Dinel DLS-27 Series User manual

Read carefully the instructions published in this manual before the rst use of the level meter. Keep the manual

at a safe place. The manufacturer reserves the right to implement changes without prior notice.

průmyslová elektronika

1 . Basic description ..................................................................................................................... 3

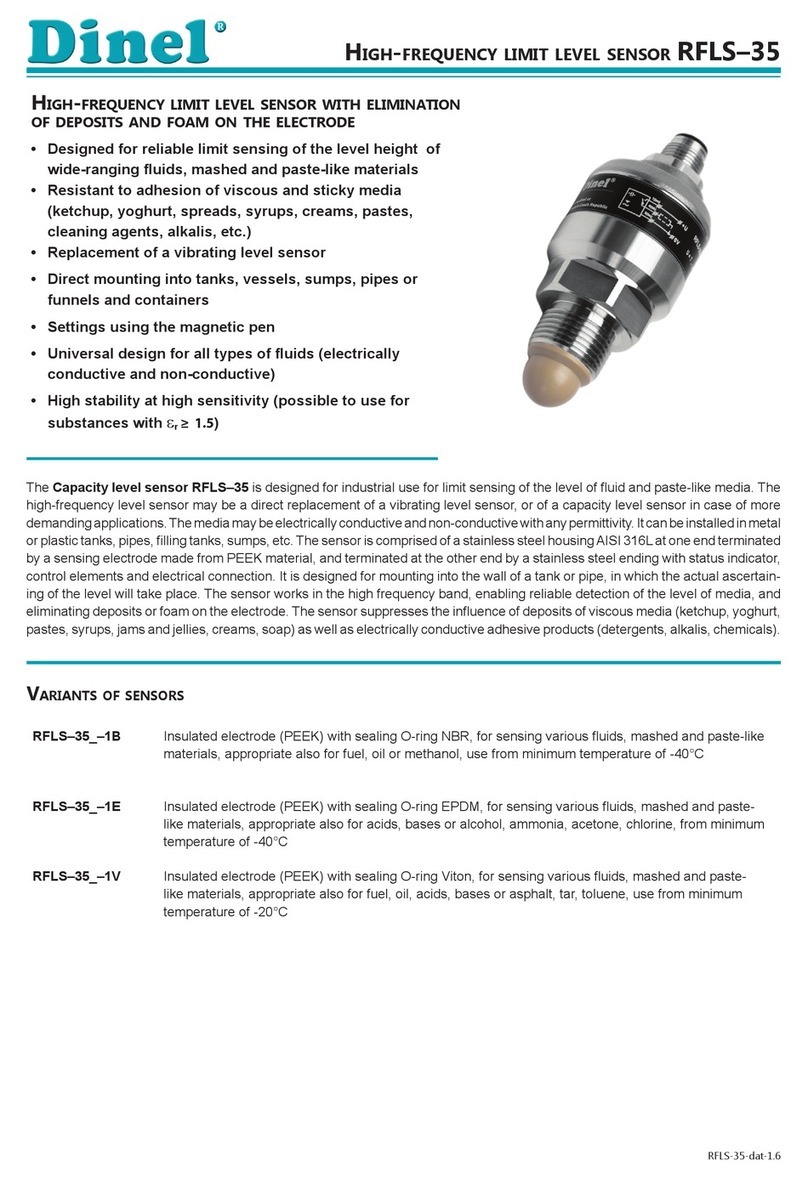

2 . Variants of sensors .................................................................................................................. 4

3 . Dimensional drawing ................................................................................................................ 5

5 . Mechanical mounting ............................................................................................................... 6

4 . Installation and putting into operation ...................................................................................... 6

6 . Range of application and installation of individual variants ...................................................... 12

7 . Electrical connection ................................................................................................................ 13

8 . Settings .................................................................................................................................... 15

9 . Function and status indication .................................................................................................. 16

10 . Order code ............................................................................................................................. 17

11 . Correct specication examples .............................................................................................. 17

12 . Accessories ............................................................................................................................ 18

13 . Safety, protections, compatibility and explosion proof ........................................................... 18

14 . Use, manipulation and maintenance ...................................................................................... 19

15 . General, conditions and warranty .......................................................................................... 20

16 . Marking of labels .................................................................................................................... 20

17. Technical specications.......................................................................................................... 23

18 . Packings, shipping and storage ............................................................................................. 26

19 . FAQ (Frequently asked questions) ........................................................................................ 27

DLS–27 © Dinel, s.r.o.

3

Capacitive level sensors DLS® are designed for limit sensing of the level of liquid and bulk

solids in tanks, sumps, tubes or, hoppers, silos, etc. The sensors are manufactured in several

modications of sensing electrodes (rod and rope). The electrodes can be given an insulating

coating, a useful feature in case of adhesive, aggressive or conductive media sensing. Rod

electrodes are also available in a version with reference tube for measuring uids in tanks made

from non-conductive material.

Sensors are manufactured in the following congurations: N – for non-explosive areas, Xd –

For use in ammable dust atmospheres; Xi – Explosion proof – intrinsically safe for hazardous

(explosive) areas and XiM – Explosion proof – intrinsically safe for use in mines with methane

or ammable dust presence danger (see technical specications). There are high temperature

performance NT, XiT, XiMT available and various types of process connection (metric and pipe

thread, jointless connection Tri-clamp).

To ensure maximum safety of control processes, we have dened the following safety instructions

and information. Each instruction is labelled with the appropriate pictogram.

This symbol informs you about particularly important instructions for installation and operation of

equipment or dangerous situations that may occur during the installation and operation. Not observing

these instructions may cause disturbance, damage or destruction of equipment or may cause injury.

This symbol indicates particularly important characteristics of the device.

This symbol indicates helpful additional information.

Alloperationsdescribed in this instructionmanualhave to becarriedout by trained personnel

or by an accredited person only. Warranty and post warranty service must be exclusively

carried out by the manufacturer.

Improper use, installation or set-up of the sensor can lead to crashes in the application.

The manufacturer is not responsible for improper use, loss of work caused by either direct

or indirect damage, and for expenses incurred at the time of installation or during the period

of use of the level sensors.

4

© Dinel, s.r.o. DLS–27

• DLS–27_–10 Uncoated short bar electrode for sensing non-adhesive bulk solids (sand,

sugar) and non-conductive liquids (petroleum products, oils), horizontal

mounting.

Electrode length 50 mm or 100 mm.

• DLS–27_–11 Fully coated short bar electrode, for sensing conductive liquids (water).

Horizontal mounting into tanks and tubes.

Electrode length 30 mm.

• DLS–27_–20 Semi-coated rod electrode for sensing slightly adhesive bulk solids

(cement, our) and non-conductive liquids (plant oils), horizontal, slant or

vertical mounting.

Electrode length from 0.1 m to 1 m.

• DLS–27_–21 Fully coated rod electrode (FEP insulation) for sensing conductive liquids

(water solutions, water), adhesive and aggressive materials, horizontal or ver-

tical mounting.

Electrode length from 0.1 m to 1 m.

• DLS–27_–22 Fully coated rod electrode (PFA insulation) with enhanced resistance,

for sensing aggressive conductive liquids and materials. Horizontal or vertical

mounting.

Electrode length from 0,1 m ... 1 m.

• DLS–27_–30 Dismountable uncoated rod electrode for sensing bulk solids and conduc-

tive or non-conductive liquids. Vertical or horizontal slant mounting.

Electrode length 0.1 m ... 3 m.

• DLS–27_–31 Fully coated rod electrode, for sensing aggressive conductive liquids (water,

various chemicals). Vertical mounting.

Electrode length from 0.1 m to 2 m.

• DLS–27_–40 Uncoated rope electrode and weight, for general purpose use in deeper

silos (bulk solids sensing – sand, gravel, cement) or sumps (sensing liquids).

Vertical mounting.

Electrode length from 1 m to 6 m.

DLS–27 © Dinel, s.r.o.

