3

B. About the LEIT X & XRC Controllers ………………………………………………… 3

C. Technical Assistance ……………………………………………………………… 3

D. Copyright and Compliance ………………………………………………………… 3

E. Features ………………………………………………………………………… 4

1. System ……………………………………………………………………………… 4

1.1 Models available ………………………………………………………………… 5

1.2 Parts identification ……………………………………………………………… 5

1.3 Required system components …………………………………………………… 5

1.4 Tools and supply requirements …………………………………………………… 6

2. Installation …………………………………………………………………………… 6

2.1 Valve installation model 160HE-XXX (2-WAY) ……………………………………… 6

2.2 LEMA Solenoid actuator installation model 1600HE (2-WAY) ……………………… 6

2.3 Wire installation and distance …………………………………………………… 7

2.4 Controller installation …………………………………………………………… 7

3. Sensor installation …………………………………………………………………… 8

3.1 Sensor connection to unused station ……………………………………………… 8

3.2 Sensor connection if station is not available ……………………………………… 8

3.3 Compatible sensors ……………………………………………………………… 8

4. Pump or any electrical equipment installation …………………………………… 9

4.1 RKIT installation to the MV/Pump terminal ………………………………………… 9

4.2 RKIT installation to one of the valve station terminal connectors …………………… 9

5. Programming ………………………………………………………………………… 12

5.1 Manual run ……………………………………………………………………… 13

5.2 Rain stop/restart ………………………………………………………………… 15

5.3 Monthly budget ………………………………………………………………… 15

5.4 Check status …………………………………………………………………… 15

5.5 History reports …………………………………………………………………… 17

5.6 Setup schedule ………………………………………………………………… 18

5.7 Setup system …………………………………………………………………… 20

5.8 Setup radio (LEIT XRC only) ……………………………………………………… 23

5.9 Help …………………………………………………………………………… 25

6. Practical troubleshooting point ……………………………………………………… 25

6.1 LEIT key ………………………………………………………………………… 25

6.2 LEIT controller …………………………………………………………………… 26

6.3 LEMA solenoid actuator …………………………………………………………… 26

6.4 Hydraulic valves ………………………………………………………………… 27

6.5 Field control wires ……………………………………………………………… 27

7. Warranty ……………………………………………………………………………… 27

8. LEIT control programming quick reference chart ………………………………… 28

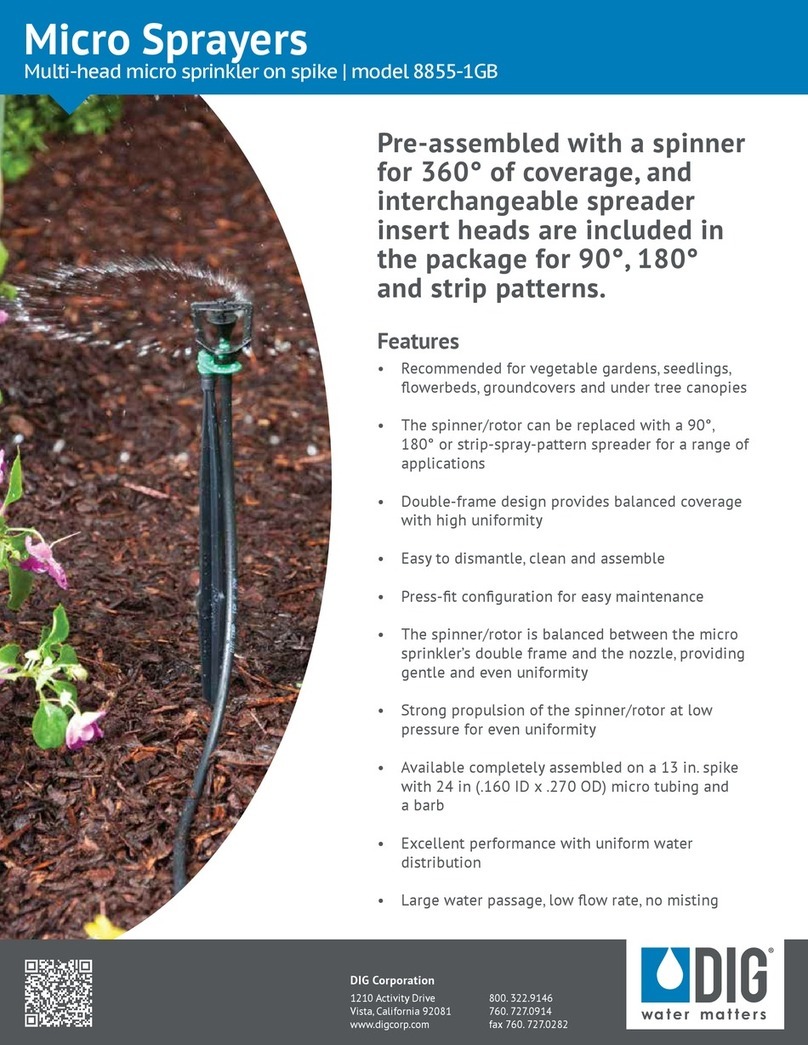

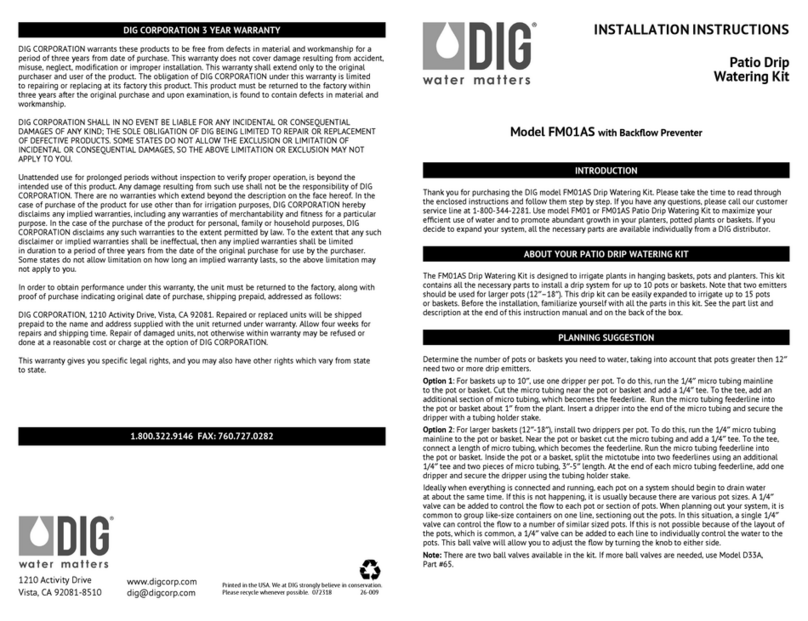

a. introduction

Thank you for purchasing DIG LEIT® X or a XRC series controller.

This manual describes how to get the LEIT X or XRC controller up and running quickly. After reading this manual

and having been familiarized with the basic functionality of the controller, the manual can be used as a reference

for less common tasks in the future.

Please take the time to read through the enclosed instructions and follow them step-by-step.

B. aBout the leit X & Xrc controller

The LEIT X and XRC Series Controllers are advanced ambient light powered water management irrigation

controllers. The LEIT X and XRC use a time tested photovoltaic module, which harnesses light energy to generate

electricity that is stored and used to power the controller day and night in any kind of weather.

DIG LEIT irrigation controllers are available in two models: LEIT X (without radio) or LEIT XRC (with radio remote

control capability).

The LEIT X and XRC series irrigation controllers have an improved menu base with straightforward programming

that allows for a wide range of irrigation programs. Features include four programs with three start times per

valve, manual runs with “skip to the next valve” option, rain delays for up to 99 days, budgeting up to 200 percent,

status checks, review history reports, modify program settings, valve grouping, verify solenoid integrity, radio

remote connection (XRC) and more.

