Dinel CLS-23 User manual

Read carefully the instructions published in this manual before the rst use of the sensor. Keep the manual

at a safe place. The manufacturer reserves the right to implement changes without prior notice

TEHNIČNI LIST IN NAVODILA

KAPACITIVNI MERILNIKI NIVJA - SERIJA: Cls – 23

www.materm.si tel: 02 608 90 10

CONTENT

1 . Safety .........................................................................................................................................4

2 . Packing, transportation and storage ..........................................................................................4

3 . Brief. ...........................................................................................................................................5

4 . Features of variants ...................................................................................................................5

5 . Dimensional drawings ................................................................................................................6

6 . Mounting recommendation .........................................................................................................7

7 . Electrical connection ..................................................................................................................9

8 . Sensor setting ............................................................................................................................11

9 . Status signalization ....................................................................................................................11

10 . Accessories ..............................................................................................................................12

11 . Order code ...............................................................................................................................13

12 . Correct specication examples ................................................................................................13

13 . Safety, protections, compatibility and explosion proof .............................................................14

14 . Use, manipulation and maintenance ........................................................................................14

15 . General conditions and warranty .............................................................................................14

16 . Marking of labels ......................................................................................................................15

17 . Specications ...........................................................................................................................16

CLS–23 © Dinel, s.r.o.

4

All operations described in this instruction manual have to be carried out by trained

personnel or by an accredited person only. Installation, commissioning, operation and

maintenance of the capacitive level sensors has to be carried out in accordance with this

instruction manual; the provisions of regulations in force regarding the installation of

electrical equipment have to be adhered to.

Improper use, installation or set-up of the sensor can lead to crashes in the application,

(overlling of the tank or damage of system components).

The manufacturer is not responsible for improper use, loss of work caused by either

direct or indirect damage, and for expenses incurred at the time of installation or during

the period of use of the level sensors.

1 . Safety

Used symbols

To ensure maximum safety of control processes, we have dened the following safety instructions

and information. Each instruction is labeled with the appropriate pictogram.

Alert, warning, danger

This symbol informs you about particularly important instructions for installation and op-

eration of equipment or dangerous situations that may occur during the installation and

operation. Not observing these instructions may cause disturbance, damage or destruction

of equipment or may cause injury.

Information

This symbol indicates particularly important characteristics of the device.

Note

This symbol indicates helpful additional information.

2 . Packing, transPortation and storage

Equipment CLS–23 is packed in a polythene bag and the whole consignment is placed in a card-

board box. The cardboard box is suitably lled to prevent mechanical damage during transport. Let

the device packed up till the use to prevent possible damage.

Transport to the customer is realized by forwarding company. Upon receipt, please check whether

the shipment is complete and corresponds to the extent of the order, or whether during the transport

did not occurred the damage of the packaging or the equipment. The device apparently damaged

during transport do not use and contact the manufacturer to resolve the situation.

If the device is transported further, then only wrapped in the original packaging and protected

against shocks and weather. Store the device in its original packaging in a dry place, sheltered from

the weather, with humidity up to 85% without the effects of chemically active substances. Storage

temperature range is from -10 °C to +50 °C.

Sensor variants CLS–23_–20 a 21 with the electrodes longer than 100 mm are tted with

protective caps at the ends of the electrodes to prevent damage of the electrodes, box

rupture or injury of handling persons. Before commissioning, remove the caps.

5

© Dinel, s.r.o. CLS–23

4 . FeatUres oF variants

3 . brieF

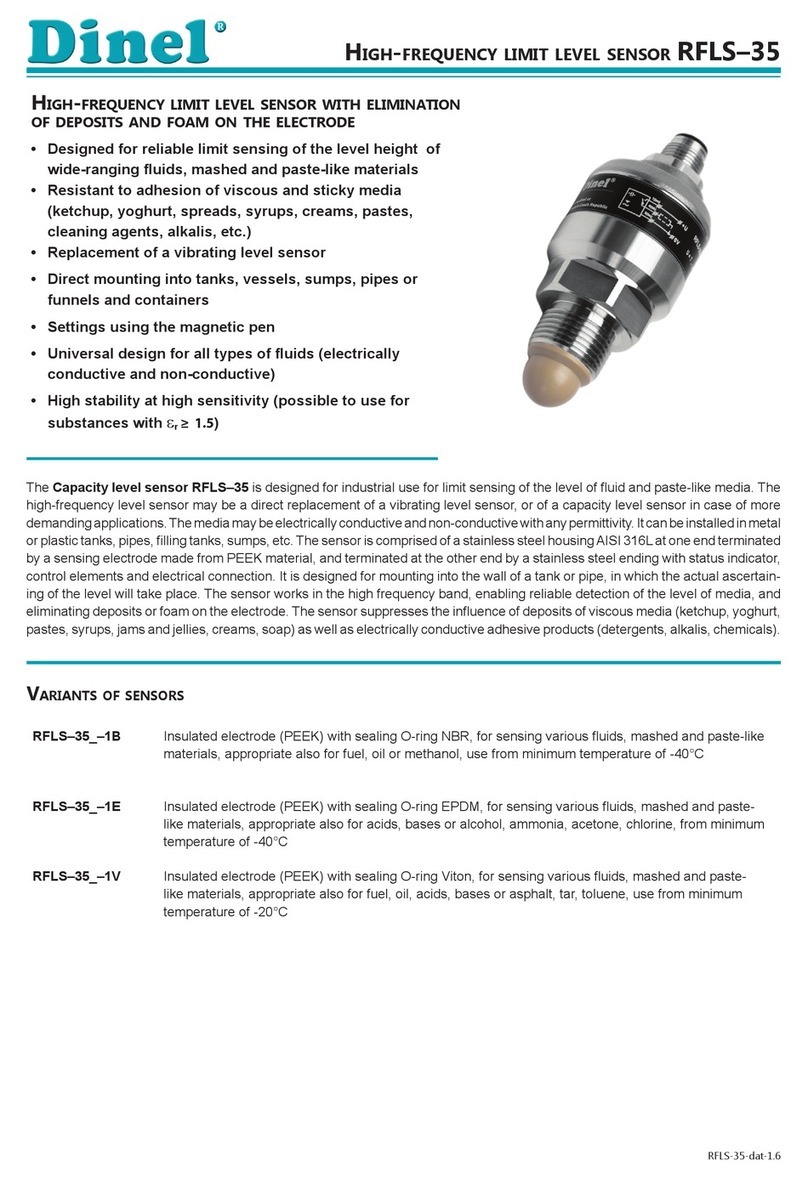

Capacitive level sensors (switches) CLS–23 are designed for limit level detection of electrically

conductive and non-conductive uids in vessels, reservoirs, sumps, pipes, tanks, etc. The sensitiv-

ity of the sensor can be easily set by placing magnetic pen on sensitive spot.

The process coupling at the housing can be with metric thread (M18x1.5 ; M20x1.5), pipe thread

(G3/8” ; G1/2”) or sealing thread (NPT 1/2–14). Output performances – transistor output with open

collector (PNP), two wire electronic switch (S) and NAMUR output.

There are next performances available: N – Normal for non-explosive areas, E – Extended tem-

perature range for non-explosives areas, Xi – Explosion proof (intrinsically safe for explosive ar-

eas), NT – High temperature variant for non-explosives areas and XiT – High temperature variant

for explosive areas.

CLS–23_–10 Uncoated short bar electrode, for sensing of electrically non-conductive

liquids (mineral and plant oils,resins, etc.). Mounting in horizontal position.

Electrode length 30 mm.

CLS–23_–11 Insulated (coated) short bar electrode, for non-aggressive electrically

conductive liquid sensing (water, water solutions). The insulation is made

from PP (Polypropylene).

Electrode length 30 mm.

CLS–23_–12 Insulated (coated) short bar electrode, for moderately aggressive electri

cally conductive liquid sensing (chemicals, water, moderately aggressive

water solutions). Higher temperature resistance than variant “11”. The insula

tion is made from FEP (Tetrauoroethylene-Peruoro-Propylene).

Electrode length 30 mm

CLS–23_–20 Partly insulated rod electrode, for level detection of conductive and non-

conductive liquids, partially resistant to vapours (water) condensation in the

sensing area. The insulation is made from FEP. Vertical mounting; horizontal

mounting (from the side) is possible for shorter electrodes (up to 200 mm)

Electrode length from 50 mm to 1 m.

CLS–23_–21 Fully insulated rod electrode, for universal use, for level detection of con

ductive liquids (water, water solutions). Resistant to vapours (water) conden

sation in the sensing area and partially resistant to medium

spraying. The insulation is made from FEP. Vertical mounting; horizontal

mounting (from the side) is possible for shorter electrodes (up to 200 mm).

