TFP191

Page 3 of 4

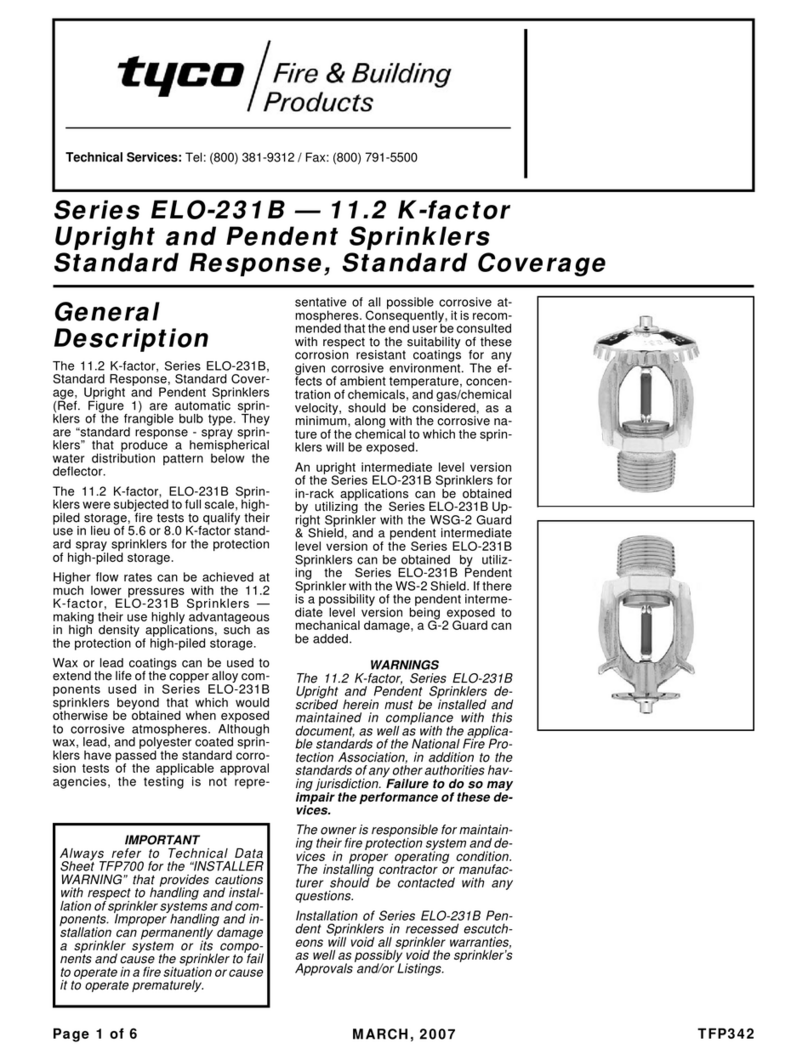

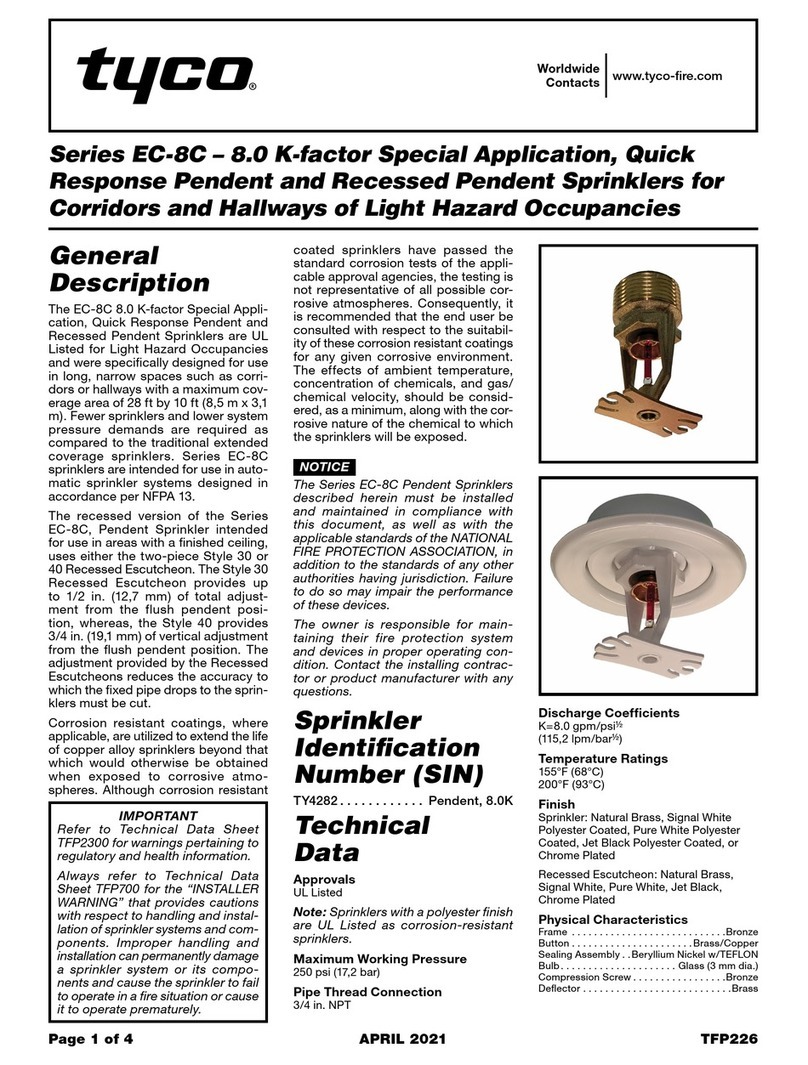

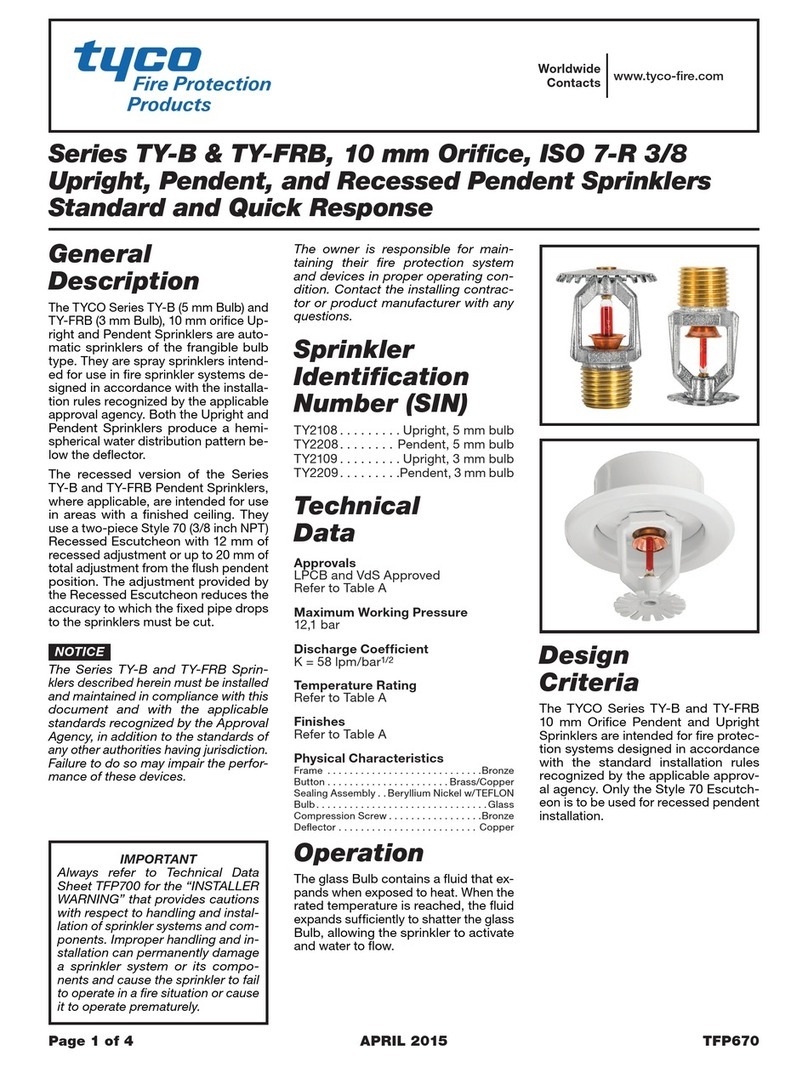

Step 4. Wrench tighten the Sprinkler

using only the Sprinkler Socket or

Wrench & Socket Combination (Ref.

Figure 3). The wrench recess of the

Socket is to be applied to the sprinkler

wrenching area (Ref. Figure 1A).

Step 5. Use the “ceiling level tolerance

limit” indicator on the Protective Cap

to check for proper installation height.

Relocate the sprinkler fitting as neces-

sary. If desired the Protective Cap may

also be used to locate the center of the

clearance hole by gently pushing the

ceiling material against the center point

of the Cap.

Step 6. After the ceiling has been com-

pleted with the 50 mm diameter clear-

ance hole, use the Protective Cap

Removal Tool (Ref. Figure 2) to remove

the Protective Cap and then push on

the Escutcheon until its flange just

comes in contact with the ceiling. Do

not continue to push the Escutcheon

such that it lifts a ceiling panel out of

its normal position. If the Escutcheon

cannot be engaged with the Sprinkler,

or the Escutcheon cannot be engaged

sufficiently to contact the ceiling, relo-

cate the sprinkler fitting as necessary.