Using the LEIT Link remote control handset in conjunction with a LEIT XRC controller, the user can review status

and history reports, modify program settings, temporarily interrupt a running program, do a manual run and test or

skip to the next valve mode from a distance of up to 800 feet line of site. The current running program and current

valve open information is provided when activated. In the Check Status mode the handset can review time, date,

budget, sensor activation and solenoid integrity. In Uplink History one can review the hourly usage of each valve by

month, or year, including Manual run usage. The LEIT Link handset is a 2-way radio device that can request or send

information and commands to a particular LEIT XRC controller and receive confirmation for the information sent or

requested.

IMPORTANT: The LEIT XRC requires greater energy for radio communication than is used for the

controller alone. The LEIT XRC controller requires daily exposure to light levels at a minimum of

10.000 lux, which is equivalent to daylight around 8-10 AM on a cloudy day. On very cloudy days the

controller requires more time to charge up and to operate with the radio. In order to retain sufficient

energy to maintain control over the valves, the controller radio will automatically turn off in low light

conditions. To maximize the energy available, the XRC controller should be installed in an open,

un-shaded area.

c. technical assistance

Should you encounter any problem(s) with this product or if you do not understand its many features, please refer

to this operating manual first. If further assistance is required DIG offers the following customer support:

Technical Service USA

• DIG’s Technical Service Team is available to answer questions from 8:00 AM to 5:00 PM (PST) Monday-Friday

(except holidays) at 800-322-9146

• Questions can be e-mailed to questions@digcorp.com or faxed to 760-727-0282

• Specification documents and manuals are available for download at

www.digcorp.com/leit_control_system

Customer Assistance outside the USA

Contact your local distributor

d. copyright and compliance

Copyright 2010 DIG Corporation. All rights reserved. LEIT and LEIT Link are registered trademarks. LEIT XRC, LEIT

Link Master and LEIT Link Multi-Pro are each, trademarks of DIG Corporation.

Patent #: 5,229,649 and 5,661,349

FCC, EC, Canada and Australia compliance

3

Important Note for LEIT XRC: To comply with FCC RF exposure compliance requirements, the antenna used for this

transmitter is installed to provide a separation distance of at least 8 inches (20 cm) from all persons (not including

hands, wrist, feet and ankles). The antenna must not be co-located or operated in conjunction with any other

antenna or transmitter.

This device is required to comply with FCC RF exposure requirements for mobile and fixed transmitting devices.

This model transceiver generates and uses radio frequency energy. If not installed and used in accordance with the

manufacturer’s instruction, it may cause interference with radio and television reception. The transceiver has been

tested and found to comply with the specification in part 15 of FCC rules for spread spectrum intentional radiators

(FCC ID: QLBPTSS2003) and FCC part 15 Subpart C, specification.

Warning: The user should make no field changes or modifications to the LEIT X, LEIT XRC Controller

or the LEIT Link Remote Control Handset.

All adjustments and changes must be made at DIG’s facility under the specific guidelines set forth in

our manufacturing process. Any change or modification to the equipment will void the users authority

to operate the unit, and render the equipment in violation of FCC part 15 subpart C, 15.247. Any

tampering with this product will void the warranty.

e. Features

• Operates 4-28 stations and a master valve or pump start without AC power hookup, batteries or conventional

solar panels

• Software in English and Spanish, Italian or French

• 4 programs with 3 start times per program

• Budgeting feature for a yearly watering schedule can be set by month

° Increase or decrease irrigation from 10-200% in 10% increments

• Review status and history reports

• Review solenoid integrity

• Built to the highest quality control standard

° Controller functions and operations are 100% tested

° Controller waterproofing is 100% tested

• Non-volatile memory holds programs indefinitely without batteries

• 2-way radio communication with a LEIT Link handset (model XRC)

• All power is provided by an internal photovoltaic module and microelectronic energy management system

fueled by ambient light

° Functions day or night in all weather conditions and in most outdoor locations

• 365 day calendar with leap year

• Assign-rain, moisture or freeze sensors to an individual valve or to the entire system using SKIT 8821-4

connector

• Manual watering by station or program

• Environmentally friendly - uses clean power

° No batteries or AC power needed

1. sysTem

This chapter will explain the components and installation of the LEIT X and XRC series controllers. The LEIT

controller must be installed according to the manufacturer’s recommendations; failure to do so will void the

manufacturer’s warranty. The LEIT X and XRC controllers can replace all SOLATROL and ALTEC 8000 controllers

and can be mounted on the same column as the ALTEC 8000 by removing the plastic sleeve from the mounting

column and mounting the new controller in its place. The LEIT X and XRC can operate with all of the old SOLATROL

and LEIT 8000 solenoids, such as LEMA 1500E, 1500-4 and 1500S. We recommend all new installations be done

using the 160HE series valves and 1600HE solenoid actuator.

NOTE: I5OOE and I500S cannot be used on the same terminal.

1.1 Models Available:

LEIT X models available: 10, 12, 16, 20, 24 and X28 stations plus MV/Pump.

LEIT XRC models available: 4, 6, 8, 10, 12, 16, 20, 24 and XRC28 stations plus MV/Pump. LEIT XRC controller

utilizes a 2-way radio communication device that operates in the ISM band 902-928 MHz (868/869 Europe).

Remote control handset not included.

4

1.2 Parts Identification

q PVM – Photovoltaic module harnesses light energy and use it to

generates electricity to power the unit day and night in any kind of

weather condition.

w LCD Display – Displays the application stored in the controller.

e

Programming Buttons – Use these 4 buttons to program, modify

and review the status of a LEIT XRC controller.

r

Location to insert the LEIT Key – To begin, insert the LEIT Key to

enter the LEIT controller’s programming screens (use 1, 9-volt battery).

The LEIT key is not included.

t

Stations and MV/P Terminal – Up to 28 terminals are available

depending on models to connect the valves wires, sensors via the SKIT

and the MV/P

LEIT Door and key – To enter the controller use the key (included) to unlock the door and remove it.

1.3 Required System Components

To properly install the LEIT controller, the following components will be needed:

1. Control unit: LEIT series controllers programmed with bilingual software versions SW Ver 2.22 and

later EE Ver 2.04 and later (LEIT Key not included).

2. LEIT Key: Programming tool required to enter and program the

controller (uses 1, 9-volt alkaline battery)

3. Mounting column: model MCOLXS (short) 40” (89 cm) or MCOLXL

(long) 55” (127 cm) steel pipe including mounting tool kit (2 screws,

2 spacing bolts, 1 hex-key 3/16”)

4. Actuator with in-line valve: each solenoid actuator comes complete with in-line valve

(160HE- 075 for 3/4”, 100 for 1”, 150 for 1-1/2” and 200 for 2”)

For drip system use a drip zone assembly model P52-075 that includes a 160HE-075

3/4” valve, 155 mesh screen filter and 30 PSI preset pressure regulator

5. LEMA actuator only :(1600HE) one for each valve being used (see available adapters

for mounting on any brand name valve).

