3

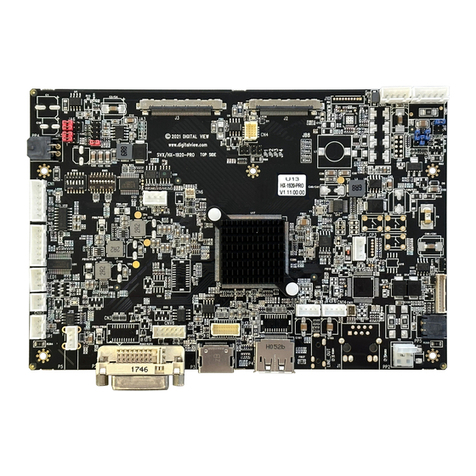

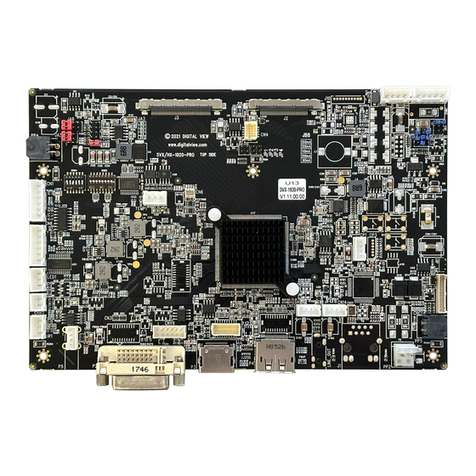

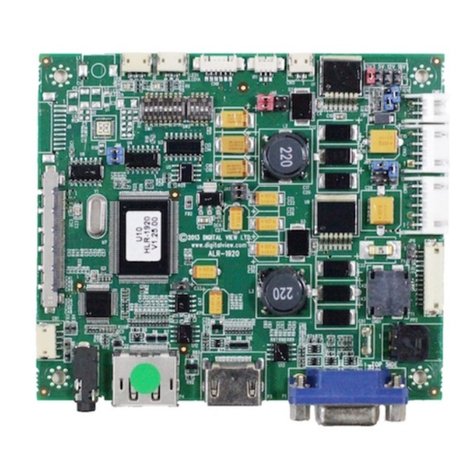

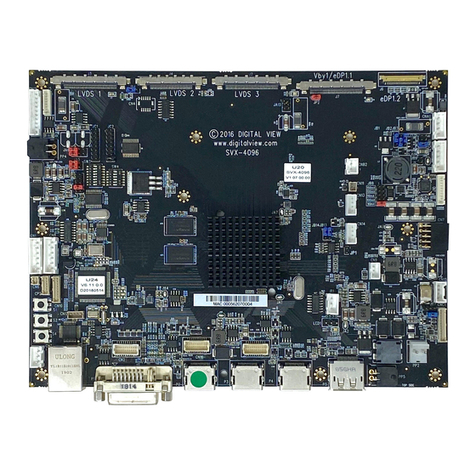

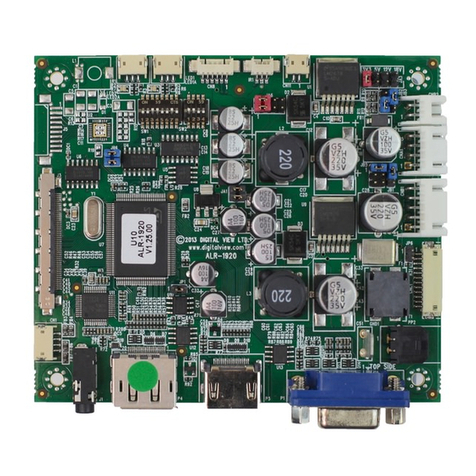

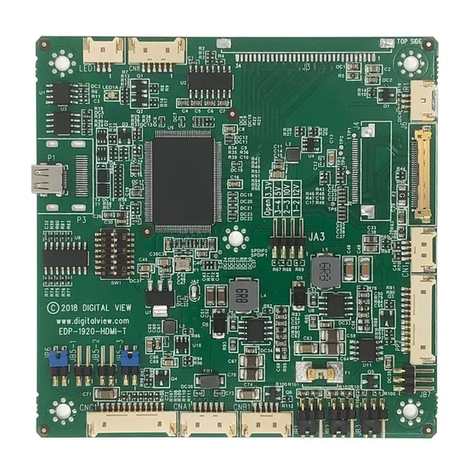

ASSEMBLY NOTES

This controller is designed for monitor and custom display projects using 1366 x 768, 1280 x 1024 or 1280 x 768 or 1024 x 768

or 800x600 or 640x480 resolution TFT panels with a VGA, SVGA, XGA, SXGA signal input. The following provides some

guidelines for installation and preparation of a finished display solution.