5

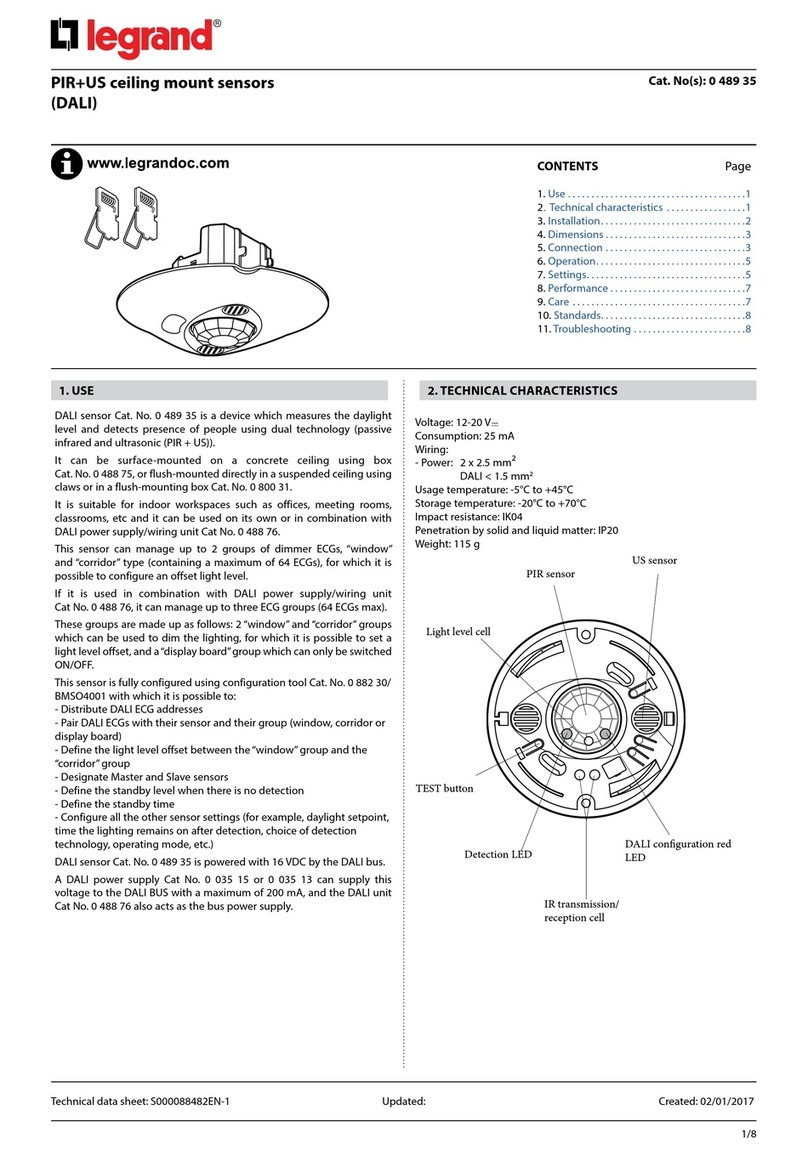

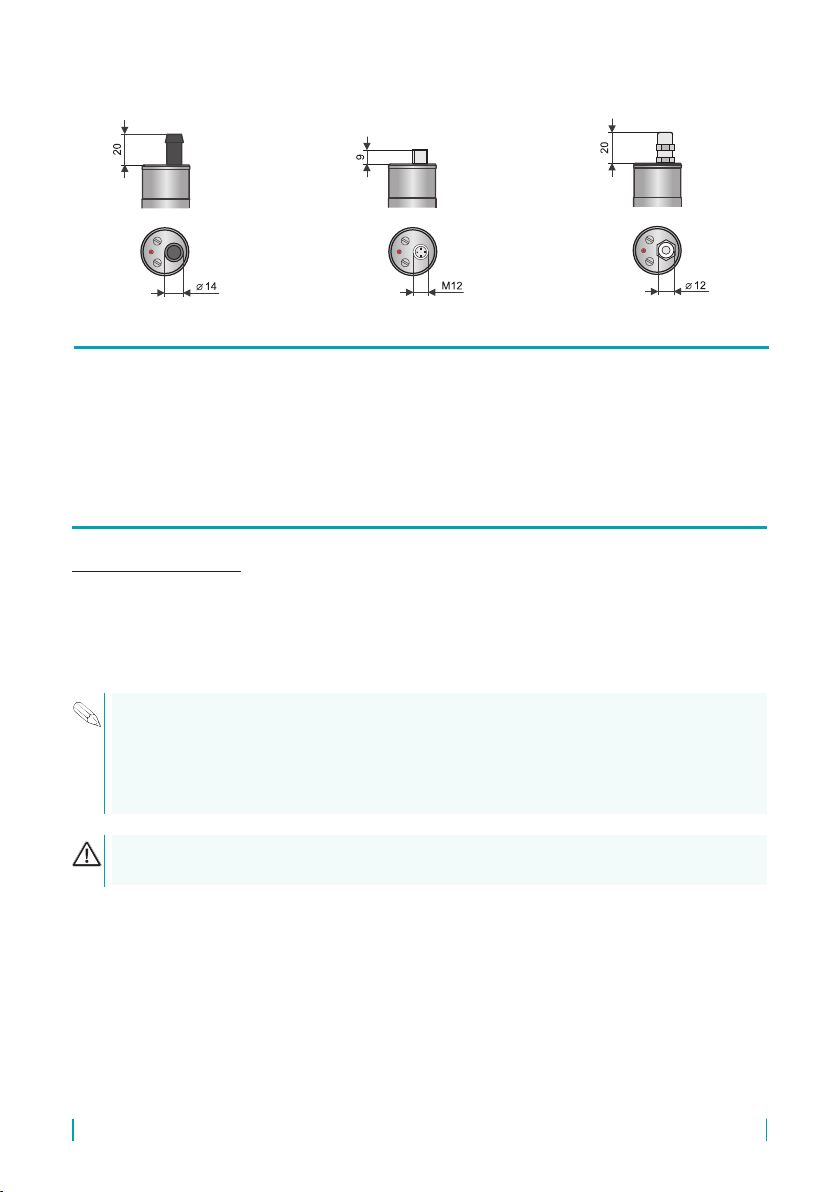

DLS – 27_ – 10 DLS – 27_ – 11 DLS – 27_ – 20 DLS – 27_ – 21, 22 DLS – 27_ – 30

DLS – 27_ – 31 DLS – 27_ – 40 High tempera-

tures variants

Tri-clamp

thread *

* Type of threads: G 3/4''

M27x2

M30x1,5

connection **

** connection:

Tri-Clamp CI34 (ø 34 mm)

6

© Dinel, s.r.o. DLS–27

Variants “C” with

connector

Variants “D” with

cable outlets

Variants “B” with cable

outlets

• DLS® level sensors can be xed in a vertical, horizontal or slanted position into the wall of

a vessel, storage tank or on a xation console in a sump by screwing into the welding ange,

using a xing nut or TriClamp® process connection.

• Basic application recommendations are mentioned below.

During assembly into the metal tank or the storage tank, it is not necessary to separately ground

the base of the level sensor. In case of installation in concrete sumps or silos, it is appropriate to

install the level sensor onto a metallic auxiliary construction (console, lid, etc.), and then connect to

ametallic, constantly submergedobject,or withsteelwith steelreinforcementsin concrete (armouring).

In the case of the reading of an aggressive medium, we recommend that the producer be consulted

If the sensors are tted with protective caps at the ends of the electrodes, remove the caps

before commissioning.

Please follow next 3 steps:

DLS–27 © Dinel, s.r.o.

7

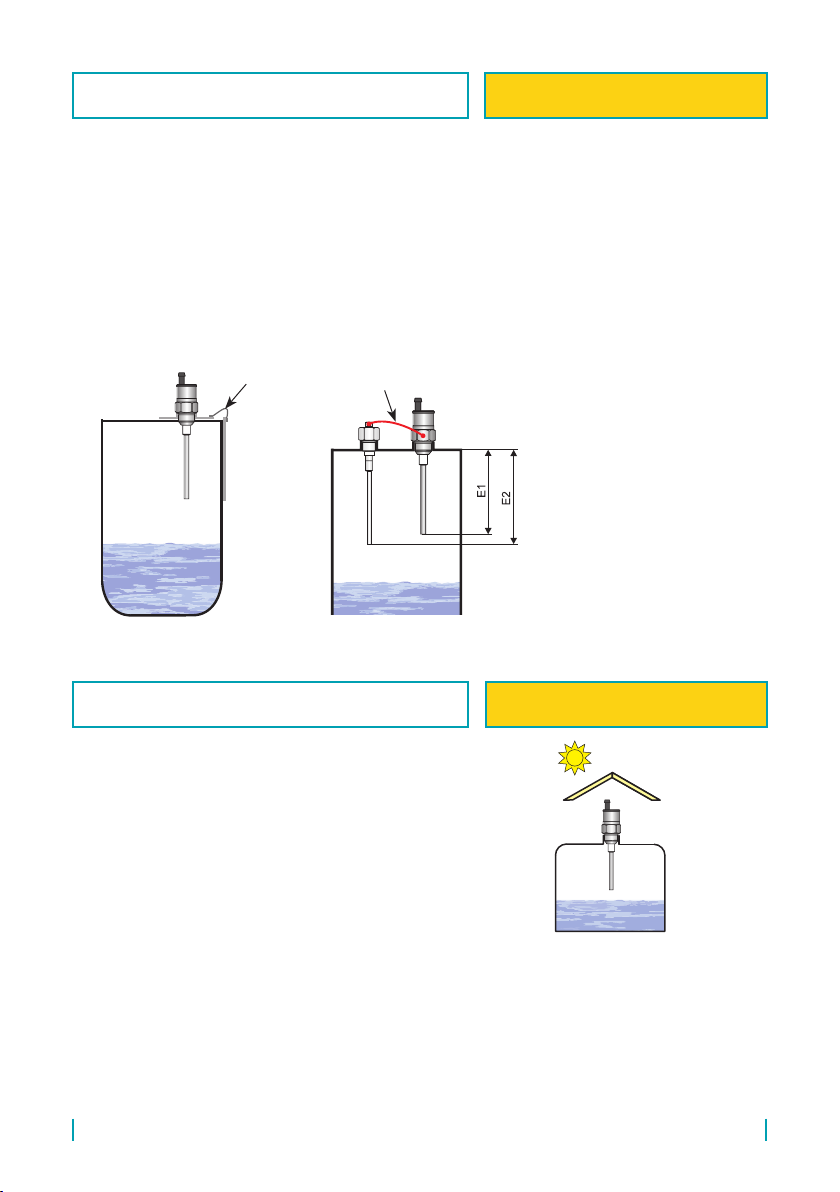

Fig. 1: Vertical mounting

In case of vertical mounting, sensors can be mounted

into open, closed and pressurized tanks. The stated dis-

tances relate to the electrode length (longer electrode).