6. 7-solenoid adapters are available to fit most valves:

a. Model 30-920 use with BERMAD 200, HIT 500 and DOROT series 80, GRISWOLD

2000 and DW, BUCKNER VB series

b. Model 30-921 use with RAIN BIRD DV, DVF, PGA, PEB (3/4” and 1” only), GB, EFB-CP, BPE,

PESB (3/4” and 1” only) and ASVF series

c. Model 30-922 use with HUNTER ASV, HPV, ICV, PGV, SRV, IBV and AS VF series

d. Model 30-923 use with WEATHERMATIC 12000 and 21000 series

e. Model 30-924 use with IRRITROL 100, 200B, 205, 217B, 700, 2400, 2500, 2600 series, TORO 220, P220

f. Model 30-925 use with SUPERIOR 950, HUNTER HBV, TORO 252 (1.5” and larger)

g. Model 30-926 use with RAINBIRD 1 1/2” and 2” PEB and PESB series

STATION 1/9

STATION 2/10

STATION 3/11

STATION 4/12

STATION 5/13

STATION 6/14

STATION 7/15

COMMON

COMMON

S/N:

STATION 8 AND 16 OR MV/P

STATION 1/9

STATION 2/10

STATION 3/11

STATION 4/12

STATION 5/13

STATION 6/14

STATION 7/15

COMMON

COMMON

S/N:

STATION 8 AND 16 OR MV/P

5

q

w

r

t

e

E1 O-ring

200-014

model #30-494

E2

Short sleeve

model #30-422

E

F1 O-ring

200-014

model #30-494

FD

D1 O-ring

200-015

model #30-494

D2 Sleeve

model #30-424

C

C1 O-ring

200-012

model #30-495

C2

Long sleeve

model #30-423

B

B1 O-ring

200-021

model #03-077

A

A1 O-ring

200-014

model #30-494

A2 Sleeve

model #30-424

G1 O-ring

200-021

model #30-926

G

7. Optional: Model SKIT 8821-4 connector: if any sensors

are used, a SKIT 8821-4 adapter is required

8. Optional: Model RKIT 8810S relay: if pumps or any electrical equipment

are used, an RKIT 8810S adapter is required

9. LEIT Link handset to communicate with a LEIT XRC controller

1.4 Tools and Supply Requirement

1. Battery: 9-volt alkaline battery for the LEIT Key

2. Standard wire stripper

3. Flathead screwdriver (9/64” or smaller)

4. Concrete: approximately three 90 lb (40 kg) bags

5. Conventional waterproof wire connectors

2. InsTallaTIon

Select the optimum location for the LEIT X and XRC series controllers. If possible locate the controller in open area

not adjacent to a wall or building. We recommend installing a rain sensor with each controller with the use of

adapter model SKIT 8821-4.

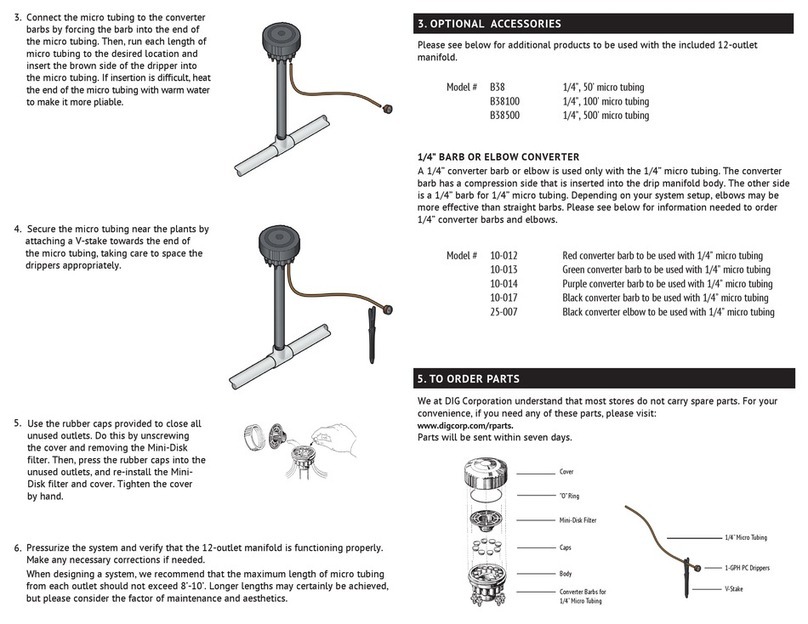

2.1 Valve Installation Model 160HE-XXX (2-WAY)

Recommended version is a complete valve assembly including LEMA solenoid actuator with plastic in-line valve

(globe), sizes from 3/4” to 2”.

Maximum static operating pressure is up to 150 PSI.

1. Shut off mainline to the valve.

2. Install series 160HE-xxx valves with a solenoid actuator according to a valve standard

installation specification (see Figure A on page 7).

3. After installation is completed, turn the water supply on and pressurize the mainline. The

valves should open momentarily and then shut off. Test each valve in manual operation by

turning the solenoid from left to right to open and right to left to close the valve, making

sure that the valve is operating correctly. The valve should open momentarily and then shut off.

4. Splice the solenoid actuator hot wires (red) to one of the color-coded wires. Splice the solenoid actuator white

wire to the single incoming white (common) wire. Use 2 conventional dry-splice waterproof connectors. Leave

the wires slightly loose on each side so that repairs, if needed, can be carried out easily. Make sure not to

exceed the maximum run recommendation of wire distance (see page 7).

2.2 LEMA Solenoid Actuator Installation Model 1600HE (2-WAY)

Select the appropriate adapter for the valve(s) that will be used (see list on page 5). The LEMA solenoid actuator

operates only with 2-way normally closed valves.

Maximum static operating pressure is up to 150 PSI.

1. Shut off mainline to the valve.

2. Unscrew the conventional solenoid from the valve and remove the solenoid

housing, solenoid stem, plunger, spring, and “O” ring (if necessary). For BUCKNER

and SUPERIOR valves, do not remove the existing “O” ring.

3. Select the appropriate conversion adapters for this valve(s) then thread and

tighten the conversion adapter clockwise to the compatible valve port, do not over

tighten.

IMPORTANT: When installing adapter on BUCKNER and SUPERIOR valves

remove the adapter sleeve (model 30-424) before installing.

4. Screw the LEMA 1600HE into the correct adapter. Firmly tighten the solenoid by

hand, but do not over tighten.

6

5. Positioning the solenoid at a 40-45° angel towards the valve creates a manual lever; helpful

for manual on/off.

6. After installation is completed, turn the water supply on and pressurize the mainline. The

valves will open momentarily and then shut off. Test each valve in manual operation by

turning the solenoid from left to right to open and right to left to close the valve, making

sure that the valve is operating correctly. The valve should open momentarily and then shut

off. If the valve remains open in manual operation, examine the adapter and the sleeve to

see that it is installed correctly and the adapter is firmly secured. Do not over tighten the

LEMA solenoid actuator to the valve and do not cross thread the adapter into the solenoid

cavity.

NOTE: For all brand name valves with internal manual bleed lever, make sure the

lever is in closed position. Do not move the lever after installing the solenoid with the valve adapter.

If the manual lever on the valve is used, it can damage the adapter or the sleeve causing the valve to

stay open.

7. Splice the solenoid actuator hot wires (red) to one of the color-coded field wires. Splice the solenoid actuator

white wire to the incoming white (common) wire. Use 2 conventional dry-splice waterproof connectors. Leave

the wires slightly loose on each side so that repairs, if needed, can be carried out easily. Make sure not to

exceed the maximum run recommendation of the wire distance (see A1 below).

WARNING: The LEMA solenoid actuators must not be tested with any AC valve tester or DC tester

over 9-volts. If you do so, it will cause irreparable damage to the LEMA solenoid actuator and the

controller unit. Testing the solenoids with equipment rated higher then 9-volts will void the warranty.

2.3 Wire Installation and Distance

Run all direct burial wires along their respective trenches from each valve box to the controller location. Use

selection of color-coded direct burial wires to connect to each solenoid red (hot) wire. Use white (common) wire to

connect to the solenoid’s white (common) wire. Make sure to label each color-coded wire inside the irrigation box

with the designated station number.

