Digiway SL500 User manual

1

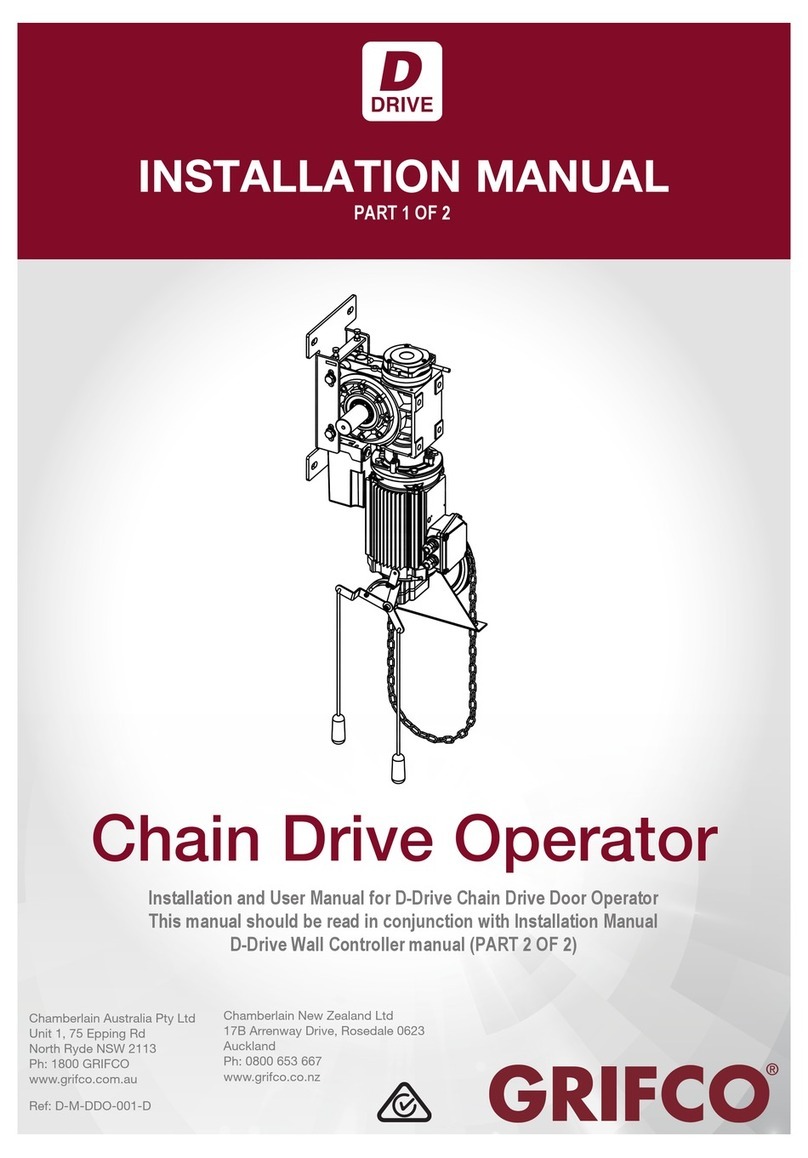

SL500 Sliding Gate Motor Rack Drive

SL500 Sliding Gate Motor Chain Drive

Version –V2.0

INSTRUCTION MANUAL

2

ATTENTION To prevent electrical shock, disconnect from power source before installing or service

ATTENTION Electricity and power motors associated accessories could be fatal or at least cause seriously

injury. All main voltage wiring must be installed by a licensed electrician.

ATTENTION Additional safety device MUST be fitted such as Photo Electric Beam, Loop Detectors.

ATTENTION Before do the manual release, the mains power switch must be off even there is no power.

ATTENTION Before power on, the manual release MUST engaged

ATTENTION Gate opened stopper and closed gate stopper MUST be installed.