Electrode length from 50 mm to 1 m.

CLS–23_–30 Uncoated removable rod electrode, for level detection of conductive and

non-conductive liquids. Vertical mounting; horizontal mounting (from the

side) is possible for shorter electrodes (up to 200 mm).

Electrode length from 50 mm to 1 m.

CLS–23 © Dinel, s.r.o.

6

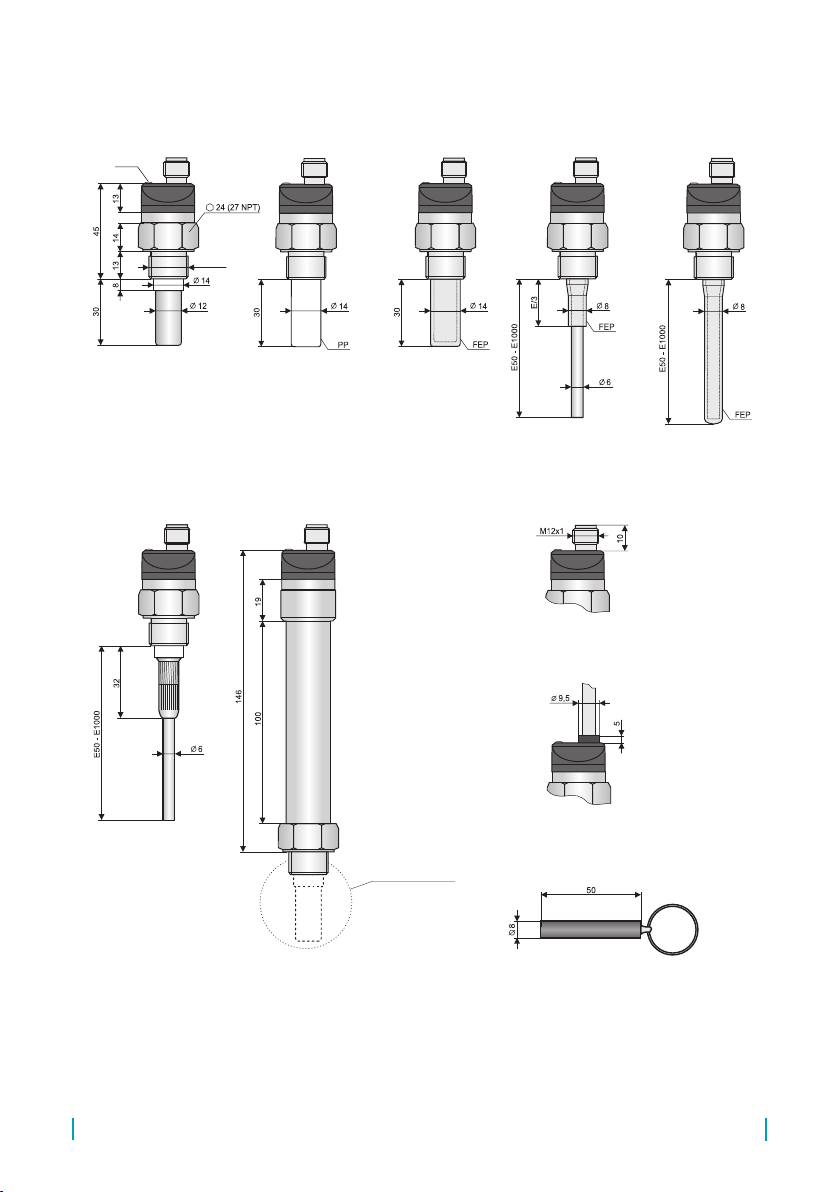

5 . dimensions drawings

CLS – 23_ – 10 CLS – 23_– 11

CLS – 23_ – 30

Variant „A“

with cable outlet

Variant „C“ with connector

(except CLS–23N, NT, Xi, XiT)

Magnetic pen MP–8

Electrode type according

to specic variants

CLS – 23_ –12

CLS – 23_ –21

High temperature variants

(CLS–23_T–10; 12; 20; 21; 30)

CLS – 23_ –20

Thread

Types of threads:

G 3/8''