MAXIMUM WIRE DISTANCE

Wire gauge recommendation LEMA 1500S SOLENOIDS LEMA 1600 HE SOLENOIDS

14 AWG (2.5 mm2) 1500 feet (300 m) 4,500 feet (1365 m)

12 AWG (4 mm2) 2400 feet (700 m) 7,500 feet (2272 m)

2.4 Controller Installation

1. To install the mounting column, set the curved bottom of the mounting column in

a 12” x 18” x 12” (30 x 45 x 30 cm) frame and pour in the three 90 lb (40 kg) sacks

of cement (see Figure A). Make sure the column is vertical and the opening in the

curved bottom is accessible and unclogged. All wires should route to the controller

through the bottom of the mounting column (see A1).

NOTE: Make sure the cement pad is dry before continuing with the

installation

7

LEIT X, XR and XRC Controller Specifications

Section 02810

moc.procgid.www2820-727-067 XAF • 6419-223-008 :enohP

LIGHT ENERGIZED IRRIGATION CONTROLLER

LEIT CONTROL X, XR AND XRC

160HE-160 1-1/2" and 160HE-200 2" REMOTE CONTROL

VALVE FOR LEIT CONTROLLER ASSEMBLY

RAIN SENSOR ASSEMBLY

COLUMN MOUNTED

160HE-075 3/4" AND 160HE-100 1" REMOTE CONTROL

VALVE FOR LEIT CONTROLLER ASSEMBLY

LEGEND

1DRY SPLICE CONNECTORS

2VALVE BOX WITH COVER 12" SIZE

3FINISH GRADE TOP

4DIG REMOTE CONTROL VALVE WITH FLOW

CONTROL AND LEIT DC SOLENOID

MODEL: 160HE-150 1-1/2"

MODEL: 160HE-200 2"

5PVC SCH 40 MALE ADAPTER

6PVC MAIN LINE

7BRICK SUPPORT AT EACH CORNER

8PEA GRAVEL SUMP MINIMUM 3"

9CONTROL WIRE TO OTHER VALVE

!º SWIVEL FITTING FOR EASY CONNECTION

MODEL: 23-152 1-1/2"

MODEL: 23-202 2"

!¡ PVC SCH 40-45° ELL

LEGEND

1VALVE BOX WITH COVER 18" SIZE

2DRY SPLICE CONNECTORS

3FINISH GRADE TOP

4DIG VALVE MODEL

3/4" 160HE-075

1" 160HE-100

5SWIVEL FITTING DIG MODEL

3/4" 23-004, 1" 23-003

6PVC SCH 40 MALE ADAPTER

7PVC LATERAL LINE

8BRICK SUPPORT AT EACH CORNER

9PEA GRAVEL SUMP – MINIMUM 3"

!º 12 OR 14 GAUGE WIRE

!¡ BACK-UP NPT PVC BALL VALVE

!™ PVC SCH 40 90° ELL

!£ SCH 40 TEE

LEGEND

1"MINI CLIK" RAIN SENSOR

2DIG PLASTIC PIPE CAP

1" PART #23-001 OR 1-1/2" #23-053

WITH HOLE FOR WIRES

3DRILL TWO 3/16" HOLES IN PIPE FOR

SENSOR BRACKET

4(2) #8-32 MACHINE SCREWS WITH

WASHER, LOCK WASHER AND NUT

51" OR 1-1/2" GALVANIZED PIPE

6-10 FEET HIGH

612" X 12" CONCRETE BASE, 8" DEEP

MINIMUM

71" OR 1-1/2" PIPE ELBOW

8FINISH GRADE

96" ROUND VALVE BOX

!º SKIT ADAPTER PART #8821-4

USE WITH EACH SENSOR

!¡ TO CONTROLLER OR VALVE

!™ (4) DRY SPLICE CONNECTORS

!£ NORMALLY CLOSED WIRE FROM SENSOR

!¢ COMMON WIRE FROM SENSOR

!∞1" OR 1-1/2" NIPPLE

!§ GRAVEL

LEGEND

1AMBIENT LIGHT POWERED

IRRIGATION CONTROLLER.

MODEL X: 10-28 STATIONS

MODEL XR (WITH OPTIONAL RADIO):

4-28 STATIONS

MODEL XRC WITH RADIO REMOTE:

4-28 STATIONS

2TERMINAL STRIP

312 OR 14 GAUGE WIRE

4PROGRAMMING KEY

MODEL #LEIT KEY

535" STEEL MOUNTING COLUMN

MODEL #MCOLXS (SHORT) OR

50" STEEL MOUNTING COLUMN

MODEL #MCOLXL (LONG)

6FINISH GRADE

76-1/2" OF BACKFILL SOIL

8POURED CONCRETE BASE –

1-1/2" CU.FT. INSTALL PER

MANUFACTURER'S INSTALL GUIDE

9DIRECT BURIAL CONTROL WIRES TO

CONTROL VALVES

Part 1 Introduction

1.1 LEIT X, XR and XRC controllers are advanced water-management irrigation controllers. The controllers utilize ambient light as the source of energy to

operate up to 28 valves using a low voltage, high efficiency, watertight, 2-way magnetic solenoid actuator that operates at 5-volts. Built to the highest

quality standards (ISO 9002), the LEIT X, XR and XRC controllers have a menu base program with straightforward programming that allows for a wide

range of irrigation programs such as valve grouping, 4 programs with 3 start times, run times up to 6 hours, budget, rain delay, status reports, history

reports, manual runs and more. The controller design uses the most advanced time-tested photovoltaic module, which provides more power to harness

light energy day and night, anytime, anyplace. Used for sprinkler or drip systems, the LEIT X, XR and XRC controllers are commercial quality water

management controllers for any type of environment and for a wide range of uses.

Part 2 Typical Installation

2.1 Drawing File no.: LEIT X.exe

LEGEND

q DRY SPLICE WATERPROOF CONNECTORS

w 18” VALVE BOX WITH COVER

e FINISH GRADE TOP

r DIG REMOTE CONTROL VALVE WITH FLOW

CONTROL AND LEIT DC SOLENOID

MODEL: 160HE-150 1-1/2”

MODEL: 160HE-200 2”

t PVC SCH 40 MALE ADAPTER

y PVC MAIN LINE

u BRICK SUPPORT AT EACH CORNER

i PEA GRAVEL SUMP MINIMUM 3”

o CONTROL WIRE TO OTHER VALVE

1) SWIVEL FITTING FOR EASY CONNECTION

MODEL: 23-152 1-1/2”

MODEL: 23-202 2”

1! PVC SCH 40-45° ELL

160HE-150 1-1/2” and 160HE-200 2” REMOTE CONTROL

VALVE FOR LEIT CONTROLLER ASSEMBLY

A1

Figure A

2. Run the field wires along their respective trenches from the

valve box up to the bottom end of the mounting column.

Make sure not to exceed the maximum recommended wire

distance (see chart for maximum wire distance on page

xxxx). Push the wires up through the column until at least

12” (30 cm) of wire extends from the top of the mounting

column (see B1).

3. Remove the door from the LEIT controller using the door key

(included) and slide the controller into place on top of the

mounting column. Make sure that 12” (30 cm) of wires are

now inside the controller and cannot slip back down into the

column (see C1).

4. Insert the two clamp spacers and the two screws (both

included with the mounting column) into the holes

located on the lower left and right side of the controller.

Tighten the screws with the hex-key (included) until the

controller does not turn or twist and cannot be pulled off

of the mounting column (see D1).

5. Connect the station wires to the controller using a standard wire stripper.

Strip 3/10” of insulation from the tip of each of the station colored (labeled)

wires. Connect the color-coded (hot) wires into the connector strip labeled

with the station number and tighten the connector screw using a screwdriver.

Connect the white (common) wire into either of the two common wire

connectors labeled “common” located at the lower part of the connector strip

and tighten the connector screw using a screwdriver. If using a master valve,

connect the red (hot) wire from the master valve into the station labeled

“MV/P” (see Figure E1). For pump or other electrical equipment, see detailed

installations on page 10.

