TFP1335

Page 9 of 26

Installation

TYCO DV-5 Deluge Valves are to

be installed in accordance with this

section.

NOTICE

Proper operation of the DV-5 Deluge

Valves depends upon their trim being

installed in accordance with the

instructions given in this Technical Data

Sheet. Failure to follow the appropri-

ate trim diagram may prevent the DV-5

Valve from functioning properly, as well

as void approvals and the manufactur-

er’s warranties.

The DV-5 Valve must be installed in a

readily visible and accessible location.

The DV-5 Valve, associated trim, and

wet pilot lines must be maintained at a

minimum temperature of 4°C.

Heat tracing of the DV-5 Valve or its

associated trim is not permitted. Heat

tracing can result in the formation of

hardened mineral deposits that are

capable of preventing proper operation.

The DV-5 Deluge Valve is to be installed

in accordance with the following

criteria:

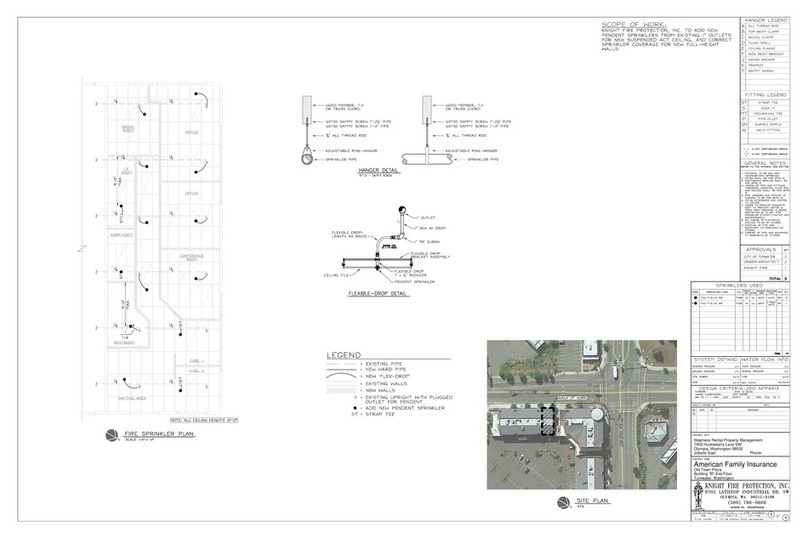

Step 1. All nipples, fittings, and devices

must be clean and free of scale and

burrs before installation. Use pipe

thread sealant sparingly on male pipe

threads only.

Step 2. The DV-5 Valve must be

trimmed in accordance with one of the

trim illustrations shown in Figures 7 thru

18, as applicable.

Step 3. Care must be taken to ensure

that check valves, strainers, globe

valves, etc. are installed with the flow

arrows in the proper direction.

Step 4. Suitable provision must be

made for disposal of drain water. Drain-

age water must be directed such that

it will not cause accidental damage to

property or danger to persons.

Step 5. Connect the Diaphragm Supply

Valve to the inlet side of the system’s

Stop Valve in order to facilitate setting

of the DV-5 Valve (Ref. Figure 19).

Step 6. An Inspector’s Test Connec-

tion, as described in the Wet Pilot Actu-

ation and Dry Pilot Actuation sections,

must be provided for Wet or Dry Pilot

Actuation systems.

Step 7. An Air Maintenance Device,

as described in the Dry Pilot Actuation

section, must be provided for Dry Pilot

Actuation.

Step 8. A desiccant dryer, when spec-

ified for Dry Pilot Actuation, is to be

installed between a drip leg and the

Air Maintenance Device.

Step 9. The Low Pressure Alarm Switch

for Dry Pilot Actuation is to be adjusted

as follows:

• Low pressure alarm setting at

approximately 0,4 bar below the

minimum pilot line service pressure

requirement shown in Graph B

• Fire alarm setting at approximately

1,0 bar below the minimum pilot line

service pressure requirement shown

in Graph B

Step 10. The Pressure Relief Valve pro-

vided with the Dry Pilot Actuation Trim

is factory set to relieve at a pressure of

approximately 3,1 bar, which can typi-

cally be used for a maximum dry pilot

actuation system pressure of 2,8 bar.

The Pressure Relief Valve may be reset;

however, it must be reset to relieve at

a pressure which is in accordance

with the requirements of the authority

having jurisdiction.

To reset the Pressure Relief Valve, first

loosen the jam nut and then adjust

the cap accordingly — clockwise for

a higher pressure setting or counter-

clockwise for a lower pressure setting.

After verifying the desired pressure

setting, tighten the jam nut.

Step 11. Conduit and electrical con-

nections are to be made in accordance

with the applicable standards of the

Approval agency.

Step 12. Before a system hydrostatic

test is performed, the DV-5 Diaphragm

Chamber is to be depressurized, the

Automatic Drain Valve is to be tem-

porarily replaced with a plug, and the

Diaphragm Cover Bolts must be uni-

formly and securely tightened using a

cross-draw sequence. After tighten-

ing, double-check to make certain that

all of the Diaphragm Cover Bolts are

securely tightened.