M18x1,5

M20x1,5

1/2–14 NPT

LED *

* Variant „E“ without LED state indicator

7

© Dinel, s.r.o. CLS–23

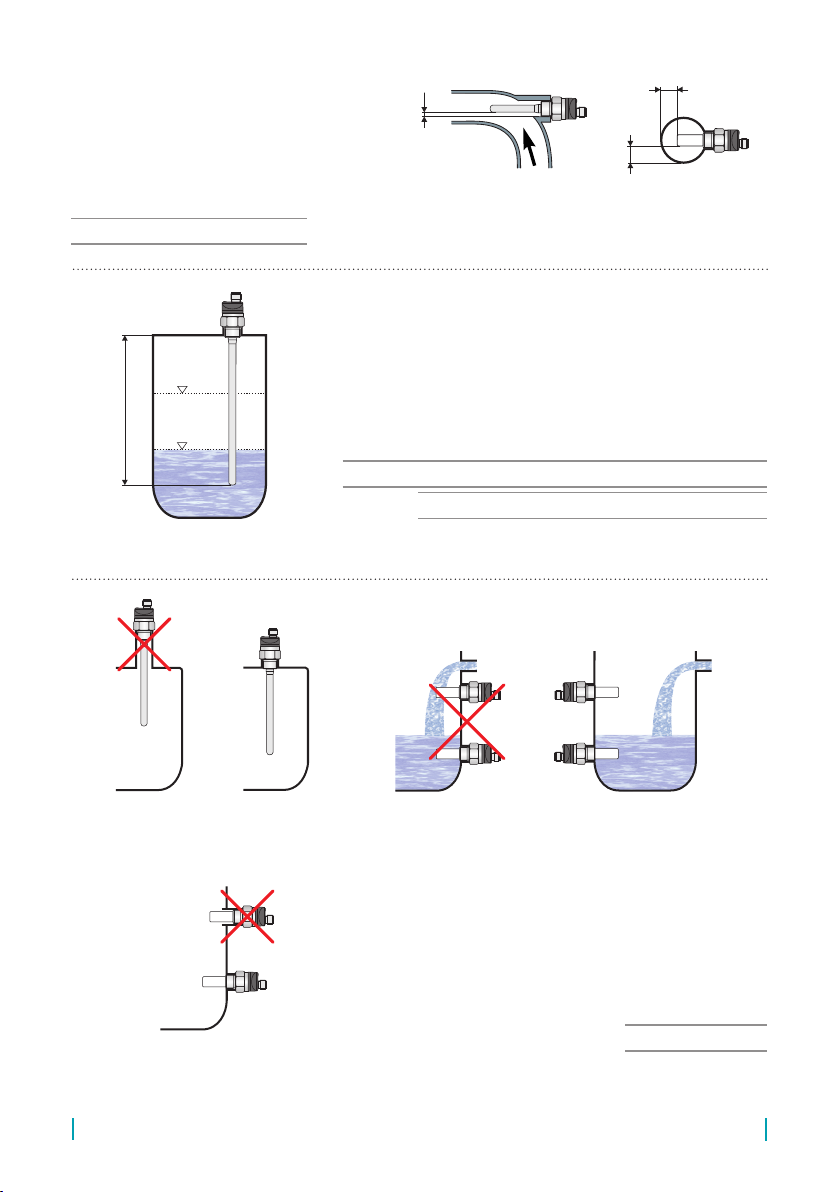

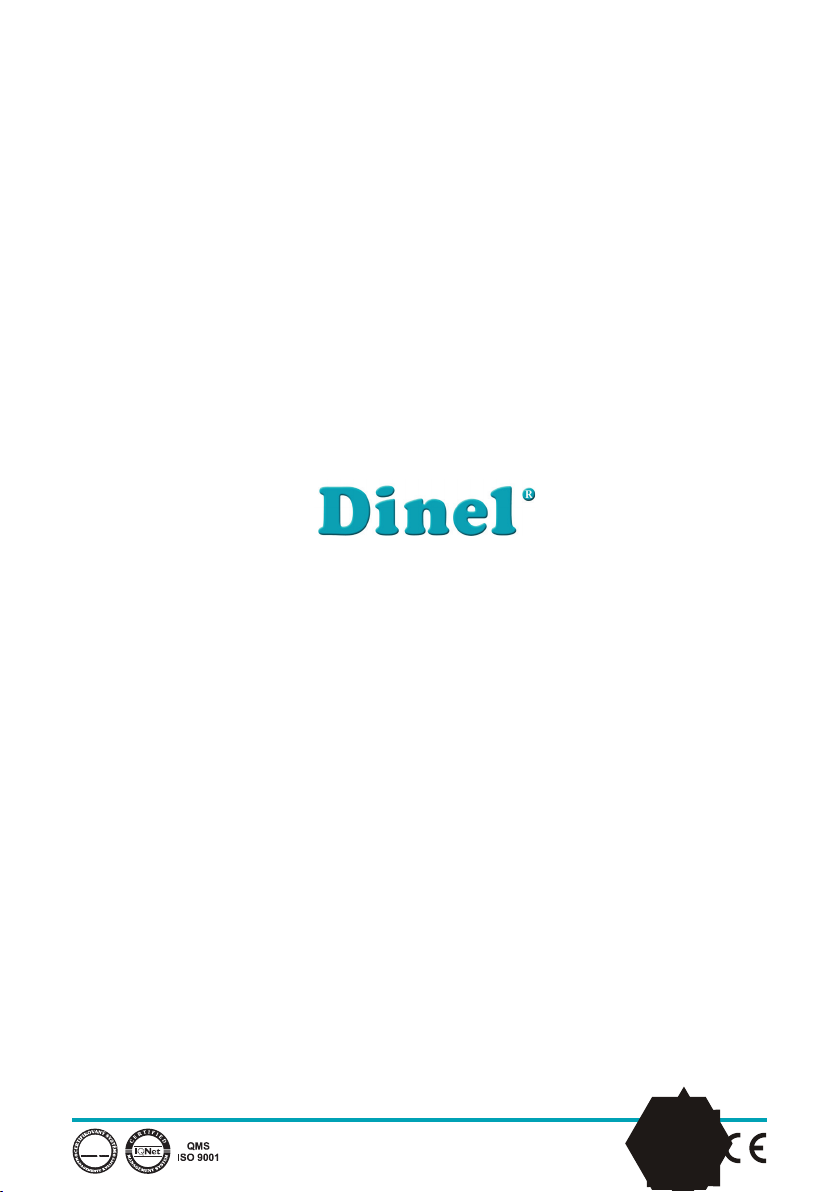

6 . moUnting recommendation

CLS-23 level sensors can be xed in a vertical, horizontal or bevelled position into the shell of the

vessel, the storage tank for the xation console in the pit, by screwing into the welding ange, using

a xing nut or NPT process connection.

Basic application recommendations are mentioned below.

During assembly into the metal tank or the storage tank, it is not necessary to separately ground the

base of the level sensor. In the case of installation in concrete tanks or silos, it is recommended to

install a level sensor on the auxiliary metal construction (console, cap, etc.) and to then connect it

using a permanently dipped metal item or with steel reinforcement in the concrete (armouring).

In the case of the reading of an aggressive medium, we recommend that the producer be consulted.

If the sensors are tted with protective caps at the ends of the electrodes, remove the

caps before commissioning.

For top mounting (vertical position) it is necessary to keep the

distances from walls and from other sensors.

All vertically mounted sensors

E – Electrode length in mm

max.

min.

E

b

E

E

k

c

d

>5

E

a

Ep

>5

>5

30

E

30a

EEp

20

E

40b

50

E

10c

40

E

40d

20

E

20k

+≈

>

+≥=

+≥=

+≥=

+≥=

30

E

30a

EEp

20

E

40b

50

E

10c

40

E

40d

20

E

20k

+≈

>

+≥=

+≥=

+≥=

+≥=

30

E

30a

EEp

20

E

40b

50

E

10c

40

E

40d

20

E

20k

+≈

>

+≥=

+≥=

+≥=

+≥=

30

E

30a

EEp

20

E

40b

50

E

10c

40

E

40d

20

E

20k

+≈

>

+≥=

+≥=

+≥=

+≥=

Mounting in a bypass measuring tube. We recommend to

keep the tube diameter.

Applies to: CLS–23_–20, 21, 30

E – Electrode length in mm

max.

min.

E

b

E

E

k

c

d

>5

E

a

Ep

>5

>5

Fig. 1: Vertical mounting

Fig. 2: Bypass measuring tube

CLS–23 © Dinel, s.r.o.

8

When installing the sensor into the pipe it

is necessary to choose properly internal di-

ameter of the tube to ensure the inner walls

distances from the electrode to min. 5 mm.

In some cases (sticky liquids, liquids with low

dielectric constant) is suitable to mount the

sensor in the knee tube.

Applies to: CLS–23_–10, 11, 12, 20, 21

When installing the sensor in vertical position it can be used

for 2-state (LO-HI) level control between the min. and max.

level. The position of the minimum and maximum level can be

changed by setting the sensor. Fluid changes require new set-

tings of the sensor

E – Electrode length in mm

Applies to: CLS–23_–20, 30 (only for electrically non-conductive liquids)

Applies to: CLS–23_–21 (for electrically conductive liquids)

max.

min.

E

b

E

E

k

c

d

>5

E

a

Ep

>5

>5

max.

min.

E

b

E

E

k

c

d

>5

E

a

Ep

>5

>5

max.

min.

E

b

E

E

k

c

d

>5

E

a

Ep

>5

>5

Sensor installation close to inlet hole, in a narrow

neck or using improper welding ange may result in

malfunction of the sensor.

Suitable welding anges can be found in the Dinel

assortment, types ON, NN – see Accessories.

Applies to: All variants

max.

min.

E

b

E

E

k

c

d

>5

E

a

Ep

>5

>5

max.

min.

E

b

E

E

k

c

d

>5

E

a

Ep

>5

>5

max.

min.

E

b

E

E

k

c

d

>5

E

a

Ep

>5

>5

max.

min.

E

b

E

E

k

c

d

>5

E

a

Ep

>5

>5

max.

min.

E

b

E

E

k

c

d

>5

E

a

Ep

>5

>5

WRONG CORRECT

WRONG

CORRECT

WRONG CORRECT

Fig. 3: Mounting in the pipe

Fig. 4: Two state regulation by hysteresis setting

Fig. 5: Long tting tubes in side wall mounting

9

© Dinel, s.r.o. CLS–23

Applies to: CLS–23_–20, 21, 30 (for electrode length up to 300 mm)

For electrodes with a length over 300 mm for the detection in non-conductive containers (sensors

in vertical position) must be used the auxiliary electrode (e.g. conductivity probe). The auxiliary

electrode is connected to the sensor housing. Recommended length of the auxiliary electrode

and the distance from the sensor are shown in the picture.

Suitable types of auxiliary electrode probes are e.g. Dinel CNP–18F–30 with M18 thread.

max.

min.

E

b

E

E

k

c

d

>5

E

a

Ep

>5

>5

Electrical connection to

the sensor housing

Conductive probe

CNP–18F–30

Non-conductive tank

30

E

30a

EEp

20

E

40b

50

E

10c

40

E

40d

20

E

20k

+≈

>

+≥=

+≥=

+≥=

+≥=

E – Electrode length in mm

30

E

30a

EEp

20

E

40b

50

E

10c

40

E

40d

20

E

20k

+≈

>

+≥=

+≥=

+≥=

+≥=

max.

min.

