TFP342_EN Page 3 of 6

the need for in-rack sprinkler protec-

tion) of cartoned or uncartoned unex-

panded Group A or B plastics, or, car-

toned expanded Group A or B plastics,

with:

•

a storage height of up to 20 feet (6,1

m);

•

a maximum ceiling height of 27 feet

(8,2 m);

•

a minimum deflector to top of stor-

age clearance of 18 inches (457

mm);

•

a minimum design density of 0.60

gpm/ft2(24,4 mm/min);

•

a minimum residual (flowing) pres-

sure of 10 psi (0,7 bar);

•

a minimum design area of 2000 ft2

(186 m2) for wet systems or 2600 ft2

(242 m2) for dry pipe systems

FM Approval

Requirements

The 11.2 K-factor, Model ELO-231B

(TY5151, TY5251 & TY5851) Sprin-

klers are to be installed in accordance

with the applicable “control mode den-

sity/area” guidelines provided by Fac-

tory Mutual. (FM guidelines may differ

from UL and C-UL Listing criteria.)

Operation

The glass bulb contains a fluid that

expands when exposed to heat. When

the rated temperature is reached, the

fluid expands sufficiently to shatter the

glass bulb, allowing the sprinkler to

activate and water to flow.

Installation

The Series ELO-231B Sprinklers must

be installed in accordance with the fol-

lowing instructions:

NOTES

Do not install any bulb type sprinkler if

the bulb is cracked or there is a loss of

liquid from the bulb. With the sprinkler

held horizontally, a small air bubble

should be present. The diameter of the

air bubble is approximately 1/16 inch

(1,6 mm) for the 155°F/68°C to 3/32

inch (2,4 mm) for the 286°F/141°C

temperature ratings.

A leak tight 3/4 inch NPT sprinkler joint

should be obtained with a torque of 10

to 20 ft.lbs. (13,4 to 26,8 Nm). A maxi-

mum of 30 ft.lbs. (40,7 Nm) of torque

is to be used to install sprinklers with

3/4 NPT connections. A leak tight 1/2

inch NPT sprinkler joint should be ob-

tained with a torque of 7 to 14 ft.lbs.

(9,5 to 19,0 Nm). A maximum of 21 ft.

lbs. (28,5 Nm) of torque may be used

to install sprinklers with 1/2 NPT con-

nections. Higher levels of torque may

distort the sprinkler inlet and cause

leakage or impairment of the sprinkler.

Do not attempt to make-up for insuffi-

cient adjustment in the escutcheon

plate by under- or over-tightening the

sprinkler. Readjust the position of the

sprinkler fitting to suit.

The Series ELO-231B Upright and

Pendent Sprinklers must be installed

in accordance with the following in-

structions.

Step 1. Pendent sprinklers are to be

installed in the pendent position, and

upright sprinklers are to be installed in

the upright position.

Step 2. With pipe thread sealant ap-

plied to the pipe threads, hand tighten

the sprinkler into the sprinkler fitting.