Contains

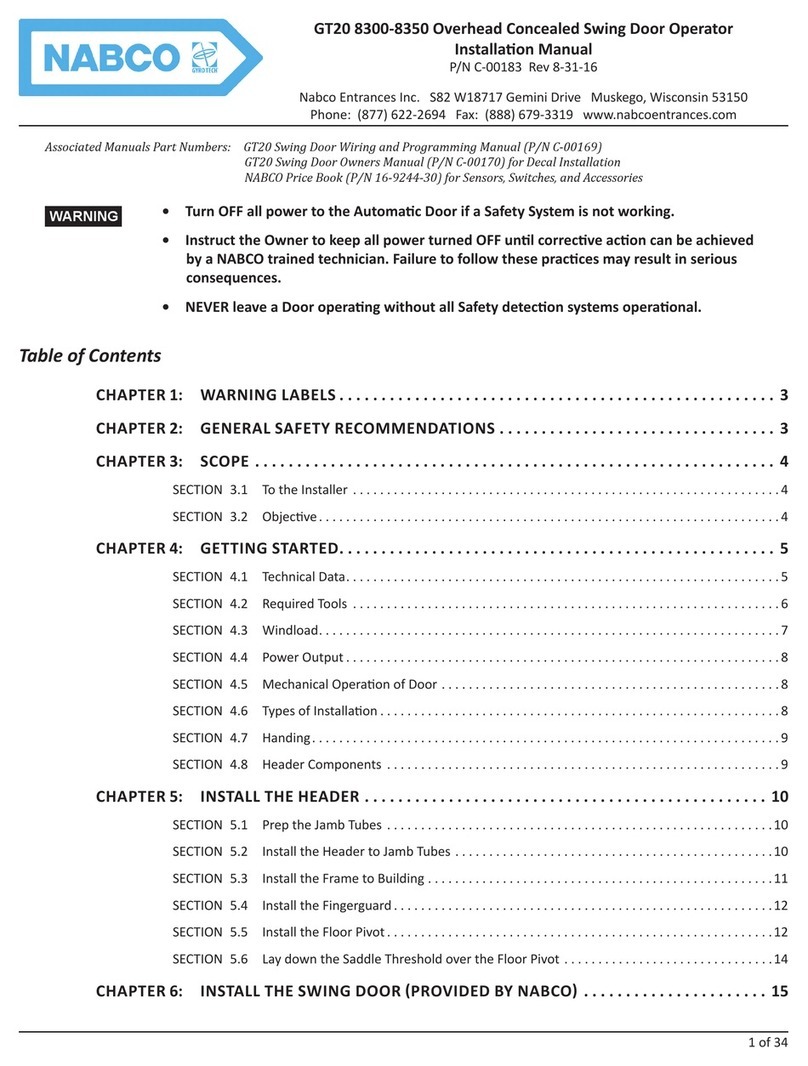

1. General layout --------------------------------------------------------------------------------------------------3

2. Specifications ---------------------------------------------------------------------------------------------------4

3. Control Board layout -------------------------------------------------------------------------------------------4

4. Control Board input---------------------------------------------------------------------------------------------5

5. DIP switch function --------------------------------------------------------------------------------------------5

6. Motor Set up ----------------------------------------------------------------------------------------------------5

7. Chain drive ------------------------------------------------------------------------------------------------------6

8. Power Supply and drive type --------------------------------------------------------------------------------- 6

9. Manual release---------------------------------------------------------------------------------------------------7

10. Trouble shooting guide----------------------------------------------------------------------------------------8

11. Condition of sales----------------------------------------------------------------------------------------------9

3

1) Motor Cabinet

2) Limit Switch

3) Steel base

4) Chain drive guide roller

5) 12V motor

6) Manual release

Limit Rack Drive Limit Chain Drive

Encoder Rack Drive Encoder Chain drive

GENERA LAYOUT

4

1. General Descriptions

The SL500 sliding gate motors was designed for domestic sliding gate or swing gate, rack drive or chain

drive, limit switch or encoder control. The controller can receive the signals from swipe card, loop

detectors, remote control, photo-electric beams and any kind of access control system. Metal zinc plated

base.

2. Technical Specifications

Power supply

230/240V AC, low voltage, solar panel

Output voltage

12V

Motor rate

12V DC 100W geared motor

Gate type

track, cantilever gate, rack or chain drive

Drive speed

Up to 200mm/sec

Max. Gate length

10M

Fully programmable

Auto close time

Access control

Remote, Keypad, Switch, Push Button etc.

3. Control Board layout

CONTROL INPUIT AND BUTTON

Control input LEDs

Encoder plug

Control

terminals

block

12V or 24V charger select

Terminals block

OSC Button

Motor obstruction force

PE Bypass

Receiver

board

Learn Button

DIP switch

Input select

5

4. Control Board Input

OSC input

The OSC inputs terminal input can be from switch, push button or relay (from any other brand

standalone receiver) N/O. It became active when short to COM. This terminal can be set to OSC or

OPN function by jumper on board. If keep active, gate will stay open.