E

b

E

E

k

c

d

>5

E

a

Ep

>5

>5

Auxiliary electrode PDE–18

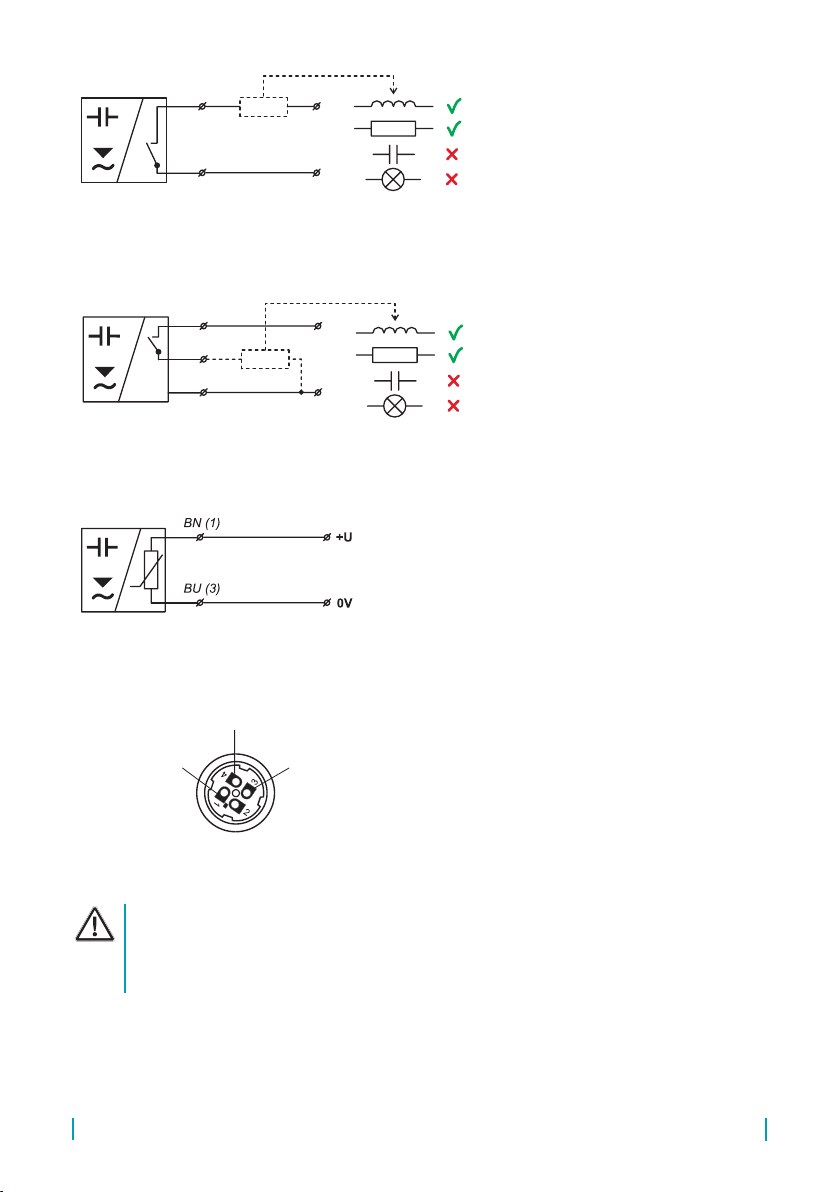

7 . electrical connection

For “A” variant with the xed cable, the individual colour cores of the connecting cable are con-

nected to the respective terminals of the related equipment (supply unit).

For “C” variant with the connector, the cable can be supplied with the sensor (length 2 or 5 m), tted

with the pressed connector socket or dismountable connector socket without the cable (see acces-

sories). In this case the cable is connected to the inside pins of the socket according to Fig. 10.

The sensor with related equipment is interconnected by a suitable three-core (P variation) or two-

core (S and R variations) cable. The length of the cable for the Xi and XiT variations must be

selected with respect to the maximum permitted parameters (usually inductance and capacity) of

the outside intrinsically safe circuit of supply units (NSSU, NDSU, NLCU). If using a dismountable

connector socket, the outside diameter of the cable is a maximum of 6 mm

Sensors CLS–23 are equipped with protection against over-voltages and current overload. The capacity

loads and low resistance (bulb) are evaluated by sensors with output type „P“ and „S“ as short circuit.

Sensors with output type „R“ are designed for interconnect to intrinsically safe supply units.

In case of strong ambient electromagnetic interference, paralleling of conductors with power distribu-

tion, or for the distribution to distance over 30 m, we recommend to use shielded cable.

Fig. 6: Auxiliary electrode in non-conductive tanks

CLS–23 © Dinel, s.r.o.

10

CLS–23_–_–_–S–_

Positive pole (+ U) of power supply

is connected through a load (relay) to

brown (blue) wire or pin connector No.

1, negative pole is connected to white

wire or pin connector No. 3.

Typ CLS–23_–_–_–P–_

Positive pole (+ U) of power supply is

connected to brown wire or pin connec-

tor No. 1, negative pole is connected to

blue wire or pin connector No. 3. Load

(relay) is connected to black wire or pin

connector No. 4.

+U

0V

BN (1)

WH, BU (3)

+U

0V

BN (1)

BU (3)

BK (4)

+U

0V

BN (1)

WH, BU (3)

+U

0V

BN (1)

BU (3)

BK (4)

Typ CLS–23_–_–_–R–_

Brown wire or pin connector No. 1 is

connected to positive pole (+U) of In-

trinsically safe supply unit. Blue wire or

pin.connector No. 3 is connected to

negative pole of Intrinsically safe sup-

ply unit.

Electrical connection must be done in de-energized state! For switching supply sources,

it is necessary to check that the input is galvanically separated from the network side

and that they are tted with a lter suppressing the conforming interference (terminals

+ and – oscillate together towards the ground potential), or the interference is removed

in another manner.

Fig. 7: “S“ type sensors connection

(2 - wire electronic switch)

Fig. 8: “P“ (PNP) type sensors connection

Fig. 9: “R“ (NAMUR) type sensors connection

Legend:

(1...3) – Terminals number for variants with connector

BN – Brown

WH – White

BK – Black

BU – Blue

Fig. 10: Inside of the connector socket

Output (BK)

0V (BU)

+U (BN)

11

© Dinel, s.r.o. CLS–23

8 . sensor settings

The setting is done by placing magnetic pen MP–8 to sensitive

spot Mlocated on the front of the sensor. Short time attaching

(up to 2 sec.) of the magnetic pen to the sensitive spot M

makes the sensor open. Long time attaching (at least 4 sec.) of

the pen when the level is changed, denes closed state of the

sensor. In this way is set the sensitivity for the measured medi-

um and switching modes SO (normally open) or SC (normally

closed).

Sensitive spot

FACTORY DEFAULT SETTINGS:

Types CLS–23_–10; –20; –30 are set to detect mineral oil, CLS–23_–11; –12; –21 to detect water.

The mode O is set (sensor closes when immersed).

When the level is low (the container is empty), attach the magnetic pen

MP–8 to the sensitive spot

M

for long time (min. 4 sec.). When the level

is high (the container is full), attach the magnetic pen MP–8 to the sensitive

spot

M

for short time (max. 2 sec.).

.

When the level is low (the container is empty), attach the magnetic pen

MP–8 to the sensitive spot M for short time (max. 2 sec.). When the

level is high (the container is full), attach the magnetic pen MP–8 to the

sensitive spot M for long time (min. 4 sec.).

mode O

(normally open)

mode C

(normally close)

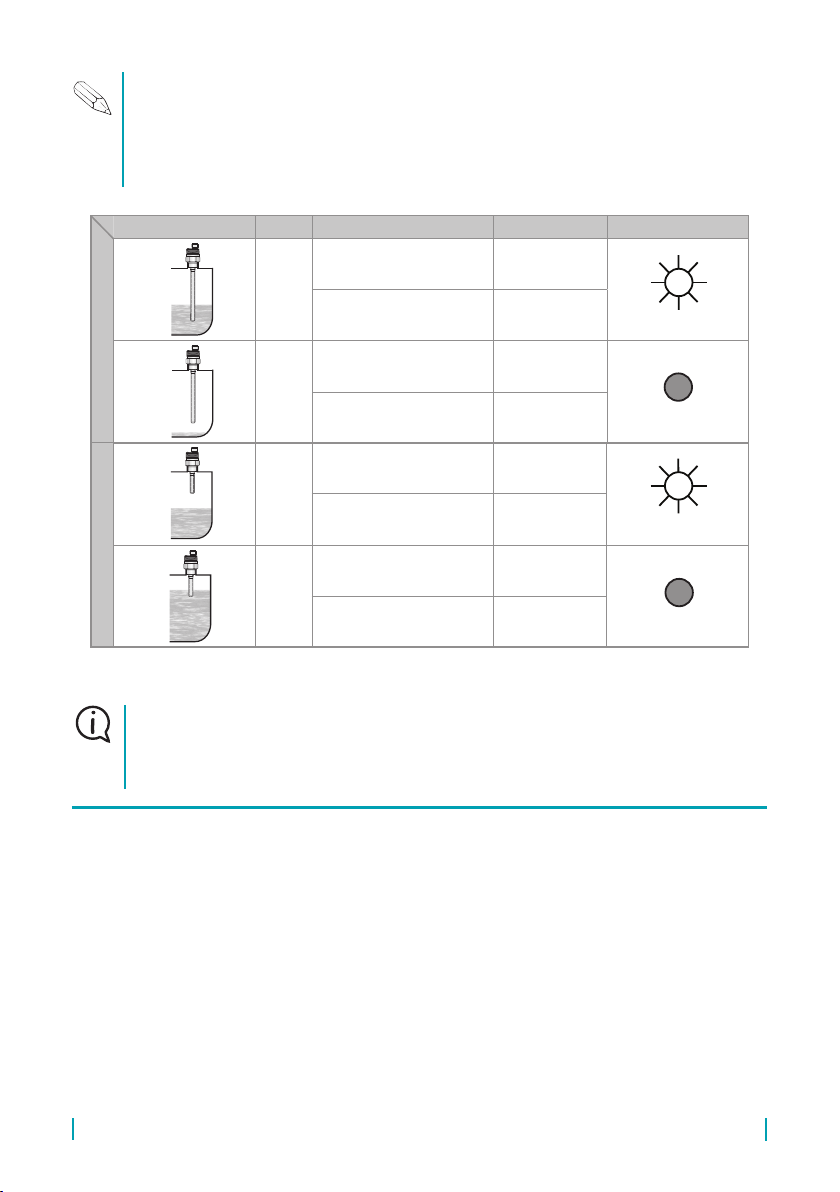

9 . statUs signalization (only with LED state indicator variant)