mm20050h

E

3

2

m

E

4

3

p

E

3

4

s

E

3

1

E

10

1

a

20

E

40b

50

E

10c

40

E

40d

20

E

20k

mm20050h

E

3

2

m

E

4

3

p

E

3

4

s

E

3

1

E

10

1

a

20

E

40b

50

E

10c

40

E

40d

20

E

20k

mm20050h

E

3

2

m

E

4

3

p

E

3

4

s

E

3

1

E

10

1

a

20

E

40b

50

E

10c

40

E

40d

20

E

20k

E– Electrode length in mm

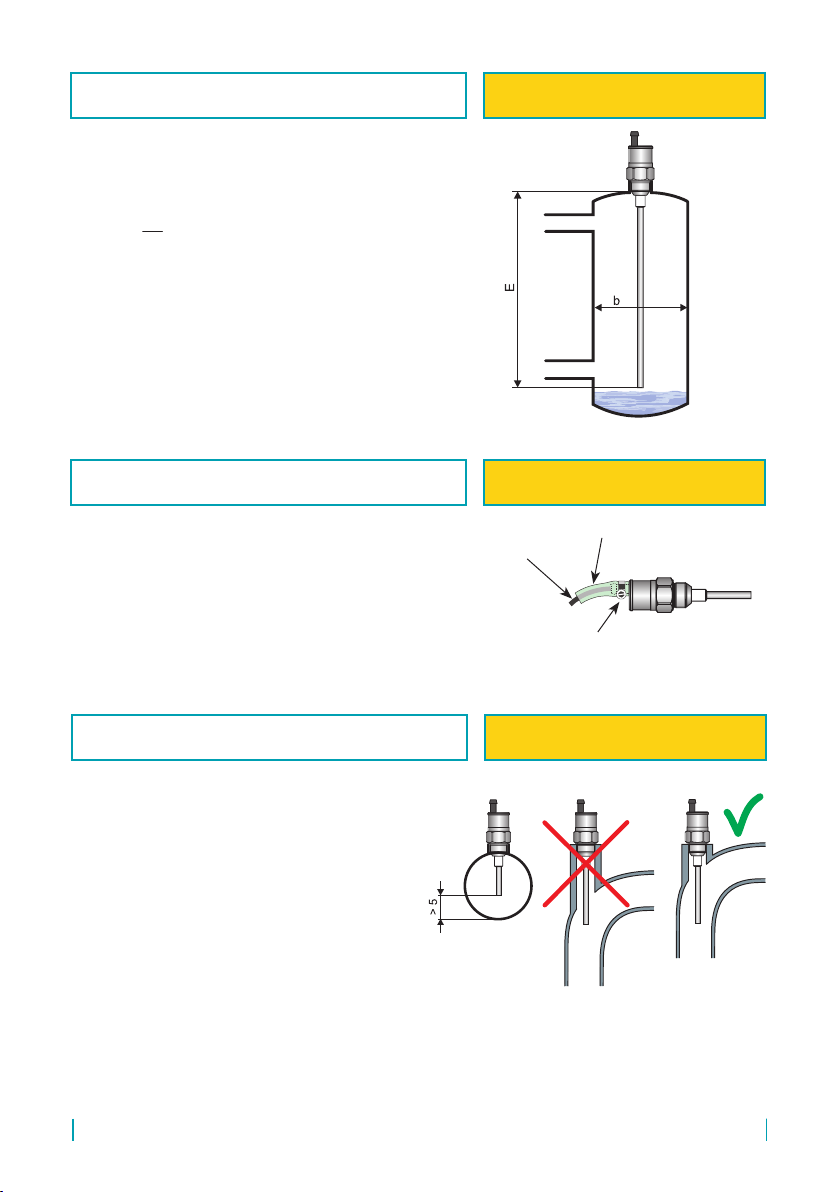

In case of side wall mounting (Fig.

3), place the sensor outside the ow

of bulk solids or liquids.

Fig. 3: Correct and incorrect installation

into storage tank side wall

In the case of side wall mounting. it

is necessary to avoid long tting tubes,

where sensed medium could accumulate

(g. on right). We recommend mounting

the sensor so that the whole sensing elec-

trode and insulation is inside the storage

tank (Figure 2 – on left).

Fig. 2: Correct and incorrect installation

with a long tube

VERTICAL MOUNTING FOR TYPE: All vertically mounted

sensors

CORRECT AND INCORRECT INSTALLATION

WITH A LONG TUBE

FOR TYPE: All from side mounted

sensors

CORRECT AND INCORRECT INSTALLATION

INTO STORAGE TANK SIDE WALL

FOR TYPE: All side mounted sen-

sors

8

© Dinel, s.r.o. DLS–27

mm20050h

E

3

2

m

E

4

3

p

E

3

4

s

E

3

1

E

10

1

a

20

E

40b

50

E

10c

40

E

40d

20

E

20k

mm20050h

E

3

2

m

E

4

3

p

E

3

4

s

E

3

1

E

10

1

a

20

E

40b

50

E

10c

40

E

40d

20

E

20k

mm20050h

E

3

2

m

E

4

3

p

E

3

4

s

E

3

1

E

10

1

a

20

E

40b

50

E

10c

40

E

40d

20

E

20k

Protective roof cover is recommended to

prevent mechanical damage of the sensor

electrode when vertical movement of ma-

terial could damage the sensing electrode

(abrasive materials, bulk-solid materials

forming blocks, piece goods).

Fig. 4: Protective roof mounting

E– Electrode length in mm

In the case of slant wall mounting it is necessary to eliminate tting tubes, thereby reducing

medium sedimentation. The wrong example of mounting is shown in Figure 5 on the left. The ap-

propriate mounting on the auxiliary vertical plate is shown in the middle. In some cases the variant

is allowed as shown in Fig. 5 on the right. But this is recommended only for measuring bulk-solid

materials by a sensor of the DLS–27_–10 type, which do not mechanically damage the electrode

and do not form separate blocks.

DLS–27_–10

!

Fig. 5: Slant wall mounting

In case of vertical installation for sensing

the level of unknown (conductive and non-

conductive) liquids in tanks or sumps, it is

appropriate to bend the electrode into a right

angle. This will increase the local sensitivity

and accuracy of sensing the level at the spot

of the bend.

When weather conditions (wind, rain, snow)

clearly inuence the electrode (open sumps),

we recommend using types with an insulated

electrode (DLS-27_-21, 31).

h = 50 to 200 mm

Fig. 6: Bending of the electrode end to sense

unknown uids

PROTECTIVE ROOF MOUNTING FOR TYPE: DLS–27_–10 and DLS–

27_–20

SLANT WALL MOUNTING FOR TYPE: DLS–27_–10 and DLS–

27_–20

BENDING OF THE ELECTRODE END TO SENSE

UNKNOWN FLUIDS FOR TYPE: DLS–27_–30

DLS–27 © Dinel, s.r.o.

9

max.

min.

E

a

b

k

d

m

p

s

E

h

> 5

E1

E

E

c

E2

Conductive probe

CNP–18

Electrically connect

Auxiliary plate

electrode PDE-27

E2 = E1+50

E1, E2 – Electrode length in mm

Fig. 7: Auxiliary electrode in non-conductive tanks

In the case of the application of the sensor in an electrically non-conductive (e.g. plastic) vessel

in the vertical position, then for the correct function, it is recommended to connect the housing of

the level sensor with an auxiliary electrode. The auxiliary electrode can consist of a bar which is

permanently dipped into the medium (e.g. conductive probe CNP–18), or can be use the auxiliary

plate electrode (PDE-27), where the rst part has thread for install of the sensor and the second part

is installed from the side on the wall into the area for the expected switching of the level sensor. Both

parts of PDE-27 are connected by steel wire. The area of the plate auxiliary electrode is a minimum

200 cm2. For non-conductive liquids, the only variation possible is with the plate auxiliary electrode

and in this case it is necessary to place the level sensor to prevent the movement of electrodes and

the axis is at the distance of lmax = E1/10, lmin = 20 mm.

The level meter must not be installed in locations exposed

to direct solar radiation and must be protected against

the eects of weather. In the event that installation in a

location with direct solar radiation is unavoidable, it is

necessary to install a shielding cover above the level

meter.

Fig. 8: Solar radiation shielding cover

AUXILIARY ELECTRODE IN NON-CONDUCTIVE

TANKS

FOR TYPE: DLS–27_–20, 21, 22,

30, 31

SOLAR RADIATION SHIELDING COVER FOR TYPE: All type

10

© Dinel, s.r.o. DLS–27

Cable

PVC hose

Hose clip

Fig. 10: Protective hose install

mm20050h

E

3

2

m

E

4

3

p

E

3

4

s

E

3

1

E

10

1

a

20

E

40b

50

E

10c

40

E

40d

20

E

20k

Mounting in a bypass measuring tube. We rec-

ommend upholding the tube diameter.

E– Electrode length in mm

Fig. 9: Bypass measuring tube

In the case of mounting in the pipe it is nec-

essary to provide the minimum distance of the

inner walls from the electrode at 5 mm. In some

cases (sticky liquids, low permittivity liquids) it

is better to mount the sensor into a pipe bend.

Fig. 11: Sensor mounting in a tube

If the sensor is placed vertically in an outdoor

environment or in the event of increased mechanical

stress, it is recommended to install a 15/10 mm PVC

protective hose on the "B" cable.