Step 3. Tighten the sprinkler into the

sprinkler fitting using only the W-Type

3 Sprinkler Wrench (Ref. Figure 2),

except that an 8 or 10 inch adjustable

Crescent wrench is to be used for wax

coated sprinklers. With reference to

TFP342 Page 3 of 6

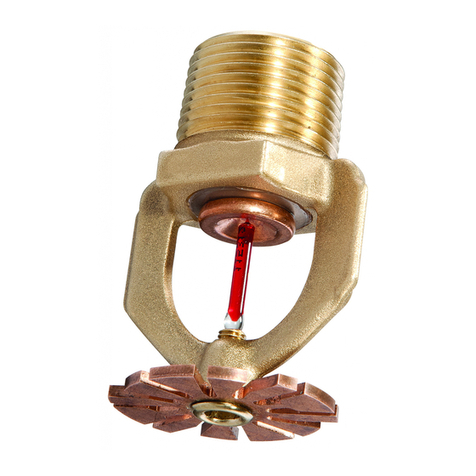

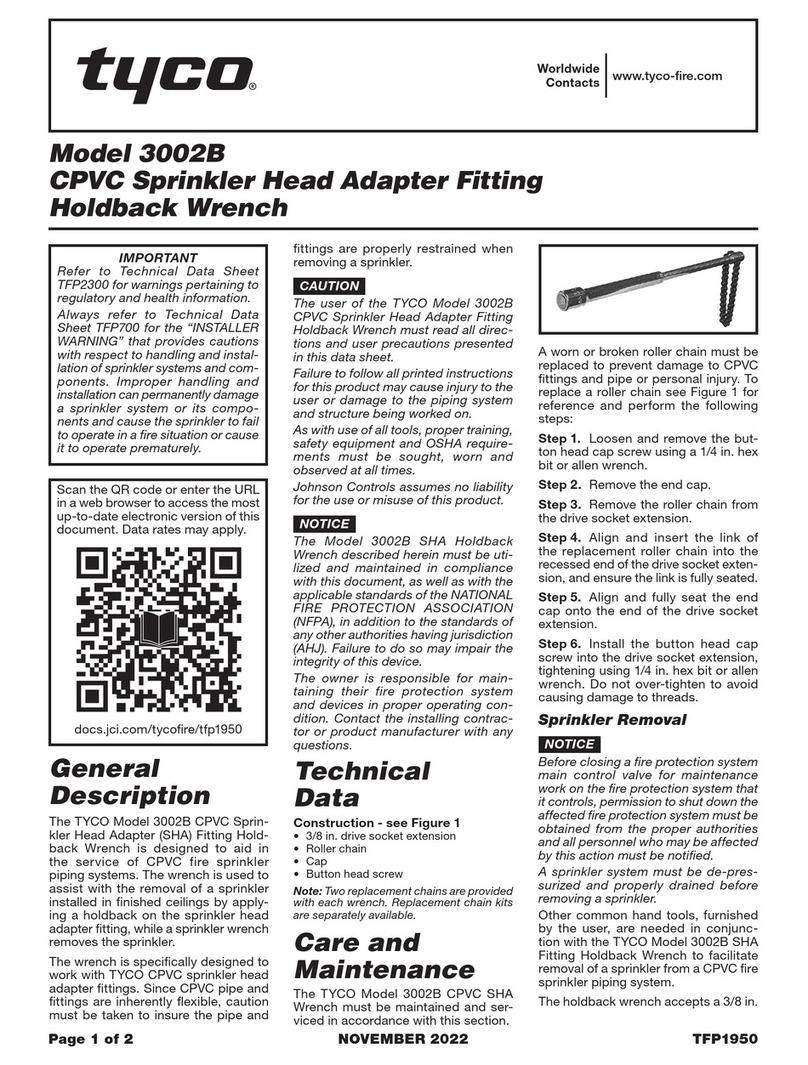

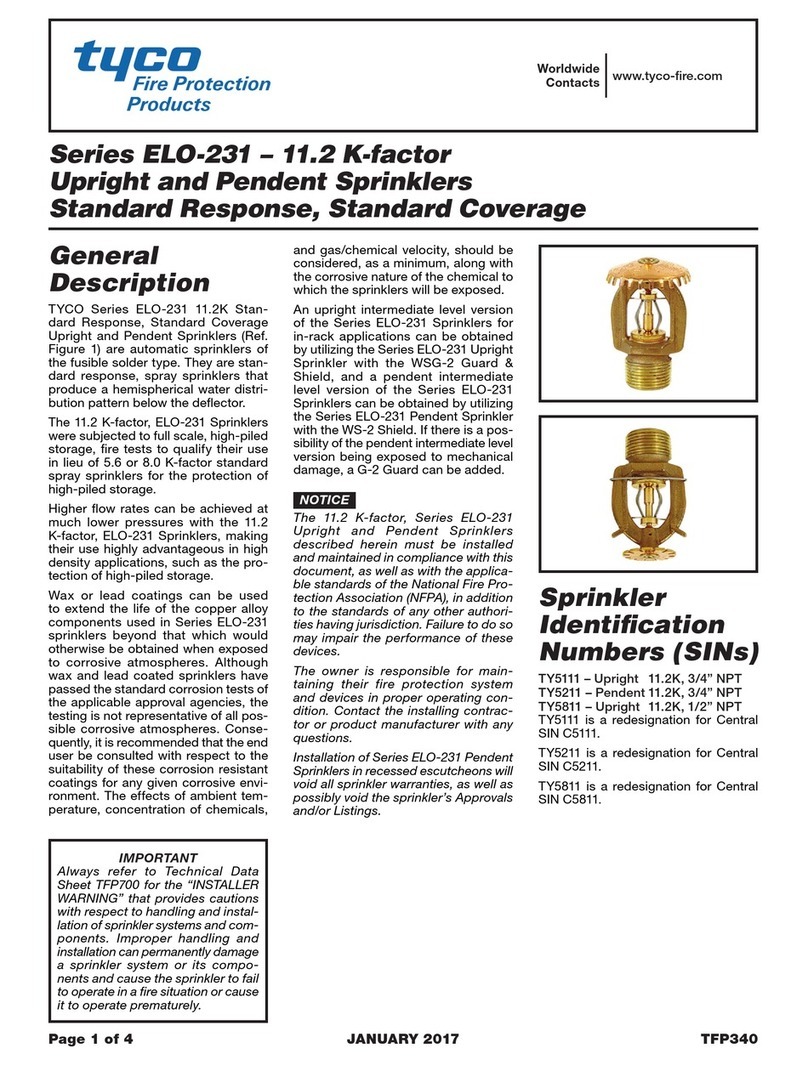

FIGURE 1

11.2 K-FACTOR SERIES ELO-231B

UPRIGHT - 3/4" NPT (TY5151), UPRIGHT - 1/2" NPT (TY5851), AND PENDENT - 3/4" NPT (TY5251) SPRINKLERS

"FITTIN

IDE"

FITTING

TOWARDS SPRINKLER

RECESS

WRENCH

(END "A")