Indicator Function

Orange LED

Continuous light – Sensor is closed (switched ON)

Dark – Sensor is open (switched OFF)

Rapid ashing (period 0.2 s) – Unrecognized upper and lower limits or setting mistake

Slow ashing (period 0.8 s) – Short circuit at sensor output

Sensors of type CLS–23E are produced without signaling indicator LED. For control of correct

settings it is necessary to interconnect the sensor to related evaluation unit or load.

In the case of the vertical mounting for detection of non-conductive liquids by sensors CLS–23_–20;

–30 and for detection of conductive and non-conductive liquids by sensors CLS–23_–21 it neces-

sary to set limits ON and OFF when electrode of the sensor is immersed to medium.

CLS–23 © Dinel, s.r.o.

12

For security reasons, we recommend to set the mode O (normally open, sensor closes when immersed)

for minimum level detection. Any failure of the sensor or wiring is equally apparent as the emergency

level state. Analogously – for the maximum level detection is recommended to set the mode C (normally

closed, sensor opens when immersed).

10 . accessories

Standard

(included in the level sensors price)

• 1pc of Magnetic pen MP–8

• 1pc of Seal (non-asbestos)

Optional

(for extra charge)

• Extra cables (over the standard length 2 m)

• Non-rewirable connector plug M12

(“N” and “NT” variants)

• Rewirable connector plug M12

(“N” and “NT” variants)

• Steel or Stainless steel welding ange

• Stainless steal xing nut UM–18x1,5

• Other seals (PTFE, Al, etc.)

Level state Mode Type of sensor Output state LED indicator *

Minimum level sensing

O

CLS–23_–_ _– _ –P–_

CLS–23_–_ _– _ –S–_ CLOSED

(Shine)

CLS–23Xi–_ _– _ –R–_

CLS–23XiT–_ _– _ –R–_

HIGHER

CURRENT

O

CLS–23_–_ _– _ –P–_

CLS–23_–_ _– _ –S–_ OPEN

(Dark)

CLS–23Xi–_ _– _ –R–_

CLS–23XiT–_ _– _ –R–_

LOWER

CURRENT

Maximum level sensing

C

CLS–23_–_ _– _ –P–_

CLS–23_–_ _– _ –S–_ CLOSED

(svítí)

CLS–23Xi–_ _– _ –R–_

CLS–23XiT–_ _– _ –R–_

HIGHER

CURRENT

C

CLS–23_–_ _– _ –P–_

CLS–23_–_ _– _ –S–_ OPEN

(nesvítí)

CLS–23Xi–_ _– _ –R–_

CLS–23XiT–_ _– _ –R–_

LOWER

CURRENT

* Variant „E“ without LED state indicator

Sensor for each ash of the LED switches its output on for approx. 3 ms. This period is sufciently

short to avoid unwanted switching of relay contacts. For binary inputs, we recommend to set the

lter so as not to respond to pulses shorter than 3 ms.

Units Dinel NSSU, NDSU a NLCU with transistor switch („T“) detects and transmitts these pulses

to the output.

13

© Dinel, s.r.o. CLS–23

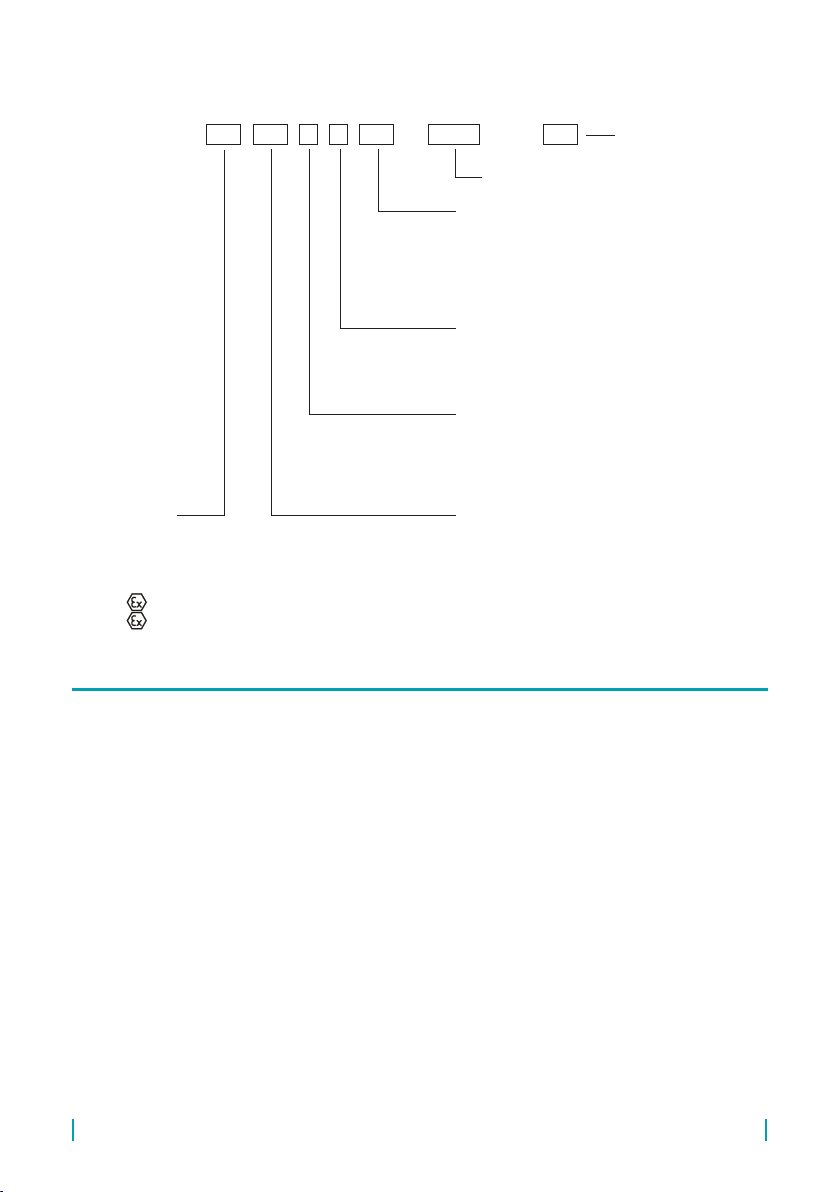

11 . order code

CLS – 23 – – – – E Cable

Performance:

N – Normal for non-explosive areas

E – Extended temperature range variants for non-explosive

areas (without LED)

NT – High temperature variants for non-explosive areas

Xi – (intrinsically safe) for hazardous areas

XiT – (intrinsically safe), high temperature variants

Process connection:

G3/8 – Pipe thread G 3/8“

G1/2 – Pipe thread G 1/2“

M18 – Metric thread M 18x1,5

M20 – Metric thread M 20x1,5

NPT – Sealing thread 1/2–14 NPT

Output type:

P – PNP (Open collector)

S– 2-wire electronic switch

R – NAMUR (For Xi variants only)

Electric connection:

A – Cable outlet (+ Spec. the length of the cable)

C – Connector – (+ Spec. type of the socket)

except variant “A“

Type and electrode performance:

10 – Uncoated short bar, length 30 mm

11 – Insulated (coated) short bar (PP), length 30 mm

12 – Insulated (coated) short bar (FEP), length 30 mm

20 – Partly insulated rod (FEP), length 50 ... 1000 mm

21 – Fully insulated rod (FEP), length 50 ... 1000 mm

30 – Uncoated removable rod, length 50 ... 1000 mm

Length of cable in meters

(variant “A“)

Electrode length in mm

12 . correct sPeciFication examPles

CLS–23N–10–A–S–G3/8 cable 5 m

(N) For non-explosive areas; (10) Uncoated short bar electrode 30 mm, (A) Cable outlet with 5 m xed cable; (S) 2-wire electronic

switch; (G3/8) Process connection with pipe thread G3/8”

CLS–23E–30–A–S–G1/2 E450 cable 10 m

(E) Extended temperature range performance for non-explosive areas; (30) Uncoated removable rod electrode; (A) Cable outlet with

10 m xed cable; (S) 2-wire electronic switch; (G1/2) Process connection with pipe thread G1/2”; (E450) Electrode length 450 mm.