BYPASS MEASURING TUBE FOR TYPE: DLS–27_–20, 21, 22,

30, 31

PROTECTIVE HOSE INSTALL FOR TYPE: All sensors with cable

outlets

SENSOR MOUNTING IN A TUBE FOR TYPE: DLS–27_–10, 11, 21, 22

DLS–27 © Dinel, s.r.o.

11

In the case of vertical mounting it is possible

to use hysteresis setting for simple two state

regulation (pump control). The height of the

controlled level is done by sensitivity setting, the

gap between the min. and max. is dened by

hysteresis.

E– Electrode length in mm

In the case of vertical mounting especially on

existing tanks, it is necessary to select the pipe

length as short as possible to avoid vapour con-

densation, or sedimentation of impurities. A simi-

lar situation occurs when the sensing electrode

goes through the concrete ceiling of the silo. The

hole diameter should be at least 50 mm (based on

ceiling thickness).

Fig. 12: Two-state level regulation by

hysteresis setting

Fig. 13: Long tting tubes in vertical mounting

mm20050h

E

3

2

m

E

4

3

p

E

3

4

s

E

3

1

E

10

1

a

20

E

40b

50

E

10c

40

E

40d

20

E

20k

÷=

≈

≈

≈

÷≈

+≥=

+≥=

+≥=

+≥=

TWO-STATE LEVEL REGULATION BY HYSTER-

ESIS SETTING

FOR TYPE: DLS–27_–20, 21, 22,

30, 31

LONG FITTING TUBES IN VERTICAL MOUNT-

ING

FOR TYPE: All vertically mounted

sensors

12

© Dinel, s.r.o. DLS–27

Produced in two versions – with 50 mm or 100 mm electrode. The shorter version (E50) is suitable

for clean non-conductive liquids level sensing (oils, diesel, petrol, etc.). The longer version (E100) is

designed for non-adhesive bulk solids or non-adhesive powder materials (plastic granulates, sand,

sugar, grains, detergents, etc.) and other slightly impure, non-conductive liquids (lubricants, plant oils).

The sensor is specied to be mounted directly into a vessel or storage tank wall (best by horizontal

position) by means of welding anges or stainless steel xing nuts. In case of level sensing of low-

permittivity media in non-metal storage tanks, we recommend mounting the sensor on an auxiliary

metal-plate electrode with min. area of 200 cm2.

Specied for level sensing of conductive liquids (water and water solutions). It can be used to identify

the boundary between uids with diering permittivity (e.g. water – oil). The sensor is mounted directly

into the side wall of the vessel or in a pipe (horizontal position) by means of a standard steel or

stainless steel welding ange.

Designed for limit level detection of bulk solids with low specic weight and permittivity (cement,

hydrated lime, our), and for materials expected to have changing properties (y ash, sawdust, feed

mixtures, etc.). It is possible to use it for sensing non-conductive liquids containing a small amount of

water (up to 2%) or other impurities (plant oils, liquid propane, etc.). The sensor is mounted directly

into the wall of a vessel or storage tank using steel welding anges or xing nuts horizontally, slanted

from the side or vertically. It is recommended to mount a sensor with an electrode longer than 300

mm only in the vertical position. Hollow spaces should be minimized between the electrode and the

wall where the sensed material can accumulate (see application notes). In non-metal storage tanks,

we recommend mounting the sensor on an auxiliary metal-plate electrode with min. area of 400 cm2.

Specied for conductive liquids level sensing (water, water solutions, mud, etc.). It reacts to partial

or full immersion of the electrode (depending on the adjusted sensitivity). The lower the sensitivity,

the higher the sensor’s resistance to contaminants and clinging remnants of material. The sensor

with electrode length of up to 200 mm can be desensitized to complete water immersion, so it can be

operated in the horizontal position. The sensor can be operated in the vertical position with any length

up to 1 m. The sensor is mounted directly into the wall of the tank in horizontal or vertical position by

applying a steel or stainless steel welding ange. For variant “22”, the material PFA is used to insulate

the electrode.

Designed for sensing conductive and non-conductive liquids and bulk solids. It is not recommended

to install the sensor into closed vessels (storage tanks) where intensive water vapour condensation

occurs. The sensor reacts to electrically conductive liquids just by touch of the end of electrode.

To react to a non-conductive liquid (bulk solid), it is necessary to have 5 ÷ 20% immersion of the

electrode according to the sensor’s adjusted sensitivity and permittivity of the sensed material. The

sensor is mounted directly into a tank, hopper or sump in slant or vertical position by means of weld-

ing ange or stainless steel xing nut. In non-metal storage tanks, we recommend mounting the

sensor on an auxiliary metal-plate electrode with min. area of 500 cm2.

DLS–27 © Dinel, s.r.o.

13

Designed for limit level detection of conductive liquids (water and solutions of various chemicals).

It is possible to place the sensor electrode into closed vessels (storage tanks), open canals and

sumps. The sensor reacts to the conductive uid level after 2 ÷ 20% immersion of the electrode based

on the sensor’s set sensitivity. The sensor is mounted vertically directly into a vessel, tank or open

(concrete, plastic) sumps by means of welding anges or xing nuts. When installing the sensor into

open sumps, it is necessary to secure conductive connection of the sensor housing with the sensed

liquid. It is possible to use a metal structure, armouring or another auxiliary electrode. If you must

sense an aggressive medium in a closed plastic container, contact the manufacturer.

For sensing conductive and non-conductive liquids and bulk solids at greater depths (sewerage

sumps, shafts, wells, cement storage tanks, sand, gravel, etc.). It is not appropriate to place the

sensor electrode into closed containers (storage tanks) where intensive condensation of water vapour

occurs. The sensor reacts to electrically conductive liquids just by touch of the end of electrode.

To react to non-conductive liquid or bulk solid, a 5 ÷ 20% immersion into the material is necessary

based on the sensitivity set on the sensor and the permittivity of the sensed material. The sensor is

mounted vertically directly into the wall of a storage tank or sump. For open (concrete) sumps, it can

be mounted on an auxiliary metal structure conductively connected with the sensed material. For

mounting, you can use supplied welding anges or xing nuts..