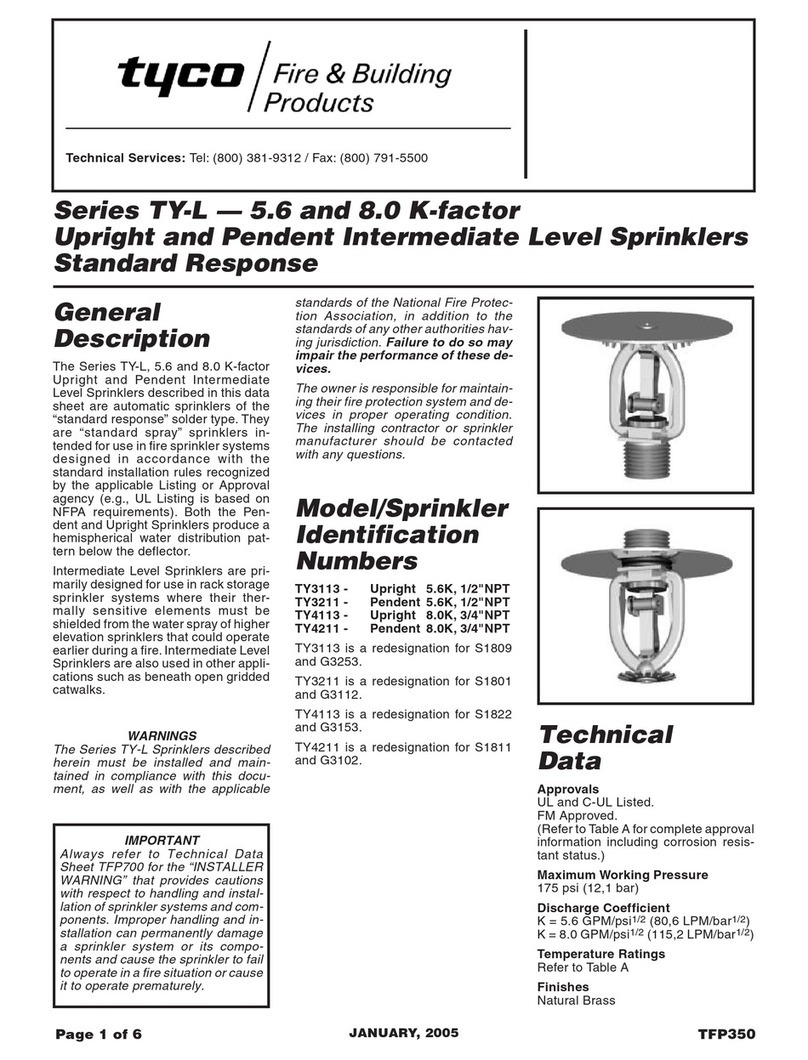

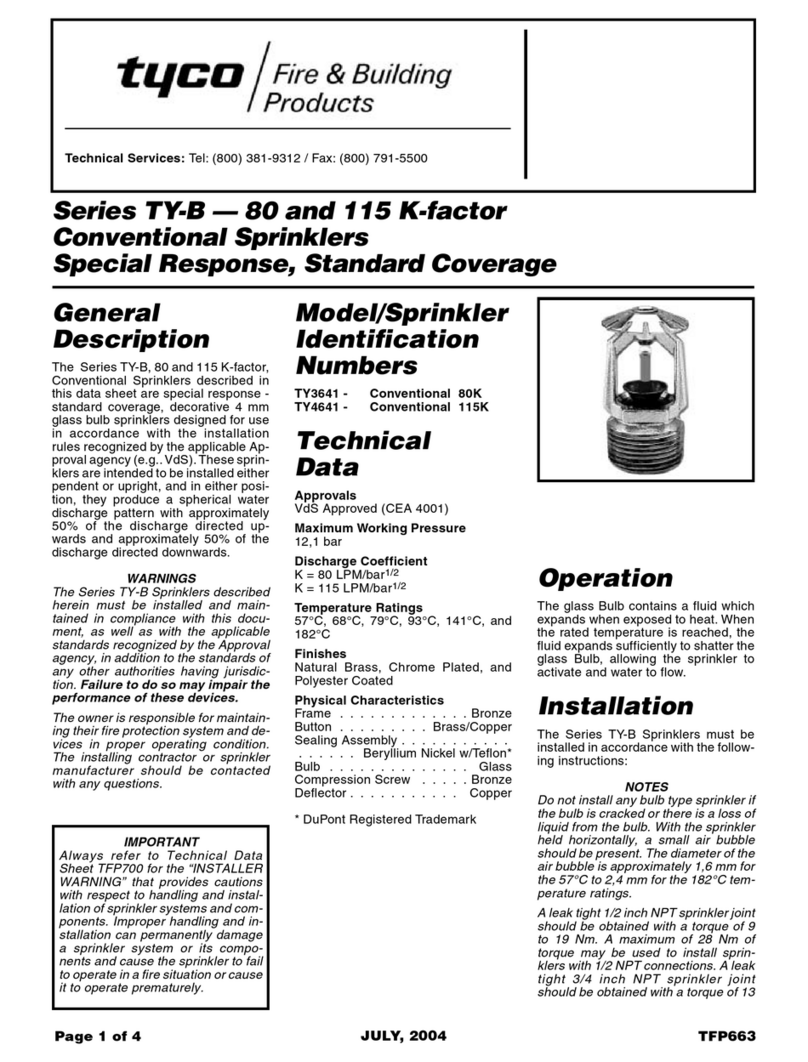

FIGURE 2

W-TYPE 3 SPRINKLER

WRENCH

PENDENT

TY5251

1/2" (12,7 mm)

NOMINAL MAKE-IN

7/16" (11,1 mm)

NOMINAL MAKE-IN

Temperature rating is indicated on deflector.

Pipe thread connections per ISO 7/1 can be provided on

TYP.

2-13/16"

(71,4 mm)

UPRIGHT

TY5851

special request.

**

*

UPRIGHT

TY5151

NOMINAL MAKE-IN

1/2" (12,7 mm)

**

NPT

1/2"

WRENCH

FLATS

**

RELIEF

THREAD

3/4"

NPT

Deflector

Screw

Compression

Bulb

Components:

Seal

Cap

Frame

-

4

2

6

5

4

3

CROSS

SECTION

6

5

-

-

NPT

**

3/4" 1

2

3

1

-

-

-

*

Assembly

FIGURE 1

K160 SERIES ELO-231B UPRIGHT - 3/4” NPT (TY5151), UPRIGHT - 1/2” NPT (TY5851), AND PENDENT - 3/4” NPT

(TY5251) SPRINKLERS

UPRIGHT

TY5851

WRENCH

FLATS

71 mm

(2-13/16”)

TYP.

NOMINAL MAKE-IN

12,5 mm (1/2”)

Components

1 - Frame

2 - Sealing

Assembly

3 - Cap

4 - Bulb

5 - Compression

Screw

6 - Deector *

* Temperature rating is indicated on deector.