CLS–23NT–20–C–S–M18 E320

(NT) High temperature variants for non-explosive areas; (20) Partly insulated rod electrode (FEP); (C) Electrically connection with

connector; (S) 2-wire electronic switch; (M18) Process connection with metric thread M18x1.5; (E320) Electrode length 320 mm.

CLS–23Xi–11–C–R–NPT

(Xi) Intrinsically safe for hazardous areas; (11) Insulated (coated) short bar (PP) electrode 30 mm (C) Electrically connection with

connector; (R) NAMUR output type; (NPT) Process connection with sealing thread 1/2 – 14 NPT.

CLS–23 © Dinel, s.r.o.

14

It is forbidden to make any changes or interventions to the CLS–23 sensor without the

consent of the producer. Any repairs must only be carried out by the producer or author-

ized service organisations.

Assembly, installation, commissioning, service and maintenance of the CLS–23 level

sensor must be carried out in accordance with this manual and the provisions of valid

standards for the installation of electrical equipment must be complied with.

14 . Use, maniPUlation and maintenance

The level meter does not require any personnel for its operation.

13 . saFety, Protections, comPatibility and exPlosion ProoF

The level sensor is equipped with a protection against electric shock on electrode, polarity, overvoltage

and short-term current overload on the output.

Electromagnetic compatibility is provided by conformity with standards EN 55011 / B, EN 61326-1, EN

61000-4-2 (8 kV), -4-3 (10 V/m), -4-4 (2 kV), -4-5 (1 kV) a -4-6 (10 V).

Explosion proof CLS–23Xi and XiT is examined FTZÚ - AO210 Ostrava - Radvanice, certicate No.

FTZÚ 12 ATEX 0106X.

Supplied electrical equipment matches the requirements of valid European directives for safety and

electromagnetic compatibility. The declaration of Conformity for the above mentioned product was

issued.

Special conditions for safe use

If the apparatus is used as device of Group II and with using of an approved power supply device,

which output parameters comply with required input parameters, it is necessary to have an galvanic

separation or in case of apparatus without galvanic separation (Zener barriers) it is necessary to

provide equipotential equalizing between sensor and barrier earthing point.

Design CLS–23Xi-11 (12, 20, 21) can be used in zone 0. Other design DLS–23Xi can be used in

zone 0 only electrode part and head with electronics can be used only in zone 1.

Ambient temperature: Tamb = - 20°C ... +75°C

Temperature of measured medium according to design variant:

Xi typ 10, 12: (- 25°C to + 105°C)

Xi typ 11: (- 10°C to + 105°C)

Xi typ 20, 21, 30, XiT: (- 30°C to + 150°C)

15 . general conditions and warranty

Dinel, s.r.o. guarantees for the period of three (3) years that the product has the characteristic as in

technical specication is mentioned. The guarantee can be invoked only when the product is com-

pleted by original invoice and guarantee list. This guarantee does not cover the damages resulting

from misuse, improper installation or incorrect maintenance.

15

© Dinel, s.r.o. CLS–23

16 . marking oF labels

This guarantee cease when user or the other person makes any changes on the product or the

product is mechanically or chemically damaged, or the serial number is not readable.

In the case of rightful complaint we replace the product or its defective part.

Real label size 81 x 9 mm.

CLS-23Xi-__-_-R-____ E____ No.:______

IP68

Štítek pro CLS-23Xi-10(30)-

FTZÚ 12 ATEX 0106X

U = 12V I = 15m A

P = 45mW C = 15nF

L = 10uH t = -20 .. . +75 °C

a

i

i

i

i

II 1/2G Ex ia IIC T6 Ga/Gb

i

CLS-23XiT-__-_-R-____ E____ No.:______

IP68

Štítek pro CLS-23XiT-10(30)-

FTZÚ 12 ATEX 0106X

U = 12V I = 15m A

P = 45mW C = 15nF

L = 10uH t = -20 .. . +75 °C

i

i

i

i

II 1/2G Ex ia IIC T6 Ga/Gb

i

CLS-23Xi-__-_-R-____ E____ No.:______

IP68

Štítek pro CLS-23Xi-11(12, 20, 21)-

FTZÚ 12 ATEX 0106X

U = 12V I = 15m A

P = 45mW C = 15nF

L = 10uH t = -20 .. . +75 °C

i

i

i

i

II 1G Ex ia IIB T6 Ga

i

CLS-23XiT-__-_-R-____ E____ No.:______

IP68

Štítek pro CLS-23XiT-11(12, 20, 21)-

FTZÚ 12 ATEX 0106X

U = 12V I = 15m A

P = 45mW C = 15nF

L = 10uH t = -20 .. . +75 °C

i

i

i

i

II 1/2G Ex ia IIB T6 Ga/Gb

i

a

a

a

1026

1026

1026

1026

Symbol of producer: Dinel logo®

Internet address: www.dinel.cz

Level sensor type and electrode length: CLS–23Xi(XiT)–_ _–_–R–_ _ Exxxx

Serial number: Ser. No.: xxxxx – (from the left: production year, serial production No.)

Label of non-explosive device: , Performance II 1/2G Ex ia IIC T6 Ga/Gb

Limit operating parameters: Ui = 12 V =, Ii = 15 mA; Pi = 45 mW; Ci = 15 nF; Li = 10 μH

Ambient temperature range: ta= -20 ... +75 °C

Number of certicate of intrinsically safety: FTZÚ 12 ATEX 0106X

Compliance mark:

Protection class: IP68, Electro-waste take-back system mark:

Level sensor label data CLS–23Xi(T)–10, 30

Symbol of producer: Dinel logo®

Internet address: www.dinel.cz

Level sensor type and electrode length: CLS–23Xi(XiT)–_ _–_–R–_ _ Exxxx

Serial number: Ser. No.: xxxxx – (from the left: production year, serial production No.)

Label of non-explosive device: , Performance II 1G Ex ia IIB T6 Ga or II 1/2G Ex ia IIB T6 Ga/Gb

Limit operating parameters: Ui = 12 V =, Ii = 15 mA; Pi = 45 mW; Ci = 15 nF; Li = 10 μH

Ambient temperature range: ta= -20 ... +75 °C

Number of certicate of intrinsically safety: FTZÚ 12 ATEX 0106X

Compliance mark:

Protection class: IP68, Electro-waste take-back system mark:

