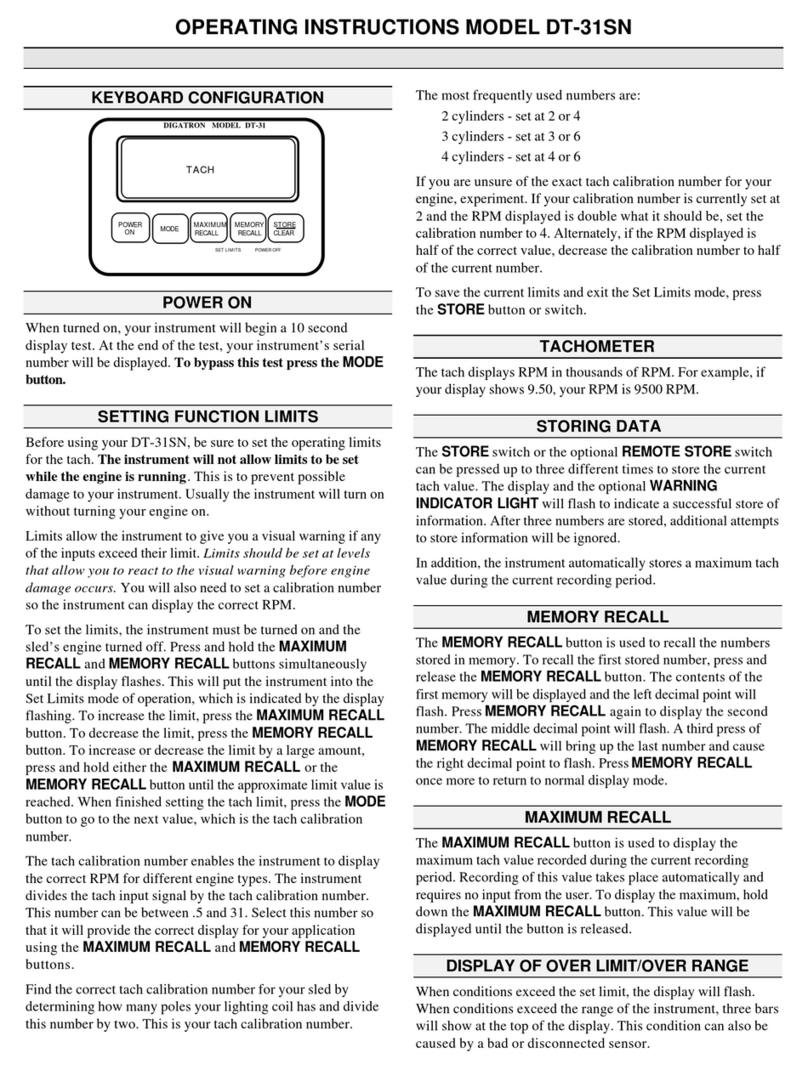

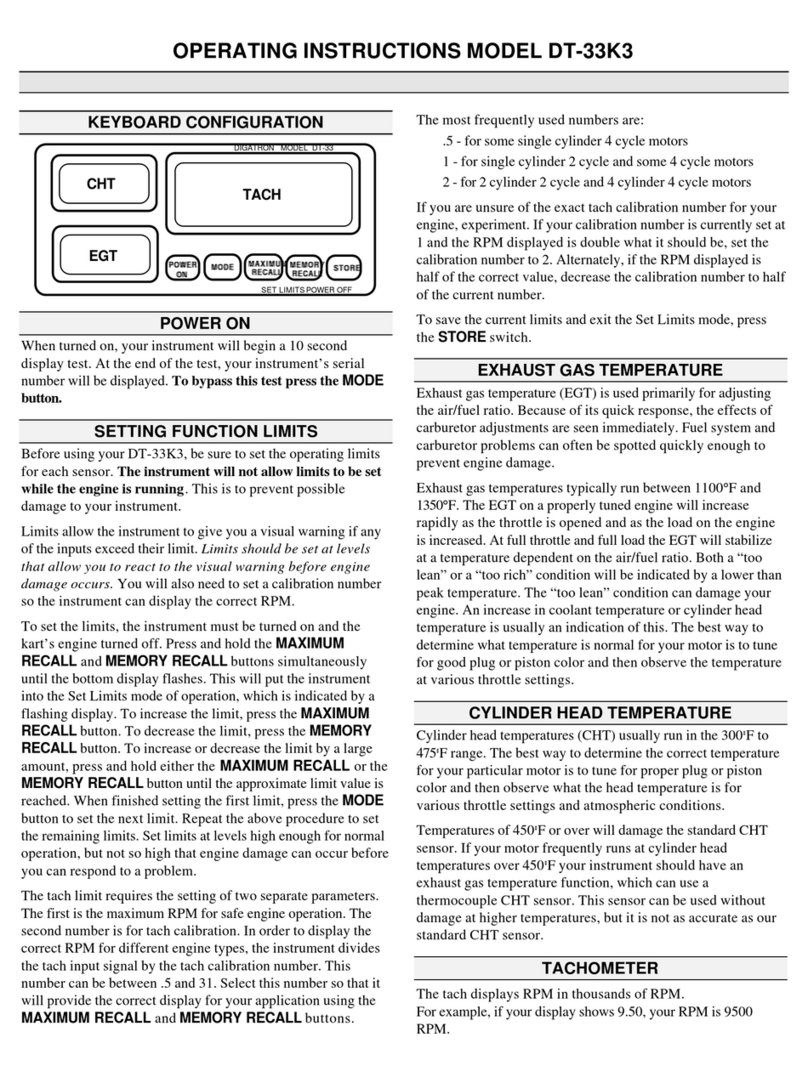

If you are unsure of the Tach calibration number for your engine, experiment. If your calibration