**Pipe thread connections per ISO 7/1 can be

provided on special request.

Operation

The glass bulb contains a uid that expands

when exposed to heat.When the rated tem-

perature is reached, the uid expands su-

ciently to shatter the glass bulb, activating

the sprinkler and allowing water to ow.

Installation

The Series ELO-231B Sprinklers must be

installed in accordance with the following

instructions:

NOTES

Do not install any bulb type sprinkler if the

bulb is cracked or there is a loss of liquid from

the bulb. With the sprinkler held horizontally,

a small air bubble should be present. The di-

ameter of the air bubble is approximately 1,5

mm (1/16”) for the 57°C (135°F) to 2,5 mm

(3/32”) for the 141°C (286°F) temperature rat-

ings.

A leak tight 3/4” NPT sprinkler joint should be

obtained with a torque of 13 to 27 Nm (10 to

20 ft.lbs.). A maximum of 41 Nm (30 ft.lbs.) of

torque is to be used to install sprinklers with

3/4 NPT connections. A leak tight 1/2” NPT

sprinkler joint should be obtained with a

torque of 9,5 to 19 Nm (7 to 14 ft.lbs.). A maxi-

mum of 29 Nm (21 ft. lbs.) of torque may be

used to install sprinklers with 1/2 NPT connec-

tions. Higher levels of torque may distort the

sprinkler inlet and cause leakage or impair-

ment of the sprinkler.

sprinkler, loosen the wrench jaws before

removing the wrench.

After installation, the sprinkler wrench ats

and frame arms must be inspected and the

wax coating retouched (repaired) whenev-

er the coating has been damaged and bare

metal is exposed. The wax coating on the

wrench ats can be retouched by gently

applying a heated 1/8 inch diameter (M3)

steel rod to the areas of wax that have been

damaged, to smooth it back over areas

where bare metal is exposed.

NOTES

Only retouching of the wax coating applied to

the wrench ats and frame arms is permitted,

and the retouching is to be performed only at

the time of the initial sprinkler installation.

The steel rod should be heated only to the

point at which it can begin to melt the wax,

and appropriate precautions need to be tak-

UPRIGHT

TY5151

PENDENT

TY5251

CROSS

SECTION

NOMINAL MAKE-IN

12,5 mm (1/2”)

NOMINAL MAKE-IN

11,1 mm (7/16”)

THREAD

RELIEF

the need for in-rack sprinkler protec-

tion) of cartoned or uncartoned unex-

panded Group A or B plastics, or, car-

toned expanded Group A or B plastics,

with:

•

a storage height of up to 20 feet (6,1

m);

•

a maximum ceiling height of 27 feet

(8,2 m);

•

a minimum deflector to top of stor-

age clearance of 18 inches (457

mm);

•

a minimum design density of 0.60

gpm/ft2(24,4 mm/min);

•

a minimum residual (flowing) pres-

sure of 10 psi (0,7 bar);

•

a minimum design area of 2000 ft2

(186 m2) for wet systems or 2600 ft2

(242 m2) for dry pipe systems

FM Approval

Requirements

The 11.2 K-factor, Model ELO-231B

(TY5151, TY5251 & TY5851) Sprin-

klers are to be installed in accordance

with the applicable “control mode den-

sity/area” guidelines provided by Fac-

tory Mutual. (FM guidelines may differ

from UL and C-UL Listing criteria.)

Operation

The glass bulb contains a fluid that

expands when exposed to heat. When

the rated temperature is reached, the

fluid expands sufficiently to shatter the

glass bulb, allowing the sprinkler to

activate and water to flow.

Installation

The Series ELO-231B Sprinklers must

be installed in accordance with the fol-

lowing instructions:

NOTES

Do not install any bulb type sprinkler if

the bulb is cracked or there is a loss of

liquid from the bulb. With the sprinkler

held horizontally, a small air bubble

should be present. The diameter of the

air bubble is approximately 1/16 inch

(1,6 mm) for the 155°F/68°C to 3/32

inch (2,4 mm) for the 286°F/141°C

temperature ratings.