Level sensor label data CLS–23Xi(T)–11, 12, 20, 21

CLS-23Xi-__-_-R-____ E____ No.:______

IP68

Štítek pro CLS-23Xi-10(30)-

FTZÚ 12 ATEX 0106X

U = 12V I = 15m A

P = 45mW C = 15nF

L = 10uH t = -20 .. . +75 °C

a

i

i

i

i

II 1/2G Ex ia IIC T6 Ga/Gb

i

CLS-23XiT-__-_-R-____ E____ No.:______

IP68

Štítek pro CLS-23XiT-10(30)-

FTZÚ 12 ATEX 0106X

U = 12V I = 15m A

P = 45mW C = 15nF

L = 10uH t = -20 .. . +75 °C

i

i

i

i

II 1/2G Ex ia IIC T6 Ga/Gb

i

CLS-23Xi-__-_-R-____ E____ No.:______

IP68

Štítek pro CLS-23Xi-11(12, 20, 21)-

FTZÚ 12 ATEX 0106X

U = 12V I = 15m A

P = 45mW C = 15nF

L = 10uH t = -20 .. . +75 °C

i

i

i

i

II 1G Ex ia IIB T6 Ga

i

CLS-23XiT-__-_-R-____ E____ No.:______

IP68

Štítek pro CLS-23XiT-11(12, 20, 21)-

FTZÚ 12 ATEX 0106X

U = 12V I = 15m A

P = 45mW C = 15nF

L = 10uH t = -20 .. . +75 °C

i

i

i

i

II 1/2G Ex ia IIB T6 Ga/Gb

i

a

a

a

1026

1026

1026

1026

CLS-23Xi-__-_-R-____ E____ No.:______

IP68

Štítek pro CLS-23Xi-10(30)-

FTZÚ 12 ATEX 0106X

U = 12V I = 15m A

P = 45mW C = 15nF

L = 10uH t = -20 .. . +75 °C

a

i

i

i

i

II 1/2G Ex ia IIC T6 Ga/Gb

i

CLS-23XiT-__-_-R-____ E____ No.:______

IP68

Štítek pro CLS-23XiT-10(30)-

FTZÚ 12 ATEX 0106X

U = 12V I = 15m A

P = 45mW C = 15nF

L = 10uH t = -20 .. . +75 °C

i

i

i

i

II 1/2G Ex ia IIC T6 Ga/Gb

i

CLS-23Xi-__-_-R-____ E____ No.:______

IP68

Štítek pro CLS-23Xi-11(12, 20, 21)-

FTZÚ 12 ATEX 0106X

U = 12V I = 15m A

P = 45mW C = 15nF

L = 10uH t = -20 .. . +75 °C

i

i

i

i

II 1G Ex ia IIB T6 Ga

i

CLS-23XiT-__-_-R-____ E____ No.:______

IP68

Štítek pro CLS-23XiT-11(12, 20, 21)-

FTZÚ 12 ATEX 0106X

U = 12V I = 15m A

P = 45mW C = 15nF

L = 10uH t = -20 .. . +75 °C

i

i

i

i

II 1/2G Ex ia IIB T6 Ga/Gb

i

a

a

a

1026

1026

1026

1026

CLS-23Xi-__-_-R-____ E____ No.:______

IP68

Štítek pro CLS-23Xi-10(30)-

FTZÚ 12 ATEX 0106X

U = 12V I = 15m A

P = 45mW C = 15nF

L = 10uH t = -20 .. . +75 °C

a

i

i

i

i

II 1/2G Ex ia IIC T6 Ga/Gb

i

CLS-23XiT-__-_-R-____ E____ No.:______

IP68

Štítek pro CLS-23XiT-10(30)-

FTZÚ 12 ATEX 0106X

U = 12V I = 15m A

P = 45mW C = 15nF

L = 10uH t = -20 .. . +75 °C

i

i

i

i

II 1/2G Ex ia IIC T6 Ga/Gb

i

CLS-23Xi-__-_-R-____ E____ No.:______

IP68

Štítek pro CLS-23Xi-11(12, 20, 21)-

FTZÚ 12 ATEX 0106X

U = 12V I = 15m A

P = 45mW C = 15nF

L = 10uH t = -20 .. . +75 °C

i

i

i

i

II 1G Ex ia IIB T6 Ga

i

CLS-23XiT-__-_-R-____ E____ No.:______

IP68

Štítek pro CLS-23XiT-11(12, 20, 21)-

FTZÚ 12 ATEX 0106X

U = 12V I = 15m A

P = 45mW C = 15nF

L = 10uH t = -20 .. . +75 °C

i

i

i

i

II 1/2G Ex ia IIB T6 Ga/Gb

i

a

a

a

1026

1026

1026

1026

CLS-23Xi-__-_-R-____ E____ No.:______

IP68

Štítek pro CLS-23Xi-10(30)-

FTZÚ 12 ATEX 0106X

U = 12V I = 15m A

P = 45mW C = 15nF

L = 10uH t = -20 .. . +75 °C

a

i

i

i

i

II 1/2G Ex ia IIC T6 Ga/Gb

i

CLS-23XiT-__-_-R-____ E____ No.:______

IP68

Štítek pro CLS-23XiT-10(30)-

FTZÚ 12 ATEX 0106X

U = 12V I = 15m A

P = 45mW C = 15nF

L = 10uH t = -20 .. . +75 °C

i

i

i

i

II 1/2G Ex ia IIC T6 Ga/Gb

i

CLS-23Xi-__-_-R-____ E____ No.:______

IP68

Štítek pro CLS-23Xi-11(12, 20, 21)-

FTZÚ 12 ATEX 0106X

U = 12V I = 15m A

P = 45mW C = 15nF

L = 10uH t = -20 .. . +75 °C

i

i

i

i

II 1G Ex ia IIB T6 Ga

i

CLS-23XiT-__-_-R-____ E____ No.:______

IP68

Štítek pro CLS-23XiT-11(12, 20, 21)-

FTZÚ 12 ATEX 0106X

U = 12V I = 15m A

P = 45mW C = 15nF

L = 10uH t = -20 .. . +75 °C

i

i

i

i

II 1/2G Ex ia IIB T6 Ga/Gb

i

a

a

a

1026

1026

1026

1026

CLS–23 © Dinel, s.r.o.

16

17 . sPeciFications

technical sPeciFications

Supply voltage 6 ... 30 V DC

Supply current – Output type P

– Output type S

max. 0,6 / 7 mA (OFF / ON state)

max. 0,6 mA (OFF state)

Switched current (Min. / Max.) – Output type P

– Output type S

max. 100 mA

3,3 mA / 40 mA (min. / max.)

Remanent voltage - ON state – Output type P

– Output type S

1,8 V

6,0 V

Output time delay 0,1 s

Protection class IP68 (0,1 MPa)

Cable

(for cable outlet performance)

CLS–23N, NT, Xi, XiT

CLS–23E

PVC 2x 0,34 mm2 (3x 0,34 mm2 – výstup type P)

Silicone 2x 0,5 mm2

Weight

(with 2 m cable and 30 mm electrode)

CLS–23N, E, Xi

CLS–23NT, XiT

Approx. 45 g

Approx. 190 g

electrical Parameters – variants Xi, XiT

Supply voltage 8 ... 9 V DC

Current supply (state OFF / ON) – NAMUR ≤ 1 mA / ≥ 2,2 mA

Max. internal values Ui = 12 V DC; Ii = 15 mA; Pi = 45 mW; Ci = 15 nF; Li = 10 µH

Coupling capacity / Electric strength 44 nF / 250 V AC

Cable LC parameters Typical C < 150 pF/m

Typical L < 0,8 µH /m

Process connection

Type Size Marking

Metric thread M18 x 1,5 M18

Metric thread M20 x 1,5 M20

Pipe thread (BSP) G 3/8'' G3/8

Pipe thread (BSP) G 1/2'' G1/2

Sealing thread 1/2–14 NPT

oUtPUt tyPe

Output Variants

S („S“) N, E, NT

PNP („P“) N, E, NT

NAMUR („R“) Xi, XiT

material PerFormance

Sensor part Variants Material

Housing All variants Plastic PP

Process coupling All variants Stainless steel W.Nr. 1.4305 (AISI 303)

Electrode All variants Stainless steel W.Nr. 1.4305 (AISI 303)

Electrode insulation CLS–23_–11 Plastic PP

Electrode insulation CLS–23_–12, 20, 21 Plastic FEP

17

© Dinel, s.r.o. CLS–23

oUtPUt tyPe

Output Variants

S („S“) N, E, NT

PNP („P“) N, E, NT

NAMUR („R“) Xi, XiT

working areas (EN 60079-10–1)

CLS – 23N

Performance for non-explosive areas

CLS – 23E

Extended temperature performance for non-explosive areas

CLS – 23NT

High temperature performance for non-explosive areas

CLS – 23Xi (XiT)–10

CLS–23Xi (XiT)–30

Performance for explosive areas (XiT–high temperature), II 1/2 G Ex ia IIC T6 Ga/

Gb

with intrinsically safe supply units, electrode part zone 0, housing

zone 1

CLS – 23Xi–11, 12, 20, 21 Performance for explosive areas, II 1 G Ex ia IIB T6 Ga with intrinsically safe

supply units, whole sensor zone 0

CLS – 23XiT–11, 12, 20, 21

High temperature performance for explosive areas,

II 1/2 G Ex ia IIB T6 Ga/Gb

with intrinsically safe supply units, electrode part zone 0, housing zone 1.