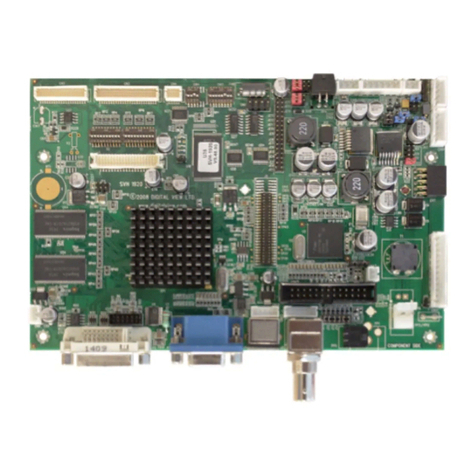

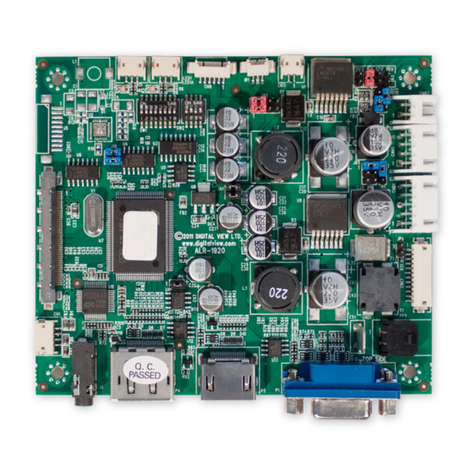

Preparation: Before proceeding it is important to familiarize yourself with the parts making up the system and the various

connectors, mounting holes and general layout of the controller. As much as possible connectors have been labeled. Guides

to connectors and mounting holes are shown in the following relevant sections.

1. LCD Panel: This controller is designed for typical LVDS or TTL interface TFT panels with panel voltage 3.3V or 5V or 12V

LVDS interface. Due to the variation between manufacturers of signal timing and other panel characteristics factory setup

and confirmation should be obtained before connecting to a panel. (NOTE: Check panel power jumper settings before

connection)

2. Controller card: Handle the controller card with care as static charge may damage electronic components.

3. LVDS signal cable : In order to provide a clean signal it is recommended that LVDS signal cables are no longer than

46cm (18 inches). If loose wire cabling is utilized these can be made into a harness with cable ties. Care should be taken

when placing the cables to avoid signal interference. Additionally it may be necessary in some systems to add ferrite cores

to the cables to minimize signal noise.

4. TTL signal cable: In order to provide a clean signal it is recommended that LCD signal cables are no longer than 33cm

(13 inches). If loose wire cabling is utilized these can be made into a harness with cable ties. Care should be taken when

placing the cables to avoid signal interference. Additionally it may be necessary in some systems to add ferrite cores to the

cables to minimize signal noise.

5. Inverter: This will be required for the backlight of an LCD, some LCD panels have an inverter built in. As panels may have

1 or more backlight tubes and the power requirements for different panel models backlights may vary it is important to

match the inverter in order to obtain optimum performance. See page 15 for the Application notes “Inverter connection

section for more informations.

6. Inverter Cables: Different inverter models require different cables and different pin assignment. Make sure correct cable

pin out to match the inverter. Using wrong cable pin out may damage the inverter.

7. Function Controls: The following section discusses the controls required and the section on connectors provides the

detail. The controls are minimal: On/Off, Backlight Brightness (depends on inverter), OSD (5 momentary buttons) analog

VR type or (8 momentary buttons) digital type.

8. Function controls cable: The cables to the function switches should be of suitable quality and length so that impedance

does not affect performance. Generally lengths up to 1 metre (3 feet) should be acceptable.

9. DVI-D Input Cable : Plug the DVI cable to the connector P2 on the controller board

10. Analog VGA Input Cable: As this may affect regulatory emission test results and the quality of the signal to the controller,

a suitably shielded cable should be utilized.

•Power Input: 12V DC is required, this should be a regulated supply. Although the controller provides power regulation for

the LCD power this does not relate to the power supplied to the backlight inverter. If an unregulated power supply is

provided to an inverter any fluctuations in power may affect operation, performance and lifetime of the inverter and or

backlight tubes.

•Power Safety: Note that although only 12VDC is supplied as ‘power-in’ a backlight inverter for panel backlighting

produces significantly higher voltages (the inverter does not connect to the ground plane). We strongly advise appropriate

insulation for all circuitry.

•EMI: Shielding will be required for passing certain regulatory emissions tests. Also the choice of external Controller to PC

signal cable can affect the result.

•Ground: The various PCB mounting holes are connected to the ground plane.

•Servicing: The board is not user serviceable or repairable. Warranty does not cover user error in connecting up to the

controller and is invalidated by unauthorized modification or repairs.

•Controller Mounting: It is recommended that a clearance of at least 10mm is provided above and 5mm below the

controller when mounted. Additionally consideration should be given to:

•Electrical insulation.

•Grounding.

•EMI shielding.

•Cable management. Note: It is important to keep panel signal cables apart from the inverter & backlight cables to

prevent signal interference.

•Heat & Ventilation: Heat generated from other sources, for example the backlight of a very high brightness panel may

generate significant heat which could adversely affect the controller.

•Other issues that may affect safety or performance.