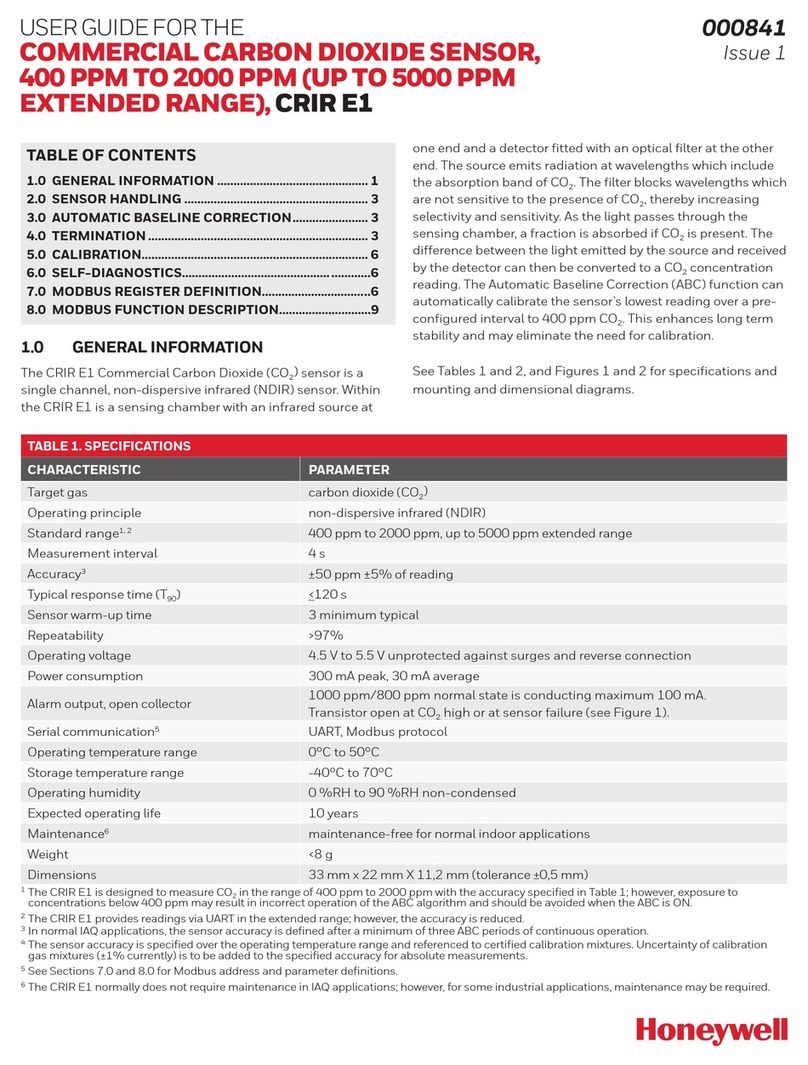

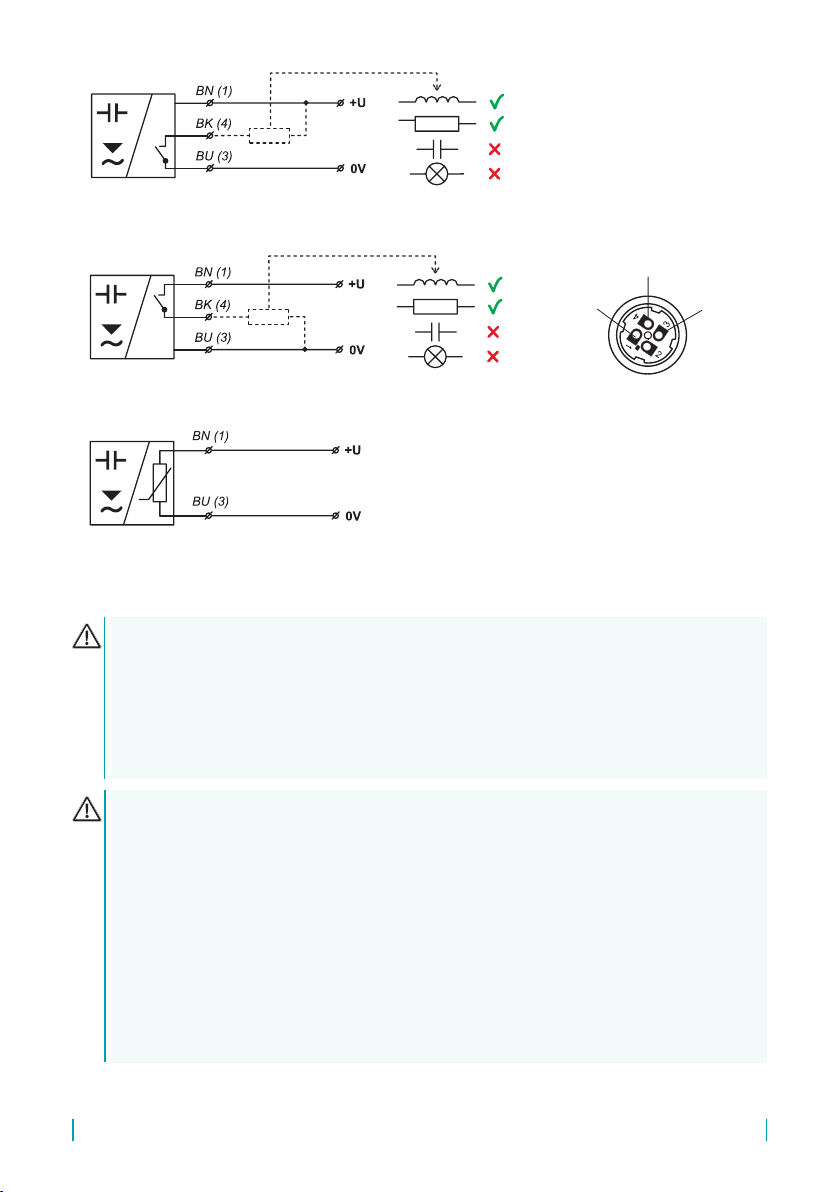

Sensor with NPN or PNP output is allowed to lead only by resistive or inductive lead. Positive

supply voltage (+U) is connected to the brown conductor BN (1), negative (0 V) to the blue

conductor BU (3) and the leads (only NPN or PNP type of output) to the black conductor BK (4).

The capacity loads and low resistance loads (bulb) is evaluated by the sensor as short circuit.

Version Xd is manufacture only with xing cable (variants “D” with cable outlets). The end of this

cable must be in terminal box with protection class IP6x.

For “B” and “D” variants with the xed cable, the individual colour cores of the connecting cable

are connected to the respective terminals of the related equipment (supply unit) see Fig. 14 to 16.

For “C” variant with the connector, the cable can be supplied with the sensor (length 2 or 5 m),

tted with the pressed connector socket or dismountable connector socket without the cable (see

accessories), the connector is not part of the sensor. In this case the cable is connected to the

inside pins of the socket according to Fig. 17.

The sensor with related equipment is interconnected by a suitable three-core (N and Xd variations)

or two-core (Xi, XiT, XiM, XiMT variations) cable. The length of the cable for the Xi, XiT, XiM,

XiMT variations must be selected with respect to the maximum permitted parameters (usually

inductance and capacity) of the outside intrinsically safe circuit of supply units (NSSU, NDSU,

NLCU).

If using a dismountable connector socket, the outside diameter of the cable is a maximum of

6 mm.

14

© Dinel, s.r.o. DLS–27

Electrical connection can only be made when de-energized!

The source of the power voltage must comprise of a stabilised safe low power source with

galvanic separation. In the event that a switch-mode power supply is used, it is essential

that its construction effectively suppresses common mode interference on the secondary

side. In the event that the switch-mode power supply is equipped with a PE safety terminal,

it must be unconditionally grounded! Spark-safe devices type DLS–27Xi(XiT, XiM, XiMT) must

be powered from a spark-safe power source meeting the above-mentioned requirements.

Legend:

(1,...) – numbers of terminals inside

the connector socket

BK – Black

BN – Brown

BU – Blue

output (BK)

0V (BU)

+U (BN)

Fig. 14: NPN output type sensor connection

(conguration N, NT, Xd)

Fig. 15: PNP output type sensor connection

(conguration N, NT, Xd)

Fig. 16: Connection of a sensor with a NAMUR

type output (conguration Xi, XiM, XiT, XiMT)

Fig. 17: Inside of the connector

socket

Due to the possible occurrence of an electrostatic charge on the non-conductive parts of

the sensor, it is necessary to ground all sensors intended for use in environments with an

explosionhazard DLS–27Xi(XiT,XiM, XiMT) andDLS-27Xd. This canbeperformed bygrounding

el. conductive tanks or el. conductive tank lids, and in the case of el. non-conductive tanks

using and grounding an auxiliary plate electrode PDE-27.

In the event that the level meter (sensor) is installed in an outdoor environment at a distance

greater than 20 m from the outdoor switchboard, or from an enclosed building, it is necessary

to supplement the electrical cable leading to the level meter (sensor) with suitable overvoltage

protection.

In the event of strong ambient electromagnetic interference, paralleling of conductors with

power distribution, or for distribution to distances over 30 m, we recommend using a shielded

cable and grounding the shielding on the side of the power source.

DLS–27 © Dinel, s.r.o.