PEB input

If the P.E input activated while gate is closing, the gate will stop or reopen. If the gate in the opened

position and P.E beam activated, the gate will stay in opened.

CLS limit input

If gate is closing cycle, when CLS limit is active, gate will stop and controller will display closed. If

controller working encode model, this terminal no function

OPEN limit input

If gate is opening cycle, when OPN limit is active, gate will stop and controller will display opened.

If controller working encode model, this terminal no function

OSC button

The OSC button operate gate (Push Open, push again Stop, push again Close) and set auto close time.

Encoder inputs

Encoder is mounted on the motor shaft inside of motor. it is not serviceable by customer. There are two

four pings socket on control board, one for right hand gate and other one for left hand gate.

5. DIP SWICTH FUNCTION

DIP1 –SET/RUN ON=SET, OFF=RUN

DIP2 –ENCODER/LIMIT ON=ENCODER OFF=LIMIT

DIP3 –POWER SELECT ON= 80% OFF= 100%

DIP4 -- AUTO CLS ON=AUTO CLS OFF=NO AUTO CLS

6. Motor Set up

6.1 Encoder control --- DIP2=ON

Motor installation as other motor and do not mention here.

Default setting is gate closing to left. If gate close to right, you need swap two motor wires and move

the encoder plug to J1. Make sure gate has opened and closed stopper installed, then power up, push

OSC button or remote, after two completely operation cycle, controller will be automatically

programmed. Do not need do anything.

6.2 Limit control --- DIP2=OFF

Default setting is gate close to left. If gate close to right, you need swap two motor wires and swap

close and open limit switch input. Push OSC button or remote, after two completely operation cycle,

controller will be automatically programmed. Do not need do anything.

6.3 Timers setting

Auto close time set

Set DISP1 On, push and hold on OSC, the time you push and hold OSC button is the time of

gate auto close time. when reached the required time simply release OSC button. Set DIP1

CONTROL INPUIT AND BUTTON

6

OFF. The gate controller will back to working mode. Factory default auto close time is 30

seconds

To restore factory setting, turn power off and set DIP1 on, push and hold CLS button then power

on. While hold CLS button, set DIP1 off, release the CLS button. Now controller restored factory

setting from memory.

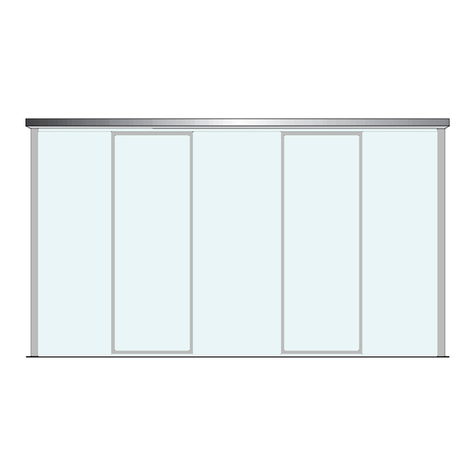

7. Chain dirve Systme Setup

This is the drawing for chain drive setup. Not need to mention the details and all those are quite simple

mechncial work.

8. Power Supply and drive type

This motor has three different power can be choose. 240V, Low voalteg and Solar.

If has 240V power near at the gate, then use 240V version SL500 eithe encoder or limit control.

If no 240V power at gate, but has 240V power in the gararge or house, then choose SL500LV low

volatge model. Run12V low volatge to the gate. Suggest use 2.5mm garden light cables either direclty

bury in the ground or in conduit.

If no 240V power at ht egate and nearby, then use solar. 20W or 40W 12V solar panel and 12V7Ah

battery is good enough for normal use. If gate is more feqencly used and the sun light is not very good,

then properly inceasing solar panel power and battery size.

7

9. Manual release

A: What to do during a power failure (battery run out) or faulty:

If got battery back, then take the red cap off or take whole cover off, using the 8mm Allen key, insert to

the release bolts holes or use hand, clockwise turn the bolts several turns, then can manually push gate

open.

Re-engage the motor, turn the manually release bolts several turns, manually move gate, gate will

engage.

Reset power (initialization), remove the 6 pins plug (AC power, battery and motor), wait about 20

seconds, then plug it back. Use remote or push button operate the gate, controller will automatic

reprogrammed.

8

10. Trouble Shooting Guide

10.1 Display information on main control board.

Between Pot and OSC button on the control board, there are two LEDs --- GREEN and RED. Different

combination and show different gate situations.