3. sensor InsTallaTIon

The SKIT switch-type, weatherproof sensor adapter provides a quick, reliable way to connect a compatible rain,

freeze, moisture or other normally closed, switch-type sensor. The connection can be made either directly to the

LEIT series irrigation controllers or to one of the micro-powered solenoid actuators.

3.1 Sensor connection to unused station

If there is an unused station on the LEIT controller, connect the sensor directly using a SKIT 8821-4.

a. Run a red (hot) wire from the unused station connector position on the LEIT controller to the red (hot) wire

on the SKIT 8821-4. Then run a white (common) wire from the common connector station position on the

LEIT controller to the white (common) wire on the SKIT. Finally, splice the two SKIT black wires to the

sensor’s two normally closed (N/C) wires (see Figure B, Option 1). If possible, choose a solenoid location

close to the controller.

3.2 Sensor connection if station is not available:

If station is unavailable, or the controller is to far from the sensor, connect the SKIT 8821-4 to LEMA actuators at a

valve closest to the desired sensor location. This method can be used to minimize excessive wire runs (see Figure

B, Option 2).

b. Choose a valve that is closest to the sensor location and, if possible, choose a sensor location close to

the controller. On the installed LEMA series actuator, splice the red (hot) wire to the SKIT’s red (hot) wire

AND to the red (hot) field wire creating a 3-wire connection. Next, splice the LEMA’s white (common)

wire to the SKIT’s white (common) wire and connect both onto the common field wire. Again, a 3-wire

connection should have been created. Finally, splice the two SKIT black wires to the sensor’s two

normally closed (N/C) wires.

3.3 Sensors compatible with LEIT controllers:

Rain sensors are the HUNTER MINI-CLICK II and the RAIN BIRD RSD.

Moisture sensors are the IRROMETER RA and TGA series.

Freeze sensor is the HUNTER FREEZE-CLICK.

8

B1

C1

E1

STATION 1

STATION 2

STATION 3

STATION 4

STATION 5

STATION 6

STATION MV/P

COMMON

COMMON

S/N:

Spacing

Bolt

Screw

3/16” Hex Key

D1

4. pump or any eleCTrICal equIpmenT InsTallaTIon

If it is required to switch ON a pump, fertilizer injector, fountain or light, two connection options are available using

the RKIT 8810S relay interface module.

The RKIT 8810S units are used to switch 10 amp electrical circuits to a voltage up to 240V AC or 30V DC.

NOTE: RKIT 8810S can be used with LEIT Series 4000, X and XRC.

4.1 RKIT Installation to the MV/Pump Terminal

To operate all the valves with the unit connected to (e.g. pump), connect the RKIT to the MV/Pump terminal (see

Figure C).

4.2 RKIT Installation to One of the Valve Station Terminal Connectors

Operate only the valve number that RKIT has been installed to (e.g. Fountain will turn on/off by only the station

that is using the RKIT).

To install the RKIT, run a red (hot) wire from the RKIT to any of the controller station terminals. Then, run

a white (common) wire from the RKIT to the common terminal connector or if not available, splice it to the

common field wire using a waterproof connector. Run the two black wires from the RKIT to the AC/DC

equipment and connect them to the corresponding circuit to be switched (e.g. pump start relay).

Make sure to use waterproof dry-splice connectors for all connections.

NOTE: If the RKIT is connected to any circuit higher than 24-volts, it must be located in its own high

voltage junction box in accordance with local electrical code.

If a pump start relay coil current is greater than 2A (Model 8810S 2A up to August 2007) or 10A (Model 8810S 10A

after August 2007) use a pilot relay.

WARNING: RKIT cannot be housed in the same box with any low voltage equipment.

Do not connect the RKIT to a circuit higher than 380-volts.

9

sensor installation options

Figure B

OPTION 1

Sensor connected to

controller using SKIT

adapter

OPTION 2

Sensor connected to

a valve using SKIT

adapter

DRY SPLICE WATERPROOF

CONNECTORS

10

ConTroller InsTallaTIon

sensor InsTallaTIon

LEGEND

1. “MINI CLIK” RAIN SENSOR.

2. DIG PLASTIC PIPE CAP – 1” CAP PART NO. 23-001 OR 1.5”

CAP PART NO. 23-153 WITH HOLE FOR WIRES.

3. DRILL TWO 3/16 HOLES IN PIPE FOR SENSOR BRACKET.

4. (2) #8-32 MACHINE SCREWS WITH WASHER, LOCK

WASHER AND NUT.

5. 1” OR 1.5” GALVANIZED PIPE 6 TO 10 FEET HIGH.

6. 12”x12” CONCRETE BASE 8” DEEP MINIMUM.

7. 1” OR 1.5” PIPE ELBOW.

8. FINISH GRADE.

9. 6” ROUND VALVE BOX.

10. PART NO. SKIT ADAPTER 8821-4 USE WITH EACH SENSOR.

11. TO CONTROLLER OR VALVE.

12. (4) DRY SPLICE WATERPROOF CONNECTORS.

13. NORMALLY CLOSED WIRE FROM SENSOR.

14. COMMON WIRE FROM SENSOR.

15. 1” OR 1.5” NIPPLE.

16. GRAVEL.

RAIN SENSOR ASSEMBLY

COLUMN MOUNTED

w

LEGEND

1. MODEL XRC WITH RADIO REMOTE

4 TO 28 STATIONS.

2. TERMINAL STRIP

3. 12 OR 14 GAUGE WIRE.

4. PROGRAMMING KEY. MODEL #: LEIT KEY

5. 35” STEEL MOUNTING COLUMN.

MODEL NUMBER: MCOLXS (SHORT)

50” STEEL MOUNTING COLUMN.

MODEL NUMBER: MCOLXL (LONG)

6. FINISH GRADE.

7. 6-1/2” OF BACKFILL SOIL.

8. POURED CONCRETE BASE – 1-1/2 CU.FT. INSTALL PER

MANUFACTURER’S INSTALLATION GUIDE.

9. DIRECT BURIAL CONTROL WIRES TO CONTROL VALVES.

LIGHT ENERGIZED IRRIGATION CONTROLLER

LEIT CONTROL X AND XRC

q

Figure C

electrical equipment relay interFace connection

LEGEND

1. FINISH GRADE

2. 6” ROUND VALVE BOX

3. RKIT ADAPTER PART NO. 8810-S. USE WITH EACH SENSOR

4. RED WIRE TO THE MV/PUMP TERMINAL OR ANY STATION

TERMINAL

5. WHITE WIRE TO THE COMMON TERMINAL

6. DRY SPLICE WATERPROOF CONNECTORS (4)

7. TO AC/DC EQUIPMENT OR PUMP START RELAY

11

valve InsTallaTIon

P52-075 3/4” REMOTE CONTROL VALVE ASSEMBLY FOR A DRIP SYSTEM

WITH A 155 MESH FILTER AND 30 PSI PRESET PRESSURE REGULATOR

t

160HE-075 3/4 AND 160HE-100 1” REMOTE CONTROL VALVE

ASSEMBLY

e

DRY SPLICE WATERPROOF

CONNECTORS

DRY SPLICE WATERPROOF

CONNECTORS

160HE-150 1-1/2” and 160HE-200 2” REMOTE CONTROL

VALVE FOR LEIT CONTROLLER ASSEMBLY

r

LEIT X, XR and XRC Controller Specifications

Section 02810

moc.procgid.www2820-727-067 XAF • 6419-223-008 :enohP

LIGHT ENERGIZED IRRIGATION CONTROLLER

LEIT CONTROL X, XR AND XRC

160HE-160 1-1/2" and 160HE-200 2" REMOTE CONTROL

VALVE FOR LEIT CONTROLLER ASSEMBLY

RAIN SENSOR ASSEMBLY

COLUMN MOUNTED

160HE-075 3/4" AND 160HE-100 1" REMOTE CONTROL

VALVE FOR LEIT CONTROLLER ASSEMBLY

LEGEND

1DRY SPLICE CONNECTORS

2VALVE BOX WITH COVER 12" SIZE

3FINISH GRADE TOP

4DIG REMOTE CONTROL VALVE WITH FLOW

CONTROL AND LEIT DC SOLENOID

MODEL: 160HE-150 1-1/2"