15

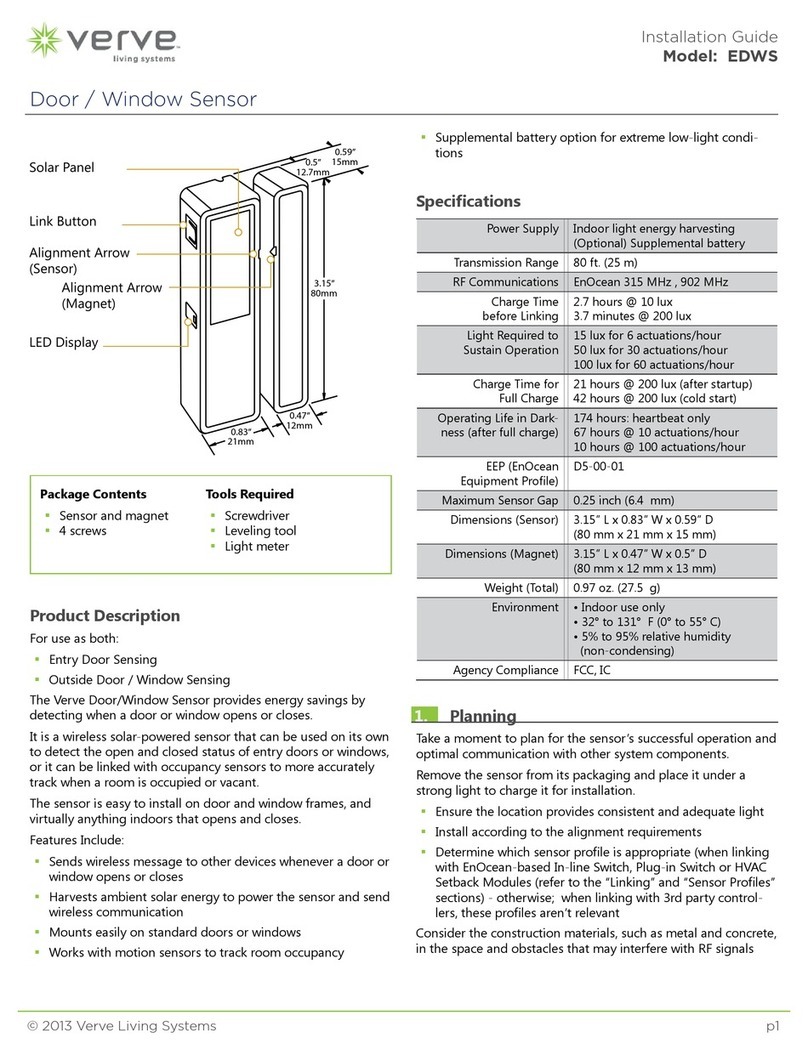

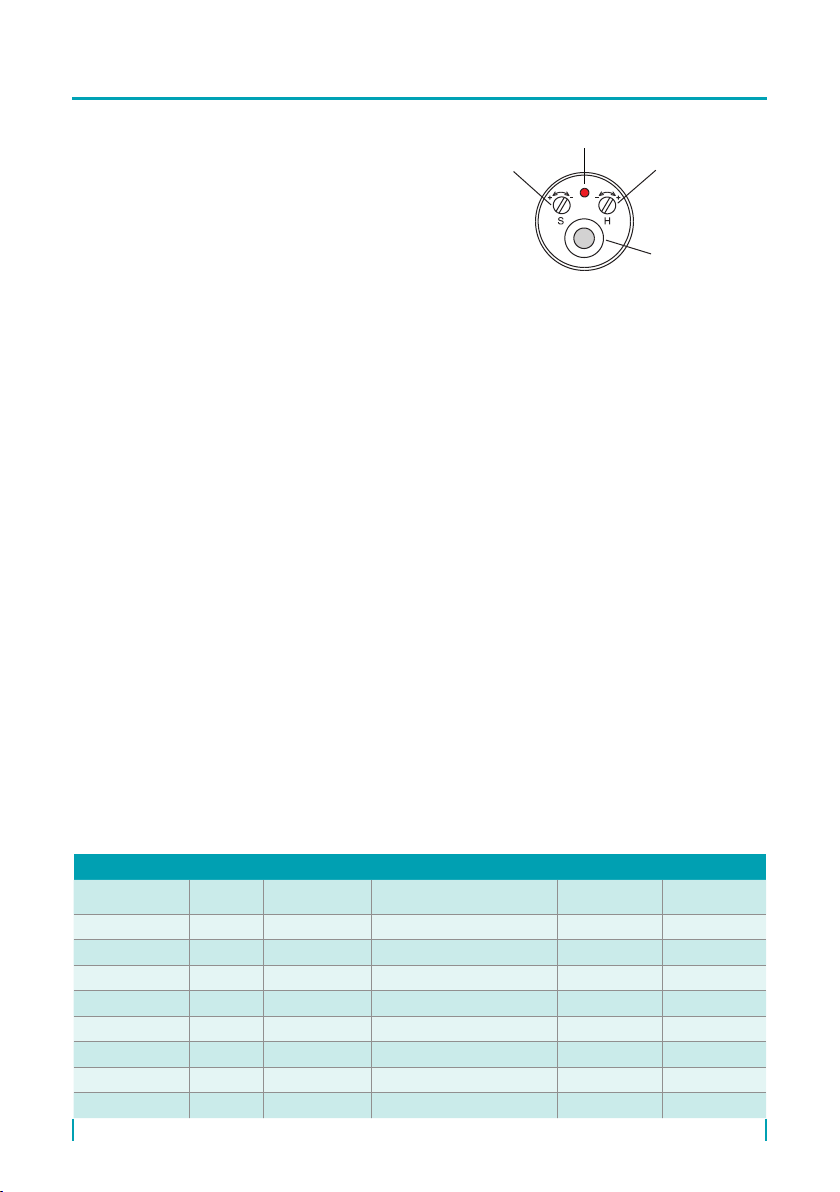

The sensitivity and hysteresis of the level sensor

are set by trimmers “S” and “H” located under the

left cover screw on the rear side.

The basic sensitivity and hysteresis is factory

adjusted and is suitable for most applications.

The sensitivity is set by trimmer “S” located under

the left cover screw on the rear side. Clockwise

turning makes the sensitivity lower, reverse

direction turning makes the sensitivity higher.

If the sensed medium is at your disposal before

setting into service it is useful to provide individual

setting as follows. In this way it is possible to achieve resistance against sediments.

1. The sensor is activated by immersion (by pouring, by ooding) the whole electrode or its part

into the sensed media. By activating the sensor changes its status (LED lights up or goes out).

2. Reduce the sensitivity (by turning the trimmer "S" to the right) until the sensor just stops

responding to this activation (immersion in the media). The LED indication is now in the same

state as before activation.

3. From this point, turn the "S" trimmer 0.5 to 1 turn (depending on the type and length of the

electrode) to the left. The sensor changes the status again and reacts to the activation (ooding)

again.

4. Verify the function by a re-activation of the sensor and watch the sensor behavior.

If the medium is not available in advance, it is possible to use the basic setting from the producer

and after some time of operation (after sedimentation of dirt) to make any correction. However,

it is always necessary to know what the permittivity of the material is and to adapt the setting on

the sensor. In the “Sensitivity characteristics” table it is stated for each type, where the change

of capacity corresponds to the 1 rotation. A denite guide can be the fact that the ooding of the

electrode in the length of 100 mm into the material with relative permeability Ɛr = 2 will cause a

change in the capacity about 1.5 to 2 pF (according to the type of electrode).

The hysteresis (position of the minimum and maximum level) can be changed by turning trimmer

“H” located under the right cover screw on the rear side. Clockwise turning makes the hysteresis

higher, reverse direction turning makes it lower. The lower the hysteresis is, the higher sensitivity is

possible to obtain, but the resistance against various disturbances get worse. For usual applications

is optimal hysteresis from ¼ to ¾ rotation of sensitivity trimmer.

After setting, it is necessary to properly tighten cover screws.

LED

Hysteresis

Cable outlet

or connector

Fig. 18: Top view of level sensor

Sensitivity

Type of sensor Treshold

sensitivity Hysteresis Sensitivity adjusting range Temperature

stability

Rel. permittivity

of material

DLS–27_–10 0,1 pF 0,1 pF ... 2 pF min. 8 pF (1 ot. = 1 pF) ± 0,004 pF/K min. 1,4

DLS–27_–11 0,2 pF 0,2 pF ... 4 pF min. 20 pF (1 ot. = 2 pF) ± 0,007 pF/K min. 5,0

DLS–27_–20 0,1 pF 0,2 pF ... 3 pF min. 15 pF (1 ot. = 1,5 pF) ± 0,006 pF/K min. 1,3

DLS–27_–21 0,3 pF 0,3 pF ... 6 pF min. 30 pF (1 ot. = 3 pF) ± 0,01 pF/K min. 4,0

DLS–27_–22 0,3 pF 0,3 pF ... 6 pF min. 30 pF (1 ot. = 3 pF) ± 0,01 pF/K min. 4,0

DLS–27_–30 0,2 pF 0,2 pF ... 4 pF min. 20 pF (1 ot. = 2 pF) ± 0,01 pF/K min. 1,6

DLS–27_–31 0,3 pF 0,2 pF ... 5 pF min. 25 pF (1 ot. = 2,5 pF) ± 0,01 pF/K min. 5,0

DLS–27_–40 0,3 pF 0,2 pF ... 6 pF min. 20 pF (1 ot. = 2 pF) ± 0,01 pF/K min. 2,0

16

© Dinel, s.r.o. DLS–27

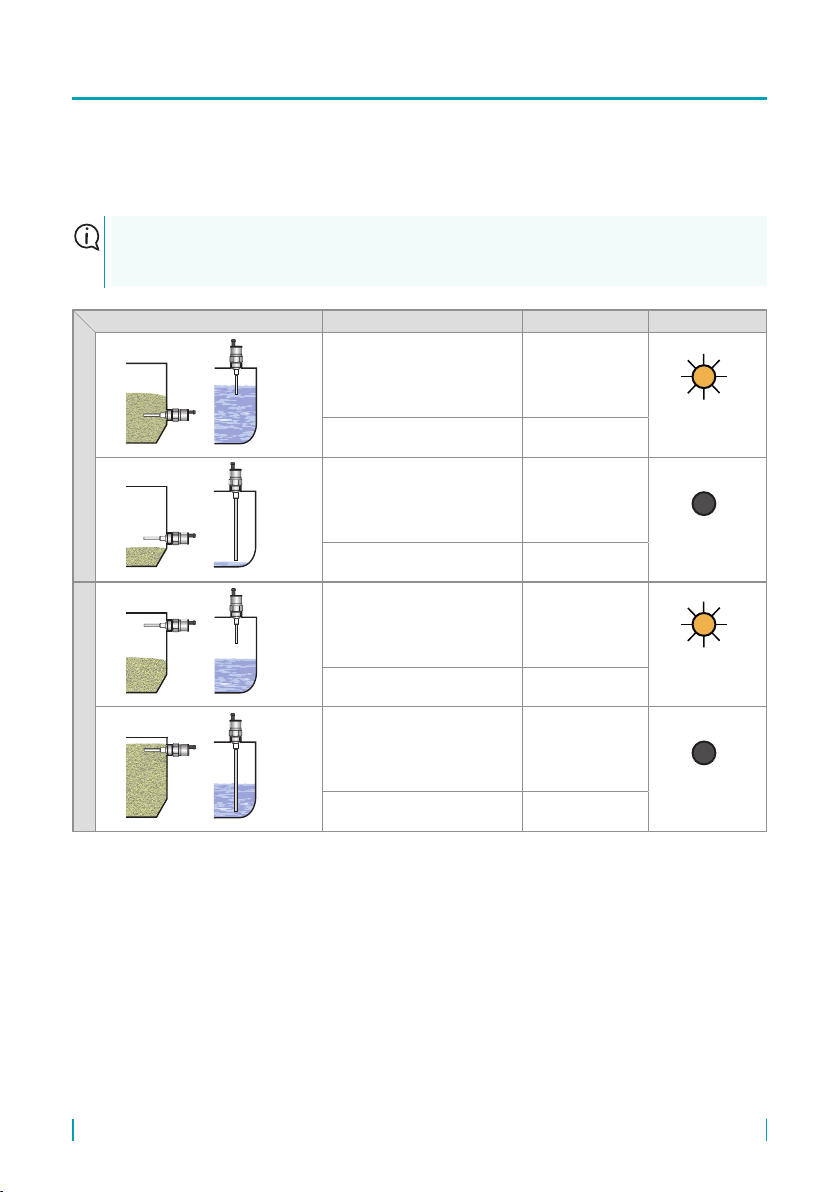

In the following table are the types of inputs and the respective statuses (ON/ OFF) in the case of

a maximum and minimum level sensing. The signalling of the status of the sensor is indicated by

the red LED located on the upper area of the sensor beside the setting trimmers of the hysteresis

(“H”) and the sensitivity (“S”).