number is currently set at 1 and the RPM displayed is double what it should be, set the calibration

number to 2. Alternately, if the RPM displayed is half of the correct value, decrease the

calibration number to half the current number.

B. Monitor Mode is Used While on the Track

When your instrument is powered on, it is in Monitor mode. This is the mode the unit will be in

so you can observe your engine functions. During Monitor mode you can make quick tuning

adjustments to your powertrain that allow you to run safe and fast. The instrument will visually

warn you, by flashing the display, if your engine exceeds it’s set limit. This limit allows you to

avoid engine damage.

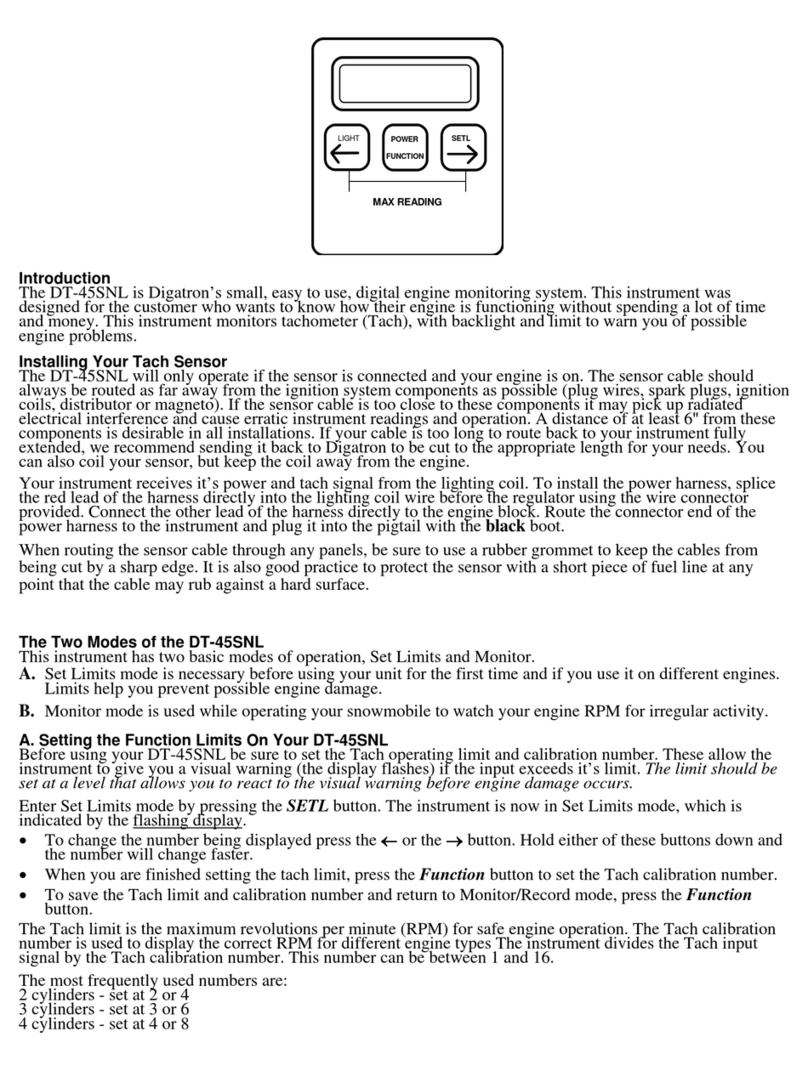

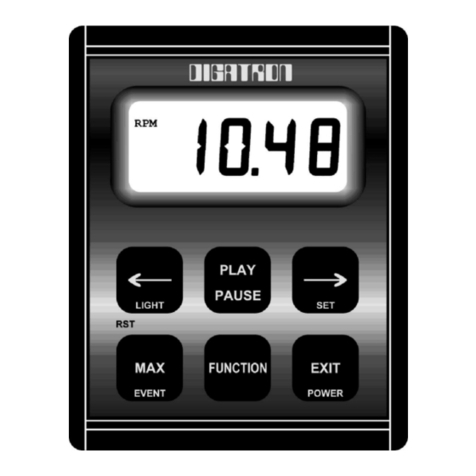

•To view your maximum readings since the engine was turned on, press the ←and the →

buttons at the same time.

•The backlight is used to illuminate your display for use at night. Press the LIGHT button to

toggle the backlight on or off. The backlight can only be turned on or off while in Monitor

mode.