Care and

Maintenance

The TYCO Model TY-QRF-EU,

(TY3260) 80 K-factor, Flush Pendent

Sprinklers must be maintained and ser-

viced in accordance with this section.

Before closing a fire protection system

main control valve for maintenance

work on the fire protection system that

it controls, permission to shut down the

affected fire protection system must be

obtained from the proper authorities

and all personnel who may be affected

by this action must be notified.

Absence of an Escutcheon Plate may

delay the time to sprinkler operation in

a fire situation.

Sprinklers which are found to be

leaking or exhibiting visible signs of

corrosion must be replaced.

Automatic sprinklers must never be

painted, plated, coated, or otherwise

altered after leaving the factory. Modi-

fied or over heated sprinklers must be

replaced.

Care must be exercised to avoid

damage before, during, and after instal-

lation. Sprinklers damaged by drop-

ping, striking, wrench twist/slippage,

or the like, must be replaced.

The owner is responsible for the

inspection, testing, and maintenance of

their fire protection system and devices

in compliance with this document, as

well as with the applicable standards

of the Authorities Having Jurisdiction,

in addition to the standards of any other

authorities having jurisdiction. Contact

the installing contractor or product

manufacturer with any questions.

Automatic sprinkler systems should be

inspected, tested, and maintained by a

qualified Inspection Service in accor-

dance with local requirements and/or

national codes.

Limited

Warranty

For warranty terms and conditions, visit

www.tyco-fire.com.

Ordering

Procedure

Contact your local distributor for avail-

ability. When placing an order, indicate

the full product name and part number

(P/N).

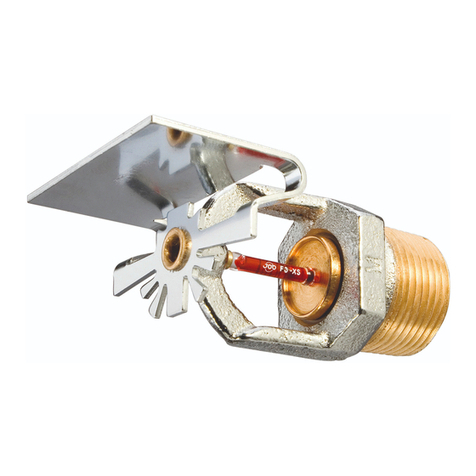

Sprinkler Assembly

Sprinkler Assembly ordered separately

from Escutcheon. See Escutcheon for

ordering information.

Specify: Model TY-QRF-EU (TY3260),

K=80, Flush Pendent Sprinkler without

Escutcheon, Pure White (RAL9010)

finish, P/N 53-261-3-162E

Escutcheon

Escutcheon ordered separately from

Sprinkler Assembly. See Sprinkler

Assembly for ordering information.