For minimum level sensing we recommend sensor with normally open output – NO, PO, RO. It is

for failure safety reasons – eventual failure of sensor behaves similarly as an exceeding of the limit

state.Analogically for maximum level sensing we recommend normally closed outputs – NC, PC, RC.

Level state Type of output Output state LED

Minimum level sensing

DLS–27N_–_ _– _ –NO–_

DLS–27Xd –_ _–D–NO–_

DLS–27N_–_ _– _ –PO–_

DLS–27Xd –_ _–D–PO–_

CLOSED

(Shine)

DLS–27Xi–_ _– _ –RO–_ HIGHER

CURRENT

DLS–27N_–_ _– _ –NO–_

DLS–27Xd –_ _–D–NO–_

DLS–27N_–_ _– _ –PO–_

DLS–27Xd –_ _–D–PO–_

OPEN

(Dark)

DLS–27Xi–_ _– _ –RO–_ LOWER

CURRENT

Maximum level sensing

DLS–27N_–_ _– _ –NC–_

DLS–27Xd –_ _–D–NC–_

DLS–27N_–_ _– _ –PC–_

DLS–27Xd –_ _–D–PC–_

CLOSED

(Shine)

DLS–27Xi–_ _– _ –RC–_ HIGHER

CURRENT

DLS–27N_–_ _– _ –NC–_

DLS–27Xd –_ _–D–NC–_

DLS–27N_–_ _– _ –PC–_

DLS–27Xd –_ _–D–PC–_

OPEN

(Dark)

DLS–27Xi–_ _– _ –RC–_ LOWER

CURRENT

DLS–27 © Dinel, s.r.o.

17

DLS–27N–10–B–NO–M27 E100 cable 5 m

(N) Normal performance; (10) Uncoated bar electrode; (B) Cable outlet with 5 m length cable; (NO) Output type NPN with

open state at non-activated electrode; (M27) Metric thread M27x2 process connection; (E100) Electrode length 100 mm

DLS–27NT–21–C–PC–G E580

(NT) High temperature performance; (21) Fully coated rod electrode (FEP); (C) Connector; (PC) Output type NPN with

closed state at non-activated electrode; (G) Pipe thread G3/4" process connection; (E580) Electrode length 580 mm.

DLS–27Xi–30–C–RO–M30 E1420

(Xi) Explosion-proof performance; (30) Dismountable uncoated electrode; (C) Connector, (RO) Output type NAMUR

with lower current at non-activated electrode, (M30) Metric thread M30x1.5 process connection; (E1420) Electrode

length 1420 mm.

DLS–27Xd–20–D–NC–G E430 cable 3 m

(Xd) Flammable dust areas performance; (20) Partly coated electrode; (D) Cable outlet; (NC) Output type PNP with

closed state at non-activated electrode; (M30) Metric thread M30x1,5 process connection; (E430) Electrode length

430 mm.

process connection:

type of output: N – NPN (open collector)

P – PNP (open collector)

R – NAMUR (change in supply current)

connection method: B – cable outlet (+ cable length)

C – connector (socket not included with

sensor, recommended type - see ac-

cessories.)

D – cable outlet (+ cable length)

type and performance of electrode:

mech. performance:

N – non-explosive areas

NT – high temperature performance

Xd – use in ammable dusts areas

(only var. “D”) only for type 10, 20, 30, 40

Xi – for explosive environments

XiM – for mining environments

XiT – high-temperature conf. for explosive environments

XiMT – high-temperature conf. for mining environments

10 – short bar, uncoated, lengths 50 or 100 mm

11 – short bar, fully coated, xed length 30 mm

20 – rod, partly coated, lengths 0.1 ... 1 m

21 – rod, coated (FEP), length 0.1 ... 1 m

22 – rod, coated (PFA), length 0.1 ... 1 m

30 – rod, uncoated coated, length 0,1 ... 3 m

31 – rod, coated (FEP), length 0,1 ... 2 m

40 – rope with weight, uncoated, length 1 ... 6 m

G– pipe thread G 3/4"

M27 – metric thread M 27x2

M30 – metric thread M 30x1,5

Cl34 – Tri-clamp (ø34 mm)

DLS – 27 – – – – E

electrode length in mm

cable – cable length in m

Output state at non activated electrode:

O – open (NAMUR – Lower current))

C – closed (NAMUR – Higher current)

18

© Dinel, s.r.o. DLS–27

optional – for a surcharge

(see catalogue sheet of accessories)

• Extra cables (over the standard length 2 m)

• Connector socket (type ELWIKA or ELKA)

• Normal steel welding ange ON –27x2

• Stainless steel welding ange NN–G3/4“

• Stainless steel xing nut UM–27x2

• Other seals (PTFE, Al, etc.)

• Auxiliary plate electrode PDE-27

standard – included in the level

sensor price

• 1 pcs. Seal (asbestos free) *

• 1 p c s . S c r e w d r i v e r f o r a d j u s t m e n t

(each 5 pcs.)

The level sensor is equipped with protection against electric shock on the electrode, reverse polarity,

output current overload, short circuit and against current overload on output.

Protection against dangerous contact is provided by low safety voltage according to EN

33 2000- 4- 41. Electromagnetic compatibility is provided by conformity with standards EN 55022 / B,

EN 61326-1, EN 61000-4-2 to -6.

Explosion proof DLS–27Xi (XiT, XiM, XiMT) is provided by conformity with standards EN 60079-

0:2013, EN 60079-11:2012.

Explosion proof DLS–27Xd is provided by conformity with standards EN 60079-0:2013, EN 60079-

11:2012, EN 60079-31:2014. Explosion proof DLS–27Xd is veried FTZÚ – AO 210 Ostrava –

Radvanice: FTZÚ 10 ATEX 0092X.

A declaration of conformity was issued for this device in the wording of Act No. 90/2016 Coll., as

amended. Supplied electrical equipment matches the requirements of valid European directives for

safety and electromagnetic compatibility.

If the apparatus is used as device of Group II and with using of an approved power supply device,

which output parameters comply with required input parameters, it is necessary to have an galvanic

separation or in case of apparatus without galvanic separation (Zener barriers) it is necessary to

provide equipotential equalizing between sensor and barrier earthing point.

If the apparatus is used in coal mine as device of Group I and with using of an approved power

supply device, which output parameters comply with required input parameters it is necessary to

have an galvanic separation.

When used in zone 0 the present explosive atmosphere of air mixture and gases, vapours of mists

must be comply with: 20°C ≤ Tamb ≤ 60°C, 0.8 bar ≤ p ≤ 1.1 bar.

Design DLS–27Xi can be used in zone 0 or zone 20. With design DLS–27XiT can be used in zone

0 and zone 20 only electrode part head with electronics can be used only in zone 1 or zone 21.

Ambient temperature: Tamb = -20°C to +75°C

Temperature of measured medium according to design variant see chapter “Specication”.

* Pressure resistance - see the

table in the accessories datasheet

in the "seals and gaskets".

DLS–27 © Dinel, s.r.o.

19

The level meter does not require any personnel for its operation. Maintenance of this equipment

consists in verication of integrity of the level meter and of the supply cable.

It is forbidden to make any changes or interventions to the DLS–27 sensor without the

consent of the producer. Any repairs must only be carried out by the producer or authorized

service organisations.

Assembly, installation, commissioning, service and maintenance of the DLS–27 level sensor

must be carried out in accordance with this manual and the provisions of valid standards

for the installation of electrical equipment must be complied with.

For design DLS–27XiMT it is necessary to observe that temperature of any surface of apparatus,

when coal dust can from a layer, do not exceed 150°C.

Ambient temperature: Tamb = -20°C to +70°C

The sensor DLS-27Xd is designed with permanent cable. The cable must be terminated in

connection box with degree of protection IP 6X.

The end of the sensor must be protected against direct daylight.

Maximum eective value of AC or DC voltage that can be applied to the terminals of device, which

are not intrinsically safe, without breaking the type of protection is Um = 253 V..

1. At the rope electrode, it is necessary to loosen three fastening screws on the weight

and to pull out the end of the rope, see g. 19.

2. Make sure that the rope length is correct after shortening – the rope is suspended

in the weight up to a distance of approximately 50 mm. Ideally, shorten the rope us-

ing diagonal cutting pliers. Be careful to prevent the end of the

cable from fraying.

3. Insert the end of the rope back into the weight and secure it in

place by tightening all three screws.