The DT-46KL Uses One AAA Batteries (not included)

The DT-46KL can run, without a backlight, for 200 hours on one AAA battery. When using the

backlight, one battery will power the instrument for 50 hours.

With the front of the instrument facing you, remove the left end cap. Remove the battery from the

holder. Observe polarity when replacing the battery. Replace the end cap.

Installing Your Sensors

Do not operate your DT-46KL unless both sensors are connected. Inputs that are left open can

cause erratic readings and possible instrument damage. If you do not want to use the

instrument’s CHT function, the pigtail on the back of the instrument must be terminated with a

shorting plug available from Digatron. The Tach function must be used to operate the instrument.

Sensor cables that run from the engine compartment to the instrument should always be routed as

far away from the ignition system components as possible (plug wires, spark plugs, ignition coils,

distributor or magneto). Sensor cables too close to these components may pick up radiated

electrical interference and cause erratic instrument readings and operation. A distance of at least

6"from these components is desirable in all installations.

When routing sensor cables through any panels, be sure to use a rubber grommet to keep the

cables from being cut by a sharp edge. It is also good practice to protect all of the sensors with a

short piece of fuel line at any point that the cable may rub against a hard surface.

If either of your cables are too long to route back to your instrument fully extended, we

recommend sending your sensors back to Digatron to be cut to the appropriate length for your

needs or coiling them each separately. If you do coil your sensors, keep the coils away from the

engine.

Tach Sensor Installation

Our standard Tach sensor can be installed on both two and four cycle engines. Use a cable tie on

the shrink tube, at the end of the green wire, to attach the sensor to the plug wire, keeping the end

at least 2"from the plug boot. Keep the sensor electronics (red) away from any ignition

component. If you experience erratically low Tach readings, attach the green wire, inch by inch,

to the plug wire until you have correct readings. Attach the end of the black ground wire to the

bare metal on the engine block. Route the sensor cable from the motor to the rear of your

instrument and secure with cable ties. Plug into the pigtail with the “push-on” type connector.

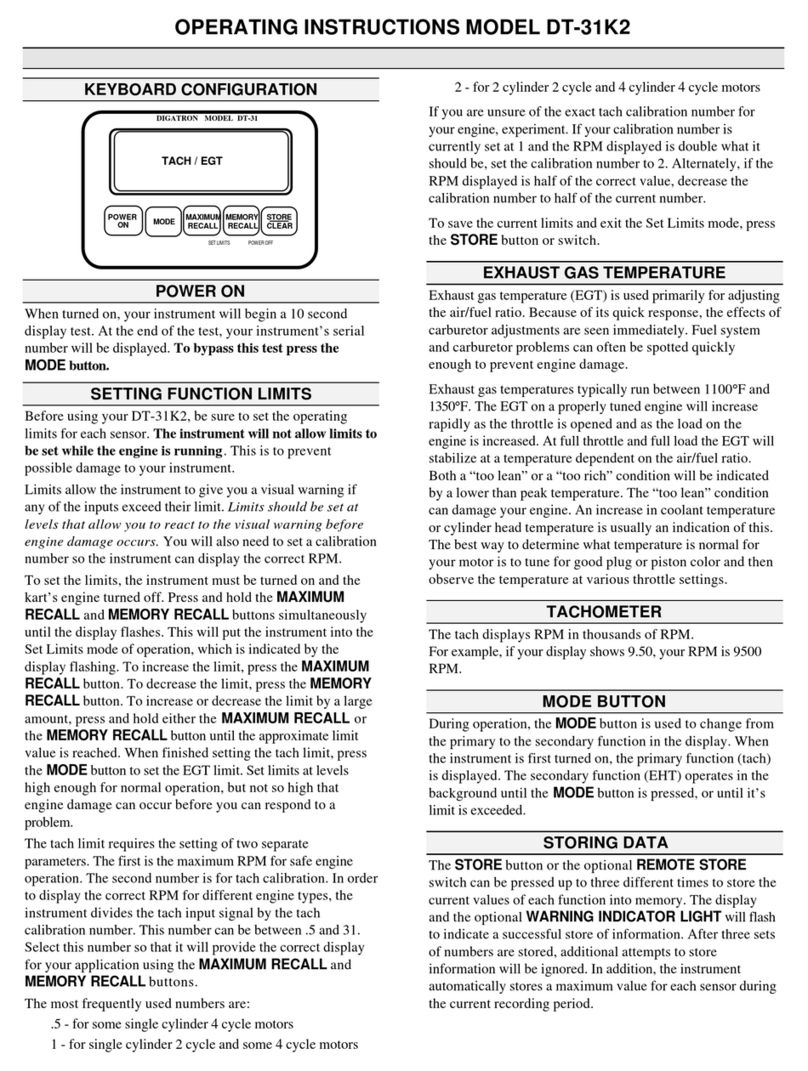

How the Tachometer Reading is Displayed

The Tach displays RPM in thousands of RPM. For example, if your display shows 9.50, your

RPM is 9500.