Specify: Escutcheon for Model TY-

QRF-EU (TY3260), K=80, Flush

Pendent Sprinkler, Pure White

(RAL9010) finish, 75 mm Outside Diam-

eter, P/N 56-123-3-001E

Accessories

Socket for Model TY-QRF-EU, Flush

Pendent Sprinkler, P/N 56-000-4-947

Wrench & Socket for Model

TY-QRF-EU, Flush Pendent Sprinkler,

P/N 56-000-4-948

Protective Cap Removal Tool for Model

TY-QRF-EU, Flush Pendent Sprinkler,

P/N 56-000-4-300

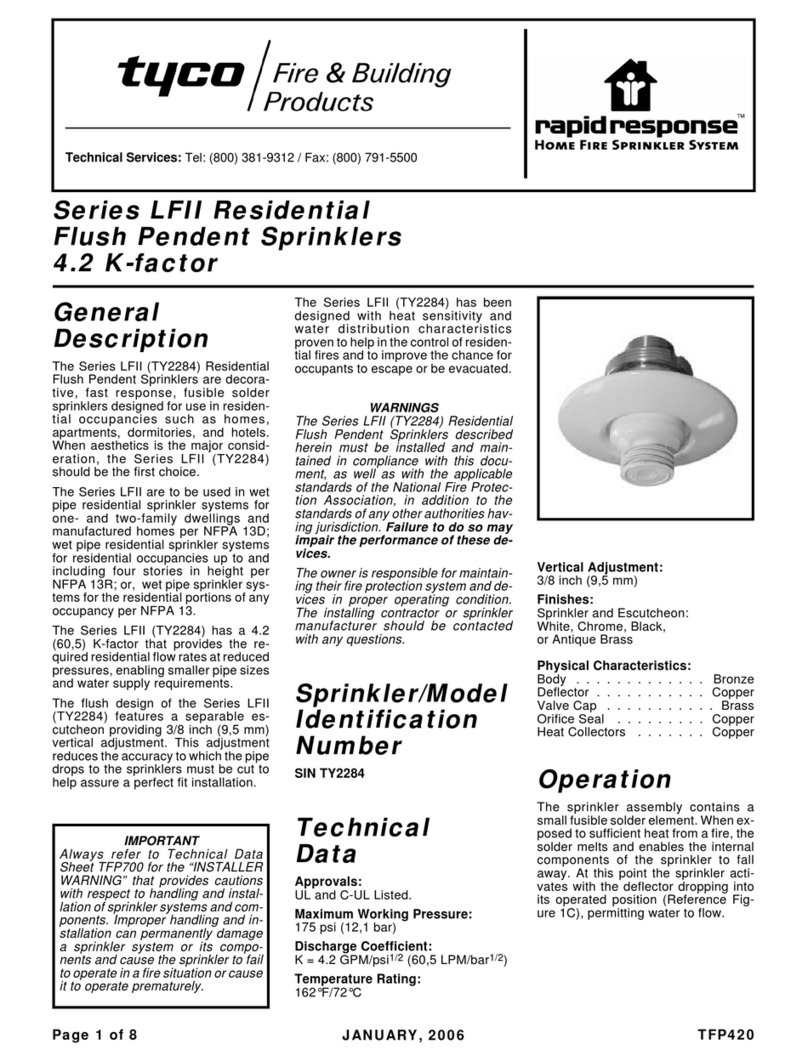

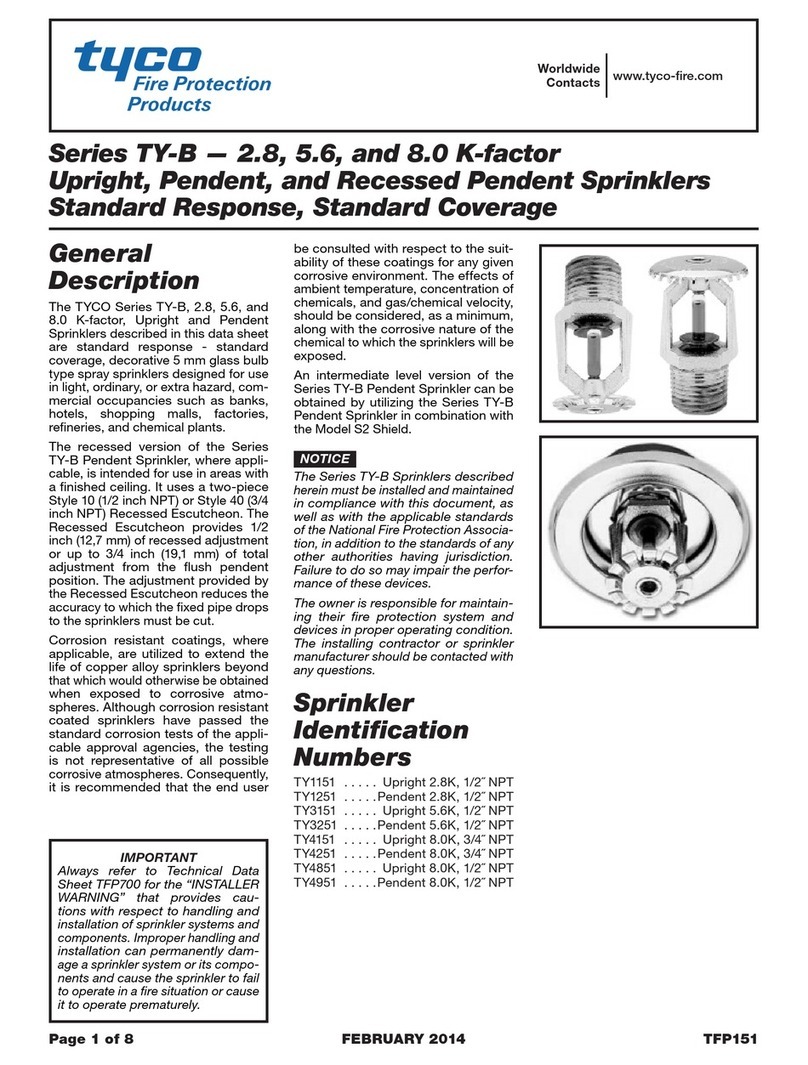

ACCEPTS

3/8" SOCKET

DRIVE

RECESS

WRENCH

#4948

WRENCH & SOCKET

COMBINATION

#4947

SOCKET

FIGURE 3

SPRINKLER SOCKET

WRENCH & SOCKET COMBINATION