MODEL: 160HE-200 2"

5PVC SCH 40 MALE ADAPTER

6PVC MAIN LINE

7BRICK SUPPORT AT EACH CORNER

8PEA GRAVEL SUMP MINIMUM 3"

9CONTROL WIRE TO OTHER VALVE

!º SWIVEL FITTING FOR EASY CONNECTION

MODEL: 23-152 1-1/2"

MODEL: 23-202 2"

!¡ PVC SCH 40-45° ELL

LEGEND

1VALVE BOX WITH COVER 18" SIZE

2DRY SPLICE CONNECTORS

3FINISH GRADE TOP

4DIG VALVE MODEL

3/4" 160HE-075

1" 160HE-100

5SWIVEL FITTING DIG MODEL

3/4" 23-004, 1" 23-003

6PVC SCH 40 MALE ADAPTER

7PVC LATERAL LINE

8BRICK SUPPORT AT EACH CORNER

9PEA GRAVEL SUMP – MINIMUM 3"

!º 12 OR 14 GAUGE WIRE

!¡ BACK-UP NPT PVC BALL VALVE

!™ PVC SCH 40 90° ELL

!£ SCH 40 TEE

LEGEND

1"MINI CLIK" RAIN SENSOR

2DIG PLASTIC PIPE CAP

1" PART #23-001 OR 1-1/2" #23-053

WITH HOLE FOR WIRES

3DRILL TWO 3/16" HOLES IN PIPE FOR

SENSOR BRACKET

4(2) #8-32 MACHINE SCREWS WITH

WASHER, LOCK WASHER AND NUT

51" OR 1-1/2" GALVANIZED PIPE

6-10 FEET HIGH

612" X 12" CONCRETE BASE, 8" DEEP

MINIMUM

71" OR 1-1/2" PIPE ELBOW

8FINISH GRADE

96" ROUND VALVE BOX

!º SKIT ADAPTER PART #8821-4

USE WITH EACH SENSOR

!¡ TO CONTROLLER OR VALVE

!™ (4) DRY SPLICE CONNECTORS

!£ NORMALLY CLOSED WIRE FROM SENSOR

!¢ COMMON WIRE FROM SENSOR

!∞1" OR 1-1/2" NIPPLE

!§ GRAVEL

LEGEND

1AMBIENT LIGHT POWERED

IRRIGATION CONTROLLER.

MODEL X: 10-28 STATIONS

MODEL XR (WITH OPTIONAL RADIO):

4-28 STATIONS

MODEL XRC WITH RADIO REMOTE:

4-28 STATIONS

2TERMINAL STRIP

312 OR 14 GAUGE WIRE

4PROGRAMMING KEY

MODEL #LEIT KEY

535" STEEL MOUNTING COLUMN

MODEL #MCOLXS (SHORT) OR

50" STEEL MOUNTING COLUMN

MODEL #MCOLXL (LONG)

6FINISH GRADE

76-1/2" OF BACKFILL SOIL

8POURED CONCRETE BASE –

1-1/2" CU.FT. INSTALL PER

MANUFACTURER'S INSTALL GUIDE

9DIRECT BURIAL CONTROL WIRES TO

CONTROL VALVES

Part 1 Introduction

1.1 LEIT X, XR and XRC controllers are advanced water-management irrigation controllers. The controllers utilize ambient light as the source of energy to

operate up to 28 valves using a low voltage, high efficiency, watertight, 2-way magnetic solenoid actuator that operates at 5-volts. Built to the highest

quality standards (ISO 9002), the LEIT X, XR and XRC controllers have a menu base program with straightforward programming that allows for a wide

range of irrigation programs such as valve grouping, 4 programs with 3 start times, run times up to 6 hours, budget, rain delay, status reports, history

reports, manual runs and more. The controller design uses the most advanced time-tested photovoltaic module, which provides more power to harness

light energy day and night, anytime, anyplace. Used for sprinkler or drip systems, the LEIT X, XR and XRC controllers are commercial quality water

management controllers for any type of environment and for a wide range of uses.

Part 2 Typical Installation

2.1 Drawing File no.: LEIT X.exe

LEGEND

q DRY SPLICE WATERPROOF CONNECTORS

w 18” VALVE BOX WITH COVER

e FINISH GRADE TOP

r DIG REMOTE CONTROL VALVE WITH FLOW

CONTROL AND LEIT DC SOLENOID

MODEL: 160HE-150 1-1/2”

MODEL: 160HE-200 2”

t PVC SCH 40 MALE ADAPTER

y PVC MAIN LINE

u BRICK SUPPORT AT EACH CORNER

i PEA GRAVEL SUMP MINIMUM 3”

o CONTROL WIRE TO OTHER VALVE

1) SWIVEL FITTING FOR EASY CONNECTION

MODEL: 23-152 1-1/2”

MODEL: 23-202 2”

1! PVC SCH 40-45° ELL

5. proGrammInG

This chapter explains the controller buttons hierarchy and how to review, modify settings, program the controller,

or to perform a manual run. To enter the controller, the user needs a LEIT Key or the LEIT Link handset (LEIT XRC).

Insert the LEIT KEY into the controller key slot and follow the steps below. After the information on the screen

comes to view, the user can select the language, then review, program, modify setting or perform a manual run.

For Programming Quick Reference, see the back page of this book or inside the door panel on the controller.

The controller is programmed with the aid of 4 buttons

Use to accept the desired programming mode, select a parameter and raise (increase) the value

of the selected parameter.

Use to deselect a parameter and lower (decrease) the value of the selected parameter.

Use to move the cursor to left.

Use to move the cursor to right.

To move between applications (left to right) use the right or left arrow buttons. To enter an application (Moving up)

uses the YES button.

INSERT LEIT KEY INTO THE SOCKET IN THE UPPER LEFT CORNER OF THE CONTROLLER

The above screens appear while the controller is charging

NOTE: If the controller is being programmed for the first time under a low light level it may take up to

5 minutes to charge the controller using the LEIT Key.

The above alternating screens appear when the LEIT controller is fully charged. When the characters are

most readable, press to select the language to use and continue to the next screen.

This screen identifies the controller model and the number of

stations it has. Press to continue.

This screen appears identifying the software versions that are

installed in the controller. Press to continue.

This screen appears with the date and time. If the controller is being

programmed for the first time it will not display the correct time and

date. Update this screen in the next few

steps. Press to continue.

12

Charging

Please wait

Cargando

Espera por favor

Press YES when

most readable

Cuando lea mejor

presiona YES

Model

LEIT nnXXX

SW Ver X.XX

EE Ver X.XX

MON 01/01/00

12:01 am

5.1 MANUAL RUN

Setting up a Manual Run

The Manual Run is useful for checking the proper operation of

stations (especially after installation), for applying additional water as

required, or for testing the valves.

The first option available on the main menu is to perform a Manual

Run.

The Manual Run feature allows one to suspend a program or valve watering schedule, test a selected valve, select

a temporary program and skip any valve if needed. Note that at the completion of Manual Run any programmed

irrigation schedule reverts back to normal operation.

To enter Manual Run press , to skip Manual Run, press .

Manual Run feature overrides any Sensor Reading, Rain Stop, or Budgeting.