A leak tight 3/4 inch NPT sprinkler joint

should be obtained with a torque of 10

to 20 ft.lbs. (13,4 to 26,8 Nm). A maxi-

mum of 30 ft.lbs. (40,7 Nm) of torque

is to be used to install sprinklers with

3/4 NPT connections. A leak tight 1/2

inch NPT sprinkler joint should be ob-

tained with a torque of 7 to 14 ft.lbs.

(9,5 to 19,0 Nm). A maximum of 21 ft.

lbs. (28,5 Nm) of torque may be used

to install sprinklers with 1/2 NPT con-

nections. Higher levels of torque may

distort the sprinkler inlet and cause

leakage or impairment of the sprinkler.

Do not attempt to make-up for insuffi-

cient adjustment in the escutcheon

plate by under- or over-tightening the

sprinkler. Readjust the position of the

sprinkler fitting to suit.

The Series ELO-231B Upright and

Pendent Sprinklers must be installed

in accordance with the following in-

structions.

Step 1. Pendent sprinklers are to be

installed in the pendent position, and

upright sprinklers are to be installed in

the upright position.

Step 2. With pipe thread sealant ap-

plied to the pipe threads, hand tighten

the sprinkler into the sprinkler fitting.

Step 3. Tighten the sprinkler into the

sprinkler fitting using only the W-Type

3 Sprinkler Wrench (Ref. Figure 2),

except that an 8 or 10 inch adjustable

Crescent wrench is to be used for wax

coated sprinklers. With reference to

TFP342 Page 3 of 6

FIGURE 1

11.2 K-FACTOR SERIES ELO-231B

UPRIGHT - 3/4" NPT (TY5151), UPRIGHT - 1/2" NPT (TY5851), AND PENDENT - 3/4" NPT (TY5251) SPRINKLERS

"FITTIN

IDE"

FITTING

TOWARDS SPRINKLER

RECESS

WRENCH

(END "A")

FIGURE 2

W-TYPE 3 SPRINKLER

WRENCH

PENDENT

TY5251

1/2" (12,7 mm)

NOMINAL MAKE-IN

7/16" (11,1 mm)

NOMINAL MAKE-IN

Temperature rating is indicated on deflector.

Pipe thread connections per ISO 7/1 can be provided on

TYP.

2-13/16"

(71,4 mm)

UPRIGHT

TY5851

special request.

**

*

UPRIGHT

TY5151

NOMINAL MAKE-IN

1/2" (12,7 mm)

**

NPT

1/2"

WRENCH

FLATS

**

RELIEF

THREAD

3/4"

NPT

Deflector

Screw

Compression

Bulb

Components:

Seal

Cap

Frame

-

4

2

6

5

4

3

CROSS

SECTION

6

5

-

-

NPT

**

3/4" 1

2

3

1

-

-

-

*

Assembly

“FITTING SIDE”

TOWARDS SPRINKLER

FITTING

WRENCH

RECESS

(END “A”)

FIGURE 2

W-TYPE 3 SPRINKLER

WRENCH

Do not attempt to make-up for insucient

adjustment in the escutcheon plate by under-

or over-tightening the sprinkler. Readjust the

position of the sprinkler tting to suit.

The Series ELO-231B Upright and Pen-

dent Sprinklers must be installed in ac-

cordance with the following instructions.

Step 1. Pendent sprinklers are to be in-

stalled in the pendent position, and upright

sprinklers are to be installed in the upright

position.

Step 2. With pipe thread sealant applied to

the pipe threads, hand tighten the sprinkler

into the sprinkler tting.

Step 3. Tighten the sprinkler into the sprin-

kler tting using only the W-Type 3 Sprin-

kler Wrench (Ref. Figure 2), except that a

200 or 250 mm (8 or 10”) adjustable Cres-

cent wrench is to be used for wax coated

sprinklers. With reference to Figure 1, the

W-Type 3 Sprinkler Wrench or the adjust-

able Crescent wrench, as applicable is to be

applied to the wrench ats.

When installing wax coated sprinklers with

the adjustable Crescent wrench, additional

care needs to be exercised to prevent dam-

age to the wax coating on the sprinkler

wrench ats or frame arms and, conse-

quently, exposure of bare metal to the cor-

rosive environment. The jaws of the wrench

should be opened suciently wide to pass

over the wrench ats without damaging

the wax coating. Before wrench tightening

the sprinkler, the jaws of the wrench are to

be adjusted to just contact the sprinkler

wrench ats. After wrench tightening the