TFP682

Page 9 of 10

qualified Inspection Service in accor-

dance with local requirements and/or

national codes.

Limited

Warranty

For warranty terms and conditions, visit

www.tyco-fire.com.

Ordering

Procedure

Contact your local distributor for

availability. When placing an order,

indicate the full product name and Part

Number (P/N).

Sprinkler Assemblies

Specify: (specify SIN), (specify Stan-

dard Response or Quick Response),

(specify K-factor), (specify) tempera-

ture rating, (specify Upright, Pendent

or HSW), P/N (specify from Table D)

Recessed Escutcheon

Specify: Style (specify 10 or 40)

Recessed Escutcheon, Grey Aluminum

(RAL9007) finish, P/N (specify*)

*Refer to Technical Data Sheet TFP770.

Sprinkler Wrench

Specify: W-Type 6 Sprinkler Wrench,

P/N 56-000-6-387

Specify: W-Type 7 Recessed Sprinkler

Wrench, P/N 56-850-4-001

Care and

Maintenance

The TYCO Series TY-B and TY-FRB

Sprinklers must be maintained and ser-

viced in accordance with this section.

Before closing a fire protection system

main control valve for maintenance

work on the fire protection system that

it controls, permission to shut down the

affected fire protection system must be

obtained from the proper authorities

and all personnel who may be affected

by this action must be notified.

The owner must assure that the sprin-

klers are not used for hanging of any

objects; otherwise, non-operation in

the event of a fire or inadvertent oper-

ation may result.

Absence of an escutcheon, which is

used to cover a clearance hole, may

delay the time to sprinkler operation in

a fire situation.

Sprinklers that are found to be leaking

or exhibiting visible signs of corrosion

must be replaced.

Automatic sprinklers must never be

painted, plated, coated or other-

wise altered after leaving the factory.

Modified sprinklers must be replaced.

Sprinklers that have been exposed to

corrosive products of combustion, but

have not operated, should be replaced

if they cannot be completely cleaned

by wiping the sprinkler with a cloth or

by brushing it with a soft bristle brush.

Care must be exercised to avoid

damage to the sprinklers before,

during, and after installation. Sprin-

klers damaged by dropping, striking,

wrench twist/slippage, or the like, must

be replaced. Also, replace any sprin-

kler that has a cracked bulb or that has

lost liquid from its bulb. (Ref. Installa-

tion Section).

Frequent visual inspections are rec-

ommended to be initially performed

for corrosion resistant sprinklers, after

the installation has been completed,

to verify the integrity of the corrosion

resistant material of construction.

Thereafter, annual inspections per

NFPA 25 should suffice; however,

instead of inspecting from the floor

level, a random sampling of close-up

visual inspections should be made, so

as to better determine the exact sprin-

kler condition and the long term integ-

rity of the corrosion resistant material

of construction, as it may be affected

by the corrosive conditions present.

The owner is responsible for the

inspection, testing, and maintenance of

their fire protection system and devices

in compliance with this document, as

well as with the applicable standards

of the National Fire Protection Asso-

ciation (e.g., NFPA 25), in addition to

the standards of any other authorities

having jurisdiction. Contact the install-

ing contractor or product manufacturer

with any questions.