If a program or valve is running, select Yes or No to continue (this

screen will not be shown unless a valve is open). Press or

and underscore Yes or No, then press to select. Press

or again to underscore OK. Press to continue.

If a valve is open, one of the options; Suspend Program # or Stop

Valve # must be selected. To continue, press or and

underscore one of the options, then press to select. Press

or again to underscore OK. Press to continue.

In this screen confirm one of the options that has been selected in the

last screen.

If Stop Valve is selected the valve # selected will closed.

If Suspend Prog is selected, a screen appears which shows valves stopping then “Program # stopped for

Today”. Press to continue.

This screen allows the user to select a stored or temporary program

or to exit the program. If Stored is selected the controller will run the

stored program available. If Temp is selected, a run time for each

valve can be added to start a temporary run time. After the temporary

run time has initiated, the user can skip valves at any time.

To set up a temporary program: press or and underscore Temp, then press to select. Press

or again to underscore OK. Press to continue.

To schedule Valve Run Time press or and underscore

the hour or minute digits, then press or and select a

duration. When finished, press or again to underscore

OK. Press to continue to the next valve. Repeat the same procedure for the remaining valves. To

skip any valve, simply set the runtime to 0, then underscore OK and press to continue to the next

valve. To exit, pass through the remaining valves.

If all valve durations are set to 0 a screen with “Program is Less Then 1 Minute” appears.

NOTE: The remaining stations will display the runtime of the previous stations unless manually changed.

13

Stop Prog/valve?

l Yes No

Suspend Prog: __

Stop Valve: __

Are you Sure?

l Yes No

Run Prog. None

Stored l Temp

Valve #1___0:01

Runtime:

s

t

s

t

s

t

MANUAL

RUN?

Press to start Manual Run (if within the spray area, remove

the LEIT Key, replace and lock the LEIT Controller door to protect the

controller). The LEIT Controller will start the manual run immediately,

running each valve for the programmed duration that has been

selected.

If the LEIT Key was not removed and station 1 has been visually

confirmed to be operating properly, press to skip to the next

valve.

NOTE: If the open or short circuit tests option has been selected (see setting the controller system)

and if the solenoid wiring is faulty the fault status is displayed

Follow the same procedure for station 2 and the remaining stations. When temporary Manual Run has been

completed, the screen will return to Manual Run. To stop Manual Run press or and underscore

No. Press or again to underscore OK. Press to continue.

In the Stop Manual Run screen, press or and

underscore YES, then press to select. Press or

again to underscore OK. Press to continue. Manual run will

stop and the screen will return to Manual Run screen. To continue Manual Run underscore NO, press

or again to underscore OK. Press to continue skip to next valve.

5.2 RAIN STOP/RESTART

Setting up a temporary suspension of all irrigation programs

The Rain Stop feature is used to temporarily suspend all irrigation

programs. For example, during rainy weather, regularly scheduled

programs can be stopped for periods from 1-99 days. At the end of the

designated period the regularly scheduled programming will resume

automatically.

To enter Rain Stop/Restart press . Press to skip Rain Stop and to move to the next feature.

Passwords screen provide the user a security against

unauthorized changes being made to the system. The Default

password is AAA. If the If the password has not been changed

press to continue. If the password has been changed, enter

the new password to continue. To enter the new password press or and underscore the digit to

be changed, then press or to select the appropriate letter. Repeat the steps for each letter. When

finished, press or to underscore OK. Press to continue.

To implement a Rain Stop press or and underscore 0

days. Press or and enter the number of days needed

to suspend irrigation (from 1-99 days). Press or to

underscore OK. Press to continue.

Rain Stop will cancel itself automatically at 12 AM on the last day of the programmed setting.

14

Skip to Next?

l Yes No

01

Stop Manual Run?

l Yes No

RAIN STOP /

RESTART?

Password: AAA

s

t

s

t

s

t

Stop for 00 Days

s

t

s

t

Start Manual Run?

If Rain Stop is active it can be canceled manually anytime in the

Cancel Rain Stop screen. Once there, press or to

underscore Yes and press to select. Press or

again to underscore OK. Press to continue, this will bring back the Rain Stop screen.

5.3 MONTHLY BUDGET

Setting a Monthly Budget

Instead of changing the duration for each program, the Monthly

Budget feature is used to increase or decrease the amount of water

used during seasonally dry or wet periods on a monthly basis.

Budget adjustments can range from 10-200% in 10% increments. The LEIT controller will automatically adjust the

previously programmed duration for each program according to the specified budget entered for each month.

To enter Monthly Budget, press . Press to skip Uplink Budget and to move to the next feature.

The password screen provides the user a security against

unauthorized changes being made to the system. The Default

password is AAA. If the password has not been changed press

to continue. If the password has been changed, enter the

new password to continue. To enter the new password press or and underscore the digit to be

changed, then press or to select the appropriate letter. Repeat the steps for each letter. When

finished, press or to underscore OK. Press to continue.

Budget information for the previous 12 months will appear with

January first and 100% as the default. Press the or to

underscore the percentage digits. Press to increase or

to decrease the percentage (in increments of 10%). Press or to underscore OK. Press to

advance to the next month.

Repeat this procedure for the remaining months as needed. To skip a month, press. Pass thru the 12

months to return to the Monthly Budget screen. Press to continue.

NOTE: To enable or disable an individual station to be budgeted see Setup System menu on page xx

5.4 CHECK STATUS

Review the Controller Status

This feature allows the user to review the current controller status

for the time, date, sensor activation, active program, if any valve is

open, manual run, rain stop progress and short or open circuit in valve

wiring. It also provides information on the controller’s availability for

communication (LEIT XRC only).

To enter Check Status press . Press to skip Check Status and move to the next feature.

15

Cancel Rain Stop?

l Yes No

MONTHLY

BUDGET?

Password: AAA

s

t

s

t

s

t

JAN 100%

Budget:

s

t

s

t

CHECK

STATUS?

This screen appears if any program or valve is active. Press

to continue.

This screen appears if any program or group of valves is active.

Press to continue.

This screen appears if a Manual Run is in progress. Press to

continue.

This screen appears if Rain Stop is active. Press to continue.

This screen appears if irrigation has stopped for a full month.

Press to continue.

If the test is enabled in Setup System, this screen appears if the

valve wiring is open. Press to continue.

If the test is enabled in Setup System, this screen appears if there

is a short in the wiring. Press to continue.

This screen appears with the current date and time of the day.

Press to continue.

This screen appears when the controller is running in local mode.

Press to continue.

NOTE: This screen is available only on model XRC with radio remote capability.

This screen appears when the sensor allows watering. Press

to continue.

This screen appears if no sensor is used. Press to continue.

16

SAT 01/01/00

12:04 am

RUNNING IN

LOCAL MODE

Prog:X Active

Valve xx Open

Prog:X Active

GRPxx:yy Open

Manrun Active

Valve:XX Open

Rainstop Active

xx More Days

Irrigation Stop

for Month XXX

Station xx O/C

Wiring Fault

Station xx S/C

Wiring Fault

Sensor allows

Watering

Sensor is

Unused.

5.5 HISTORY REPORTS

Review The Controller History Reports

This feature allows the user to review the controller operating history

reports for a total watering time for each valve with overall total and

manual run total. This information is available for the current month

and the previous 11 months.

To enter History Report press . Press to skip History Report and move to the next feature

This screen shows total time usage for each valve for the current

month. Press to continue.

This screen shows total time usage for the current month. Press

to continue.

This screen shows total manual run usage for the current month.

Press to continue.

These screens allow a review of information on a specific month.

To review this information, select Yes for the selected month or

No to skip to the next month. Press or and underscore

Yes or No, then, press to select. Press or again

to underscore OK. Press to continue.