(1) Gate status LED

Gate Status (Position) \ LEDs

Status LED-Green

Status LED-Red

Gate in closed position

Slow Flash

on

Gate is opening

Fast flash

off

Gate in opened position

on

Slow flash

Gate is closing

off

Fast flash

Gate stop in the middle

Alternatively, flash

Alternatively, flash

Gate stop in the middle: which means the gate stop by OSC input and at this position the auto close

does not apply.

(2) Input LEDs

Inputs LEDs\ Input status

Input Active

Input inactive

OSC LED--- OSC input

on

off

PEB LED --- Photo Electric Beam-

on

off

Open Limit LED

off

on

Close Limit LED

off

on

10.2 Trouble Shooting Guide

Malfunction

Possible causes

What to do

Gate not open

1) No power

2) Already in opened

position

1) Check the power

2) Reset the power, remove 6 pins plug and

wait 20 seconds, and plug it back

Gate not close

1) Safety input PEB active,

PEB LED is on

2) OSC input active, OSC

LED is on

1) Check the safety device, N/C contact

required.

2) Check control switch button in case it is

on

Gate run little bit

then stop and both

Status LEDs flash

1) No encoder input

2) mechanical jammed

1) encoder plug wrong or faulty

2) power off and disengage the motor and

push and pull the gate manually

Gate opened or

closed position not

right

1) encoder or limit wrong

2) Rack jumps over drive

pinion

1) Reset the power, remove 6 pins plug and

wait 20 seconds, and plug it back

TROUBLE SHOOTING GUIDE

9

1. Orders

The placement of any orders upon Digiway implies acceptance of these terms and

conditions and takes precedence over any other terms and conditions written or oral.

2. Deliveries

(a) Time of delivery will be complied with wherever possible. It is not guaranteed and

is subject to extensions to cover delays caused by strikes, vehicle breakdown, traffic

delays, weather and any causes beyond Digiway’s control.

(b) The Purchaser shall not be entitled to be compensated for any loss or damage due

to any of the causes stated.

(c) Most of the motors are stock items, but temporarily runs out of stock. Restock

time can experience of approximately 8-12 weeks from receipt of official written

order.

3. Warranty

(a) Digiway has 12 months return base warrants from date of purchase in normal use

condition.

(b) Digiway control boards can be up to two years warranty. subject the application

conditions.

(c) In lieu of all other warranties expressed or implied. Digiway shall not be liable for

any special indirect, incidental or consequent damages of any kind or nature.

Equipment manufactured and installed by it to be free from defects in material and

workmanship for. Digiway will repair or replace at its option any product or part

which it determines to contain defective material and workmanship. Defective parts

must be returned to Digiway for repair or replacement. Costs associated with the

return of the goods will be the responsibility of the sender. On site repairs will incur

travel and labor charges. Liability for replacement parts or repairs carried out by

Digiway does not extend the original twelve-month warranty period.

4. Payment

(a) Unless agreed expressly in writing, otherwise the terms of payment shall be made

prior to shipment or where agreed on completion of the installation. Methods of

payment are by:

(i) Direct bank transfer with remittance advice supplied from purchaser.

(ii) Cheque’s need to be received and cleared before shipment.

5. Returns

Returns only accepted within 14 days of invoice. Credits only paid after inspection of

goods. All returns subject to 30% re-stocking fee on product. Damaged goods are

subject to further charges to the value of the damage.

CONDITION OF SALE

This manual suits for next models

2

Table of contents

Other Digiway Door Opening System manuals

Popular Door Opening System manuals by other brands

B&S

B&S Smart Pro SDO-9V3 installation instructions

Record

Record 102-020.110.805 Maintenance and troubleshooting

SECO-LARM

SECO-LARM SD-969-A18Q installation manual

LCN

LCN 4840 installation instructions

Assa Abloy

Assa Abloy Corbin Russwin ED4000 Series installation instructions

Assa Abloy

Assa Abloy RD3 user manual

GEZE

GEZE Slimdrive SL NT Installation and service instructions

Manaras

Manaras Opera-MH Installation instructions manual

Assa Abloy

Assa Abloy Norton 9540 Series installation instructions

BFT

BFT ELI-250 Installation and user manual

Dormakaba

Dormakaba UNIVERSAL PT 60 Mounting instructions

AGS

AGS TST40 Assembly instructions