Rhein-Nadel Automation GmbH 2

VT-BA-SCU2000_EN_2023.docx

Table of Contents

1. About this document ..............................................................................................................4

1.1. Document description:......................................................................................................4

2. Safety information..................................................................................................................4

2.1. Design of safety directives ...............................................................................................4

2.2. Fundamental safety directives..........................................................................................4

2.3. Personnel.........................................................................................................................4

2.4. Intended use ....................................................................................................................5

2.5. Residual hazards .............................................................................................................5

2.5.1. Device ........................................................................................................................5

2.5.2. Protection of the drive system....................................................................................5

2.5.3. Degree of protection - Protection of persons and equipment .....................................6

3. Product information................................................................................................................6

3.1. Functional description ......................................................................................................6

3.2. Difference between SCU1000 and SCU2000 ..................................................................6

3.3. Technical data..................................................................................................................7

3.4. Products, spare parts and accessories ............................................................................8

4. Notes on start-up....................................................................................................................8

4.1. Modes of operation...........................................................................................................8

4.2. Automatic mode change...................................................................................................9

4.3. Start/Stop by external controller.......................................................................................9

4.4. Status signals to an external controller...........................................................................11

4.5. Changing the supply voltage..........................................................................................12

4.6. Measuring the output voltage or output current..............................................................13

5. Connections on the controller...............................................................................................13

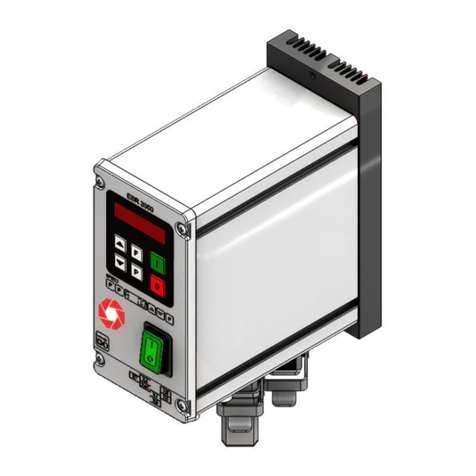

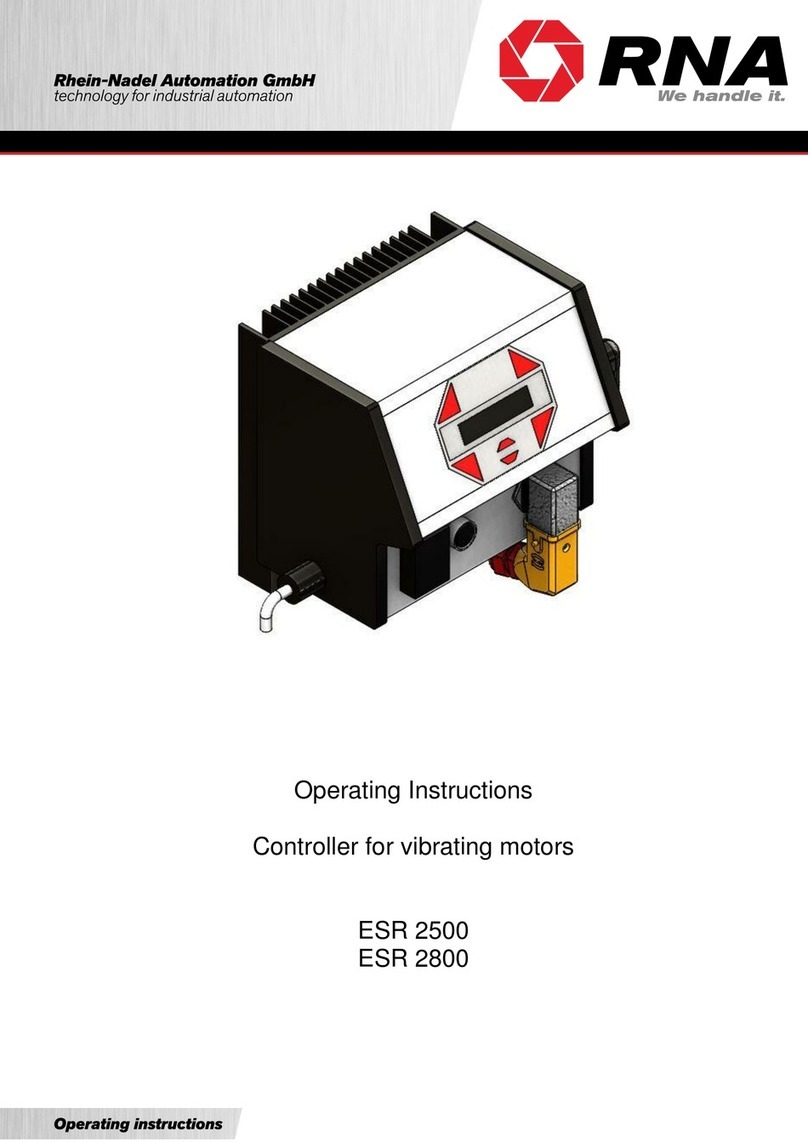

5.1. SCU2000........................................................................................................................13

6. SCU2000 connection diagram .............................................................................................14

7. Operation of SCU2000.........................................................................................................15

7.1. SCU2000 menu structure...............................................................................................16

7.2. Description of SCU2000 parameters..............................................................................17

8. Dimensional drawing of SCU2000 .......................................................................................18