Fig. 19: Picture of the rope

with the weight

60

50

20

© Dinel, s.r.o. DLS–27

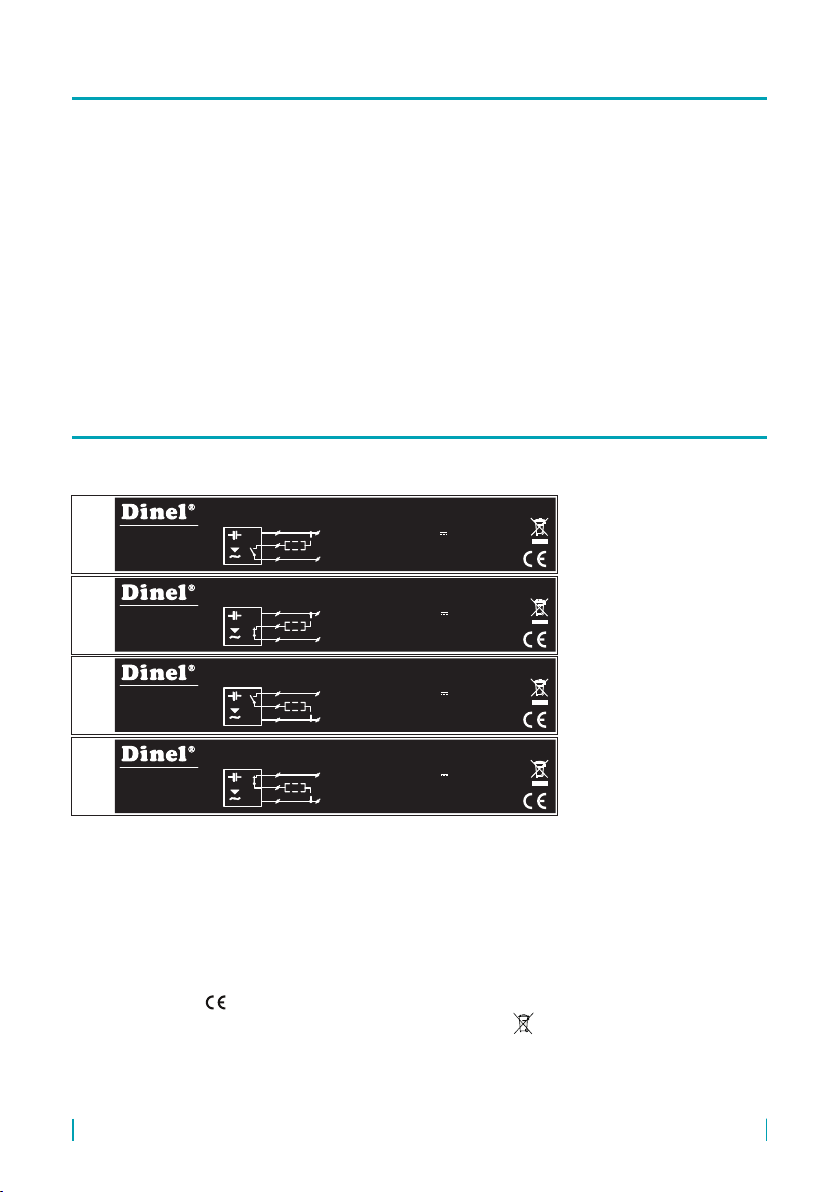

Labels for device of the type DLS–27N:

Dinel, s.r.o. guarantees for the period of three (3) years that the product has the characteristics as

mentioned in the technical specication.

Dinel, s.r.o. is liable for defects ascertained within the warranty period and were claimed in writing.

This guarantee does not cover the damages resulting from misuse, improper installation or incorrect

maintenance.

This guarantee ceases when the user or the other person makes any changes on the product or the

product is mechanically or chemically damaged, or the serial number is not readable.

The warranty certicate must be presented to exercise a claim.

In the case of a rightful complaint, we will replace the product or its defective part. In both cases, the

warranty period is extended by the period of repair..

U

I

U

I

7...36V

3/10mA

200 mA

7...36V

3/10mA

200 mA

BN

BU

BK

+U

0V

BN

BU

BK

+U

0V

Iomax

Iomax

BN

BN

BU

BU

BK

BK

+U

+U

0V

0V

U

I

U

I

7...36V

3/10mA

200 mA

7...36V

3/10mA

200 mA

Iomax

Iomax

DLS-27N_-__-_-NO_-___ E____ No.: ______Cable: __ m

DLS-27N_-__-_-NC_-___ E____ No.: ______Cable: __ m

DLS-27N_-__-_-NO_-___ E____ No.: ______Cable: __ m

DLS-27N_-__-_-PO_-___ E____ No.: ______Cable: __ m No.: ______Cable: __ m

DLS-27N_-__-_-PC_-___ E____ No.: ______Cable: __ m No.: ______Cable: __ m

IP67

IP67

IP67

IP67

Dinel, s.r.o.

U Tescomy 249

760 01 Zlín

Czech Republic

www.dinel.cz

Dinel, s.r.o.

U Tescomy 249

760 01 Zlín

Czech Republic

www.dinel.cz

Dinel, s.r.o.

U Tescomy 249

760 01 Zlín

Czech Republic

www.dinel.cz

Dinel, s.r.o.

U Tescomy 249

760 01 Zlín

Czech Republic

www.dinel.cz

U

I

U

I

7...36V

3/10mA

200 mA

7...36V

3/10mA

200 mA

BN

BU

BK

+U

0V

BN

BU

BK

+U

0V

Iomax

Iomax

BN

BN

BU

BU

BK

BK

+U

+U

0V

0V

U

I

U

I

7...36V

3/10mA

200 mA

7...36V

3/10mA

200 mA

Iomax

Iomax

DLS-27N_-__-_-NO_-___ E____ No.: ______Cable: __ m

DLS-27N_-__-_-NC_-___ E____ No.: ______Cable: __ m

DLS-27N_-__-_-NO_-___ E____ No.: ______Cable: __ m

DLS-27N_-__-_-PO_-___ E____ No.: ______Cable: __ m No.: ______Cable: __ m

DLS-27N_-__-_-PC_-___ E____ No.: ______Cable: __ m No.: ______Cable: __ m

IP67

IP67

IP67

IP67

Dinel, s.r.o.

U Tescomy 249

760 01 Zlín

Czech Republic

www.dinel.cz

Dinel, s.r.o.

U Tescomy 249

760 01 Zlín

Czech Republic

www.dinel.cz

Dinel, s.r.o.

U Tescomy 249

760 01 Zlín

Czech Republic

www.dinel.cz

Dinel, s.r.o.

U Tescomy 249

760 01 Zlín

Czech Republic

www.dinel.cz

U

I

U

I

7...36V

3/10mA

200 mA

7...36V

3/10mA

200 mA

BN

BU

BK

+U

0V

BN

BU

BK

+U

0V

Iomax

Iomax

BN

BN

BU

BU

BK

BK

+U

+U

0V

0V

U

I

U

I

7...36V

3/10mA

200 mA

7...36V

3/10mA

200 mA

Iomax

Iomax

DLS-27N_-__-_-NO_-___ E____ No.: ______Cable: __ m

DLS-27N_-__-_-NC_-___ E____ No.: ______Cable: __ m

DLS-27N_-__-_-NO_-___ E____ No.: ______Cable: __ m

DLS-27N_-__-_-PO_-___ E____ No.: ______Cable: __ m No.: ______Cable: __ m

DLS-27N_-__-_-PC_-___ E____ No.: ______Cable: __ m No.: ______Cable: __ m

IP67

IP67

IP67

IP67

Dinel, s.r.o.

U Tescomy 249

760 01 Zlín

Czech Republic

www.dinel.cz

Dinel, s.r.o.

U Tescomy 249

760 01 Zlín

Czech Republic

www.dinel.cz

Dinel, s.r.o.

U Tescomy 249

760 01 Zlín

Czech Republic

www.dinel.cz

Dinel, s.r.o.

U Tescomy 249

760 01 Zlín

Czech Republic

www.dinel.cz

U

I

U

I

7...36V

3/10mA

200 mA

7...36V

3/10mA

200 mA

BN

BU

BK

+U

0V

BN

BU

BK

+U

0V

Iomax

Iomax

BN

BN

BU

BU

BK

BK

+U

+U

0V

0V

U

I

U

I

7...36V

3/10mA

200 mA

7...36V

3/10mA

200 mA

Iomax

Iomax

DLS-27N_-__-_-NO_-___ E____ No.: ______Cable: __ m

DLS-27N_-__-_-NC_-___ E____ No.: ______Cable: __ m

DLS-27N_-__-_-NO_-___ E____ No.: ______Cable: __ m

DLS-27N_-__-_-PO_-___ E____ No.: ______Cable: __ m No.: ______Cable: __ m

DLS-27N_-__-_-PC_-___ E____ No.: ______Cable: __ m No.: ______Cable: __ m

IP67

IP67

IP67

IP67

Dinel, s.r.o.

U Tescomy 249

760 01 Zlín

Czech Republic

www.dinel.cz

Dinel, s.r.o.

U Tescomy 249

760 01 Zlín

Czech Republic

www.dinel.cz

Dinel, s.r.o.

U Tescomy 249

760 01 Zlín

Czech Republic

www.dinel.cz

Dinel, s.r.o.

U Tescomy 249

760 01 Zlín

Czech Republic

www.dinel.cz

Symbol of producer: logo Dinel®

Contact: Dinel,s.r.o., U Tescomy 249, 760 01 Zlín, www.dinel.cz

Type of level meter: DLS–27N_–__–_–___–___ Exxxx

Cable length: Cable: _ _ m

Serial number: Ser. No.: ______ – (from the left: production year, serial production number)

Supply voltage: U = 7...36V=

Current supply: I = 3 / 10 mA

Maximum switching current: Iomax = 200 mA

Compliance mark:

Protection class: IP67, Electro-waste take-back system mark:

This manual suits for next models

8

Table of contents

Other Dinel Accessories manuals