©2009 Digitrax, Inc www.digitrax.com 3

inserted through the slots of the motor tabs. Squeeze the frame halves

together to hold the decoder in place.

4. Tighten the frame screws. Replace the trucks if they have fallen out during

the installation of the decoder. Place the locomotive on the track, select

address 03 on your throttle and apply power. If the motor does not respond

but you can control the lights, check the installation for motor short circuits.

5. Replace the locomotive shell. Digitrax decoders are set up with configura-

tion variable (CV) default values so you can run your locomotive right

away using address 03. See the Digitrax Decoder Manual for complete

instructions on setting up the CVs for customizing your locomotive’s per-

formance characteristics.

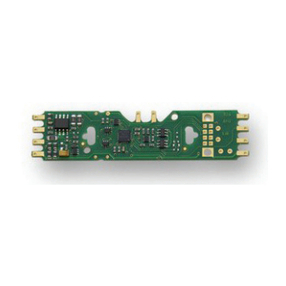

Note: Motor contacts may optionally be bent to engage provided slots on

the decoders (See figure 6) Be sure to check clearance to frame after instal-

lation.

Installation Notes:

1. Do not exceed the decoder’s 500mA total function output rating.

2. To use a function output with an inductive (coil) type load, see the Digitrax

Decoder Manual for more information to avoid damage to the decoder.

3. See the Digitrax Decoder Manual for full details of wiring 12-16V lamps,

1.5V lamps, and LEDs. Lamps that draw more than 80 mA when running

require a 22 ohm 1/4 watt resistor in series with the directional light func-

tion lead to protect the decoder.

C

Cu

us

st

to

om

mi

iz

zi

in

ng

gY

Yo

ou

ur

rD

De

ec

co

od

de

er

r

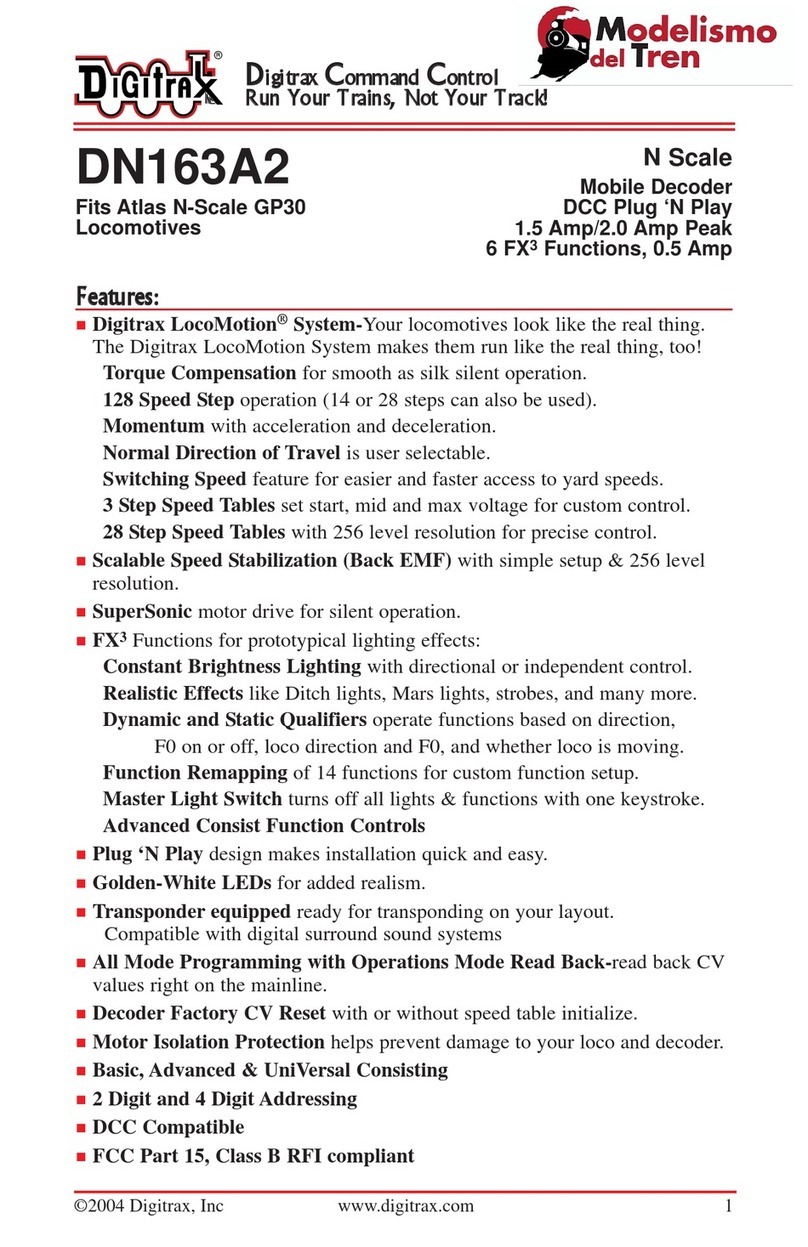

Your Digitrax decoder is ready to run and will operate using address 03 with no

additional programming. For a more prototypical railroading experience, your

decoder can be customized for your specific locomotive by programming some

of the Configuration Variables, or CVs, available. See the Digitrax Decoder

Manual or the Digitrax web site for more information.

C

Ch

ha

an

ng

gi

in

ng

gt

th

he

eD

De

ec

co

od

de

er

rA

Ad

dd

dr

re

es

ss

s

The first CV most people change is the decoder address so that the loco can be

independently controlled with it’s own unique address. All Digitrax decoders

are shipped with CV01 (AD2), the two digit address, set to 03. See your Starter

Set Manual for complete programming instructions. Following is a brief

description of how to change the decoder address with a DT series throttles.

1. Place the loco on the programming track. Go into Program Mode on your

system. On DT400 press PROG. On DT300, DT100 & DT200 press

RUN/STOP & FN/F0.

2. Choose AD2 for 2 digit addressing or AD4 for 4 digit addressing (DT300 &

DT400). (Ad for DT100 & DT200, see set manual for 4 digit instructions).

2

24

44

43

3T

Tr

ra

an

ns

sm

mi

it

tt

te

er

rR

Rd

dT

T8

85

50

0-

-8

87

72

2-

-9

98

89

90

0

P

Pa

an

na

am

ma

aC

Ci

it

ty

y,

,F

FL

LU

US

SA

A3

32

24

40

04

4F

F8

85

50

0-

-8

87

72

2-

-9

95

55

57

7

w

ww

ww

w.

.d

di

ig

gi

it

tr

ra

ax

x.

.c

co

om

mE

Es

sa

al

le

es

s@

@d

di

ig

gi

it

tr

ra

ax

x.

.c

co

om

m