Your Dillenger bike is fully assembled in our factory and tested to our high standards.

To t into an appropriately sized shipping carton to comply with the various courier

networks, some basic parts of the bike are temporarily removed. This is so that the bike

can t into the shipping carton safely, and so that we can adequately package each part of

the bike so that it is delivered in perfect condition.

These simple instruction will show you how to perform the nal setup. Your bike may

arrive in a more assembled state than what is shown here. These are the steps required

for most customers (packaging and nal assembly can vary by country).

In summary, these are the main steps.

Step 1, Unpacking/Unboxing

Step 2, Identify the pieces that require nal assembly

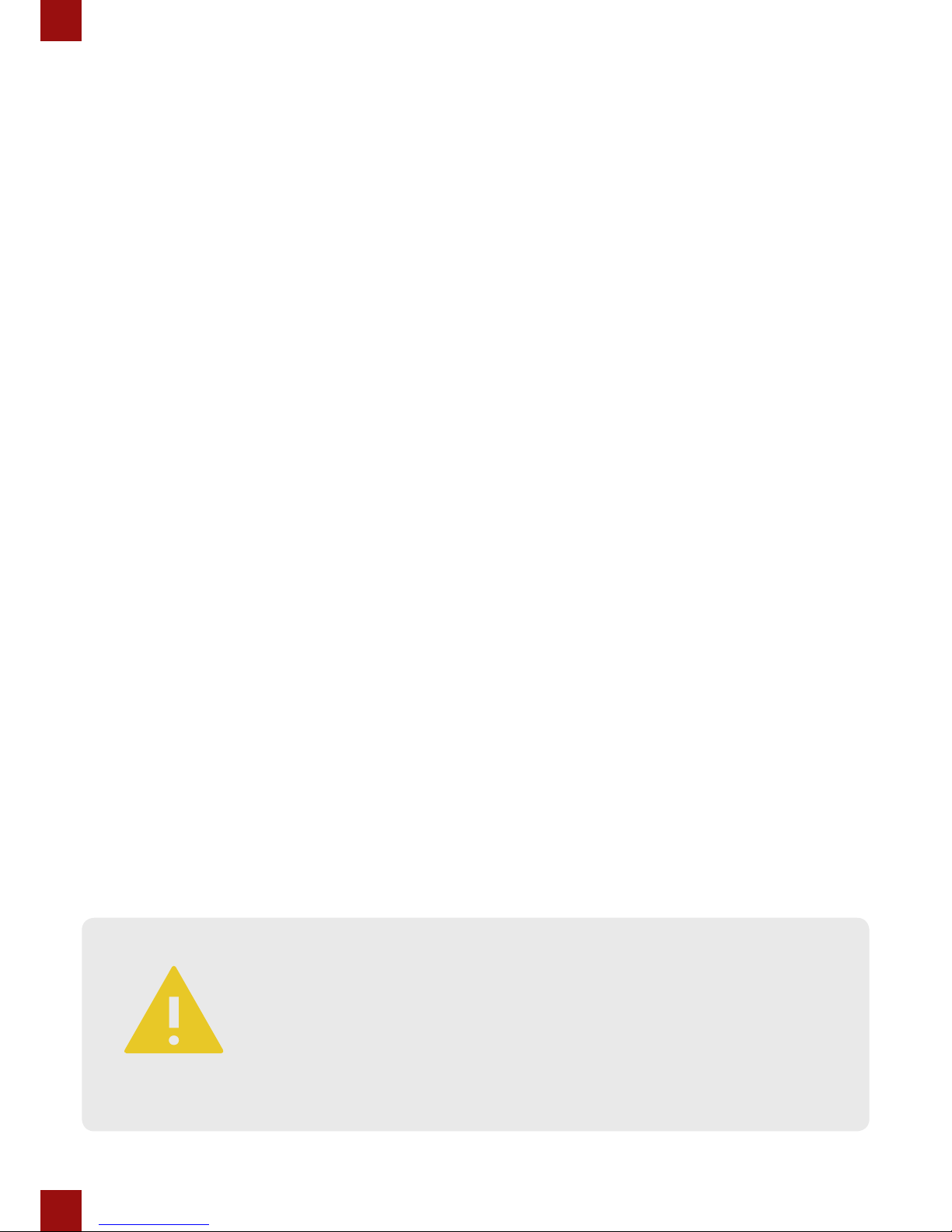

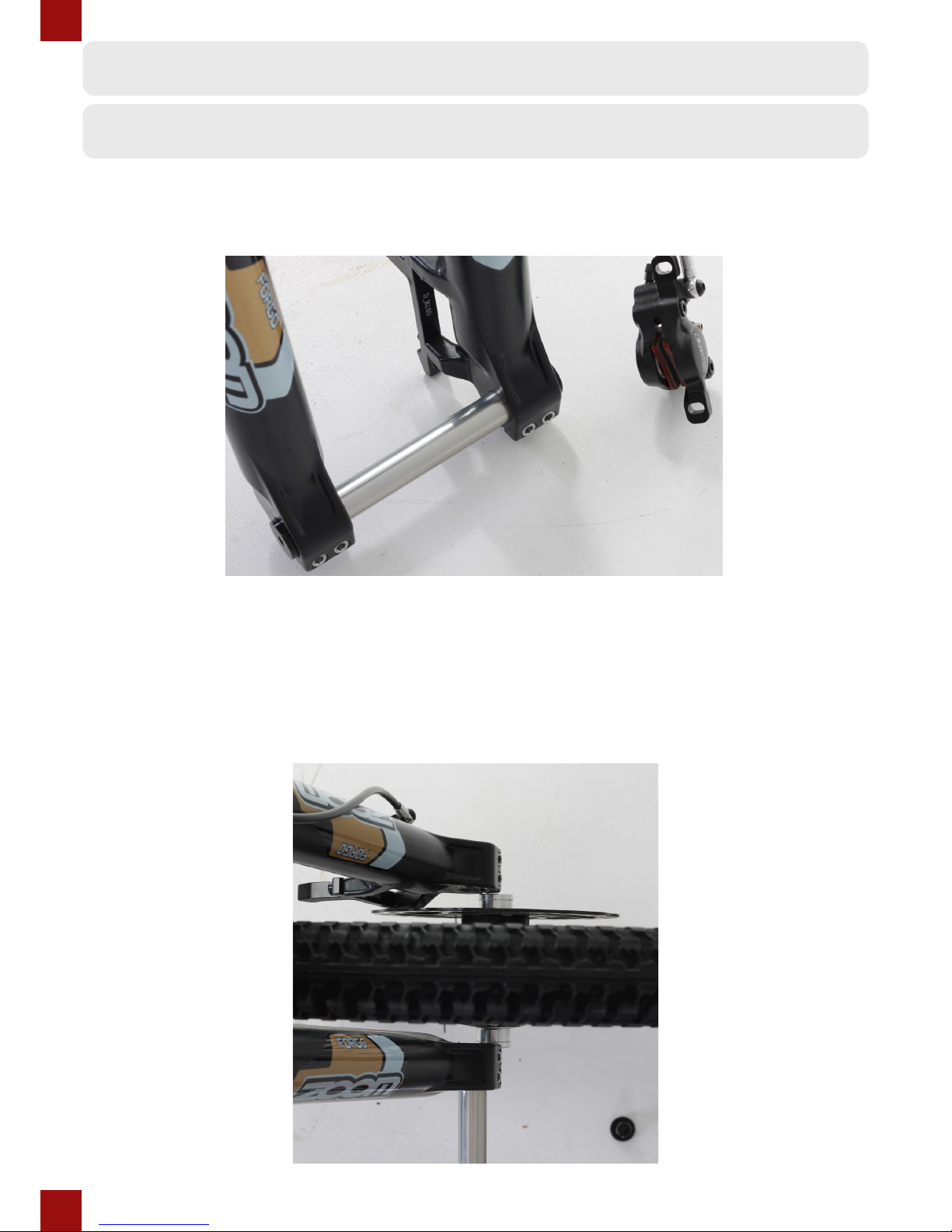

Step 3, Front wheel fastening

Step 4, Handlebar alignment

Step 5, Left and right side pedals

Step 6, Seat

Step 7, BBS Shield Installation

Tools required:

Allen keys (5 and 6mm)

These are provided and can be found in the charger box.

Other equipment not provided:

Bike pump (or service station car tyre pump)

3mm allen key, 11mm spanner (or shifter) for the BBS Shield