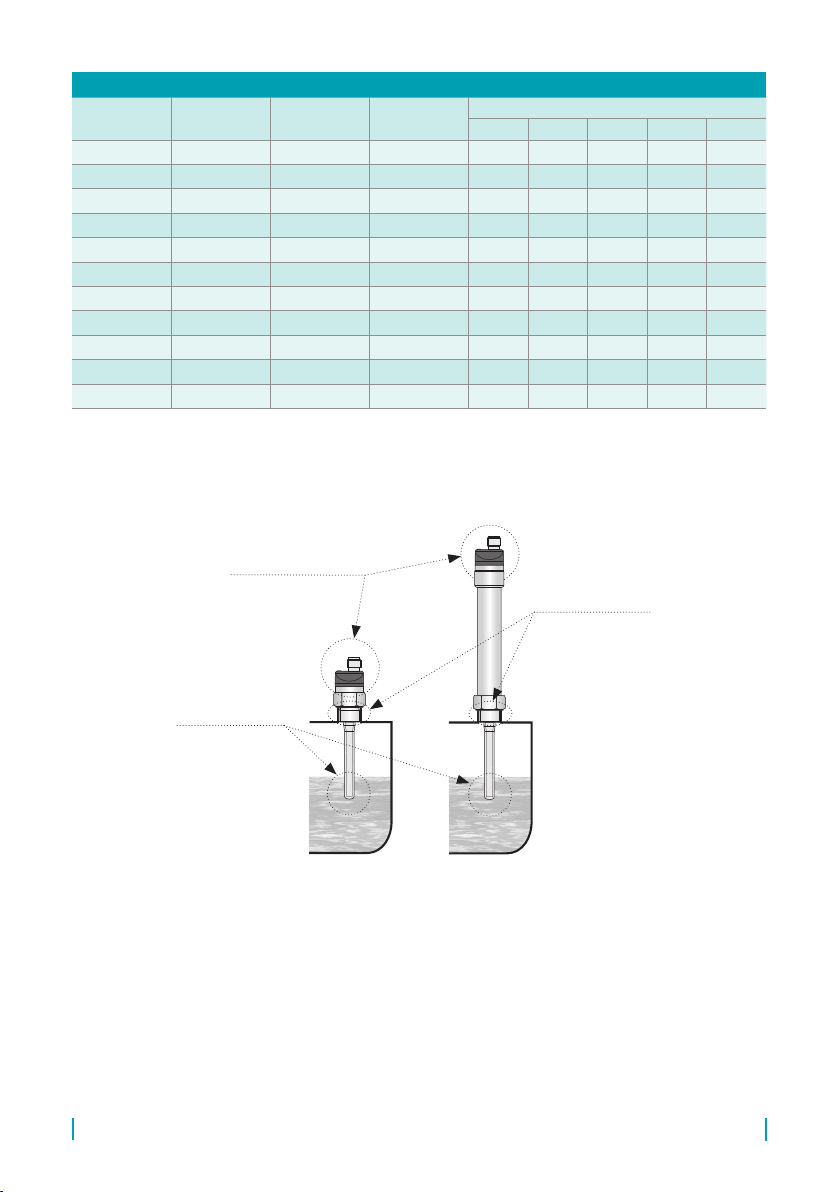

temPeratUre and PressUre resistance – variants N, E, NT

Variant

(Performance) Temperature tpTemperature tmTemperature taMax. operating pressure for temperature tp

to 30°C to 85°C to 105°C to 130°C do 150°C

CLS–23N–10 -25°C ... +105°C -25°C ... +105°C -20°C ... +80°C 8 MPa 6 MPa 5 MPa – –

CLS–23E–10 -25°C ... +120°C -25°C ... +120°C -25°C ... +105°C 8 MPa 6 MPa 5 MPa – –

CLS–23NT–10 -30°C ... +150°C -30°C ... +150°C -20°C ... +80°C 8 MPa 6 MPa 5 MPa 4 MPa 3 MPa

CLS–23N–11 -10°C ... +105°C -10°C ... +105°C -10°C ... +80°C 7 MPa 5 MPa 4 MPa – –

CLS–23E–11 -10°C ... +105°C -10°C ... +105°C -10°C ... +105°C 7 MPa 5 MPa 4 MPa – –

CLS–23N–12 -25°C ... +105°C -25°C ... +105°C -20°C ... +80°C 8 MPa 6 MPa 5 MPa – –

CLS–23E–12 -25°C ... +120°C -25°C ... +120°C -25°C ... +105°C 8 MPa 6 MPa 5 MPa – –

CLS–23NT–12 -30°C ... +150°C -30°C ... +150°C -20°C ... +80°C 8 MPa 6 MPa 5 MPa 4 MPa 3 MPa

CLS–23N–20 -25°C ... +105°C -30°C ... +150°C * -20°C ... +80°C 3 MPa 2,5 MPa 2 MPa – –

CLS–23E–20 -25°C ... +120°C -30°C ... +150°C * -25°C ... +105°C 3 MPa 2,5 MPa 2 MPa – –

CLS–23NT–20 -30°C ... +150°C -30°C ... +150°C -20°C ... +80°C 3 MPa 2,5 MPa 2 MPa 1,5 MPa 1 MPa

CLS–23N–21 -25°C ... +105°C -30°C ... +150°C * -20°C ... +80°C 3 MPa 2,5 MPa 2 MPa – –

CLS–23E–21 -25°C ... +120°C -30°C ... +150°C * -25°C ... +105°C 3 MPa 2,5 MPa 2 MPa – –

CLS–23NT–21 -30°C ... +150°C -30°C ... +150°C -20°C ... +80°C 3 MPa 2,5 MPa 2 MPa 1,5 MPa 1 MPa

CLS–23N–30 -25°C ... +105°C -30°C ... +150°C * -20°C ... +80°C 8 MPa 6 MPa 5 MPa – –

CLS–23E–30 -25°C ... +120°C -30°C ... +150°C * -25°C ... +105°C 8 MPa 6 MPa 5 MPa – –

CLS–23NT–30 -30°C ... +150°C -30°C ... +150°C -20°C ... +80°C 8 MPa 6 MPa 5 MPa 4 MPa 3 MPa

* Valid for top mounting (in vertical position)

CLS–23 © Dinel, s.r.o.

18

temPeratUre and PressUre resistance – variants Xi, XiT

Variant

(Performance) Temperature tpTemperature tmTemperature taMax. operating pressure for temperature tp

to 30°C to 85°C to 105°C to 130°C to 150°C

CLS–23Xi–10 -25°C ... +105°C -25°C ... +105°C -20°C ... +75°C 8 MPa 6 MPa 5 MPa – –

CLS–23XiT–10 -30°C ... +150°C -30°C ... +150°C -20°C ... +75°C 8 MPa 6 MPa 5 MPa 4 MPa 3 MPa

CLS–23Xi–11 -10°C ... +105°C -10°C ... +105°C -10°C ... +75°C 7 MPa 5 MPa 4 MPa – –

CLS–23Xi–12 -25°C ... +105°C -25°C ... +105°C -20°C ... +75°C 8 MPa 6 MPa 5 MPa – –

CLS–23XiT–12 -30°C ... +150°C -30°C ... +150°C -20°C ... +75°C 8 MPa 6 MPa 5 MPa 4 MPa 3 MPa

CLS–23Xi–20 -25°C ... +105°C -30°C ... +150°C * -20°C ... +75°C 3 MPa 2,5 MPa 2 MPa – –

CLS–23XiT–20 -30°C ... +150°C -30°C ... +150°C -20°C ... +75°C 3 MPa 2,5 MPa 2 MPa 1,5 MPa 1 MPa

CLS–23Xi–21 -25°C ... +105°C -30°C ... +150°C * -20°C ... +75°C 3 MPa 2,5 MPa 2 MPa – –

CLS–23XiT–21 -30°C ... +150°C -30°C ... +150°C -20°C ... +75°C 3 MPa 2,5 MPa 2 MPa 1,5 MPa 1 MPa

CLS–23Xi–30 -25°C ... +105°C -30°C ... +150°C * -20°C ... +75°C 8 MPa 6 MPa 5 MPa – –

CLS–23XiT–30 -30°C ... +150°C -30°C ... +150°C -20°C ... +75°C 8 MPa 6 MPa 5 MPa 4 MPa 3 MPa

* Valid for top mounting (in vertical position)

tm– Medium

operating temp

tp– Temp. in process

connection place

ta–

Ambient temperature

range (on housing)

Variants:

N; E; Xi;

Variants:

NT; XiT;

Materm d.o.o.

2313 Fram

Tel.: 02 608 90 10

Fax: 02 608 90 18

E-mail: i[email protected]

www.materm.si

The latest version of this instruction manual can be found at www.materm.si

Version:

industrial electronics

10/2013

Other manuals for CLS-23

2

Table of contents

Other Dinel Accessories manuals

Popular Accessories manuals by other brands

ROSE DISPLAYS

ROSE DISPLAYS ANOQUICK SQUARE WITH GOTCHA AND MULTICLIPS manual

Joolz

Joolz footboard instruction manual

SilentCall

SilentCall MEDALLION DB2-MC Installation and operating instructions

SAFEasy

SAFEasy SF2 Series instruction manual

Panasonic

Panasonic Grid-EYE AMG88 Series manual

ETC

ETC Unison Echo E-OCC-SR installation guide