If any month is selected this screen shows the total time usage

for each valve in the selected month. Press to continue.

If any month is selected this screen shows the total time usage

for the month select. Press to continue.

If any month is selected this screen shows the total manual run

time usage for the selected month. Press to continue.

These example screens provide the monthly watering totals as requested. This information is available by month

for the previous 11 months.

17

HISTORY

REPORT?

Valve# TOT This

Month: 4:30

JAN06 TOTAL

Month: 12:34

JAN06 MANRUN

Month: 0:30

DEC05 Tot/Valve

Yes l No

NOV05 Tot/Valve

l Yes No

Valve# TOT NOV

Month: 4:30

NOV05 TOTAL

Month: 12:50

NOV05 MANRUN

Month: 1:30

5.6 SETUP SCHEDULE

Review or change the Programming Schedule

This feature allows the user to review, change or set a schedule with

up to four separate programs for each station, each with up to three

individual start times per day. It also allows the user to group stations

together.

NOTE: Be careful not to exceed hydraulic limitations.

To enter Setup Schedule press . Press to skip Setup Schedule and to move to the next feature.

The Default password is AAA. If the password has not been

changed press to continue. If the password has been

changed, enter the new password to continue.

To enter the new password press or and underscore the digit to be changed, then press or

to select the appropriate letter. Repeat the steps for each letter. When finished, press or to

underscore OK. Press to continue.

SELECTING A PROGRAM NUMBER

This screen displays a choice of 4 programs. Program #1 is

highlighted by default. Press to continue programming

Program #1. To select another program, underscore the program number using or and press

to highlight the program number. Press the or to underscore OK. Press to continue.

NOTE: Additional programs will not run unless you have activated the program number.

SETTING WATERING CALENDAR

This screen provides watering frequency options. To select the

preferred option, press or and underscore one of the 4

options. Press to select. Press or again to underscore OK. Press to continue.

WATERING FERQUENCY OPTIONS INCLUDE:

Every: operates stations from once a day to once every 39 days

Even: every even-numbered day

Odd: every odd-numbered day

MTWTFSS: select specific day(s) of the week

NOTE: If MTWTFSS is selected, in the next screen select the day of the week.

If the specific day(s) of the week screen has been selected.

Underscore the appropriate box of the preferred day using

or and press to confirm. The selected day will show a

checkmark instead of the empty box. Repeat the steps again to select other days. When all desired days are

selected, press or to underscore OK. Press to continue.

To de-select a day press .

18

SET UP

SCHEDULE?

Password: AAA

s

t

s

t

s

t

Program Number:

l 1 2 3 4

Every.. Even

l MTWTFSS Odd

Water M T W T F S S

Days: 4

SETTING START TIME

In this screen select up to 3 start times per day (including AM

or PM). To select the first start time underscore the appropriate

digit using the or . Then, press to increase

to decrease the value of the appropriate digit. Repeat the steps again for each digit. When finished, press

or again to underscore OK. Press to continue.

If a second start time is needed, underscore and highlight Yes

using or . Press to select. Press or

again to underscore OK. Press to continue. Repeat the

steps for a second and third start time settings.

NOTE: You can later cancel any of the additional start times simply by selecting No instead of Yes

within each start time.

SETTING WATERING DURATION

When scheduling or changing a watering duration time for each

valve, note that a runtime from 1 minute to 5 hours and 59 minutes in

1minute increments can be set. Any number of valves can operate at

the same time if hydraulic limitations are not exceeded.

To set the valve duration, underscore the appropriate digits using the or . Press to increase

or to decrease the hour or minute digit. Press or again to underscore OK. Press to

continue to the second valve. Follow the same procedure as before for the second and remaining valves. To

skip a valve, leave the duration on zero and press to continue.

NOTE: The duration selected for each valve will be repeated with each of the three start times (if

used).

GROUPING VALVES TO OPERATE AT THE SAME TIME

In the Valve Runtime screen the user can program more than one valve to open or close together in a group

as opposed to the normal operating mode (one valve at the time). To select valves to be grouped together for

operation at the same time, set the duration for the first valve and add the letter G to the rest of the valves in this

group. The first valve and the remaining valves are now linked together.

Example: Linking Valve #2 to Valve #1

Set a run time for Valve #1. While in the Valve #2 Runtime screen, press or and underscore

the icon left of the hour position. Press and the letter G will appear. Press or again to

underscore OK. Press to confirm.

The letter G signifies that Valve #2 is now grouped to Valve #1, with Valve #1 being the group leader. The

watering time for this group leader will be applied to all consecutive valves that show the letter G in the

19

1st 12:00 am

Start s

t

s

t

s

t

s

t

s

t

2nd Start Time?

l Yes No

Valve #____ 0:01

Runtime: s

t

s

t

s

t

s

t

Valve 1 0:12

Runtime:

Valve #2 G0:00

Runtime:

Valve Runtime screen. Press or and underscore the letter G located to left of the hour digit in the

runtime screen to remove the letter G (group leader) from a group of valves. Press and the letter G will

disappear. Repeat with the other valves as needed. Press or again to underscore OK. Press

to continue.

The following examples are of groups (G or 0 can be set for intermediate valves in a group).

It is possible to set more than one group.

Valves #1-4 grouped with runtime of 20 min.

Valve #1 set for 0:20 minutes

Valve #2 set for G0:00 or 0:00

Valve #3 set for G0:00 or 0:00

Valve #4 set for G0:00

NOTE: When selecting or changing a grouped setting, cycle through all the valves on this setting to

save the changes before exiting.

IMPORTANT: Using valves grouping

1. For any valve number that is assigned to a group leader and the G is disabled, there are two options available:

a. If any unassigned “Valve Runtime” is left on 0, the valve will be a slave within a group.

b. A runtime may be entered for this valve making up the valve a new group leader or for

stand-alone operation.

2. If any of the assigned group leaders are disabled by setting runtime (duration) to 0:00, there are three options

available:

a. If the setting of a group leader is 0 (“Valve # Runtime”), there is no preceding valve within a group; a default

run time of one minute is used by Valve #1 to prevent from disabling the complete group setting.

b If a valve is assigned as a second group leader and the setting for this valve has been changed to 0. All the

valves attached to the disabled group leader will become part of the preceding group.

3. Valves can be grouped in one program and run separately in another.

4. The master valve will be operating for all/any valves in the group that are selected in system setup.

5. If a moisture sensor governs the lead valve of a group, this will govern the operation of the entire group,

regardless of the individual (sensor governs) selections of the slave valves.

6. If operating individually in another program, all valves will follow their own sensor selections.

Be very careful not to duplicate or overlap schedules.

7. If any of the programs are not finished by the start of the following program, the second program will stack up

to start later.

8. Make sure that programs do no overlap.

9. A manual run can interrupt a running program, which will resume at the completion of the manual run

5.7 SETUP SYSTEM

Setting the Controller System

The Setup System menu allows the user to set the current controller

date and time, activate or de-activate programs, activate or deactivate

the budget, enter or change master valve/pump settings, and activate

monthly irrigation suspension. In this menu the user can also activate

a feature that checks the solenoid for shorts or open wires, activate a

sensor, assign a sensor to one valve, all valves or a MV/P and change the passwords.

To enter Setup System press . Press to skip Setup System and move to the next feature

20

Valves #5 and 6 not grouped

Valve #5 with runtime of 10 min.

Valve #6 with runtime of 15 min.

Valves #7-10 grouped with runtime of 25 min.

Valve #7 set for 0:25 minutes

Valve #8 set for G0:00 or 0:00

Valve #9 set for G0:00 or 0:00

Valve #10 set for G0:00

SETUP

SYSTEM

This manual suits for next models

1

Table of contents

Other DIG Irrigation System manuals