Automatic sprinkler systems should be

inspected, tested, and maintained by a

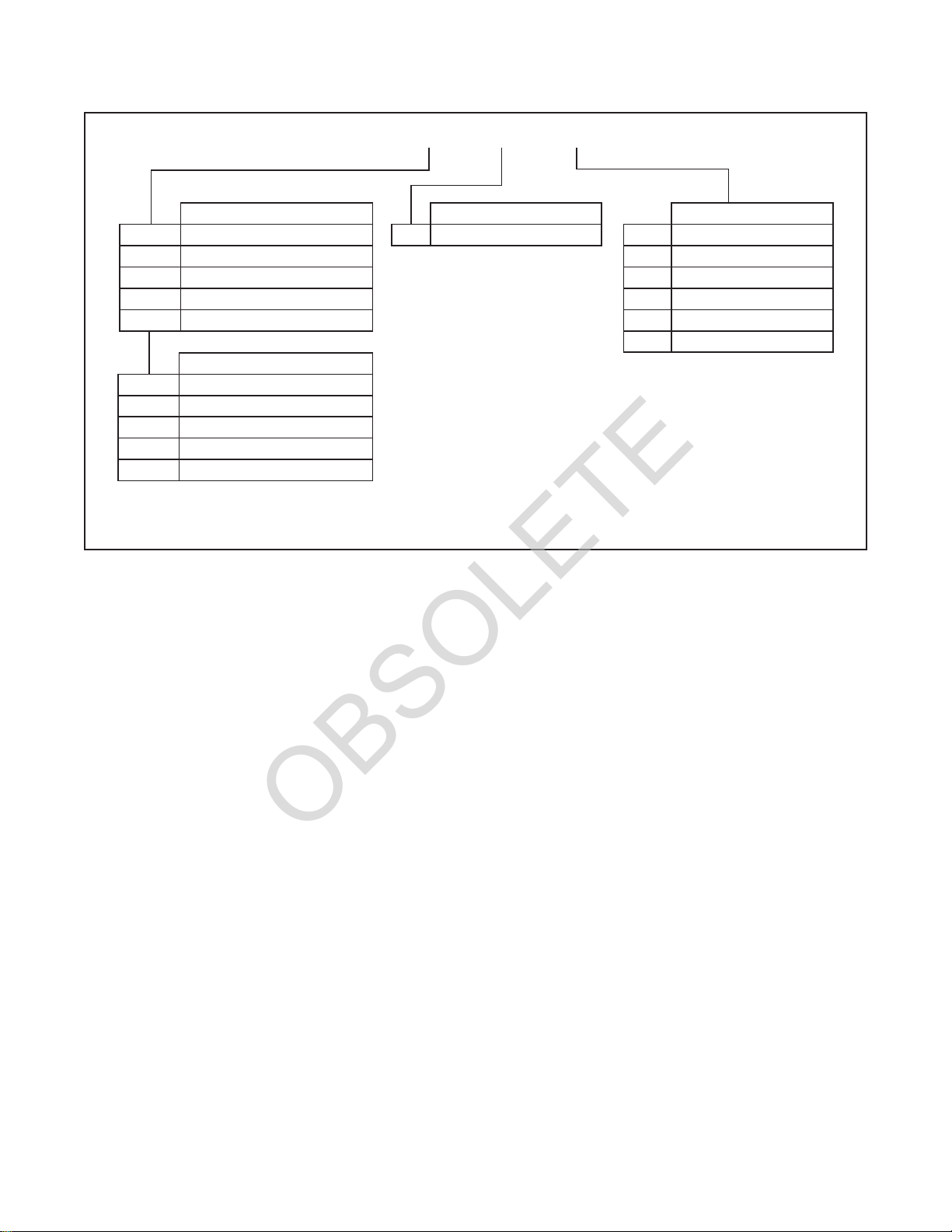

P/N 57 — XXX — X — XXX

SR – Standard Response

570 TY-B 5.6K Upright SR

590 TY-B 8.0K Upright SR

571 TY-B 5.6K Pendent SR

591 TY-B 8.0K Pendent SR

578 TY-B 5.6K HSW SR

QR – Quick Response

370 TY-FRB 5.6K Upright QR

390 TY-FRB 8.0K Upright QR

371 TY-FRB 5.6K Pendent QR

391 TY-FRB 8.0K Pendent QR

378 TY-FRB 5.6K HSW QR

Sprinkler Finish

2Grey Aluminium (RAL9007)

Temperature Rating

135 135°F (57°C)

155 155°F (68°C)

175 175°F (79°C)

200 200°F (93°C)

286 286°F (141°C)

360 360°F (182°C)*

* TY-B - Only

TABLE D

POLY-STAINLESS SERIES TY-B AND TY-FRB

UPRIGHT, PENDENT AND HORIZONTAL SIDEWALL SPRINKLERS

PART NUMBER SELECTION